Membrane treatment process for heavy metal waste water generated during PCB production process

A production process, heavy metal technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve problems affecting production efficiency, ion exchange resin regeneration difficulties, etc. Achieve the effects of preventing the transfer of pollution, optimistic development prospects, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

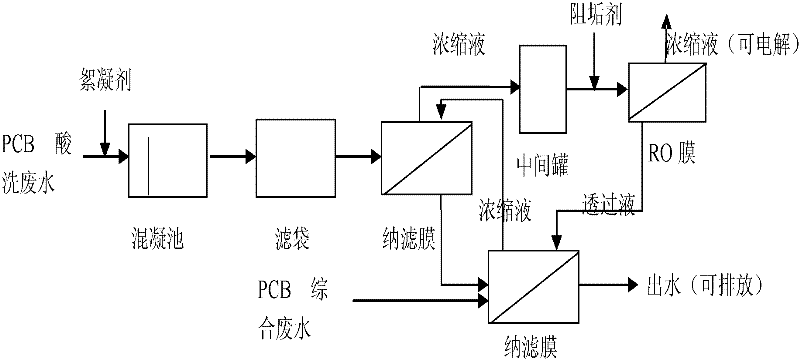

[0026] The general pickling wastewater generated in the PCB production process passes through the filter bag pretreatment system after flocculation and precipitation, and the filtrate (300 liters) enters the roll-type nanofiltration system with a membrane pore size greater than 1nm. The operating temperature of the nanofiltration system is controlled at 30°C and the pressure 1.25MPa; the concentrate (30L) passes through a reverse osmosis membrane system with a pore size of 0.2nm at a temperature of 40°C and a pressure of 2.0MPa to finally obtain a concentrate (5L), in which the concentration of copper ions reaches 3g / L, can enter the electrolysis process; obtain the nanofiltration permeate (270 liters), which is similar to the composition of the comprehensive wastewater, so it can be mixed with the comprehensive wastewater to enter the nanofiltration system. The operating temperature of the nanofiltration system is 30 ° C and the pressure is 3.0 MPa.

Embodiment 2

[0028] The general pickling wastewater generated in the PCB production process passes through the filter bag pretreatment system after flocculation and precipitation, and the filtrate (300 liters) enters the roll-type nanofiltration system with a membrane pore size greater than 1nm. The operating temperature of the nanofiltration system is controlled at 35°C and the pressure The concentrated solution (60L) passes through a reverse osmosis membrane system with a pore size of 0.2nm at a temperature of 40°C and a pressure of 2.0MPa. Finally, the concentrated solution (6 liters) is obtained, in which the nickel ion concentration is about 1g / L, which can enter the electrolysis process; the nanofiltration permeate (240 liters) is obtained, which is similar to the composition of the comprehensive wastewater, so it can be mixed with the comprehensive wastewater into the nanofiltration system. The operating temperature of the nanofiltration system is 35°C and the pressure is 2.5MPa.

Embodiment 3

[0030] The comprehensive wastewater generated in the PCB production process passes through the filter bag pretreatment system after flocculation and precipitation, and the filtrate (300 liters) rises into the roll-type nanofiltration system with a membrane pore size greater than 1nm. The temperature of the nanofiltration system is controlled at 20°C and the operating pressure is 1.25MPa. Finally, 270L permeate and 30L concentrate are obtained. The concentrate can enter the reverse osmosis treatment process of general pickling wastewater, and the permeate can meet the national discharge standard and can be discharged directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com