Tool for ball screw pair outer raceway grinding and grinding force loading

A ball screw pair and outer raceway technology, used in metal processing equipment, grinding machine parts, grinding/polishing safety devices, etc., can solve the problems of high cost of whirl milling and inability to guarantee the accuracy requirements of ball screws. , to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

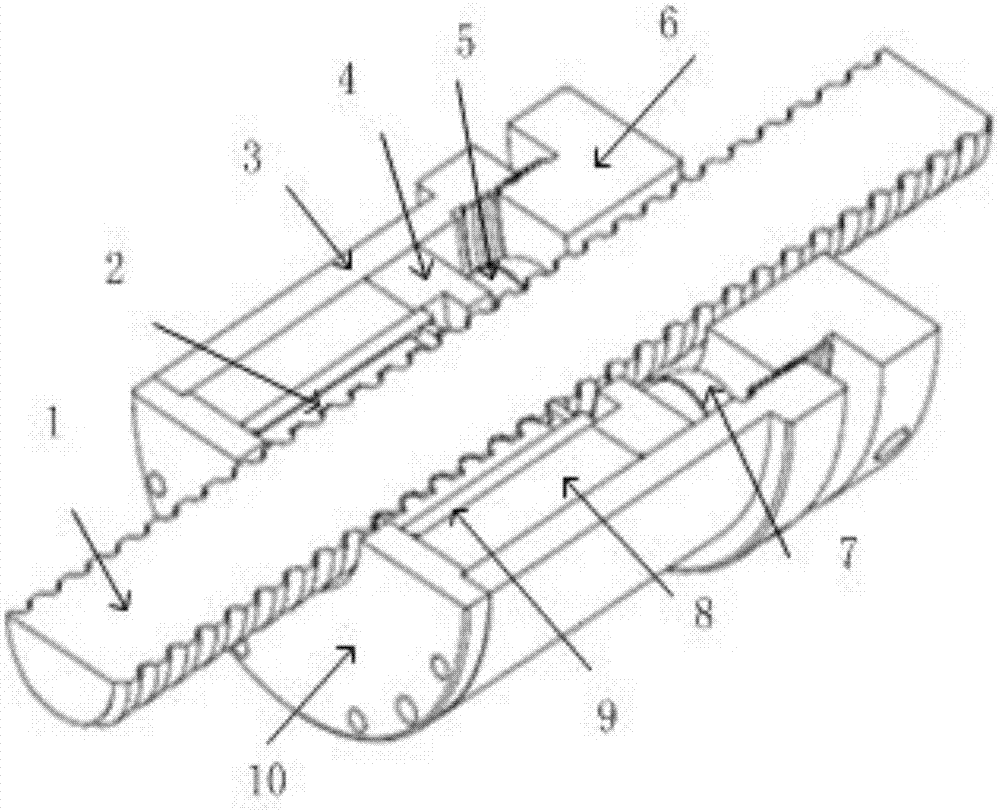

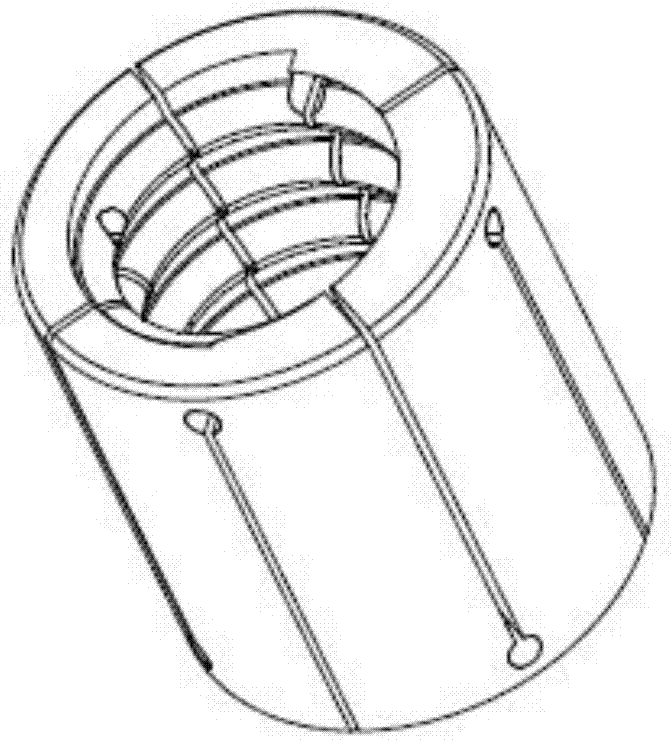

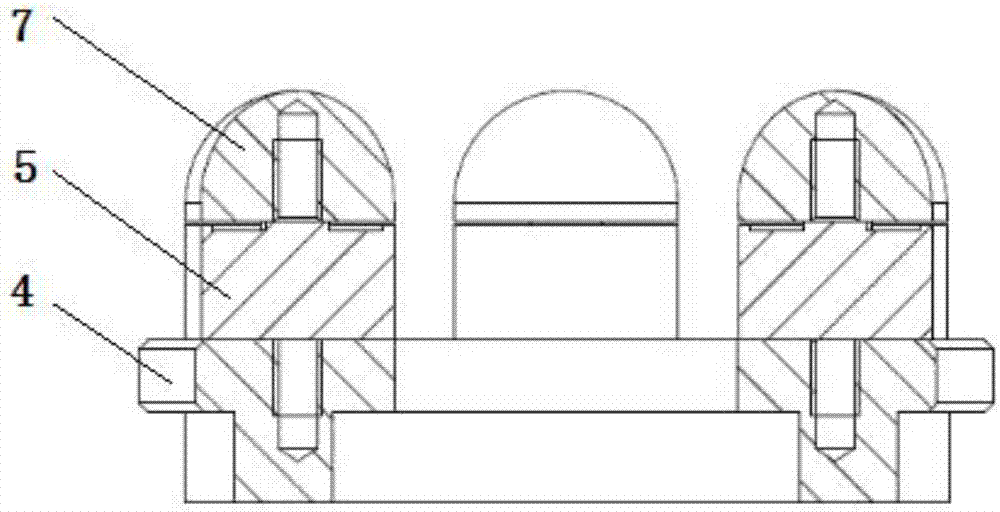

[0013] to combine figure 1 , a tooling for grinding the outer raceway of a ball screw pair and loading the grinding force. The whole tooling is composed of a grinding part and an afterburning device. The grinding part is composed of a flexible grinding nut 2 and a lead screw 1. The reinforcing part is composed of polyurethane elastic body 8, polyurethane buffer body 9, grinding jacket 3 and threaded end cap 6 for applying pressure to the rubber ring. In addition, a sensor assembly and a housing base 10 are included. Outer base 10 is set at the front end of grinding outer cover 3 and forms a grinding cavity with grinding outer cover 3. Outer cover base 10 is provided with a first lead screw through hole, flexible nut 2 is arranged in the grinding cavity and is matched with lead screw 1, and 9 sets of polyurethane buffers On the flexible nut 2, the polyurethane elastic body 8 is set on the polyurethane buffer body 9, the inner wall of the polyurethane elastic body 8 is closely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com