Separation method and device of zirconium tetrachloride synthesis gas

A technology of zirconium tetrachloride and separation method, applied in chemical instruments and methods, zirconium halide, zirconium compounds, etc., can solve the problems of energy consumption, complex separation process of zirconium tetrachloride synthesis gas, etc. The effect of reducing separation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]This embodiment provides a method for separating zirconium tetrachloride synthesis gas. The zirconium tetrachloride synthesis gas is obtained by preparing zirconium tetrachloride by a chlorination method, including the following steps:

[0045] 1) cooling the zirconium tetrachloride synthesis gas to 150-180°C, and depositing the first crude zirconium tetrachloride to obtain the first synthesis gas;

[0046] 2) Lowering the temperature of the first synthesis gas to 80-120° C. to precipitate the second crude zirconium tetrachloride to obtain the second synthesis gas.

[0047] The present embodiment provides a kind of device used in the separation method of above-mentioned zirconium tetrachloride synthesis gas, comprising:

[0048] The first cooling separator is used to lower the temperature of the zirconium tetrachloride synthesis gas to 150-180°C, and precipitate the first crude zirconium tetrachloride to obtain the first synthesis gas;

[0049] The second cooling separa...

Embodiment 2

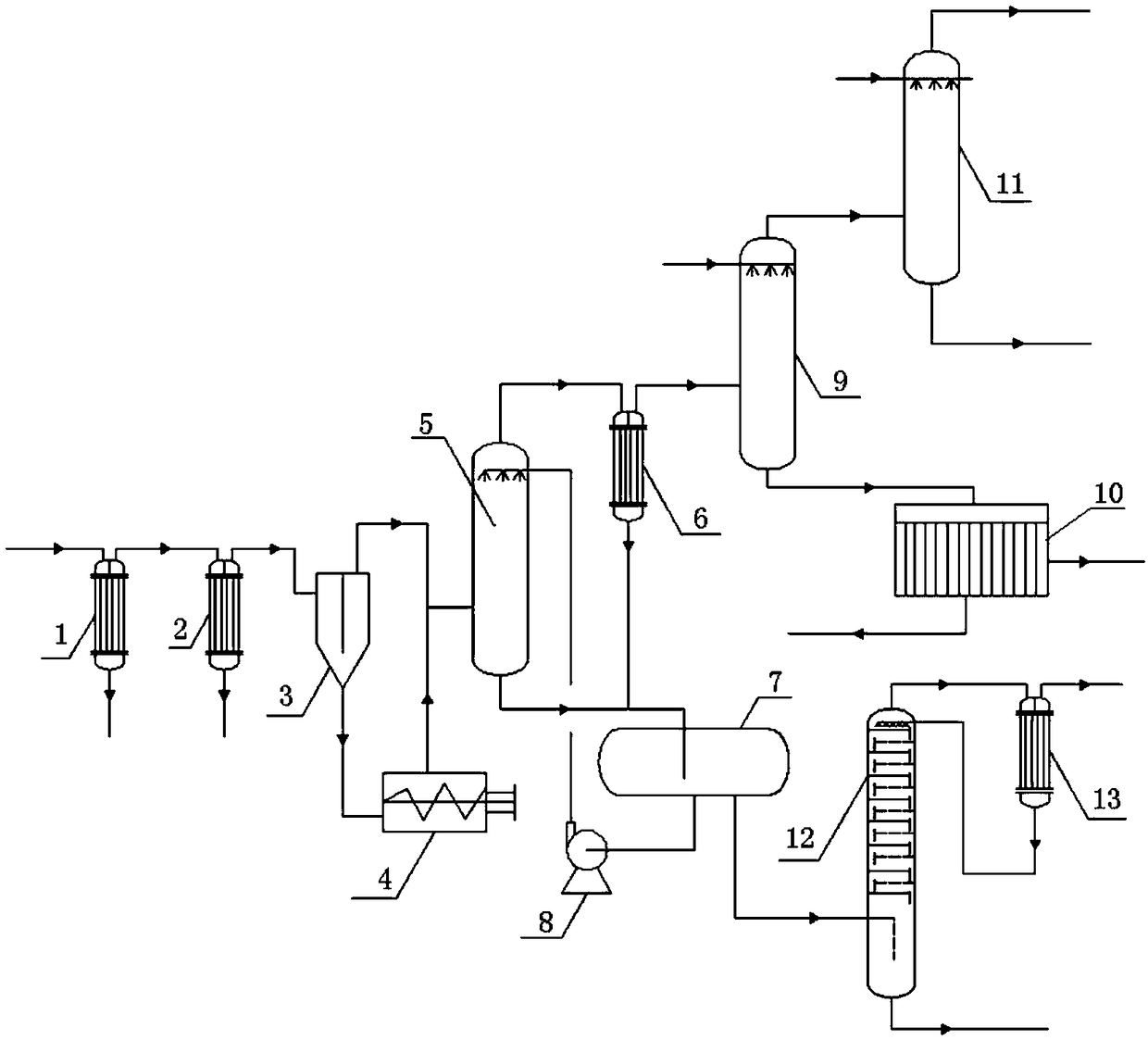

[0052] Such as figure 1 As shown, the present embodiment provides a device for the separation method of zirconium tetrachloride synthesis gas, including:

[0053] The first cooling separator 1 is used to lower the temperature of the zirconium tetrachloride synthesis gas and precipitate the first crude zirconium tetrachloride to obtain the first synthesis gas;

[0054] The second cooling separator 2 is connected with the first cooling separator 1 , and the second cooling separator 2 is used to lower the temperature of the first synthesis gas to precipitate the second crude zirconium tetrachloride to obtain the second synthesis gas.

[0055] The vacuum settler 3 is connected to the second cooling separator 2, and the vacuum settler 3 is used to vacuum settle the second synthesis gas to obtain the separated third synthesis gas and sedimentation precipitate;

[0056] The dryer 4 is connected with the vacuum precipitator 3, and the dryer 4 is used to heat the sediment to obtain th...

Embodiment 3

[0083] This example provides a method for separating zirconium tetrachloride synthesis gas using the device in Example 2. The zirconium tetrachloride synthesis gas is obtained by preparing zirconium tetrachloride through the chlorination method. The difference from the method in Example 2 for:

[0084] 1) In the first cooling separator 1, the temperature of the zirconium tetrachloride synthesis gas from the chlorination reactor is lowered to 180°C.

[0085] 2) In the second cooling separator 2, the temperature of the first syngas is lowered to 100°C.

[0086] 3) The second synthesis gas is settled in vacuum in the vacuum settler 3, the vacuum degree of the vacuum settling is 50000 Pa, and the temperature is 55°C.

[0087] 4) Cool down to 25° C. by eluting with silicon tetrachloride eluent.

[0088] 5) The temperature of the fifth synthesis gas is lowered to -25° C. in the cooler 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com