Green and environment-friendly method for preparing silk fibroin powder

A technology of protein powder and silk protein solution, which is applied in the field of natural polymers, can solve the problems of complex operation process, high cost, and reduction of silk protein molecular weight, etc., and achieve the effects of high biological safety, short production cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

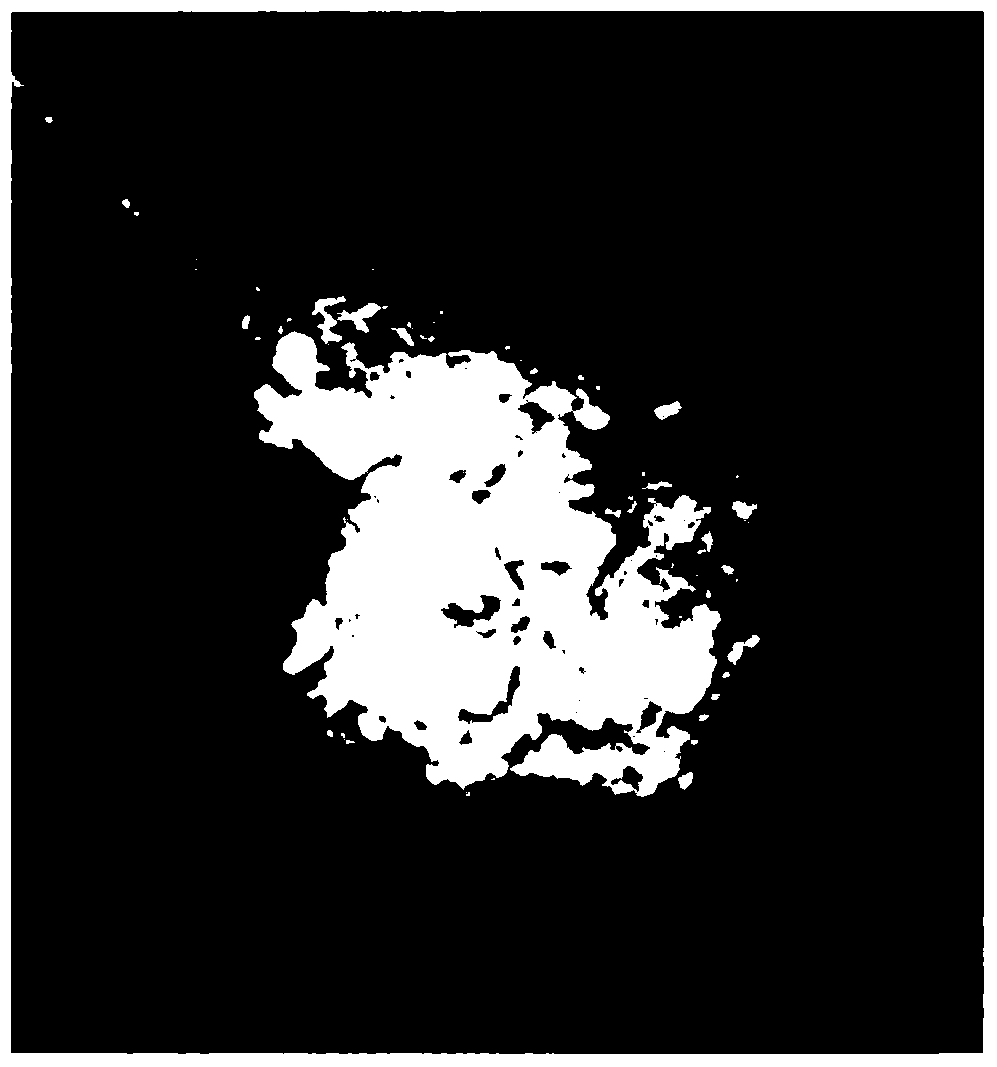

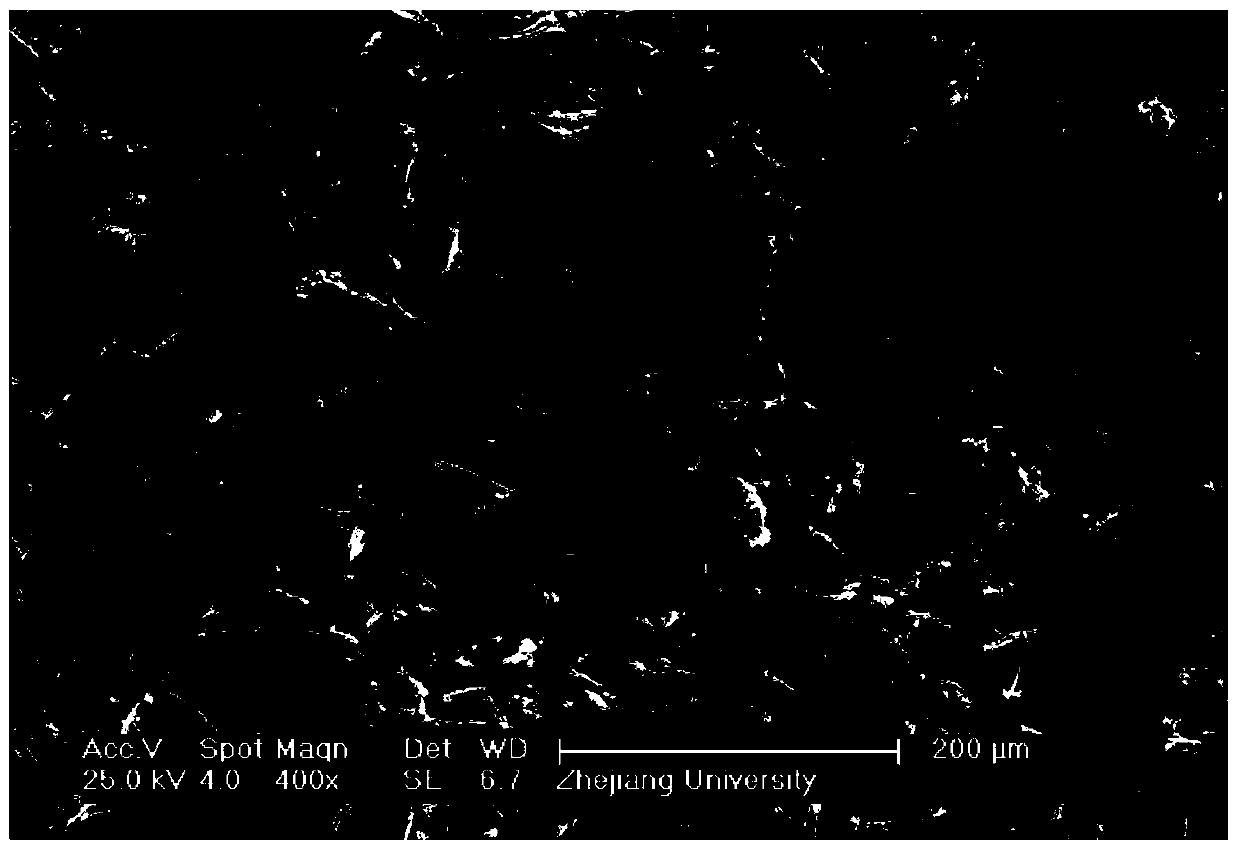

Image

Examples

Embodiment 1

[0026] (1) degumming; 7g silkworm cocoon shell is 0.5wt%Na in 700mL concentration 2 CO 3 The aqueous solution is boiled for degumming twice, and the degummed silk is washed with water and dried to obtain silk fibers; (2) pre-alkali washing; all the obtained silk fibers are added to 80mL of NaOH solution (0.02mol / L), Stand still at room temperature for 30 minutes; (3) high temperature and high pressure treatment; transfer the system substances in the above steps to an autoclave, and keep at 121° C. for 20 minutes to obtain a silk protein solution. (4) Purification; the silk protein solution obtained in the above steps is neutralized with 0.1mol / L hydrochloric acid, the pH is 7.0, then put into a dialysis bag, and dialyzed with deionized water for 24 hours; (5) Pre-concentration and drying; Part of the water was evaporated from the obtained silk solution by air drying to obtain a silk solution with a concentration of 8 wt%. The silk fibroin powder is obtained after freeze-dryi...

Embodiment 2

[0028] (1) degumming; 5 g The concentration of tussah cocoon shell in 500mL is 0.5wt%Na 2 CO 3 The aqueous solution was boiled for degumming treatment, each time for 30 minutes, and repeated three times. Wash the degummed tussah silk with water afterwards to obtain tussah silk fibers; (2) pre-alkali washing; add the obtained tussah silk fibers to 80mL of NaOH solution (0.1mol / L), and let stand at room temperature for 2 hours; (3 ) high temperature and high pressure treatment; transfer the system substances in the above steps to an autoclave, keep at 121° C. for 30 minutes, and obtain tussah silk protein solution. (4) Purification; neutralize the tussah silk protein solution obtained in the above steps with 1mol / L hydrochloric acid, put it into a dialysis bag, and perform dialysis with deionized water for 24 hours; (5) pre-concentrate and dry; the obtained silk protein Part of the water is evaporated from the solution by air-drying to obtain a tussah silk fibroin protein sol...

Embodiment 3

[0030] (1) degumming; 7g silkworm cocoon shell is 0.5wt%Na in 700mL concentration 2 CO 3 The aqueous solution is boiled and degummed twice, and the degummed silk is washed with water and dried to obtain silk fibers; (2) high temperature and high pressure treatment; all the obtained silk fibers are added to 0.01mol / L KOH solution, and then transferred to In an autoclave, keep at 121° C. for 30 minutes to obtain a silk protein solution. (3) Purification; neutralize the silk protein solution obtained in the above steps with 0.5mol / L hydrochloric acid, put it into a dialysis bag, and perform dialysis with deionized water for 12 hours; (4) Pre-concentrate and dry; the obtained silk protein The solution was concentrated by a vacuum rotary evaporation method to obtain a silk fibroin solution with a silk fibroin solution concentration of 5 wt%. After freeze-drying, silk fibroin powder is obtained; (5) 1 g of silk fibroin powder is dissolved in 10 mL of formic acid solution to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com