Composite column of fiber reinforced plastic and machining method of composite column

A technology of fiber-reinforced plastics and processing methods, which is applied in the field of composite columns, can solve the problems of limited improvement in bending resistance, poor radial bending resistance, and low cost of hollow columns, and achieve structural strength and rigidity improvement and strong bending resistance , The effect of improving the connection strength of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

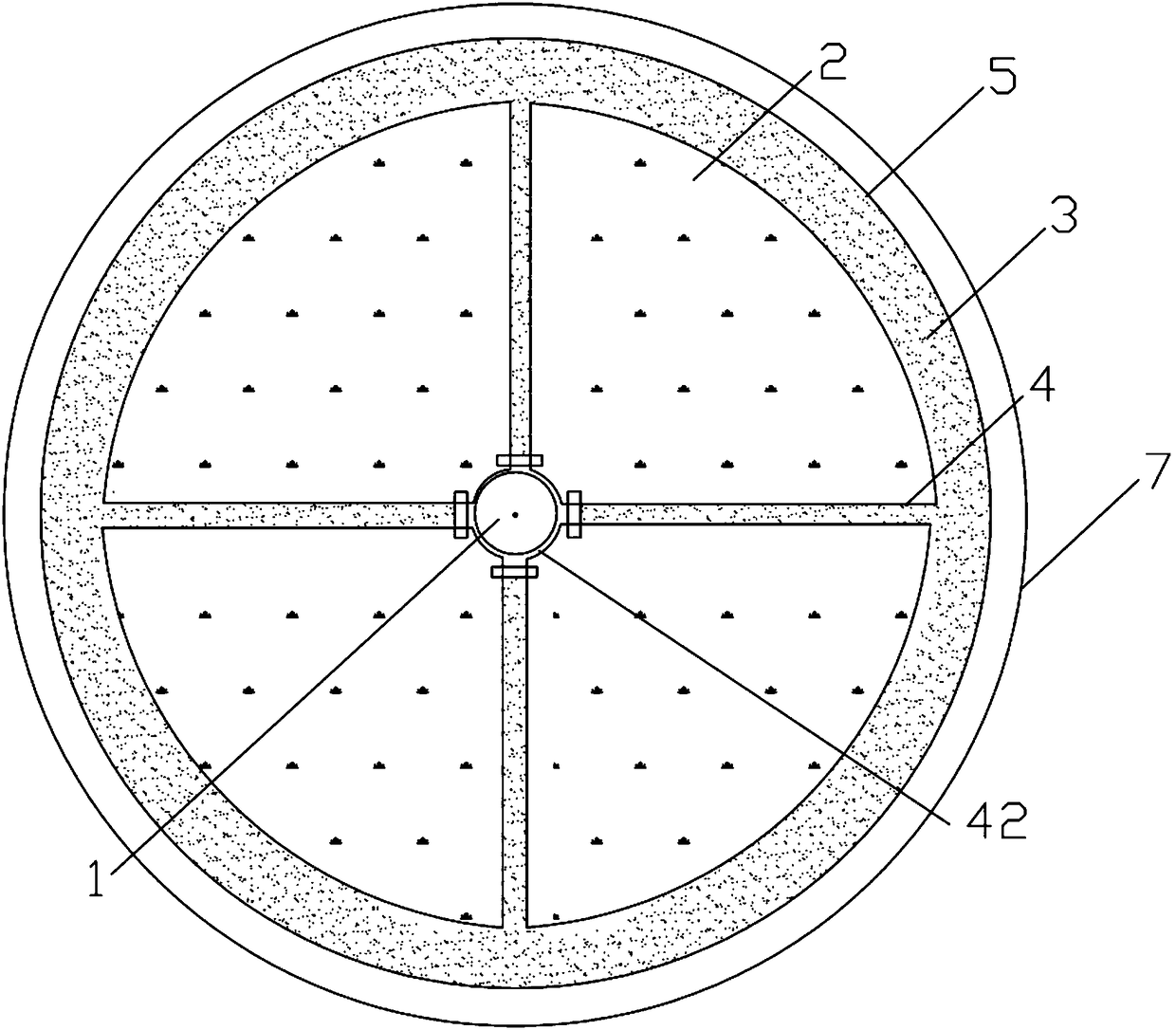

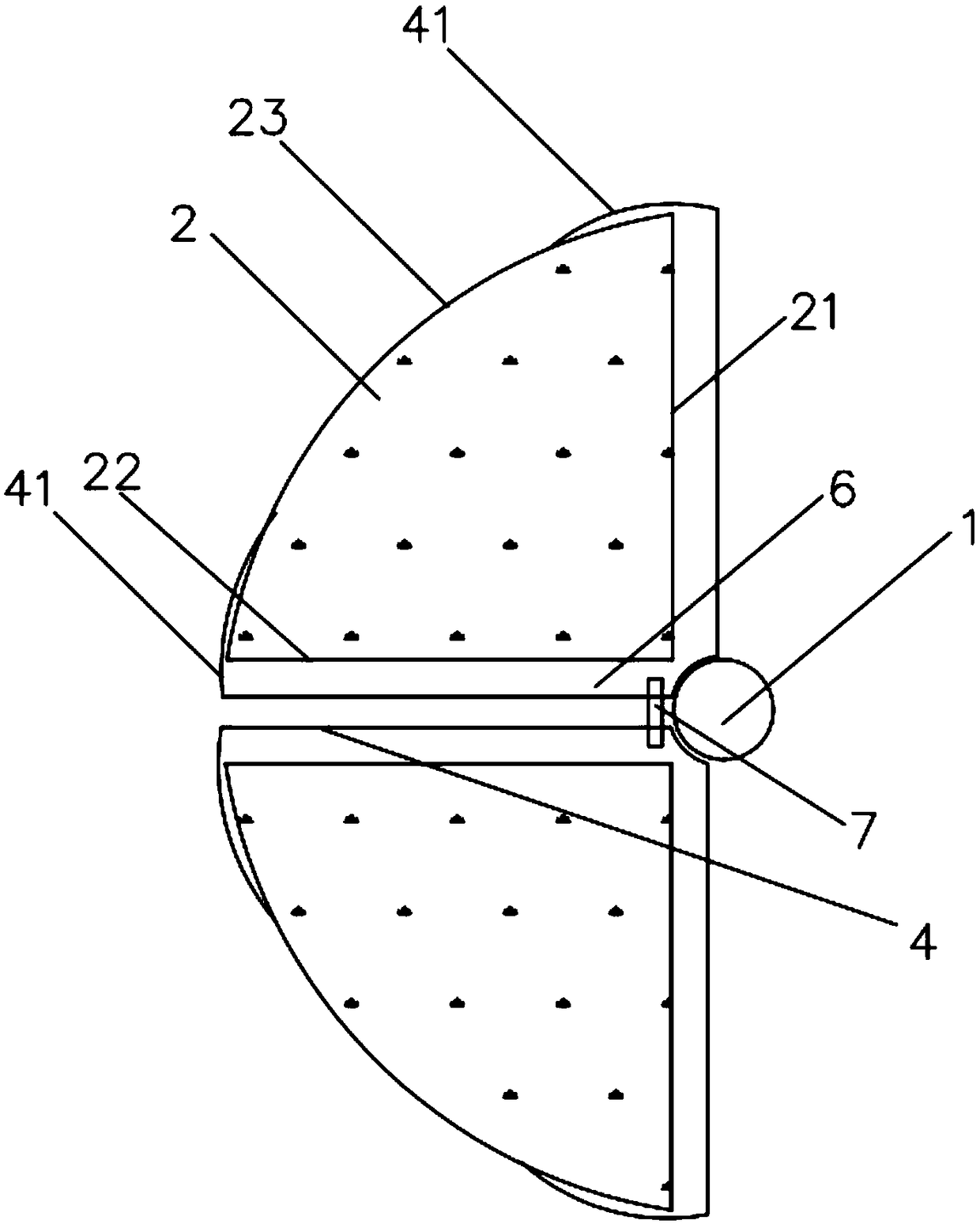

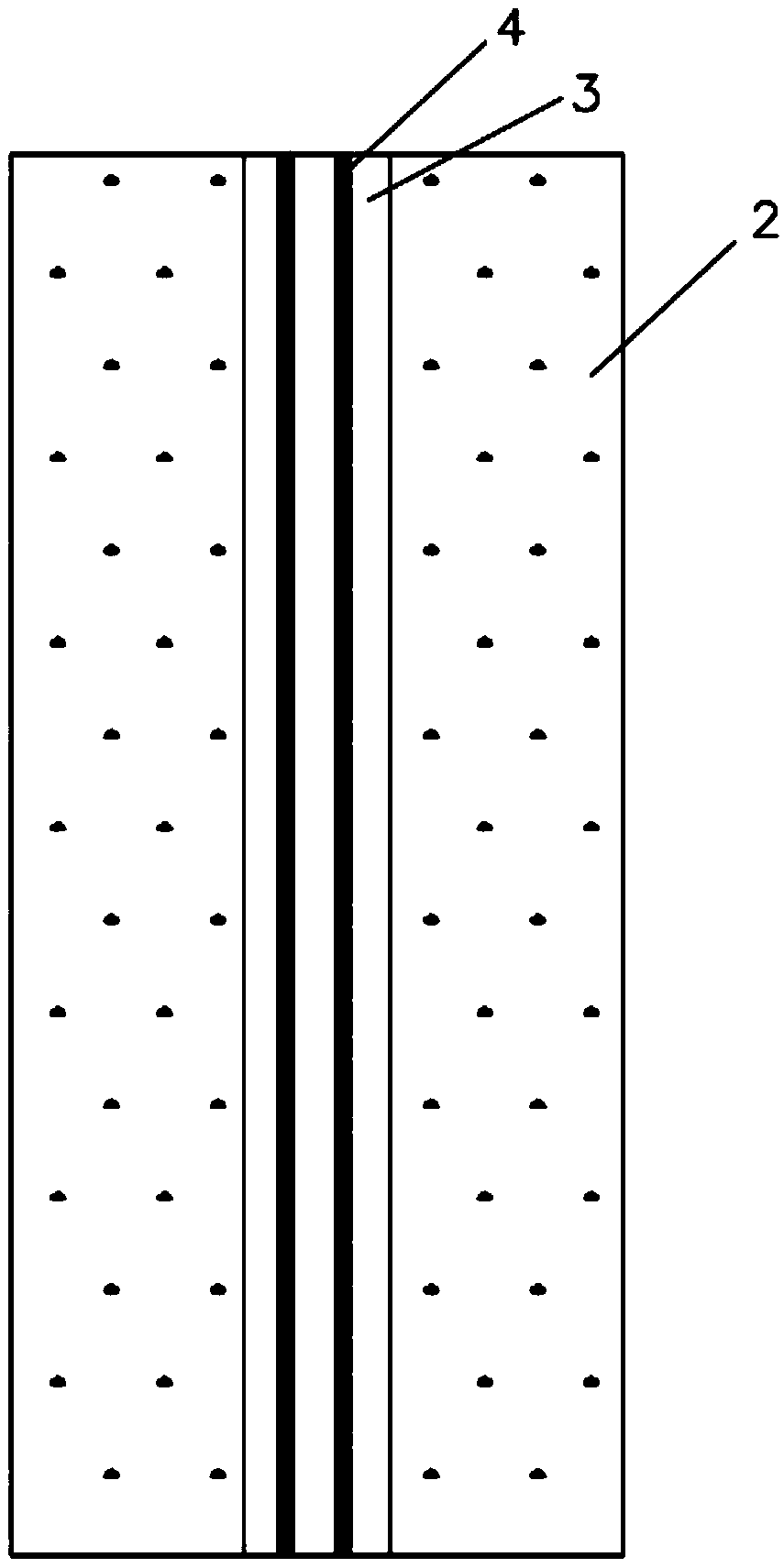

[0034] Such as Figure 1 to Figure 4 As shown, a fiber-reinforced plastic composite column in this embodiment includes a core material 1, a rigid foamed plastic body 2, a resin 3, a reinforcing fiber member 4 and a structural layer 5, and a plurality of rigid foamed plastic bodies 2 surround The core material 1 is arranged at intervals. There are gaps 6 between adjacent rigid foamed plastic bodies 2 , the reinforcing fiber pieces 4 are arranged in the gaps 6 , and the reinforcing fiber pieces 4 are connected to the core material 1 . The structural layer 5 is arranged around the outer side of the rigid foamed plastic body 2 , and the resin 3 is filled in the gap 6 . In the above technical solution, when the composite column receives a radial force, the rigid foamed plastic body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com