Plate type evaporation air-cooling condenser with obliquely-arranged heat exchange plate bundles

An air-cooled condenser and plate-type evaporation technology, which is used in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of unfavorable thermal power generation cooling, large circulating cooling water flow, complex cooling system structure, etc., and achieve water quality. Low requirements, reducing circulating water and water consumption, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a plate-type evaporative air-cooled condenser in which heat exchange plate bundles are arranged obliquely. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

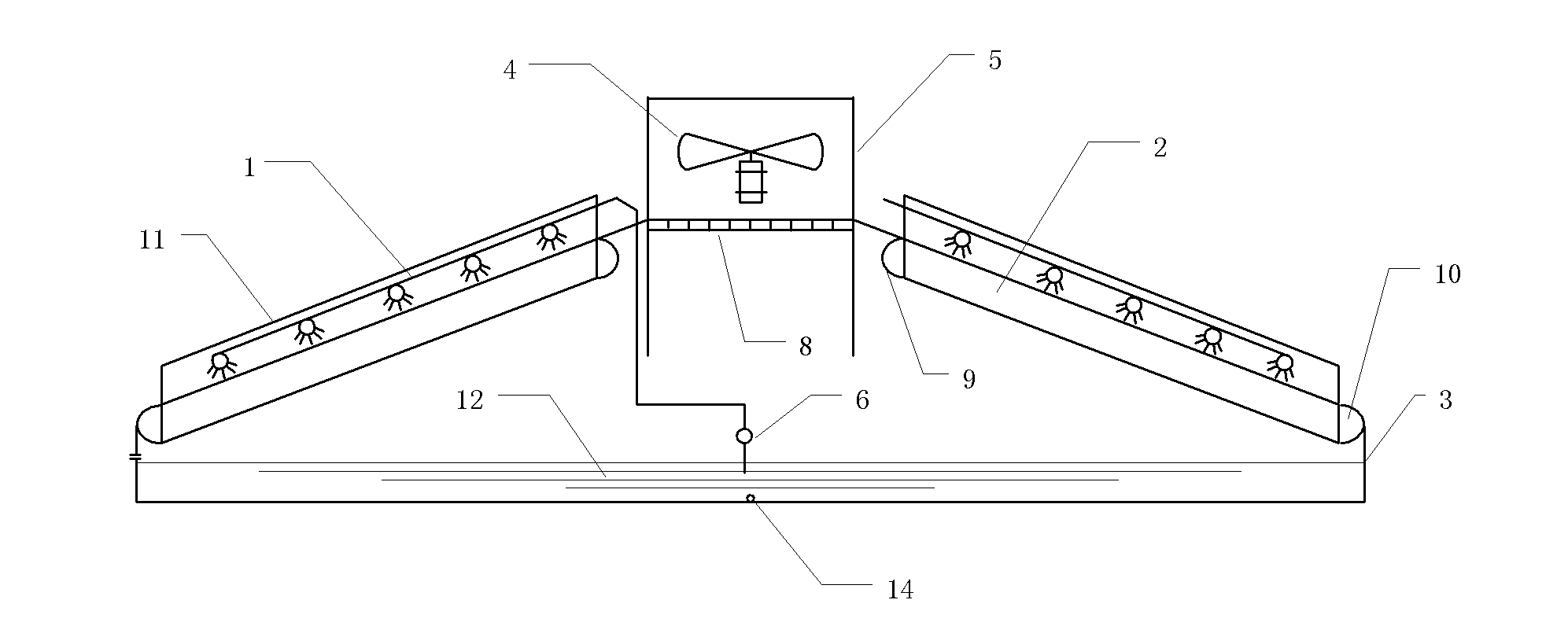

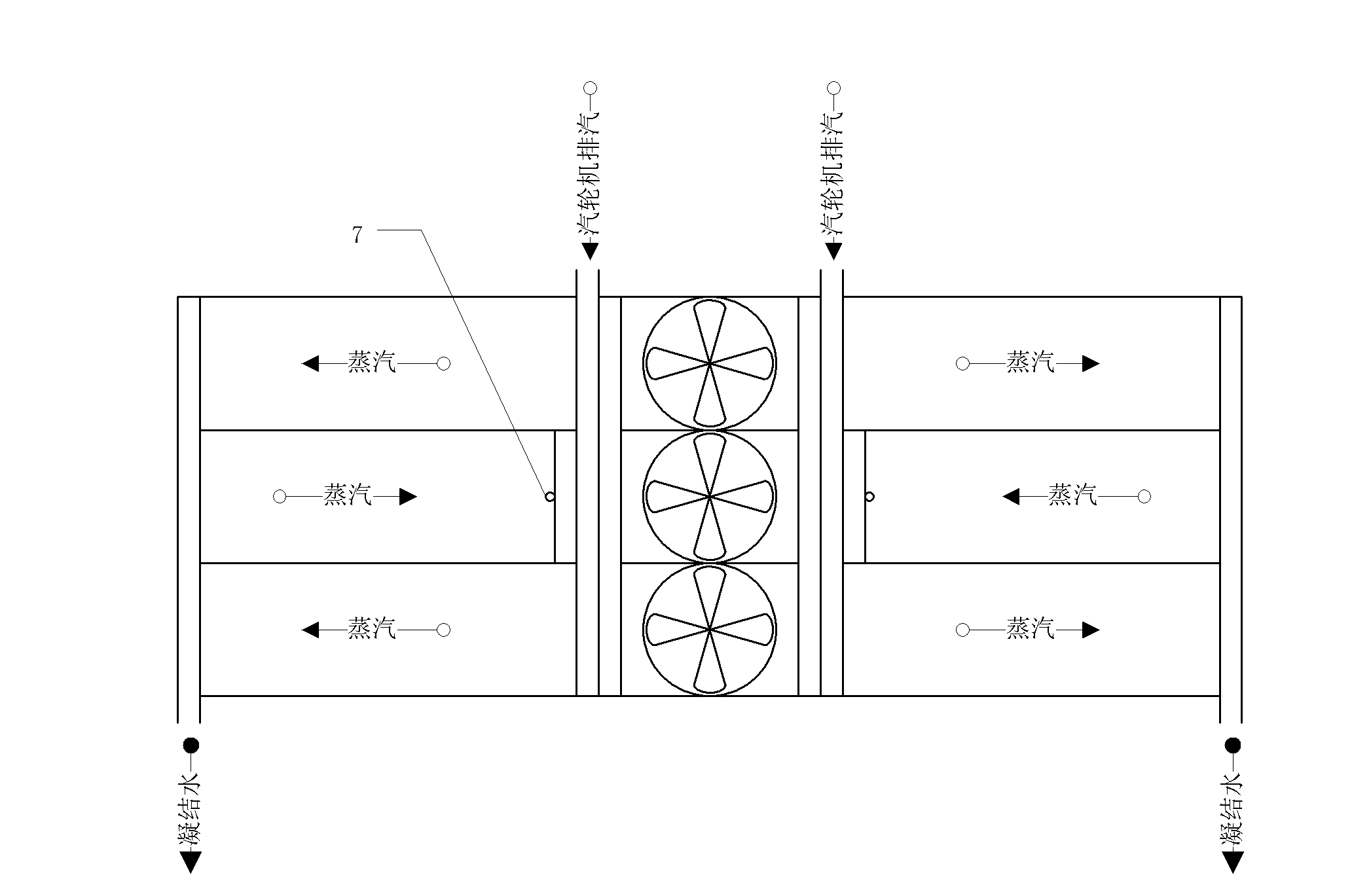

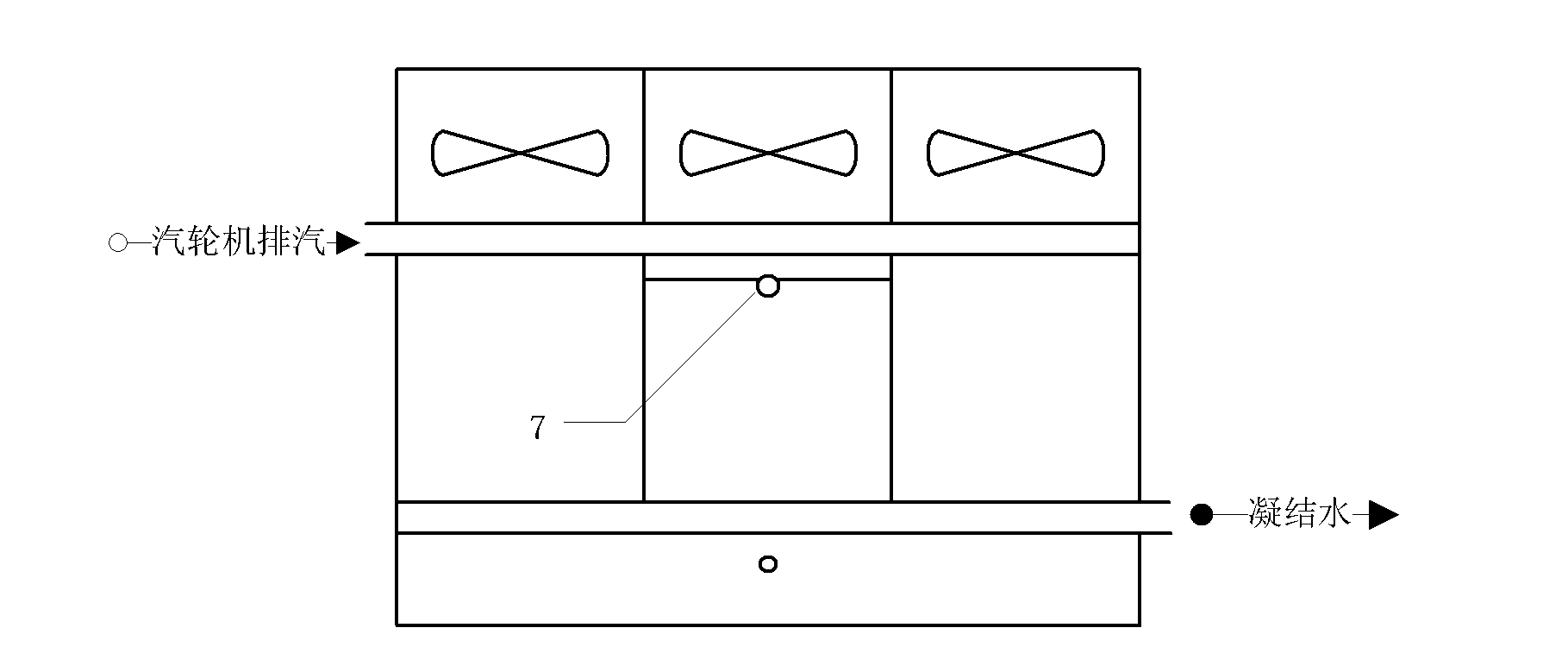

[0024] Such as figure 1 , figure 2 with image 3 As shown, the condenser includes a spray device 1 , a heat exchange plate bundle 2 , a box body 3 , a fan 4 , an air outlet tube 5 , and a circulating water pump 6 . The top of the box 3 is provided with an air outlet 5, and the air outlet 5 extends to the inside of the box 3, which is conducive to the formation of a uniform air flow field; two sets of heat exchange plate bundles 2 are respectively arranged on both sides of the air outlet 5 On the box body 3 and arranged downwards, the two sets of heat exchange plate bundles 2 form an included angle of 110°-130°, and an included angle of 120° is specially selected here, which is conducive to the discharge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com