Tert-butanol recovery method by using cyclohexanone ammoximation reaction heat

A technology of cyclohexanone ammonia oxime and recovery method, which is applied in the field of separation of chemical products, can solve the problems of high heat consumption, low energy grade, large heat release, etc., and achieve the effect of reducing the amount of circulating water and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

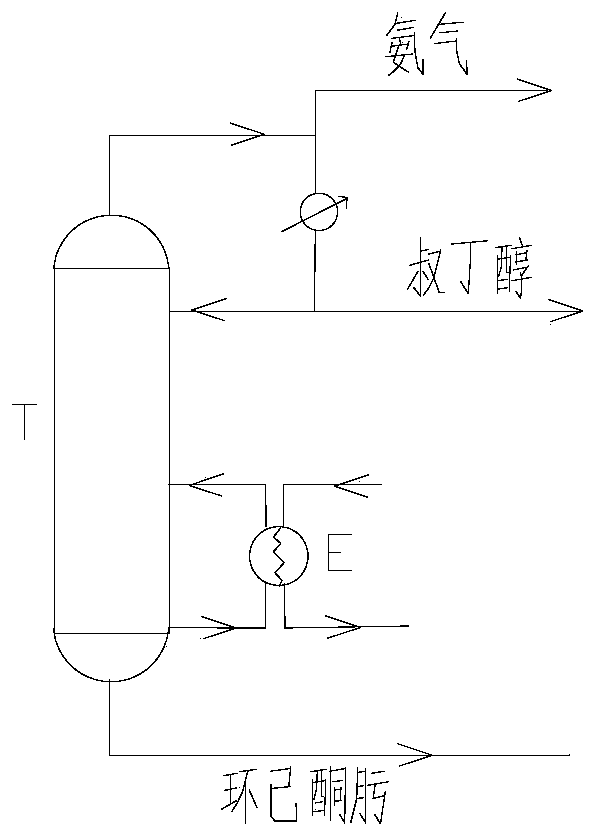

Method used

Image

Examples

Embodiment 1

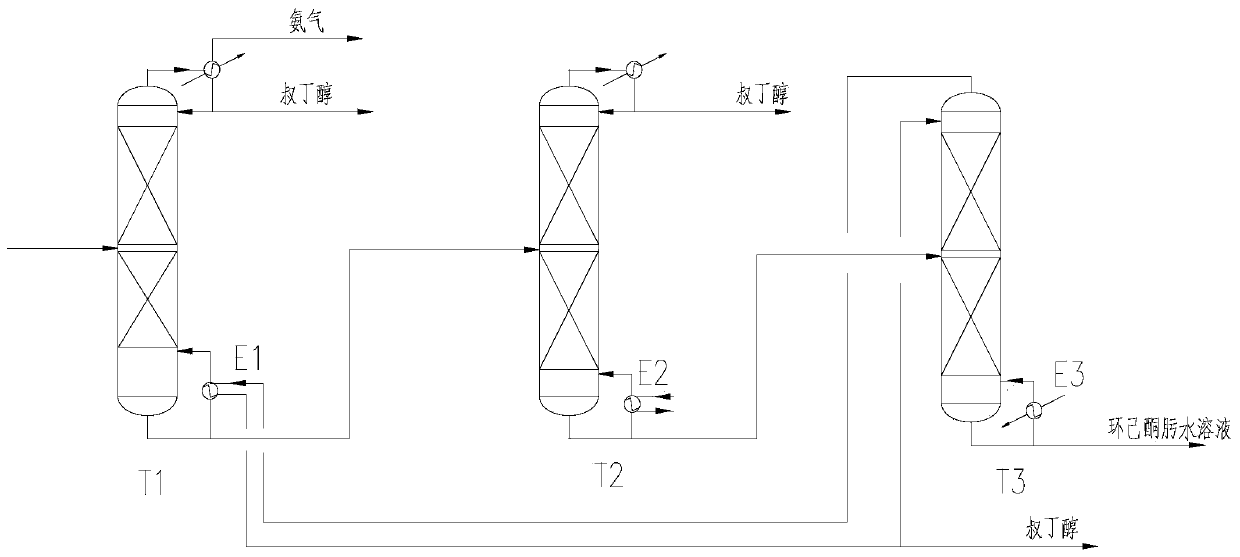

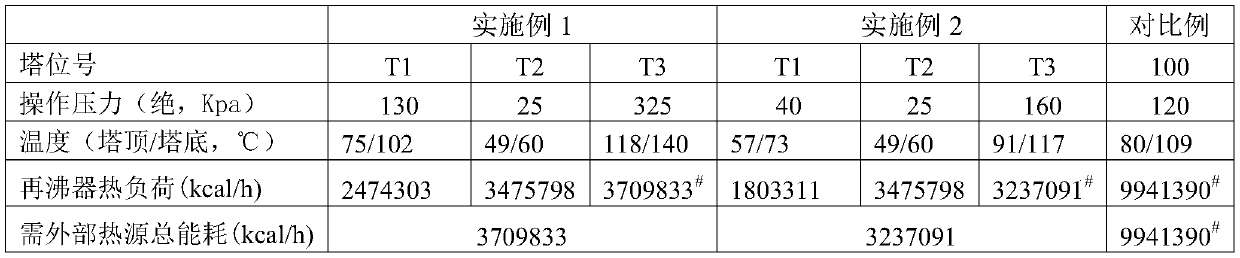

[0023] Taking a 100,000-ton unit as an example, a method for recovering tert-butanol using the heat of ammoximation reaction of cyclohexanone, in which E2 uses the direct heat exchange of reaction materials to provide heat. The raw material of tert-butanol, which contains 40.9% of tert-butanol, 20.3% of cyclohexanone oxime, 2.8% of ammonia, 35.6% of water, and 0.1% of non-condensable gas, enters the deamination tower, containing the ammoximation reaction product of tert-butanol First enter the deamination tower T1, the operating pressure is 130kpa, all ammonia, non-condensable gas and part of tert-butanol are separated from the top of the tower, and the material in the deamination tower tower enters the tert-butanol decompression tower T2 for tert-butanol distilling Second separation, in order to make full use of the heat of reaction, the tower is a decompression operation, operating pressure 25kpa, because the tower still temperature is lower after decompression, in order to a...

Embodiment 2

[0025] Taking a 100,000-ton unit as an example, a method for recovering tert-butanol using the heat of ammoximation reaction of cyclohexanone, in which E2 is heated by MVR steam generated by MVR steam equipment. The raw material of tert-butanol, which contains 40.9% of tert-butanol, 20.3% of cyclohexanone oxime, 2.8% of ammonia, 35.6% of water, and 0.1% of non-condensable gas, enters the deamination tower, containing the ammoximation reaction product of tert-butanol First enter the deamination tower T1, the operating pressure is 40kpa, and all ammonia, non-condensable gas and part of tert-butanol are separated from the top of the tower, and the material in the tower kettle of the deamination tower enters the tert-butanol decompression tower T2 for tert-butanol distilling Second separation, in order to make full use of the heat of reaction, the tower is a decompression operation, operating pressure 25kpa, because the tower still temperature is lower after decompression, in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com