Regeneration method of molecular sieve catalyst

A catalyst and molecular sieve technology, applied in the field of molecular sieve catalyst regeneration, can solve problems such as damage to the internal structure of the catalyst, and achieve the effects of protecting from damage, alleviating strong heat release, and reducing flying temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

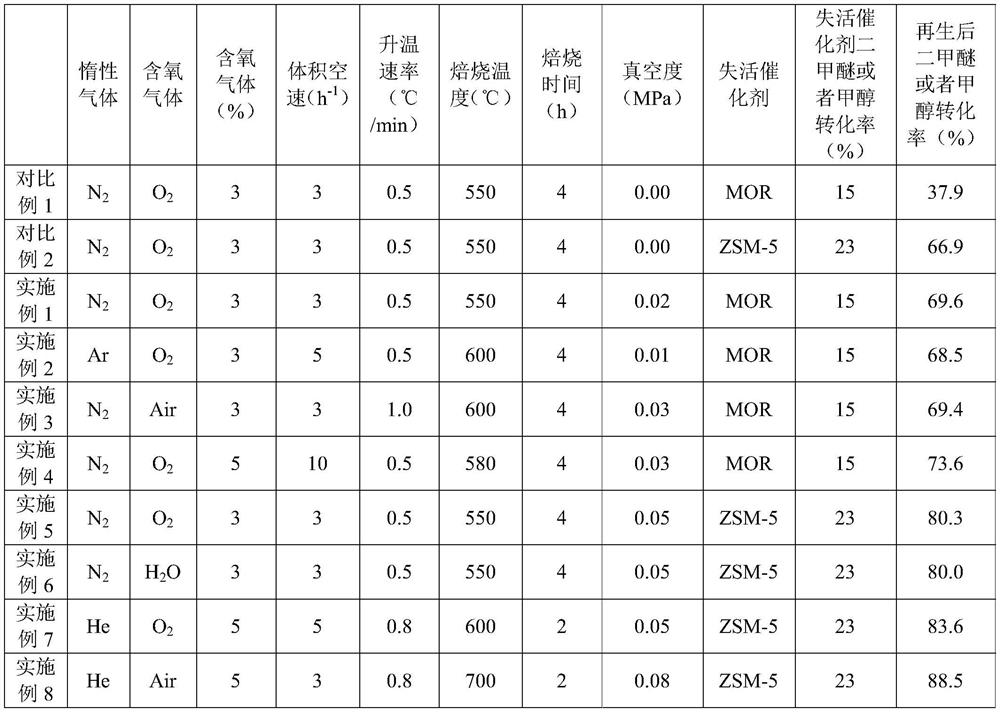

Embodiment 1

[0052] Take 10ml of Cat.1, fill it into the fixed bed regeneration device, feed the mixed gas of nitrogen and oxygen into the fixed bed regeneration reaction tube, the volume content of oxygen is 3%, and the total gas velocity is 3.0h -1 , the tail gas is connected to the vacuum pump, turn on the vacuum pump, keep the vacuum at 0.02MPa, raise the temperature to 550°C at 0.5°C / min, and roast for 4h.

Embodiment 2

[0054] Take 10ml of Cat.1, fill it into the fixed bed regeneration device, feed the mixed gas of argon and oxygen into the fixed bed regeneration reaction tube, the volume content of oxygen is 3%, and the total gas velocity is 5.0h -1 , the tail gas is connected to the vacuum pump, the vacuum pump is turned on, the vacuum degree is kept at 0.01MPa, the temperature is raised to 600°C at 0.5°C / min, and roasted for 4h.

Embodiment 3

[0056] Take 10ml of Cat.1, fill it into the fixed bed regeneration device, feed the mixed gas of nitrogen and air into the fixed bed regeneration reaction tube, the volume content of oxygen is 3%, and the total gas velocity is 3.0h -1 , the tail gas is connected to the vacuum pump, turn on the vacuum pump, keep the vacuum at 0.03MPa, raise the temperature to 600°C at 1°C / min, and roast for 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com