An Actively Regulated Gas Turbine Distributed Combined Cooling, Heating and Power Supply System

A combined cooling, heating and power supply and gas turbine technology, which is applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problem of affecting the energy-saving characteristics of distributed cooling, heating and power systems, hindering the promotion and application of distributed cooling, heating and power technology, and affecting the system Waste heat utilization equipment and other issues to achieve the effect of improving comprehensive energy utilization, strengthening energy cascade utilization, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

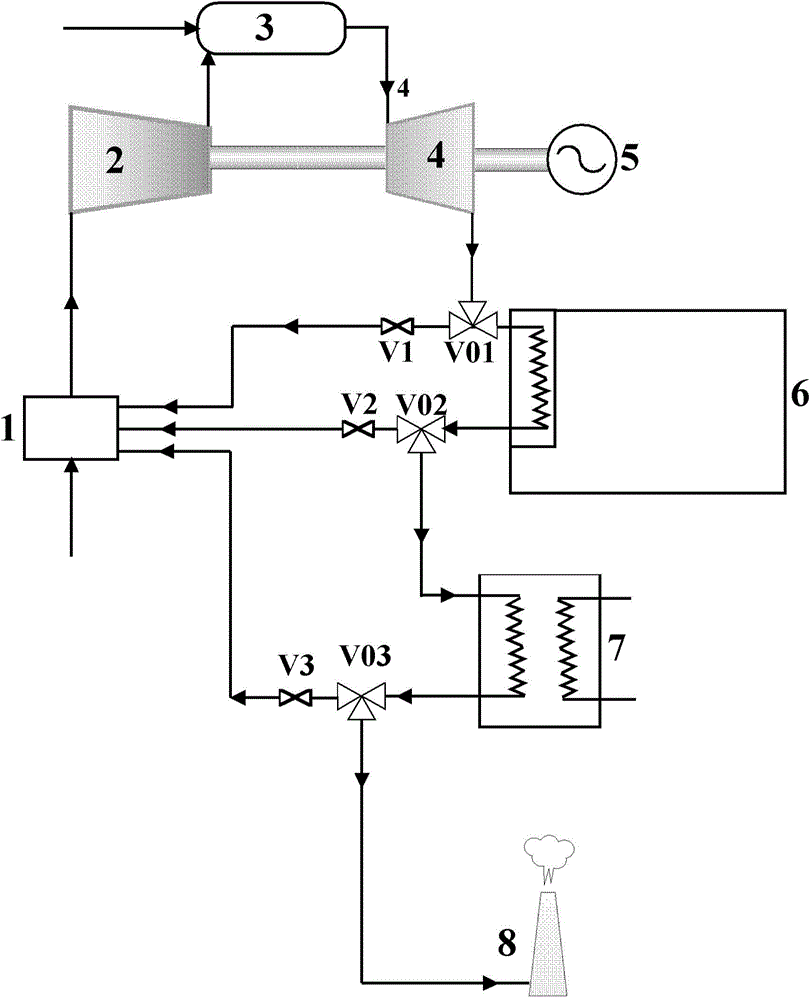

[0048] Such as image 3 As shown, image 3 It is a structural diagram of an active control gas turbine distributed cooling, heating and power cogeneration system according to the first embodiment of the present invention. The system includes an air flue gas mixer 1, a compressor 2, a combustion chamber 3, a turbine 4, and a generator 5. Lithium bromide absorption unit 6, flue gas hot water heat exchanger 7, chimney 8, valves V1 ~ V3, three links V01 ~ V03.

[0049] In this embodiment, the waste heat driving subsystem adopts the first type lithium bromide absorption heat pump unit. This embodiment is a schematic diagram of the system operation of the active control gas turbine distributed combined cooling, heating and power system under heating conditions in winter. The lithium bromide unit operates in the heating mode to produce the heating load of the user, and the flue gas hot water heat exchanger produces domestic hot water. When the user's heating load needs to be reduced, t...

Embodiment 2

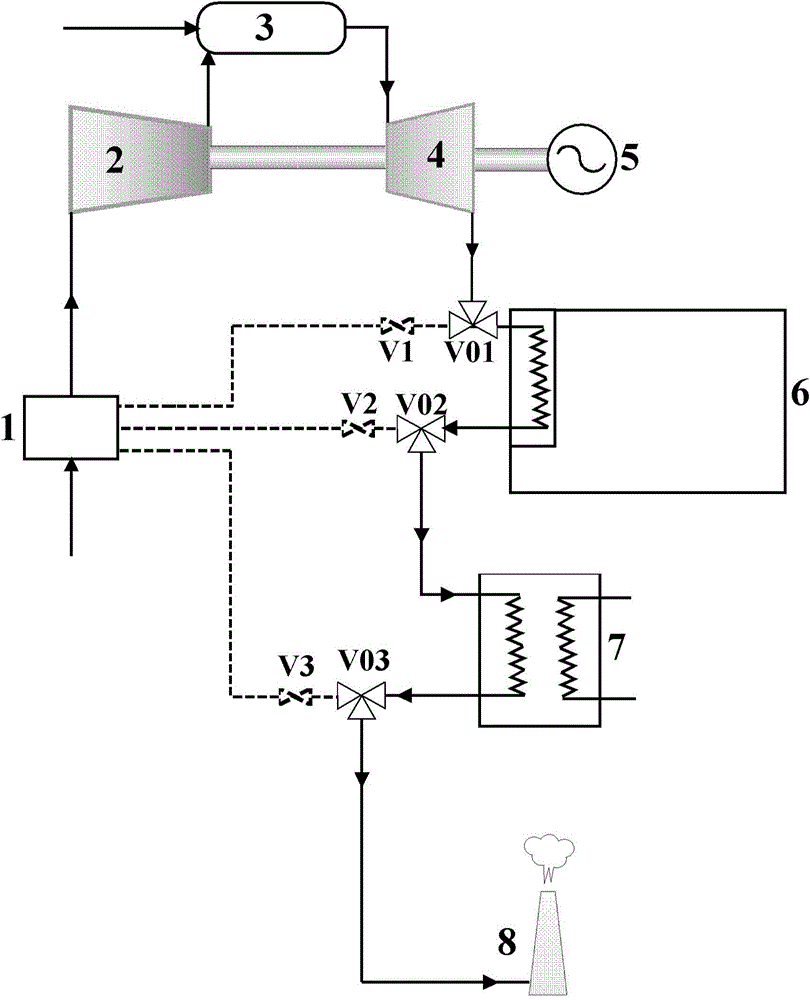

[0052] Such as Figure 4 As shown, Figure 4 It is a structural schematic diagram of an active control gas turbine distributed cooling, heating and power cogeneration system according to the second embodiment of the present invention. The system includes an air flue gas mixer 1, a compressor 2, a combustion chamber 3, a turbine 4, and a generator 5. Lithium bromide absorption unit 6, flue gas hot water heat exchanger 7, chimney 8, valves V1 ~ V3, three links V01 ~ V03.

[0053] In this embodiment, the waste heat driving subsystem adopts a double-effect lithium bromide absorption refrigeration unit. This embodiment is a schematic diagram of the system operation of the active control gas turbine distributed cooling, heating and power cogeneration system under summer cooling conditions. Lithium bromide cold and hot water units operate in refrigeration mode to produce the cooling load required by users, and the flue gas hot water heat exchanger produces domestic hot water. When the ...

Embodiment 3

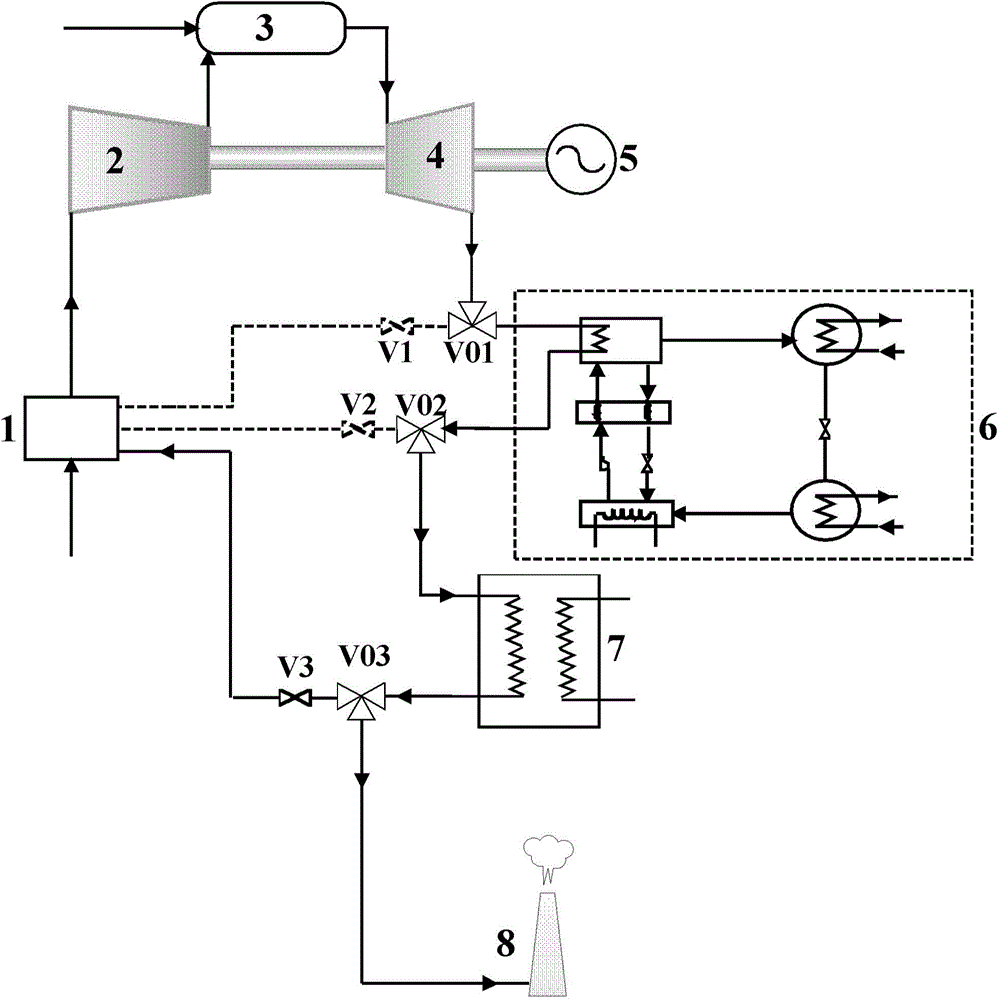

[0056] Such as Figure 5 As shown, Figure 5 It is a schematic structural diagram of an active control gas turbine distributed cooling, heating and power cogeneration system according to the third embodiment of the present invention. The system includes an air flue gas mixer 1, a compressor 2, a combustion chamber 3, a turbine 4, and a generator 5. Steam power Rankine cycle 6, flue gas hot water heat exchanger 7, chimney 8, valves V1 ~ V3, three links V01 ~ V03.

[0057] In this embodiment, the waste heat driving subsystem adopts a Rankine cycle power system using water as a working substance. This embodiment is a schematic diagram of system operation under an active control gas turbine combined cycle working condition. In the steam power subsystem 6, the waste heat boiler recovers and utilizes the heat of the flue gas to produce superheated steam, and a steam turbine performs external work to drive a generator to generate electricity. The flue gas hot water heat exchanger pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com