Magneto-rheological elastomer double-annular-membrane damper

A magnetorheological elastomer and damper technology, applied in springs/shock absorbers, springs, shock absorbers, etc., can solve the problems of large piston mass, difficult to apply vibration reduction requirements, and small gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

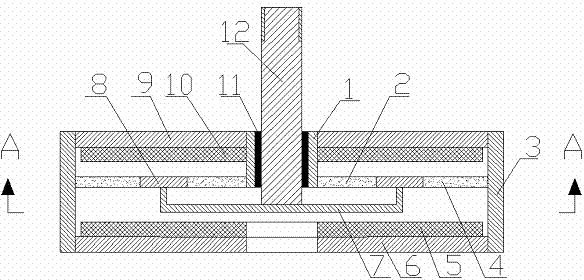

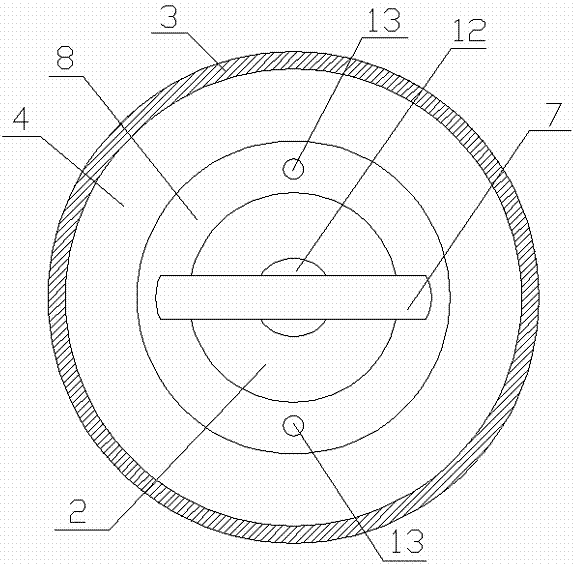

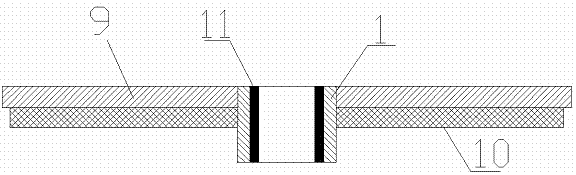

[0015] see Figure 1 to Figure 6 , which is a specific structure of the present invention,

[0016] A magneto-rheological elastomer double-ring film damper, which includes a working cylinder 3, a damping rod 12, two large and small ring-shaped damping films 4 and 2, a ring-shaped damping sheet 8 and two single-sided ring electromagnets 6 and 9 Working cylinder 3 wherein is made of cylinder 3 and two single-sided annular electromagnets 6 and 9, and single-sided annular electromagnet 6 only has 4 pairs of magnetic poles 5 evenly distributed on a ring surface, on each magnetic pole 5 Excitation coils 16 are all wound around, and on the single-sided annular electromagnet 9, there are only 4 pairs of magnetic poles 10 evenly distributed on the toroidal surface, and on each magnetic pole 10, excitation coils 17 are all wound around, and on the single-sided annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com