Steel bar bending hoop bending machine with numerical control belt pressure clutch and semicircular gear

A steel bar bending hoop and clutch technology, applied in the field of steel bar bending hoop bending machine, can solve the problems of inconvenient lubrication of the gear system of the steel bar bending machine, excessive rotation of the working disc, personal injury, etc., and achieve high automation, easy maintenance, and low failure rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

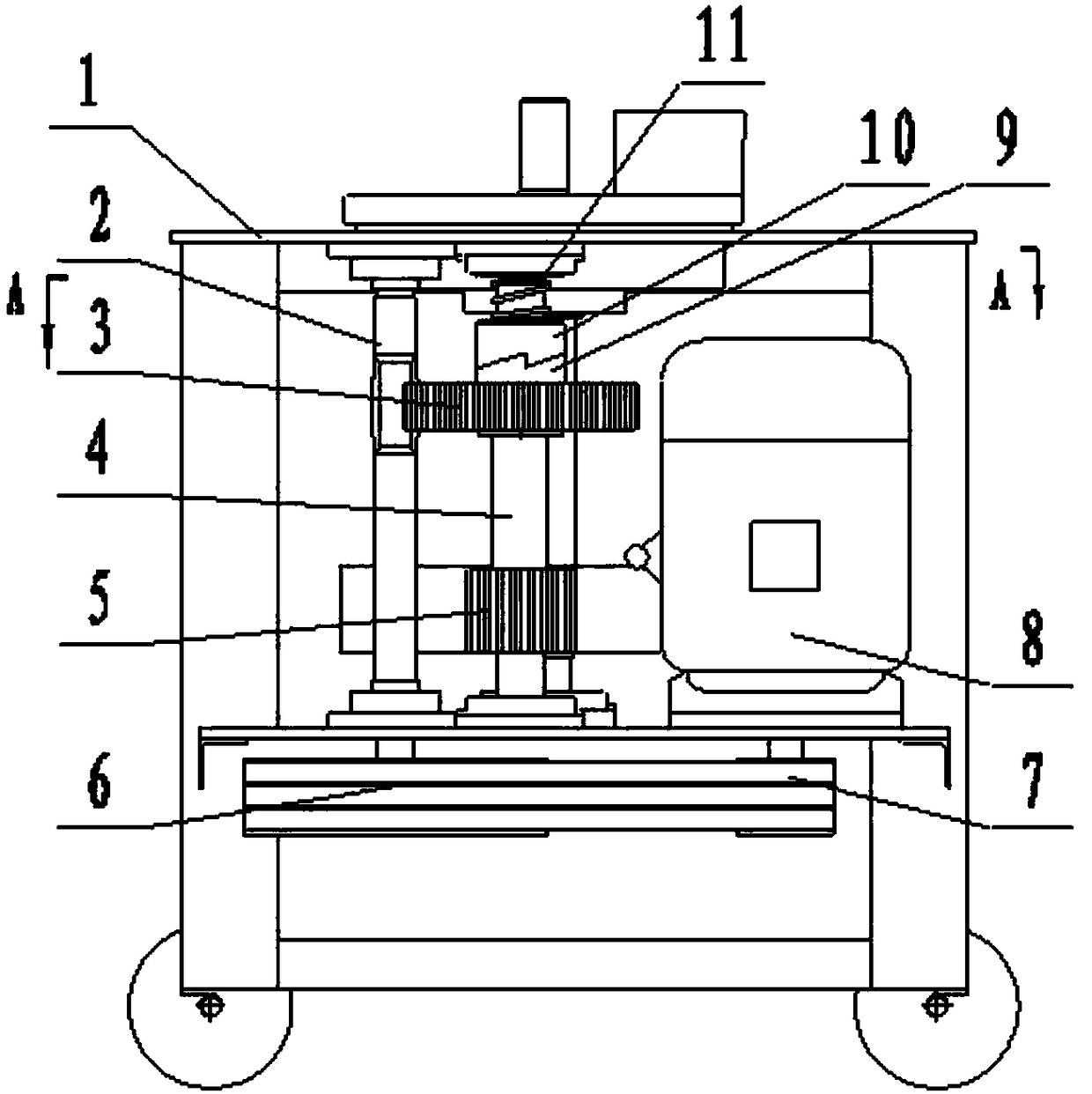

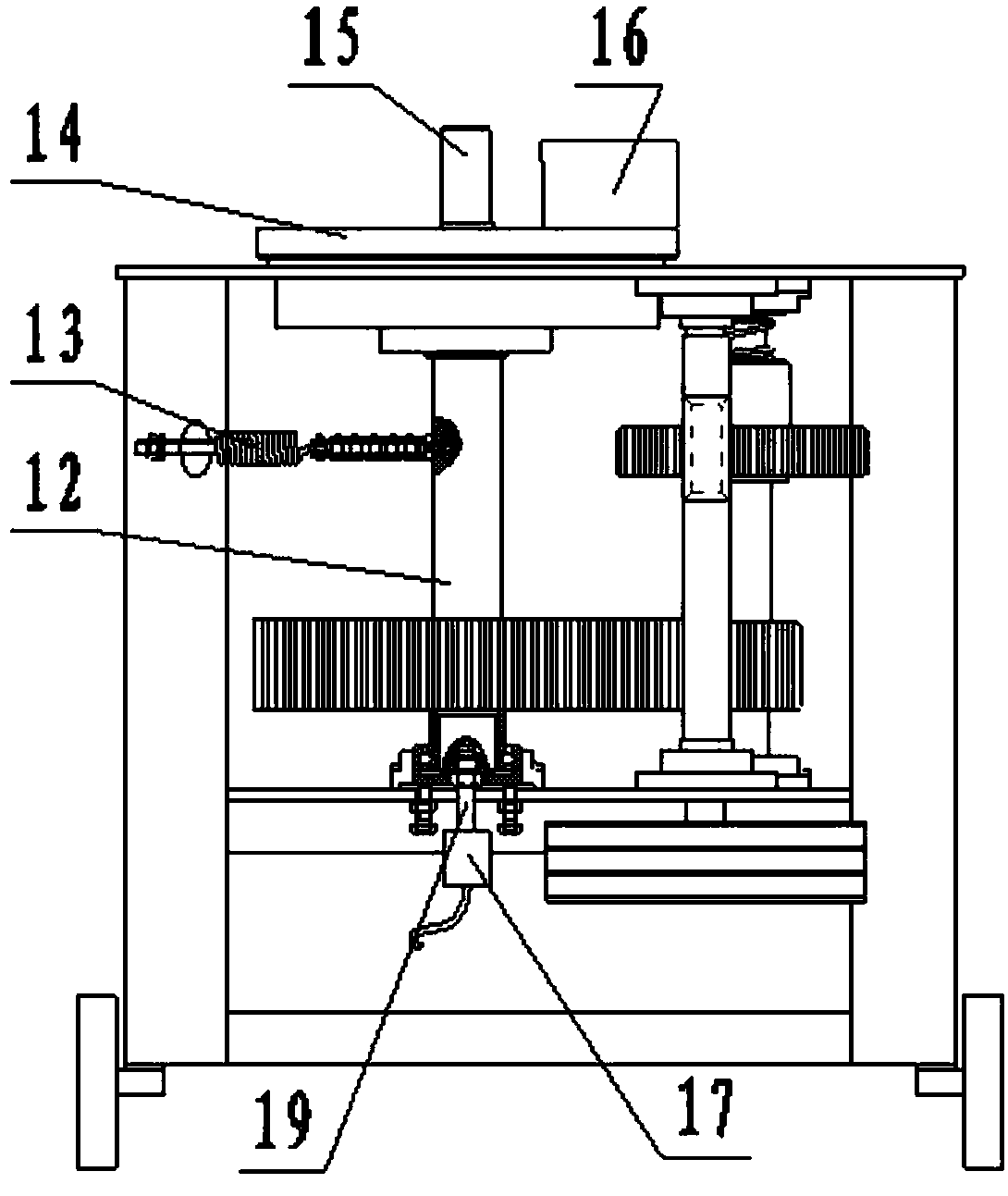

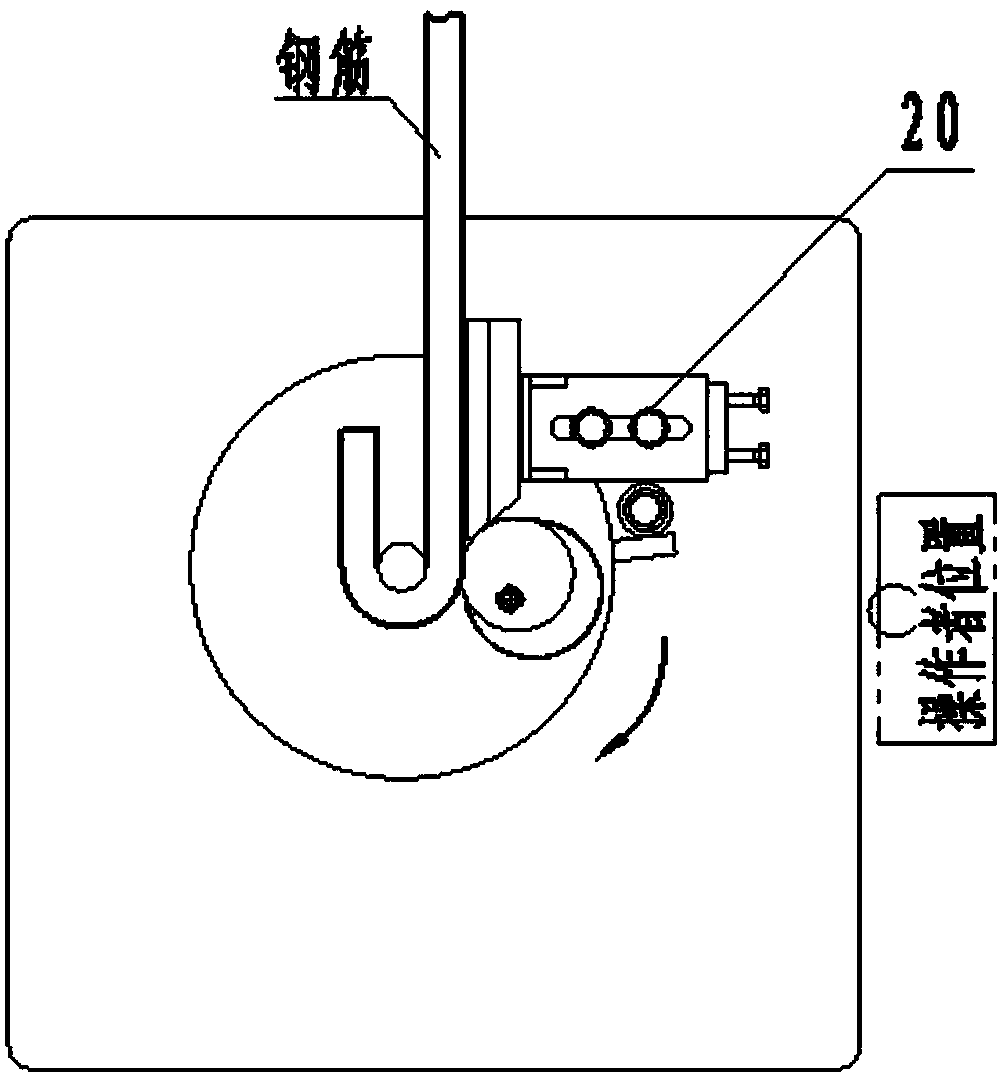

[0031] A numerically controlled steel bar hoop bending machine with a pressure clutch and a semicircular gear, please refer to the attached figure 1 - attached Figure 4 As shown, it includes the frame 1, the power assembly arranged in the frame 1 and the working disk 14 arranged on the frame 1. The center of the working disk 14 is provided with a central pile head 15, and one side of the central pile head 15 is provided with a The pile head 15 rotates in a circle to complete the bending shaft 16 for bending the steel bar; the power assembly includes the input gear shaft 2, the secondary reduction gear 3, the secondary gear shaft 4, the secondary follow-up gear 5, the input pulley 6, the motor pulley 7, Motor 8, main gear shaft 12 and main gear 18; main gear shaft 12 top and working disc 14 are installed and fixed, and main gear shaft 12 top is also provided with upper hole, and center pile head 15 is installed in the upper hole; main gear shaft 12 bottom The main gear 18 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com