A surface-enhanced Raman scattering substrate material for gas detection and its preparation method

A surface-enhanced Raman and gas detection technology, used in Raman scattering, material analysis, material excitation analysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a surface-enhanced Raman scattering base material for gas detection, specifically comprising the following steps:

[0034] Step 1. Cut the glass into small squares of 0.6×0.6cm, grind the base with sandpaper to form a rough working surface, and then use acetone, isopropanol, and ethanol for ultrasonic cleaning in sequence, each ultrasonic cleaning time is 20-30min, and finally dry the glass with nitrogen piece;

[0035] Step 2. Soak the substrate prepared in step 1 in 10mL of 10mM tetrachloroauric acid trihydrate aqueous solution, add ammonia water with a concentration of 0.6%, control pH 8-10, and oscillate at an oscillation frequency of 500rpm for 5min to make chloroauric acid Ions are adsorbed on the rough working surface;

[0036] The substrate prepared in step 3 and step 2 is soaked in 1mM sodium borohydride aqueous solution, and the oscillation frequency is 500rpm for 5 minutes, so that the gold ions are rapidly reduced to nucleate and form...

Embodiment 2

[0039] Embodiment two, different from embodiment one,

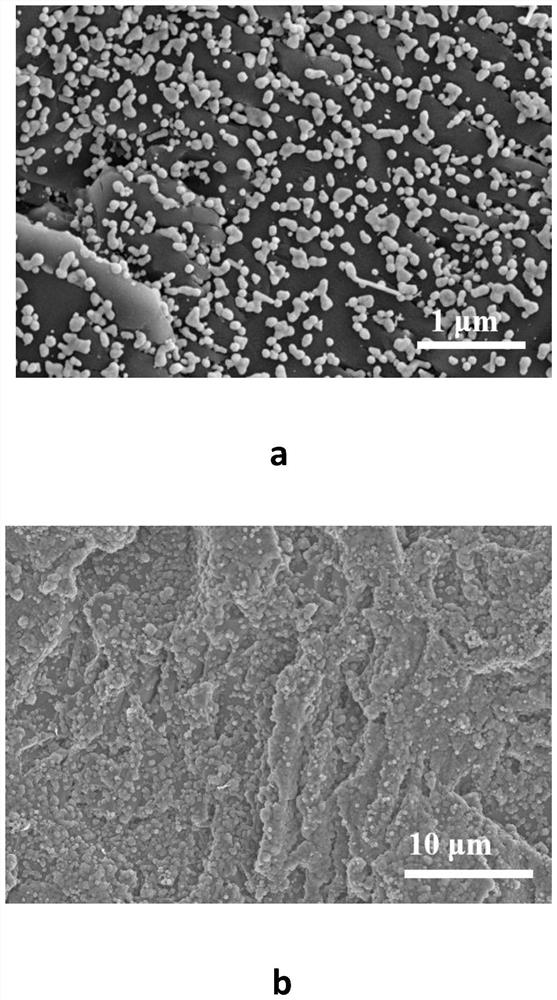

[0040] Step 4. Soak the substrate obtained in step 3 in a mixed solution containing 10mL of 0.6mM tetrachloroauric acid hydrate and 10mL of 0.6mM hydroxylamine hydrochloride, fully shake the reaction, and make the gold particles grow to form larger gold nanoparticles. Island particles, the particle size is 40-150nm, and the distance between adjacent particle sizes is about 1-80nm, rinsed with pure water and blown dry with nitrogen.

Embodiment 3

[0041] Embodiment three, different from embodiment one,

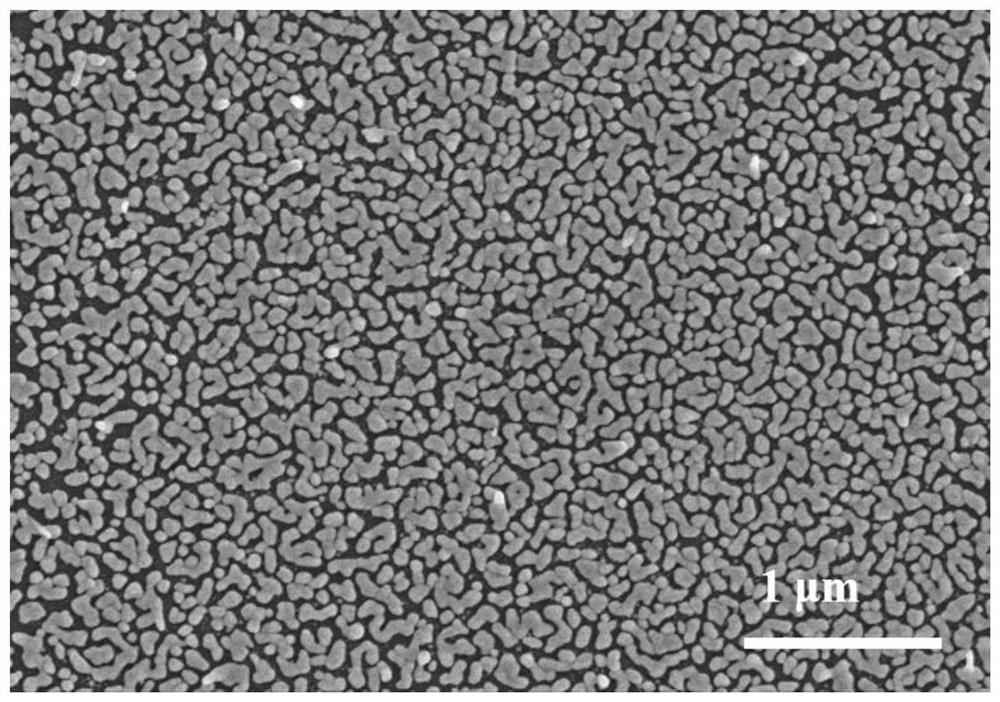

[0042] Step 4. Soak the substrate obtained in step 3 in a mixed solution containing 10mL of 1.4mM tetrachloroauric acid hydrate and 10mL of 1.4mM hydroxylamine hydrochloride, fully shake the reaction, and make the gold particles grow to form larger gold nanoparticles. Island particles, the particle size is 80-250nm, and the distance between adjacent particle sizes is about 1-50nm, rinsed with pure water and blown dry with nitrogen.

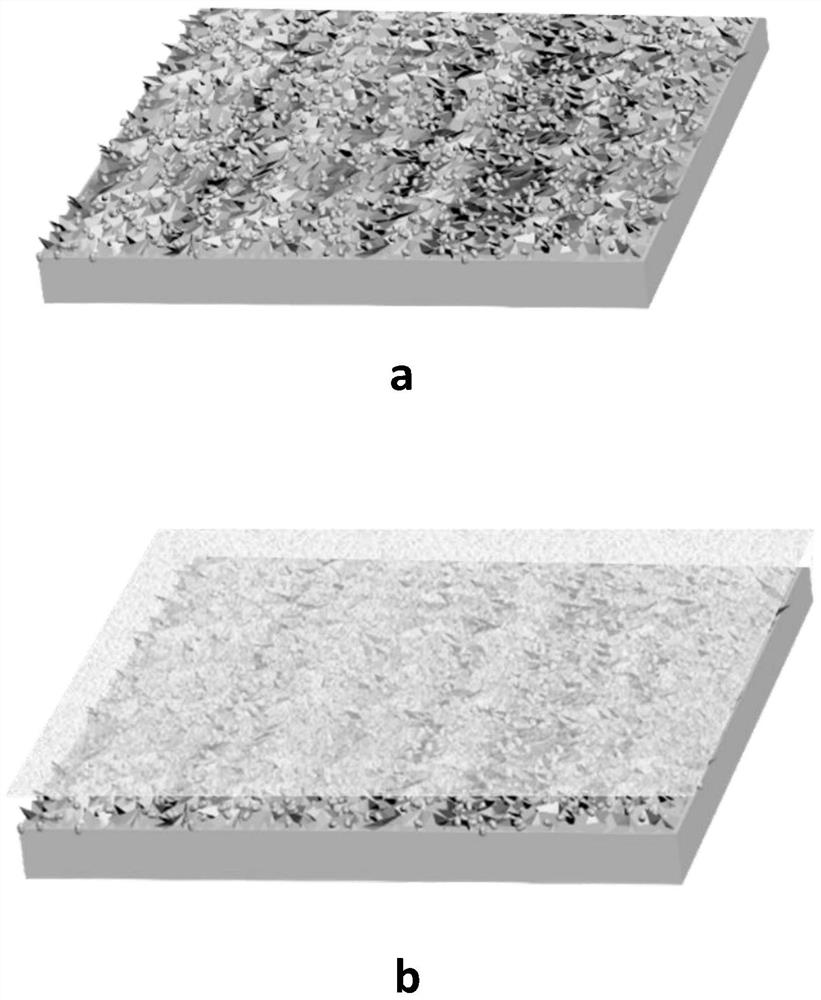

[0043] The schematic diagram of the base material is as figure 1 Shown in a and b, the higher the concentrations of hydroxylamine hydrochloride and tetrachloroauric acid, the larger the growth of gold particles, observing the scanning electron microscope images of Examples 1-3, Figure 5 a is the scanning electron microscope picture of embodiment 1, Figure 5 B is the scanning electron microscope figure of embodiment 2, Figure 5 c is the scanning electron microscope picture of embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com