SCAL indirect air cooling system

An air-cooling system and indirect technology, applied in indirect heat exchangers, steam/steam condensers, fixed conduit components, etc., can solve the problems of high capital investment and large footprint of air cooling towers, and achieve low capital investment, investment savings, The effect of easy water quality control and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

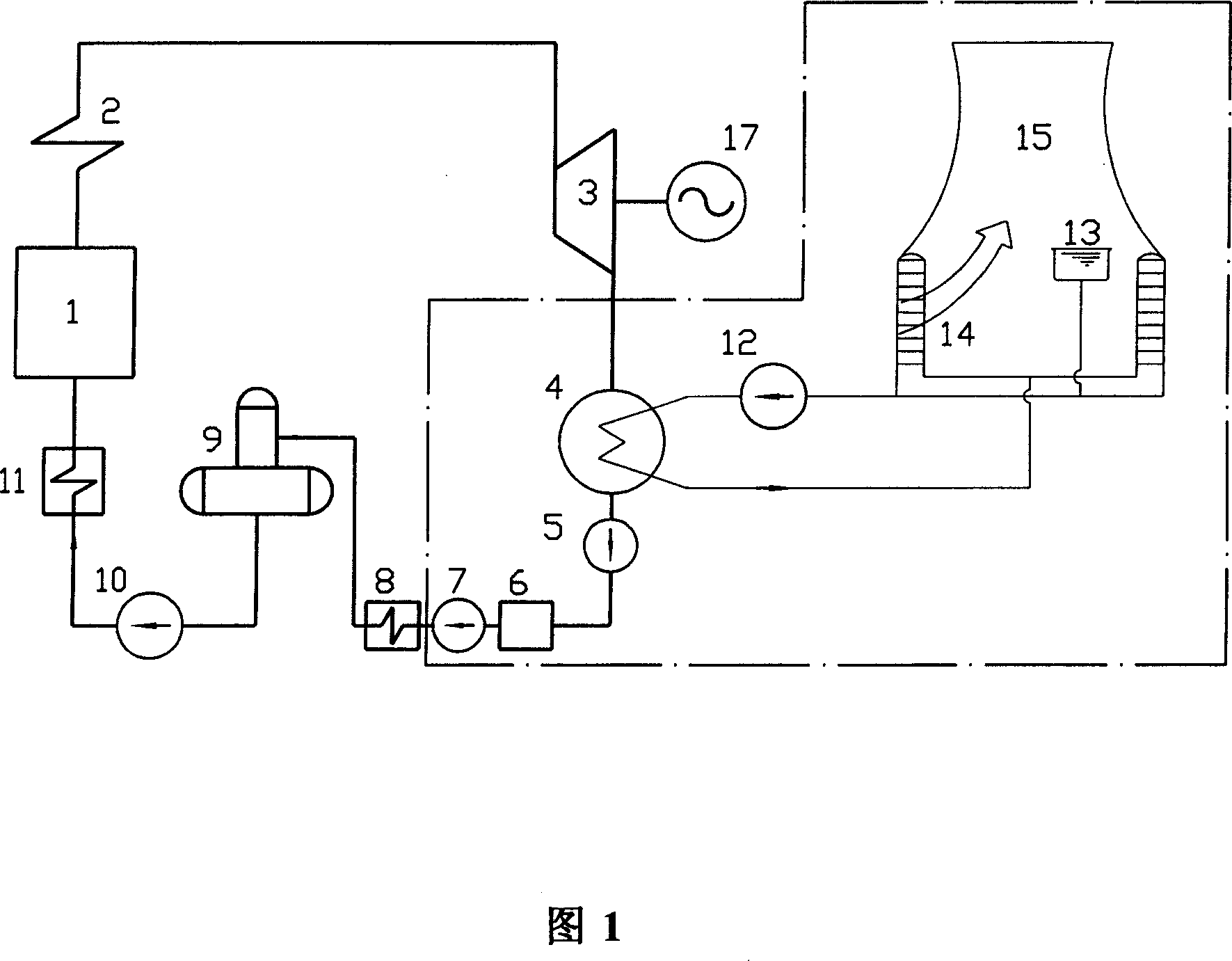

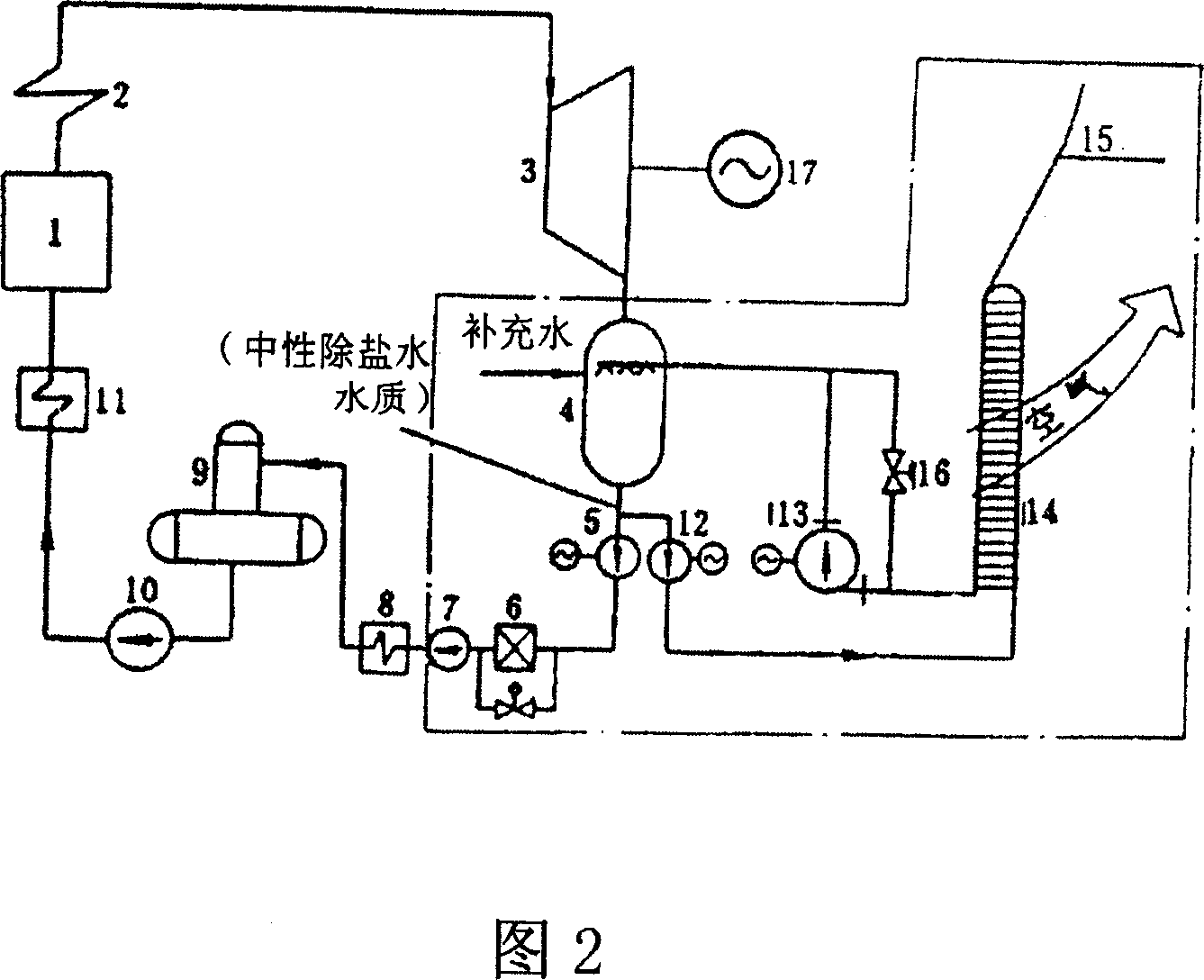

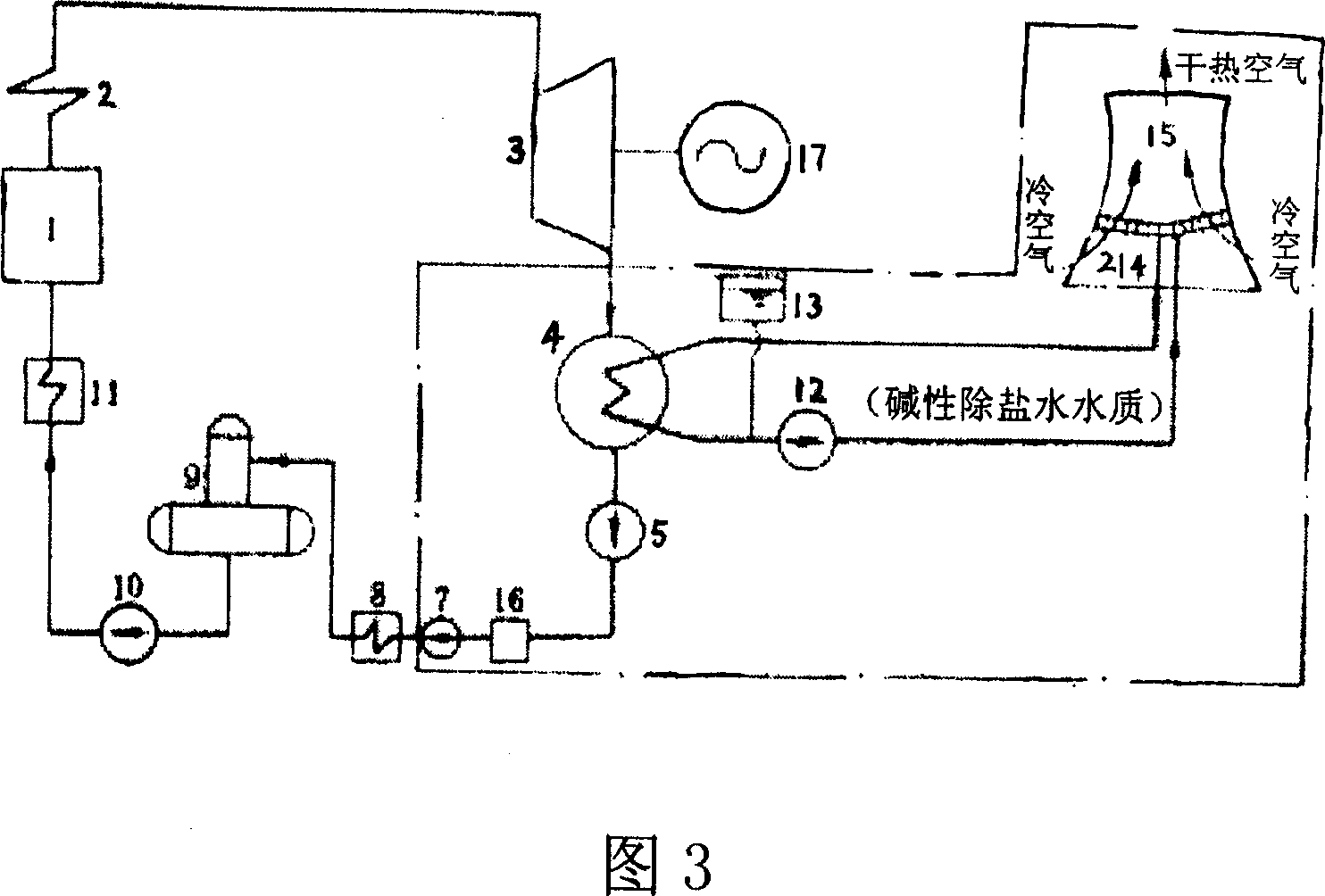

[0034] In order to enable the responsible examiner to understand the structure and composition of the present invention, as well as the overall operation mode, it is described as follows in conjunction with the drawings:

[0035] At present, there are two kinds of indirect air-cooling systems in the world. The Heller-type indirect air-cooling system requires that the cooling water system and the boiler feed water be connected together. Due to the strict quality control of the boiler feed water, it is particularly difficult to control and treat the feed water quality of the 600MW unit with high parameters and large capacity. The application of Heller indirect air cooling system in the world is limited to below 300MW units. The Harmon-type indirect air cooling system adopts steel pipe and steel sheet radiators, which are arranged radially in the air cooling tower horizontally, which fails to make full use of the ventilation area of the air cooling tower, resulting in a large ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com