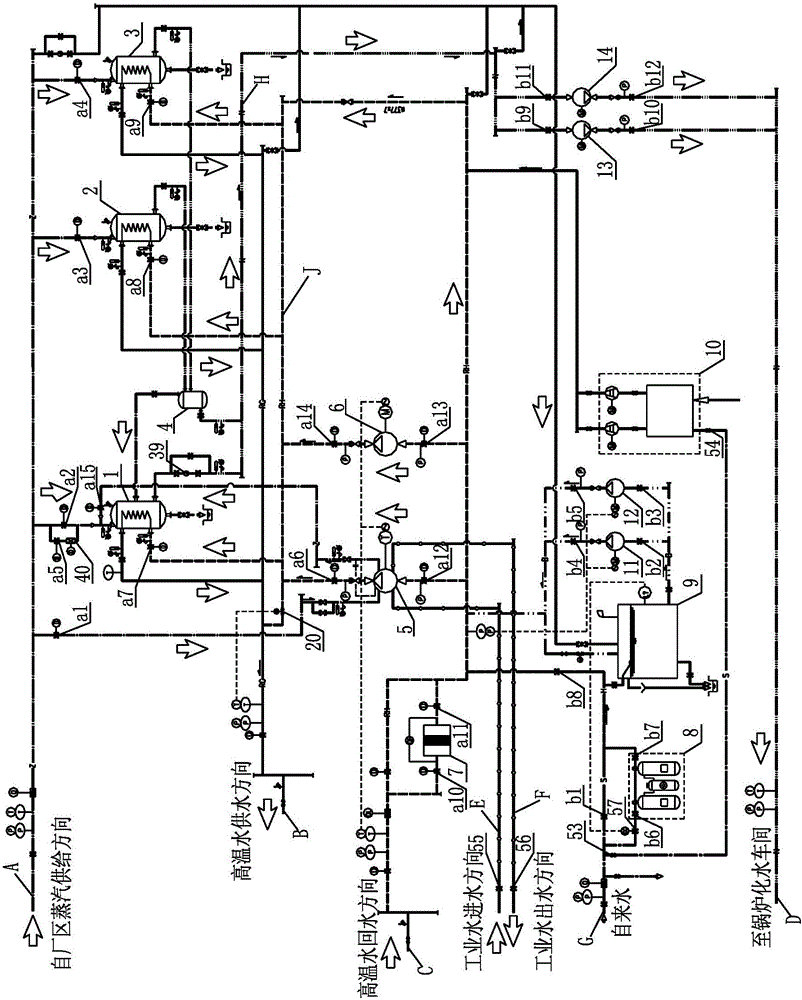

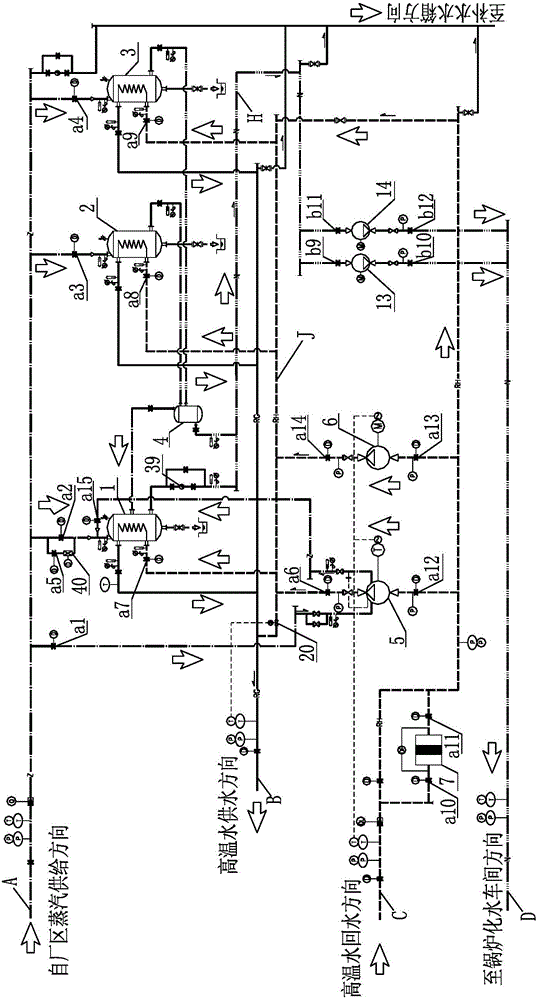

Heat efficiency-optimized first steam-water heat exchange station and running method thereof

A steam-water heat exchange and operation method technology, applied in heating methods, hot water central heating systems, household heating, etc., can solve the problems of long operation time, high operation cost, and impact on equipment life, and achieve small steam pressure drop, The effect of small heat transfer area and large heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments should not be construed as limiting the present invention, but only as examples, and the advantages of the present invention will become clearer and easier to understand.

[0049] Thermal efficiency optimization steam-water heat exchange first station, including the first heat exchanger 1; the steam input end of the first heat exchanger 1 is connected with the main steam pipeline A from the factory area through the second electric butterfly valve a2; the steam of the first heat exchanger 1 The input end is also connected to the steam output end of the steam-driven circulating water pump 5 through the fifteenth electric butterfly valve a15; the steam input end of the first heat exchanger 1 is also connected to the steam output end of the hydrophobic expansion vessel 4;

[0050] The steam condensed water output end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com