Sodium sulfate evaporation crystallization device

A technology of evaporative crystallization and sodium sulfate, applied in the field of evaporative separation equipment, can solve problems such as temperature drop and heat energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

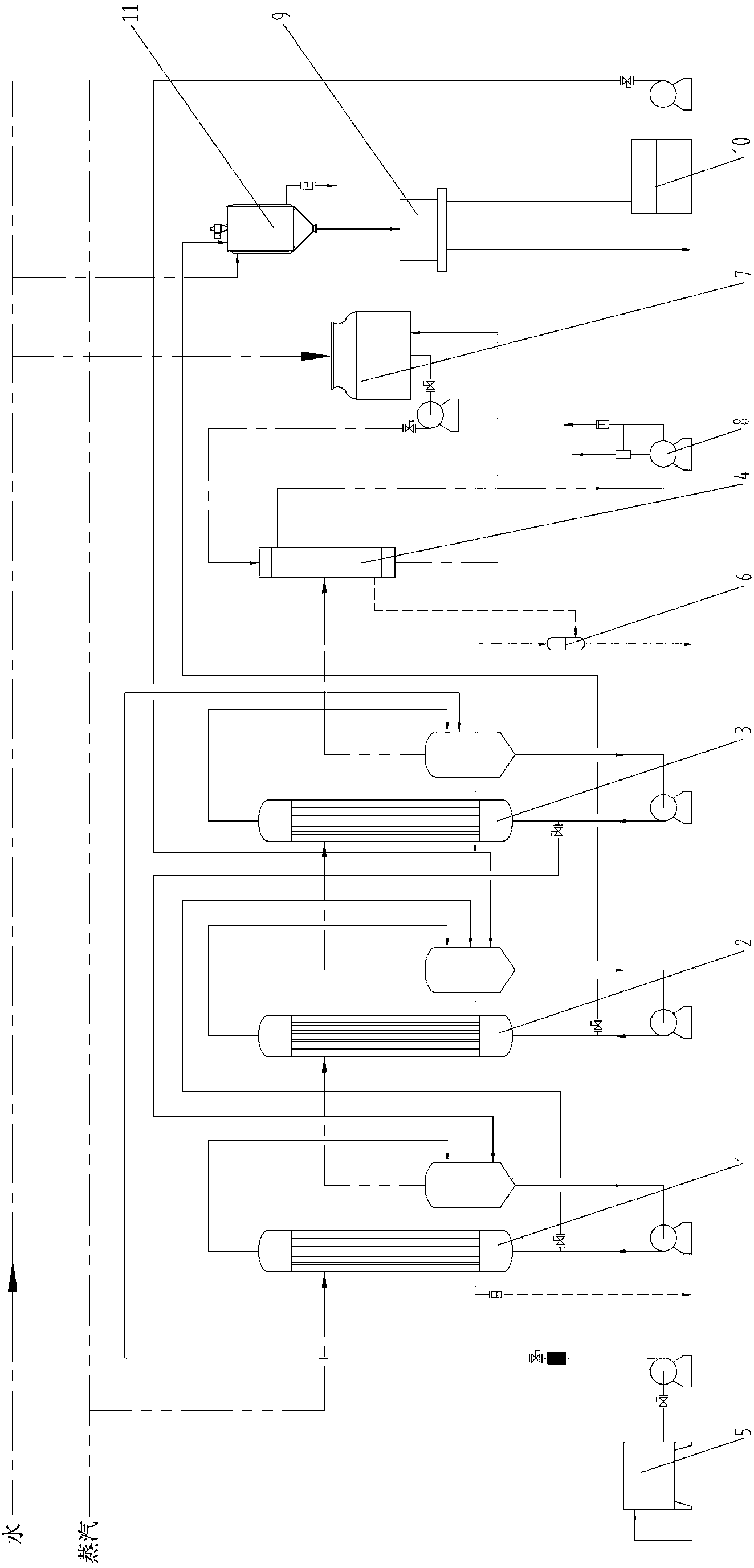

[0011] Embodiment: the structure of the sodium sulfate evaporative crystallization device provided by the invention is as figure 1 As shown, it includes the first effect evaporator unit 1, the second effect evaporator unit 2 and the third effect evaporator unit 3, which are connected in sequence. The design first achieves the purpose of saving steam by using a multi-effect device, and each effect evaporator Circulation pumps are used inside the unit for forced circulation, so that the material has a faster flow rate and evaporation speed in the system.

[0012] Wherein the first effect evaporating unit 1 is connected to the steam input pipe, the steam passes through the heaters of the first effect evaporating unit 1, the second effect evaporating unit 2 and the third effect evaporating unit 3 successively, and then condenses and recovers, and the temperature decreases successively. And the third effect evaporating unit 3 is connected with the feeding tank 5, and the sewage con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com