Freeze-condensing vacuum deodorizing method and equipment for fat and oil

A deodorization and oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of large cooling tower and centrifugal pump configuration, heavy intermediate condenser load, air pollution around the factory area, etc., to achieve easy maintenance and repair, energy saving , the effect of increasing the amount of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

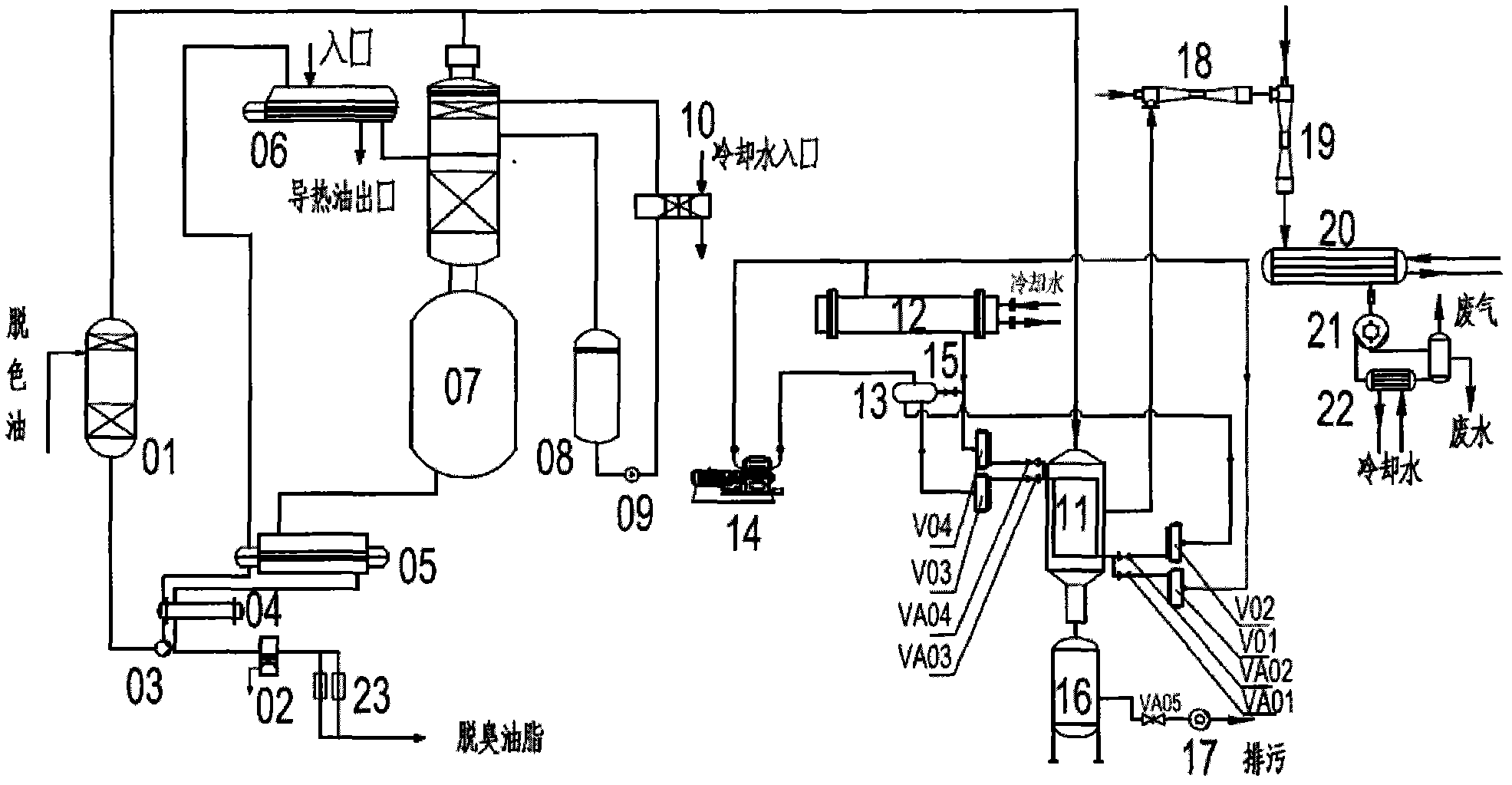

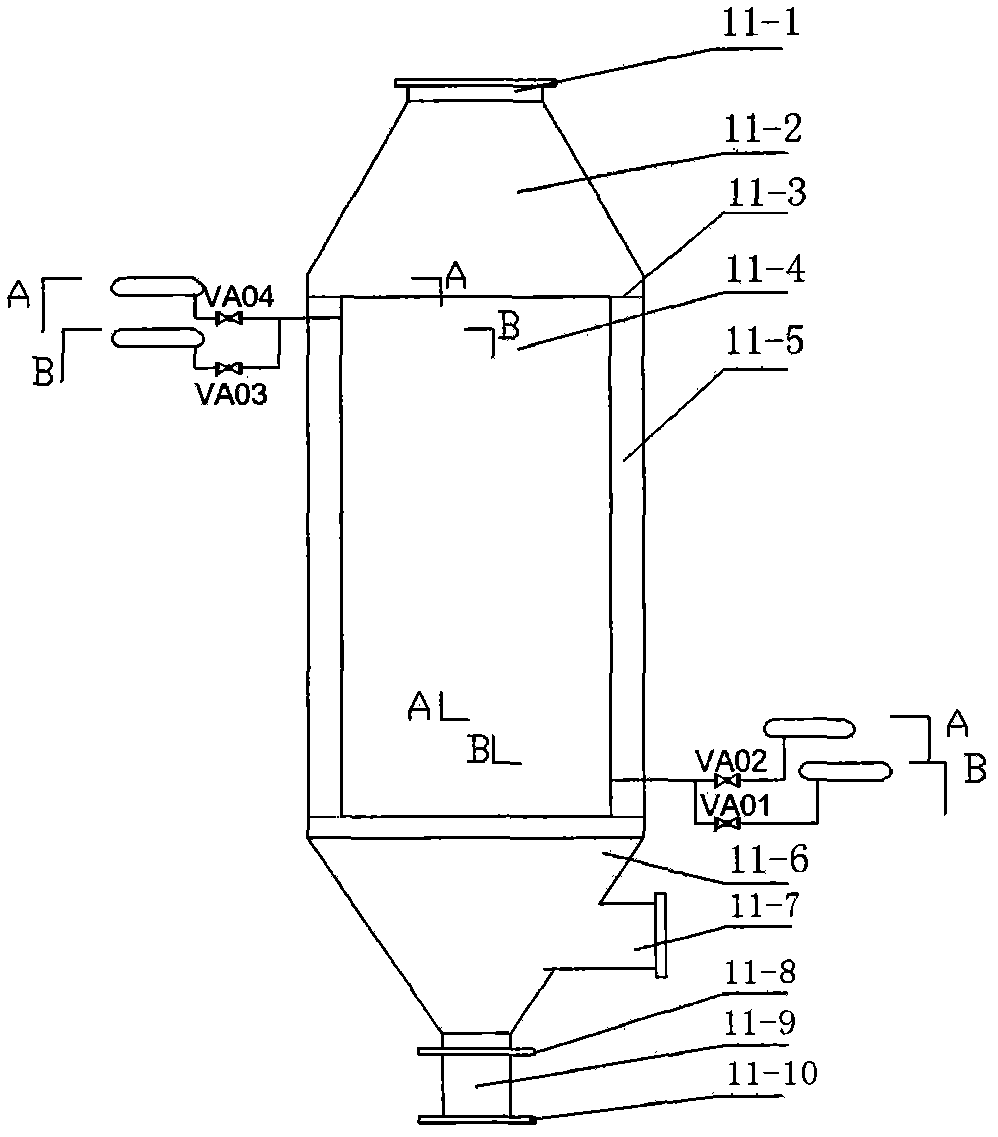

[0046] Embodiment 1: On the 200 tons / day soybean oil refining production line, the technology of the present invention is used to deodorize soybean oil, see figure 1 . The equipment used includes:

[0047] (1) Gas separator unit: including gas separator 01, which has an outlet and an inlet, and the inlet is used to enter grease.

[0048] (2) Heating unit: including oil delivery pump 03, heat exchangers 04, 05, and 06 connected in series; the inlet of oil delivery pump 03 communicates with the outlet of gas separator 01, and the The heating medium channel communicates with the outlet of the oil delivery pump 03, and the heated working medium channel in the heat exchanger 06 is finally heated by the heat transfer oil;

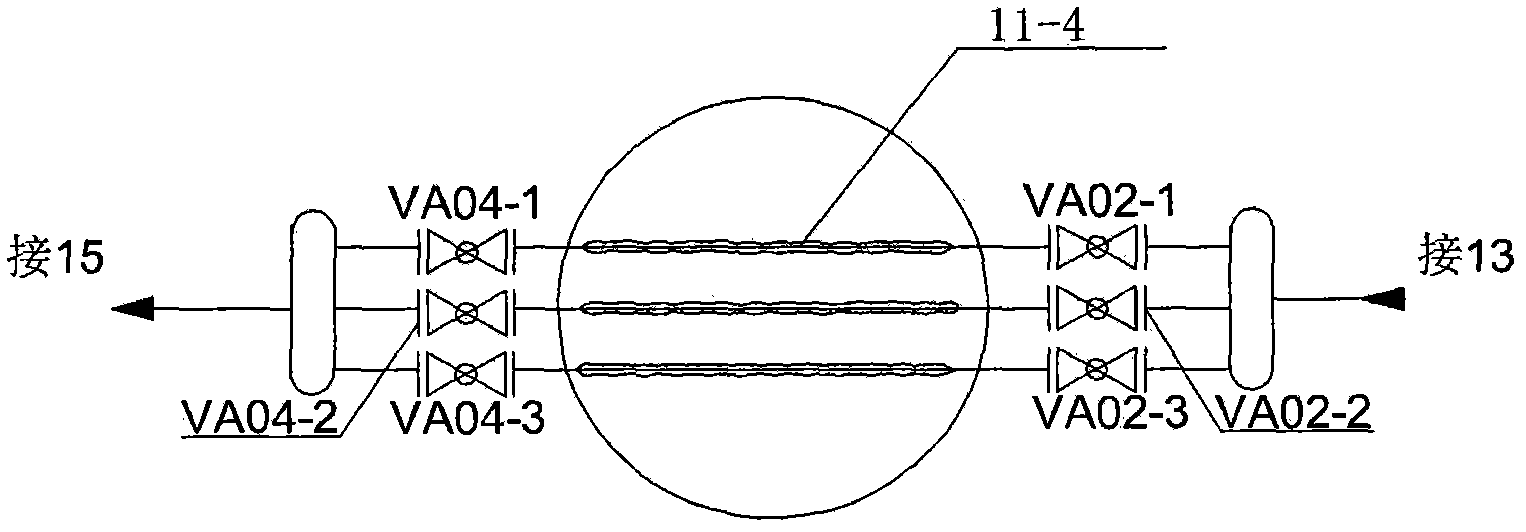

[0049] (3) Deodorization unit: including deodorization tower 07, its top is connected with fatty acid collection tank 08, its bottom is connected with one end of the heating medium channel of heat exchanger 05, and is connected with the heating medium channel, ...

Embodiment 2

[0064] Embodiment 2: On the 400 tons / day rapeseed oil refining production line, the technology of the present invention is used to deodorize rapeseed oil; see figure 1 .

[0065] 1. Preparation, start the vacuum system before production and make preparations. When the absolute pressure of the deodorization tower reaches 50Pa and the temperature of the refrigerant in the dry freezer 11 reaches -40°C, it starts to work;

[0066] 2. Gas analysis and oxygen removal, pump the oil to be deodorized, and enter the gas analyzer 01 for oxygen removal;

[0067] 3. Heating, heat up to about 140°C through plate heat exchangers 04 and 05, then exchange heat with heat transfer oil heat exchanger 06, and enter the deodorization tower 07 with a temperature greater than or equal to 255°C.

[0068] 4. Deodorization, adjust the direct steam consumption of deodorization tower 07, the pressure is 0.1Mpa; the amount of fatty acid spraying is controlled at 20M 3 per hour at a temperature of 60°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com