Large-temperature-difference cold water composite gradient utilization system based on waste heat utilization

A large temperature difference, refrigeration system technology, applied in the direction of heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of limited use range, limited space for reducing the outlet water temperature of electric refrigeration units, deviation from energy saving, etc., to achieve reduction The effect of conveying energy consumption and cooling loss, improving the utilization rate of primary energy, and reducing the water volume of cold water circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

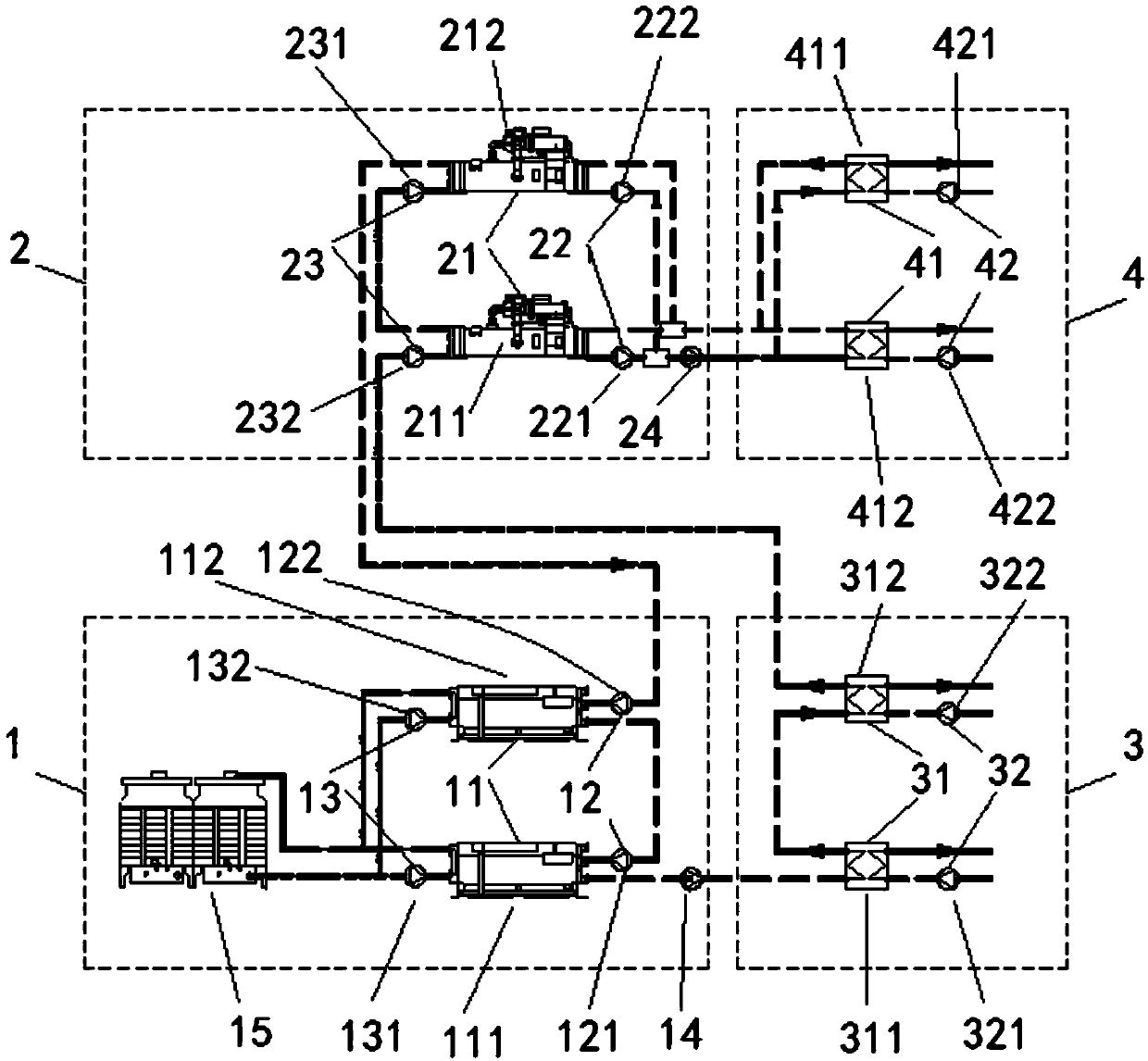

[0022] combine figure 1 , a large temperature difference cold water composite cascade utilization system based on waste heat utilization, including waste heat absorption large temperature difference cascade refrigeration system 1, chilled water cascade utilization system 3, cooling water cascade utilization system 2, and district cooling user system 4.

[0023] The waste heat absorption type large temperature difference cascade refrigeration system 1 supplies cold water to the chilled water cascade utilization system 3 through pipes, the chilled water cascade utilization system 3 supplies cold water to the cooling water cascade utilization system 2 through pipes, and the cooling water cascade utilization system 2 supplies cold water to the area The cold user system 4 supplies cold water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com