Surface-type indirect air cooling system plate-type condenser of thermal power plant

A technology for thermal power plants and air cooling systems, which is applied in steam/steam condensers, lighting and heating equipment, etc., and can solve the problems of high end difference, reduced thermal efficiency, and increased investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

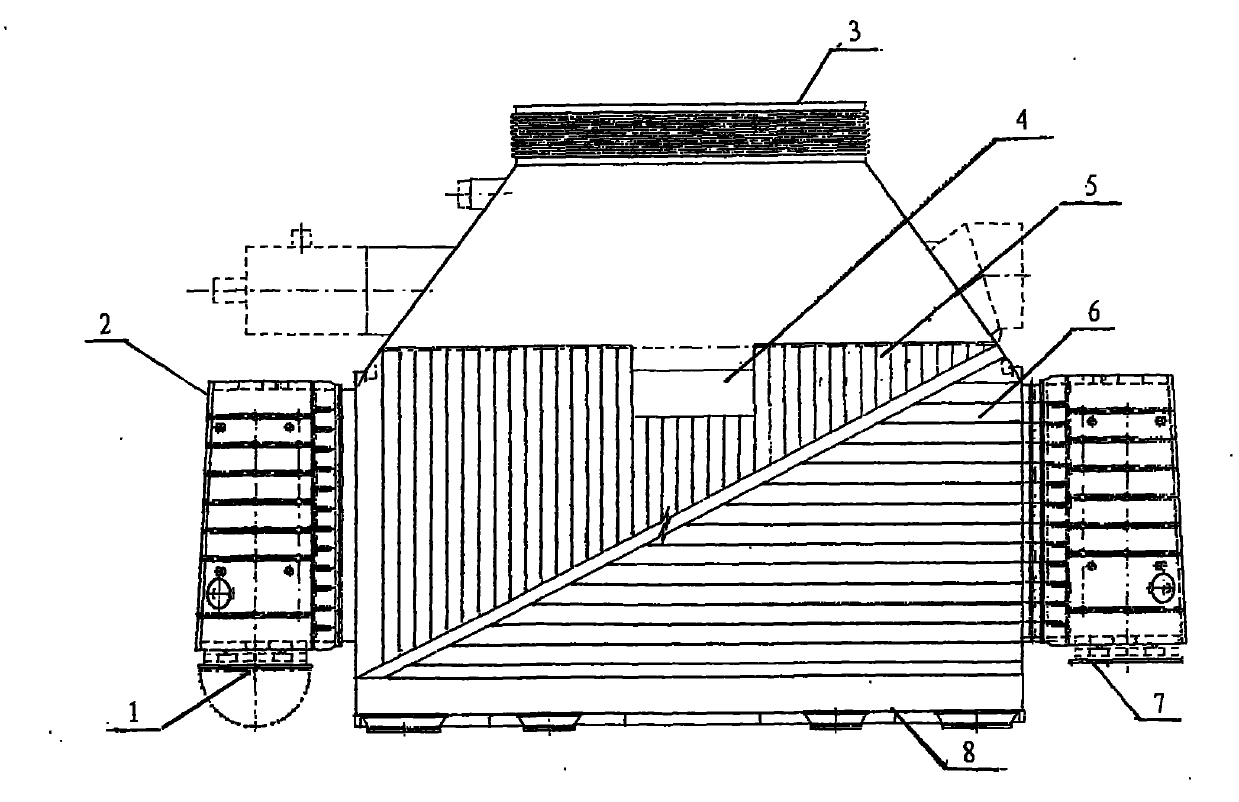

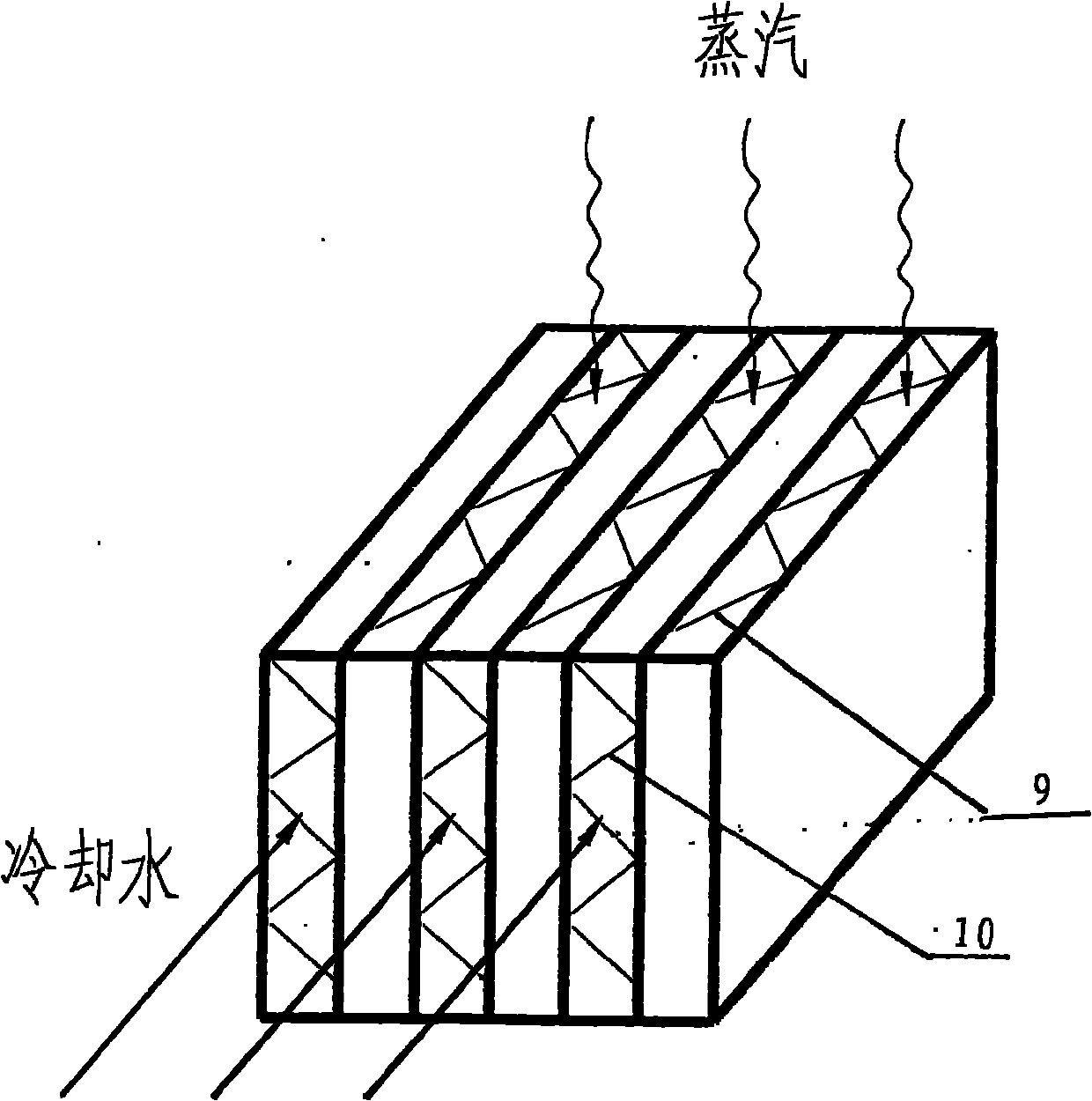

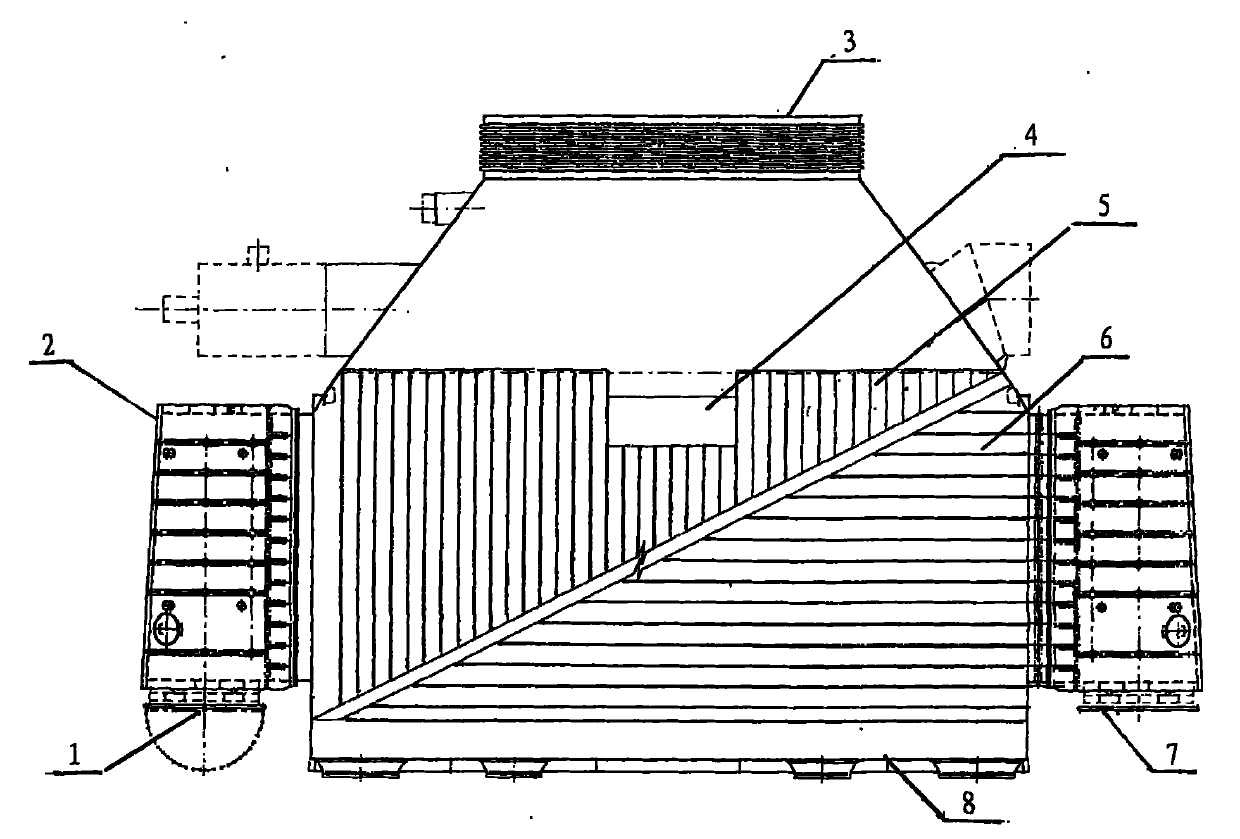

[0009] as attached figure 1 As shown, the headers of the condenser are arranged symmetrically on the left and right. There are cooling water inlets and outlets on the headers. There are steam inlets above the headers and condensate wells below the headers. Plate heat exchangers are connected between the headers. The stainless steel plates are vertically and equally spaced, and the horizontal partitions are arranged between the stainless steel plate 1 and the plate 2. The horizontal partitions are arranged in a triangle, and the partitions are at an angle of 60 degrees to each other to form a corrugated cooling water channel. The box is connected; a vertical partition is set between the plate 2 and the plate 3, and the end faces of the plate 2 and the plate 3 are sealed. A horizontal partition is set between the plate 4 and the plate 4 to form a cooling water channel; a longitudinal partition is set between the plate 4 and the plate 5 to form a water vapor channel, and so on to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com