Preparation of functionalized carbon nano-tube modification polyurethane elastomer

A technology of carbon nanotube modification and polyurethane elasticity, which is applied in the field of preparation of functionalized carbon nanotube modified polyurethane elasticity, can solve the problem of changing the performance effect of polymer materials, poor dispersion of carbon nanotubes, weak binding force, etc. problems, to achieve the effect of facilitating large-scale industrial production, improving mechanical properties, and enhancing interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

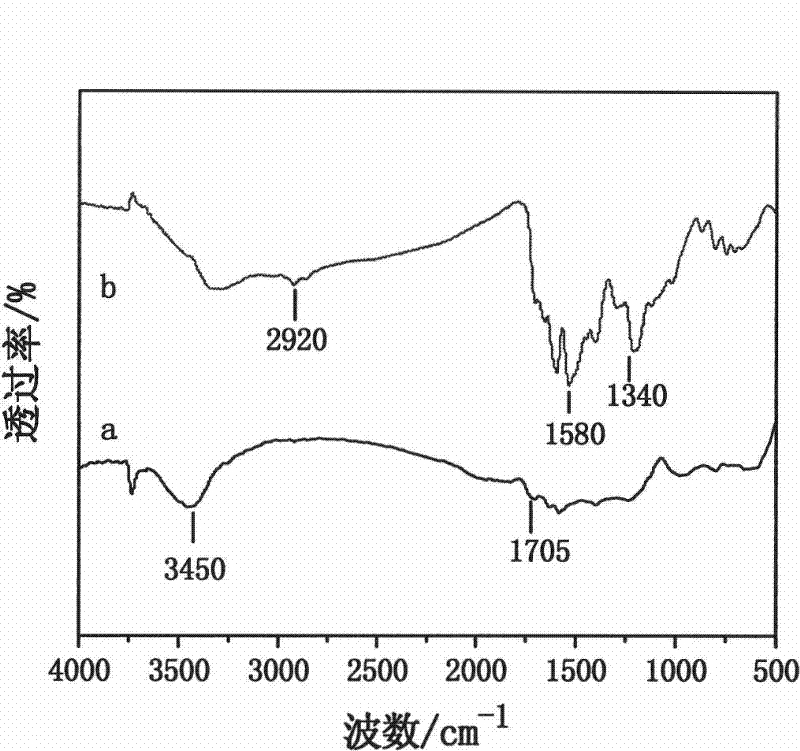

[0022] (1) Put 2g of multi-walled carbon nanotubes (MWNT) into a single-necked flask, add 70% concentrated nitric acid and 95% concentrated sulfuric acid mixture (100ml, volume ratio 1:3) for ultrasonication for 1h, then heat in a water bath at 80°C Condensate and reflux for 3 hours, centrifuge, add deionized water and wash for several times until the pH value of the mixed solution is about neutral, put the washed MWNT in a vacuum oven and dry for 48 hours to obtain oxidized multi-walled carbon nanotubes MWNT-COOH, which are placed in Store in a desiccator.

[0023] (2) Dissolve 0.05g of dried oxidized MWNT in 10ml of DMAC and ultrasonically shake for 1h to completely disperse the carbon nanotubes in DMAC, then heat it in a water bath to 70°C, add 0.8ml of TDI, and react for 4h to obtain surface-grafted Carbon nanotubes with TDI groups.

[0024] (3) 10 g of thermoplastic polyurethane particles were dissolved in 30 ml of DMAc solvent, swelled at room temperature for 4 hours, a...

Embodiment 2

[0029] (1) Same as Example 1, except that the multi-walled carbon nanotubes are replaced by single-walled carbon nanotubes (SWNTs).

[0030] (2) Dissolve 0.15g of dry oxidized SWNT in 10ml DMF and oscillate ultrasonically for 1h to completely disperse the carbon nanotubes in DMF, then heat in a water bath to 70°C, add 2.5ml of TDI, and react for 4h to obtain surface-grafted Carbon nanotubes with TDI groups.

[0031] (3) As in Example 1, mix the carbon nanotubes grafted with TDI in (2) into the prepared polyurethane solution.

[0032] (4) The carbon nanotube / polyurethane solution prepared in (3) is cast into a film to obtain a carbon nanotube / polyurethane composite material with a mass percentage of SWNT-TDI of about 1.5%. The measured tensile strength of the composite material is 21MPa, and the elongation at break is 426%.

Embodiment 3

[0034] (1) With embodiment 1.

[0035] (2) Dissolve 0.3g of dried oxidized MWNT in 10ml DMSO and ultrasonically shake for 1h to completely disperse the carbon nanotubes in DMSO, then heat in a water bath to 70°C, add 5mlMDI, and react for 4h to obtain MDI grafted on the surface groups of carbon nanotubes.

[0036] (3) Same as Example 1, mix the carbon nanotubes grafted with MDI in (2) into the prepared polyurethane solution.

[0037] (4) The carbon nanotube / polyurethane solution prepared in (3) is cast into a film to obtain a carbon nanotube / polyurethane composite material with a mass percentage of MWNT-MDI of about 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com