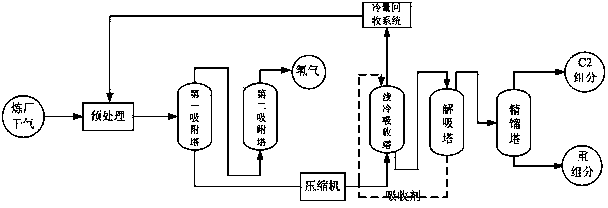

Method and device for separating hydrogen and ethylene from refinery dry gas by shallow condensing adsorption-absorption

A refinery dry gas, shallow cold absorption technology, applied in hydrogen separation, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve the problems of low product purity, high energy consumption, etc., to reduce energy consumption, save refrigeration amount, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The hydrogen content is 56.2%, ethane content is 7.2%, ethylene content is 6.2%, methane content is 22.2%, nitrogen content is 5.5%, carbon two or more components content is 0.9%, acid gas content is 1.8% (the gas percentages mentioned in this article are all The dry gas of a refinery with a pressure of 1 MPa is pretreated. Then reduce the temperature of the pretreated refinery dry gas to 5 to 10 degrees Celsius, and enter the first adsorption tower for the first adsorption. The temperature during the first adsorption is controlled at 5 to 10 degrees Celsius; the pressure at the time of entry remains unchanged .

[0024] It is clear to those skilled in the art that low-pressure adsorption is an existing process, and its principle will not be repeated here. In this step, the adsorbent filled in the first adsorption tower adsorbs carbon two components, a small amount of hydrogen, methane, nitrogen and more than carbon two components, and the unadsorbed hydrogen, methane and...

Embodiment 2

[0035] In this embodiment and on the basis of embodiment 1, the carbon dioxide mixture discharged from the top of the desorption tower is further processed, and a rectification tower is added. The middle inlet of the rectification tower is connected to the top outlet of the desorption tower

[0036] The discharge from the top of the desorption tower is sent to the rectification tower for rectification. The carbon two components from the top of the rectification tower can directly enter the ethylene rectification tower to obtain high-purity product ethylene. It is sent to the ethane cracking furnace to obtain high-purity product ethylene.

[0037] In this embodiment, the recovery rate of ethylene in the refinery dry gas can reach 90%, and the recovery purity can reach 99%.

Embodiment 3

[0039] The device and method used in this embodiment are the same as those used in embodiment 2. The gas components of the dry gas input to the refinery are 41.4% hydrogen content, 11.3% ethane content, 8.4% ethylene content, 21.4% methane content, 11% nitrogen content, The content of C2 and above components is 2.9%, the acid gas content is 3.6%, the dry gas pressure of the refinery is 1 MPa; the temperature of the dry gas of the refinery is reduced to 5 degrees Celsius, and the temperature during the first adsorption is controlled at 5 degrees Celsius; The pressure is 1 MPa, the hydrogen recovery rate is 90%, the recovery purity is over 99%, the ethylene recovery rate can reach 92%, and the recovery purity reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com