Method and system for preparing part through additive manufacturing, equipment and storage medium

A technology of additive manufacturing and parts, applied in the direction of additive manufacturing, additive processing, etc., can solve the problems of complex manufacturing process, difficult to manufacture material structure, limit the development and application of intelligent material structure, etc., achieve good designability, prevent heat Stress destruction, reducing the effect of sudden changes in physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

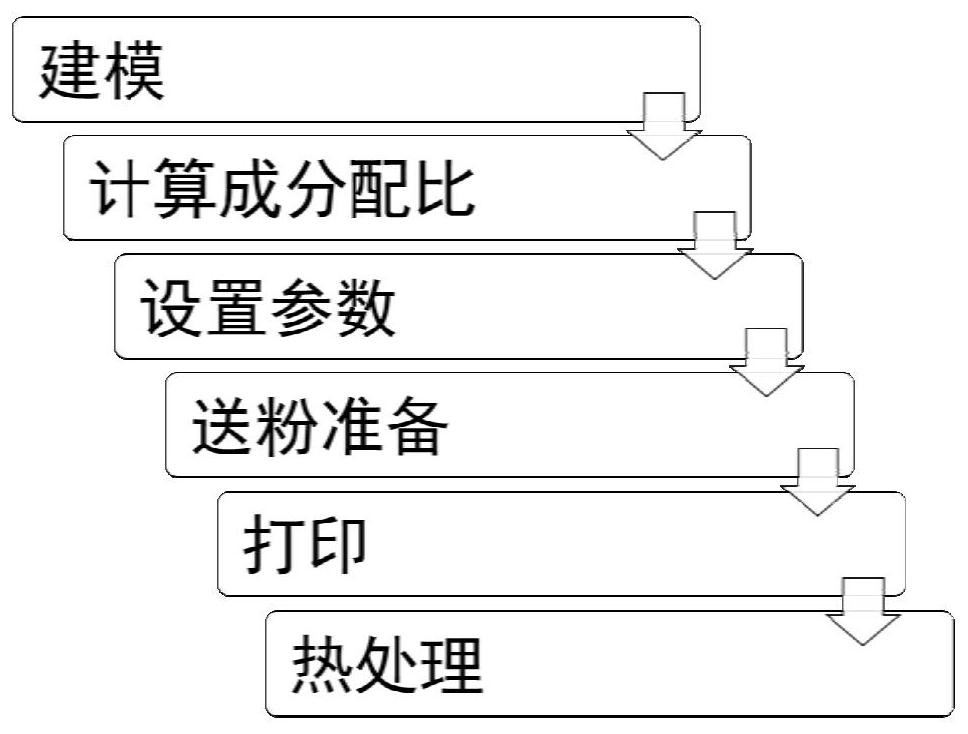

[0029] Such as figure 1 As shown, the method for preparing parts for the additive manufacturing described in the present invention includes the following steps.

[0030] 1) Modeling: According to the requirements of the use conditions of the parts to be prepared, a physical model of material performance is established based on computer simulation analysis software, and the overall physical model of the material is subjected to regional micro-element processing. The regional micro-element processing process is: the entire physical model Divide into multiple cubes of the same size and shape, and then divide the area according to the composition and performance of different materials in different positions; analyze the performance requirements of materials in different areas, and then carry out the result inversion to determine the material composition of each area, any a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com