Novel composite lean iron ore pre-concentration technology and production system thereof

An iron ore and new process technology, which is applied to a new pre-selection process of composite lean iron ore and its production system, and the field of medium and low-grade magnetite ore, can solve the problem of insufficient gangue sorting, large amount of tailings, and energy consumption. Advanced problems, to achieve the effect of improving grade, reducing ore volume, power consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

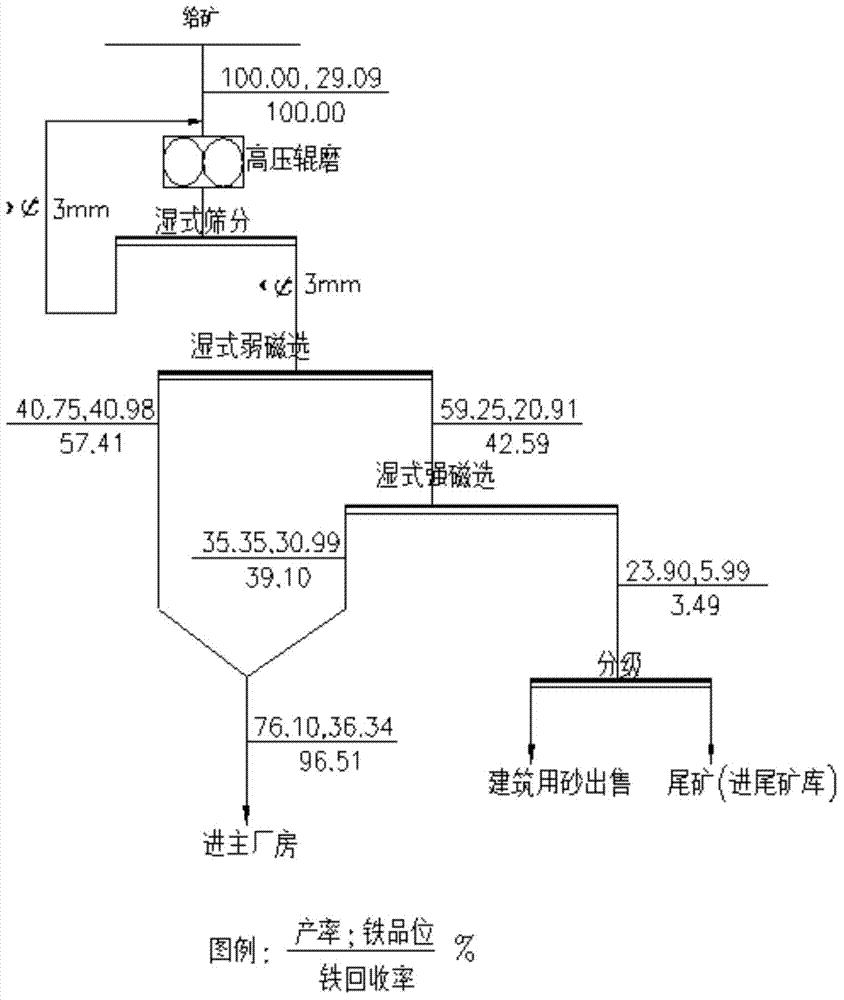

[0045] For further describing the present invention, below in conjunction with accompanying drawing and example the present invention will be further described:

[0046] The ore samples in this example are taken from the mixed iron ore of Huoqiu Zhouji Iron Mine in Anhui Province. The analysis results of multi-element and iron phase of the original ore are shown in Table 1 and Table 2 below.

[0047] Sample multi-element analysis results Table 1

[0048] the element

TF

S Fe

FeO

S

P

Content (%)

29.09

17.29

8.12

0.069

0.034

the element

CaO

MgO

SiO 2

al 2 o 3

caustic soda

Content (%)

1.86

1.39

46.20

3.23

2.07

[0049] Sample iron phase analysis results Table 2

[0050] mineral name

Content (%)

Proportion(%)

14.09

48.44

False Hematite

3.20

11.00

4.10

14.09

iron carbonate ...

Embodiment 2

[0070] In step B of Example 1, since the ore-discharging product of the high-pressure roller mill is a cake-shaped material, it directly enters the linear vibrating screen I for wet screening. Since the vibrating screen does not have the function of breaking up the material, the cake-shaped material is difficult to sieve points, resulting in low production efficiency of the entire production process.

[0071] A new process for the pre-selection of composite lean iron ore in this embodiment, the process steps are the same as in embodiment 1, the difference is that in order to improve the production efficiency of the whole process, the cake-like materials are first dispersed by a wet high-efficiency disperser.

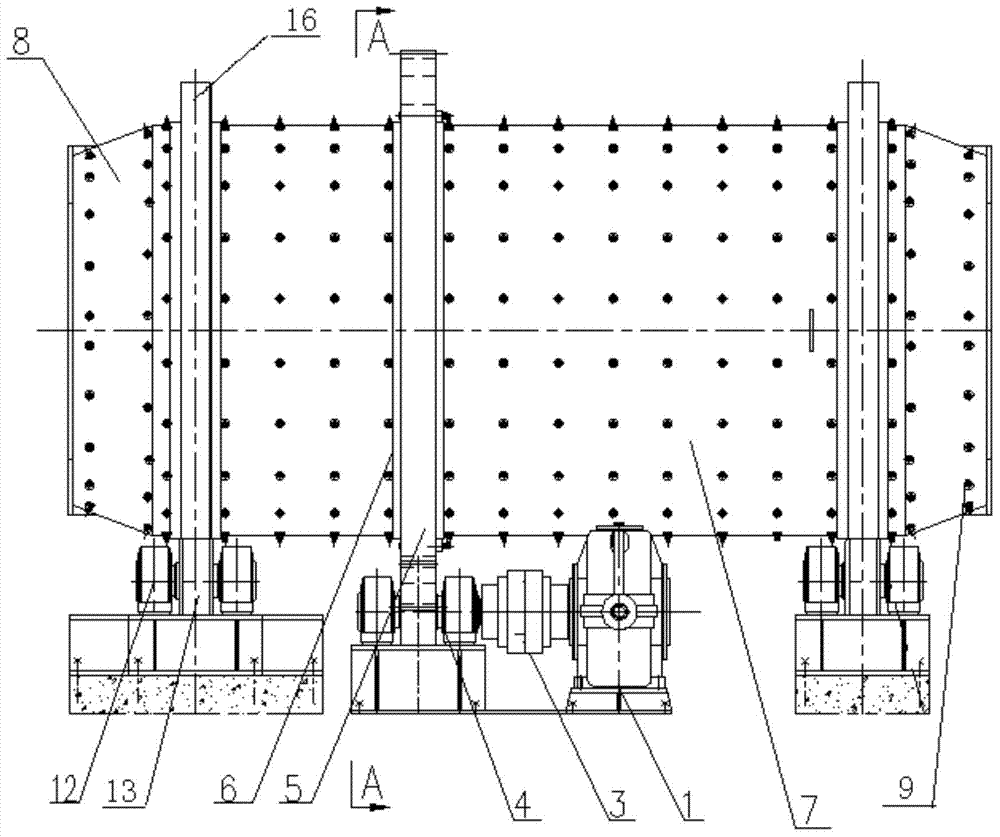

[0072] The wet high-efficiency dispersing machine used in a new process for the pre-selection of composite lean iron ore in this embodiment, such as figure 2 As shown, it includes a cylinder 7, a power device and a transmission device. The power device is fixed on the g...

Embodiment 3

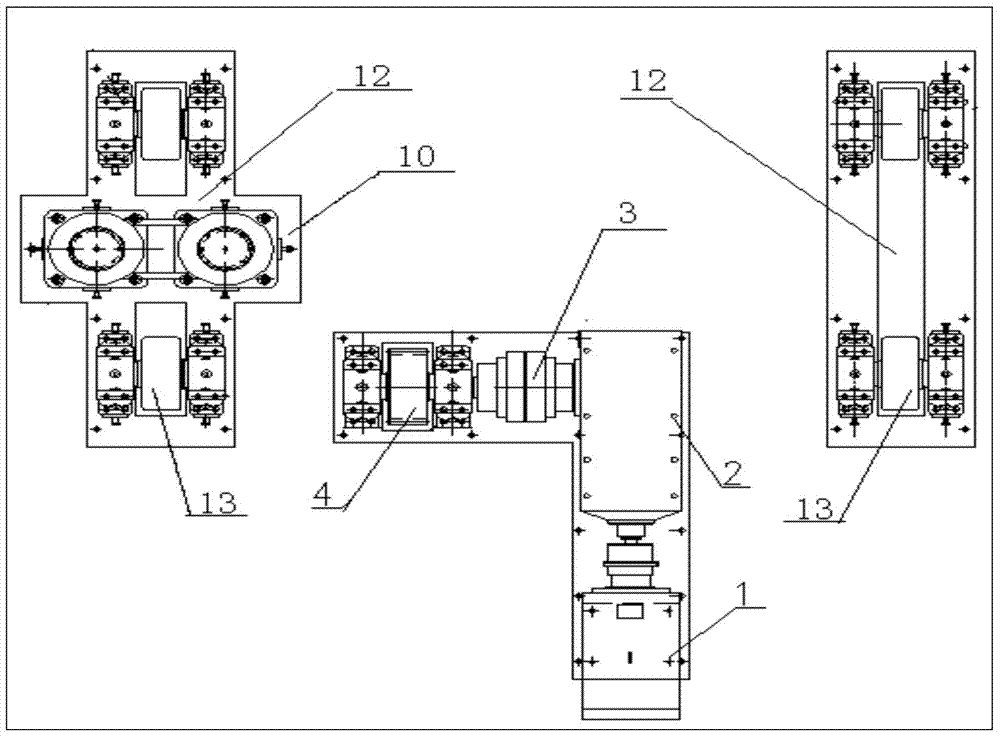

[0078] A kind of composite poor iron ore pre-selection novel process of the present embodiment, process step is the same as embodiment 2, and difference is: as image 3 As shown, the wet high-efficiency dispersing machine used also includes a supporting wheel device 12 and a blocking wheel device 10; the supporting wheel device 12 is fixed on the ground and is a rotating shaft type rolling bearing supporting wheel set, including 4 supporting wheels and 2 The runners 13 are divided into two groups of front and rear symmetry, and each group has the runners 13 in the middle, and the support rollers are symmetrically arranged on both sides of the runners 13, and the runners 13 and the rolling rings 16 arranged on the left and right outer walls of the cylinder 7 The rotating connection is used to bear the weight of the entire rotating body and the material. The supporting wheel 13 and the running wheel 13 are used in symmetry, the structure is simple, the maintenance is convenient, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com