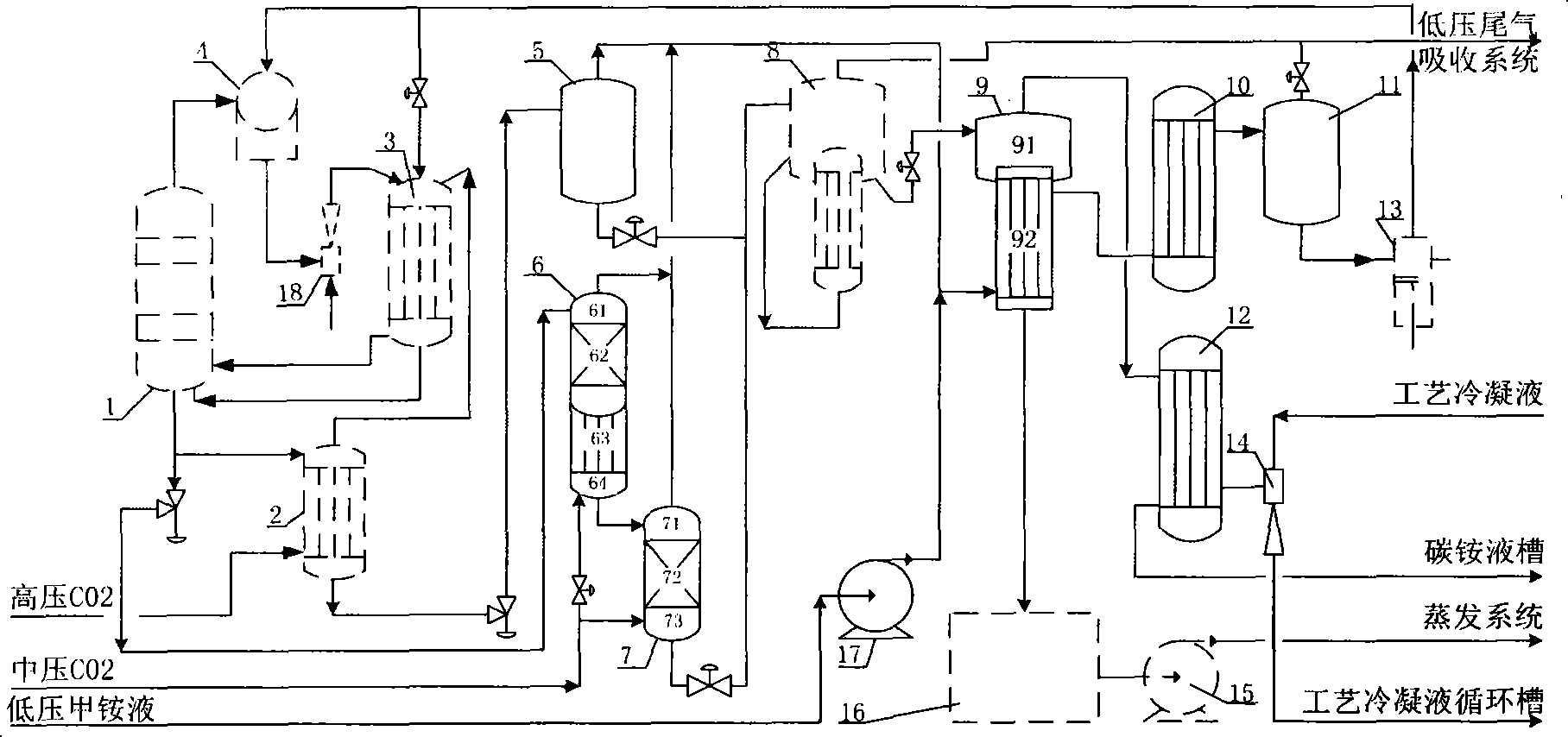

CO2 gas-striping parallel /serial connection medium-pressure urea energy-saving and yield-increasing novel technology

A new process, medium-pressure technology, which is applied in the process field of improving the production capacity of CO2 stripping urea process unit and reducing energy consumption, can solve the problems of low conversion rate of urea synthesis tower, increased steam and electricity consumption, etc., and achieves a significant increase in production effect. , The effect of reducing the consumption of circulating cooling water and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] With the method of the present invention, domestic existing 400,000 tons / year CO 2 The air-lifting urea unit underwent energy-saving and production-increasing transformation, and the production capacity was increased from 1,350 tons / day to 2,000 tons / day, and the transformation investment cost was 32 million yuan; after the transformation, the steam consumption per ton of urea was reduced by 30-60kg, and the unit consumption was 940-970kg; The consumption is reduced by 8-12 kWh, and the unit consumption is 78 kWh; the consumption of circulating cooling water is also greatly reduced; 400,000 tons / year of CO 2 After the successful transformation of the gas stripping urea unit, the company shut down the 200,000-ton / year aqueous solution full-circulation urea production unit. Before the aqueous solution unit was shut down, the average steam consumption per ton of urea was 1250 kg, and the power consumption was 160 kWh. According to the market price, the cost of urea product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com