I-shaped steel and U-shaped steel plate pile engaged fabricated composite fender pile

A steel sheet pile and I-beam technology, applied in the field of prefabricated composite enclosure piles, can solve the problems of unreliable support of the lateral earth pressure of the foundation pit, large cement consumption, weak bending resistance, etc. The effect of reliable lateral earth pressure and strong bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

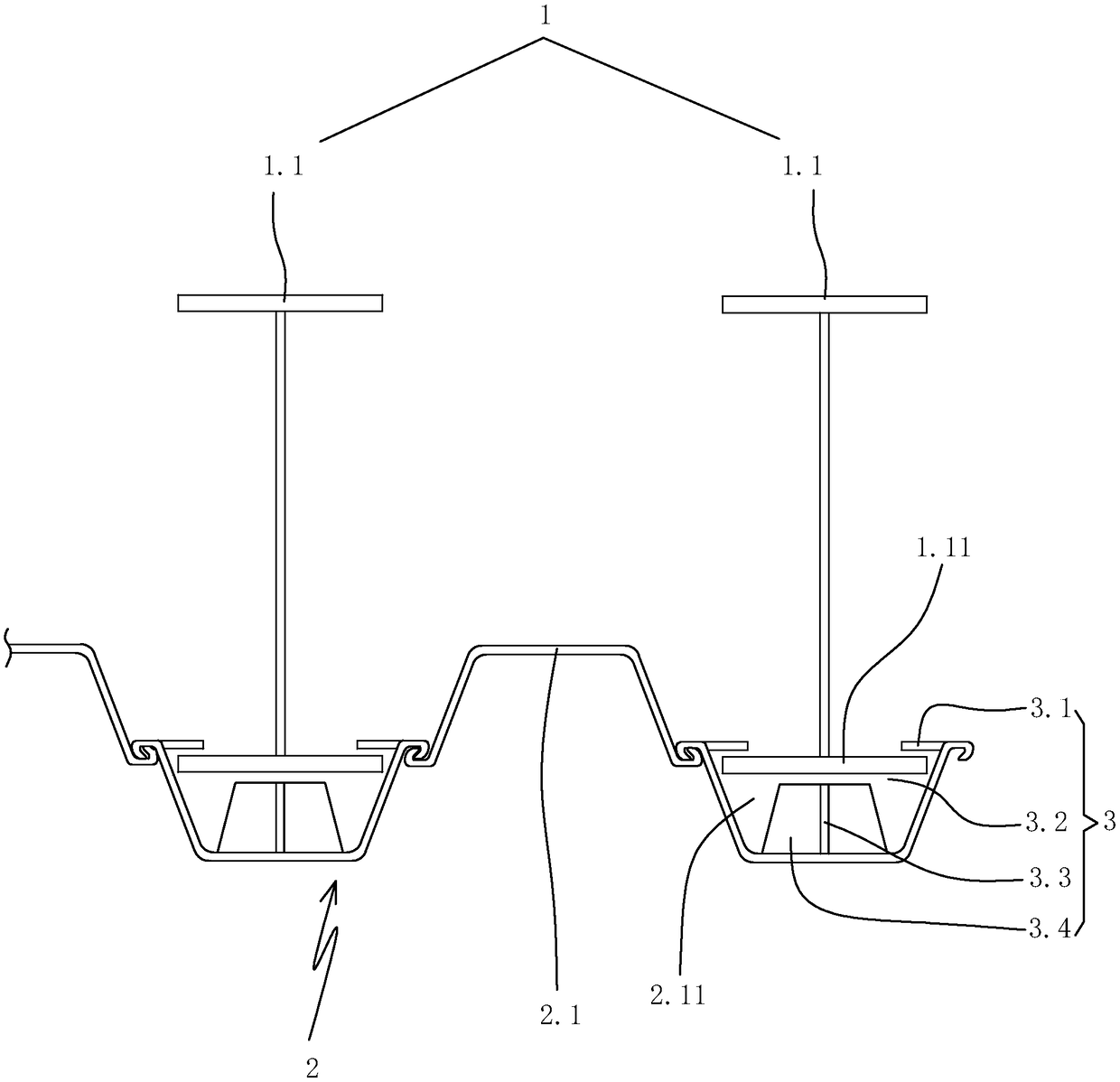

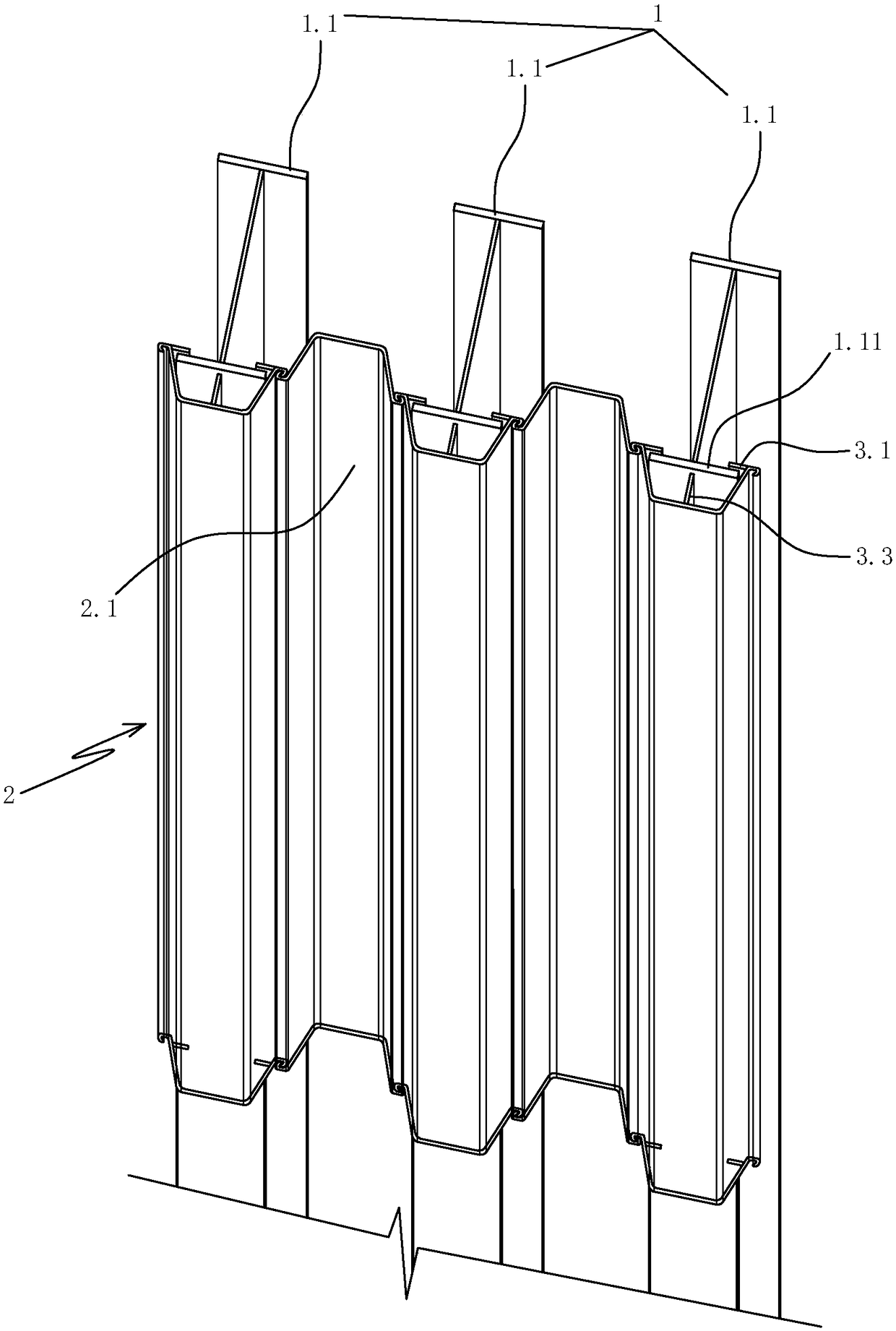

[0037] Specific embodiment one: as figure 1 , figure 2 As shown, an assembled composite enclosure pile in which I-shaped steel and U-shaped steel sheet piles are engaged, includes a supporting main pile 1 and a water-stopping auxiliary pile 2 .

[0038] The supporting main pile is used to bear the lateral earth pressure of the foundation pit. The supporting main pile includes several vertical supporting piles 1.1 arranged side by side. In this embodiment, the vertical support piles are I-beams. The vertical support piles are pressed into the soil layer of the foundation pit by static pressure.

[0039] The auxiliary water-stop piles include several U-shaped steel sheet piles 2.1 that are interlocked and connected. Waterstop auxiliary piles are used to prevent groundwater from entering the foundation pit. The U-shaped steel sheet pile is pressed into the soil layer of the foundation pit by static pressure.

[0040]Some U-shaped steel sheet piles in the U-shaped steel she...

specific Embodiment 2

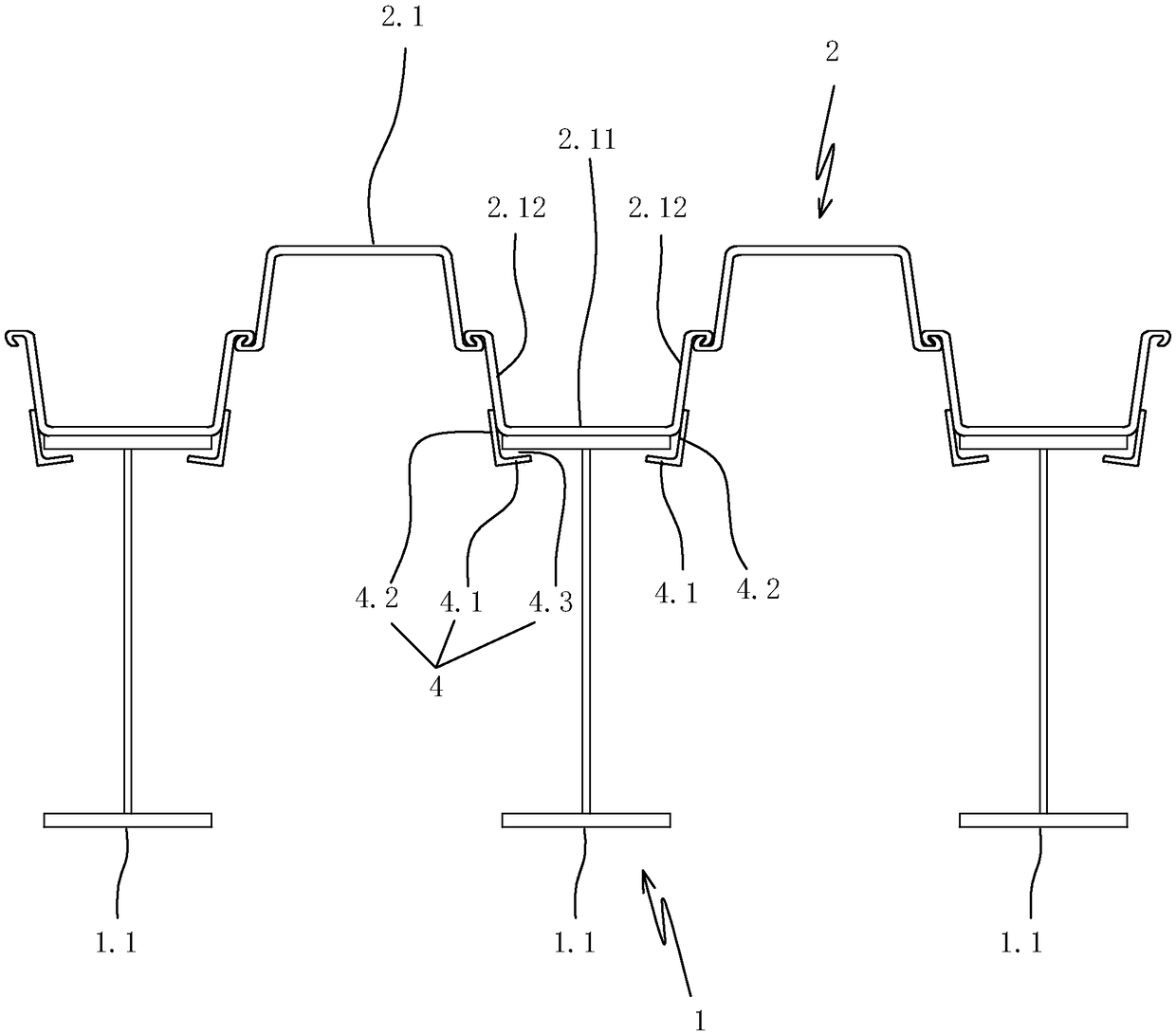

[0048] Specific embodiment two: as image 3 , Figure 4 As shown, an assembled composite enclosure pile in which I-shaped steel and U-shaped steel sheet piles are engaged, includes a supporting main pile 1 and a water-stopping auxiliary pile 2 .

[0049] The supporting main pile is used to bear the lateral earth pressure of the foundation pit. The supporting main pile includes several vertical supporting piles 1.1 arranged side by side. In this embodiment, the vertical support piles are I-beams. The vertical support piles are pressed into the soil layer of the foundation pit by static pressure.

[0050] The auxiliary water-stop piles include several U-shaped steel sheet piles 2.1 that are interlocked and connected. Waterstop auxiliary piles are used to prevent groundwater from entering the foundation pit. In this embodiment, the U-shaped steel sheet pile is preferably a Larsen steel sheet pile. The U-shaped steel sheet pile is pressed into the soil layer of the foundatio...

specific Embodiment 3

[0056] Specific embodiment three: as Figure 5 , Figure 6 As shown, an assembled composite enclosure pile in which I-shaped steel and U-shaped steel sheet piles are engaged, includes a supporting main pile 1 and a water-stopping auxiliary pile 2 .

[0057] The supporting main pile is used to bear the lateral earth pressure of the foundation pit. The supporting main pile includes several vertical supporting piles 1.1 arranged side by side. In this embodiment, the vertical support piles are I-beams. The vertical support piles are pressed into the soil layer of the foundation pit by static pressure.

[0058] The water-stop auxiliary pile 2 is arranged between two adjacent vertical support piles, and the above-mentioned water-stop auxiliary pile is arranged between two adjacent vertical support piles. In this embodiment, there is only one auxiliary water-stop pile between two adjacent vertical support piles.

[0059] The auxiliary water-stop piles include a plurality of U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com