Homogeneous ion-exchange membrane electrodialysis reduction treatment process for desulfurization waste water of coal-fired power plant

A homogeneous ion exchange and desulfurization wastewater technology, which is applied in the field of water treatment, can solve problems that do not involve the specific process and control methods of the concentration and weight loss process, and achieve the effects of reducing energy consumption, improving efficiency, and high concentration and weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

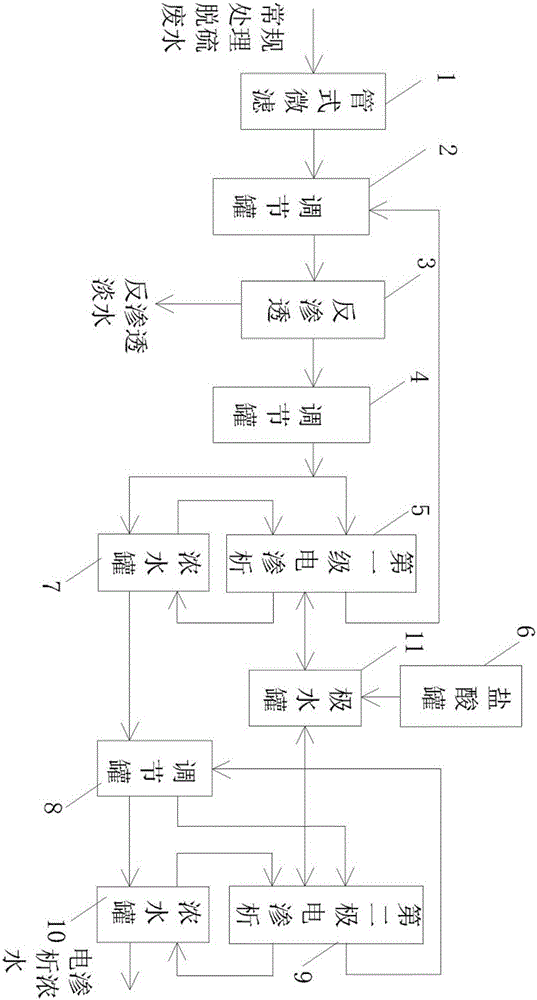

[0016] refer to figure 1 As shown, the conventionally treated desulfurization wastewater, TDS=19209mg / L, is filtered through the tubular microfiltration device 1 to remove impurities such as suspended solids, and obtain clarified desulfurization wastewater with SS=4. The clarified desulfurization wastewater flows into the regulating tank 2 . The clarified desulfurization waste water is pre-concentrated through the reverse osmosis device 3 (one stage and two stages) to obtain pre-concentrated desulfurization waste water with TDS=31890 mg / L and reverse osmosis fresh water with TDS=410 mg / L. The reverse osmosis device 3 adopts low-pressure anti-pollution brackish water reverse osmosis membrane elements, the width of the water inlet channel is 40mil, and the membrane flux is 40L / (m 2 h), the desalination rate is 99.5%. The reverse osmosis concentrated water has a salt concentration of 3.3% (mass percentage) to achieve pre-concentration of desulfurization wastewater; the reverse ...

Embodiment 2

[0022] refer to figure 1 As shown, the conventionally treated desulfurization wastewater, TDS=21080mg / L, is filtered through a tubular microfiltration device to remove impurities such as suspended solids, and obtain clarified desulfurization wastewater with SS=4. The clarified desulfurization wastewater is pre-concentrated through the reverse osmosis device (one stage and two stages). 2 h), the desalination rate is 99%. The reverse osmosis concentrated water has a salt concentration of 2.8% (mass percentage) to achieve pre-concentration of desulfurization wastewater; the reverse osmosis fresh water has a salt concentration of ≤0.05% (mass percentage) and is returned to the desulfurization tower for flue gas desulfurization.

[0023] The pre-concentrated desulfurization wastewater (reverse osmosis fresh water TDS=430mg / L) with TDS=32870mg / L was obtained. The pre-concentrated desulfurization wastewater is pre-concentrated through the first-stage electrodialysis device, the cap...

Embodiment 3

[0026] refer to figure 1 As shown, the conventionally treated desulfurization wastewater, TDS=21080mg / L, is filtered through a tubular microfiltration device to remove impurities such as suspended solids, and obtain clarified desulfurization wastewater with SS=4. The clarified desulfurization wastewater was pre-concentrated through a reverse osmosis device (one stage and two stages) to obtain pre-concentrated desulfurization wastewater with TDS=32870 mg / L (reverse osmosis fresh water TDS=430 mg / L). The pre-concentrated desulfurization wastewater is pre-concentrated through the first-stage electrodialysis device, the capacity of the adjustment tank 2 is 15 times that of the concentrated water tank 1, the flow rate of the feed liquid is 3.4cm / sec, and the average current density is 450A / cm 2 , to obtain desulfurization wastewater after primary concentration of TDS=96500mg / L (conductivity 125mS / cm). The pre-concentrated desulfurization wastewater is deeply concentrated through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com