Preparation method of nano-micron pyrrhotite soft magnetic material

A technology of pyrrhotite and soft magnetic materials, applied to the magnetic properties of inorganic materials, iron sulfide, etc., can solve the problems of nano-micron pyrrhotite soft magnetic materials that have not been studied or practiced before, and achieve low coercive force , avoid the process, the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh the analytically pure reduced iron powder (Fe) and sublimated sulfur (S) respectively, so that the ratio of Fe to S is 1:1, put them in a mortar and grind them until they are evenly mixed; put the mixed powder in a crucible , sealed and put into a vacuum heating device. Vacuumize the vacuum heating device to 6*10 -2 Pa. According to the heating rate of 5 °C / min, the temperature was raised to 300 °C for 22 hours, and then cooled to room temperature according to the cooling rate of 5 °C / min, and the product in the crucible was taken out to obtain gray-black powder particles.

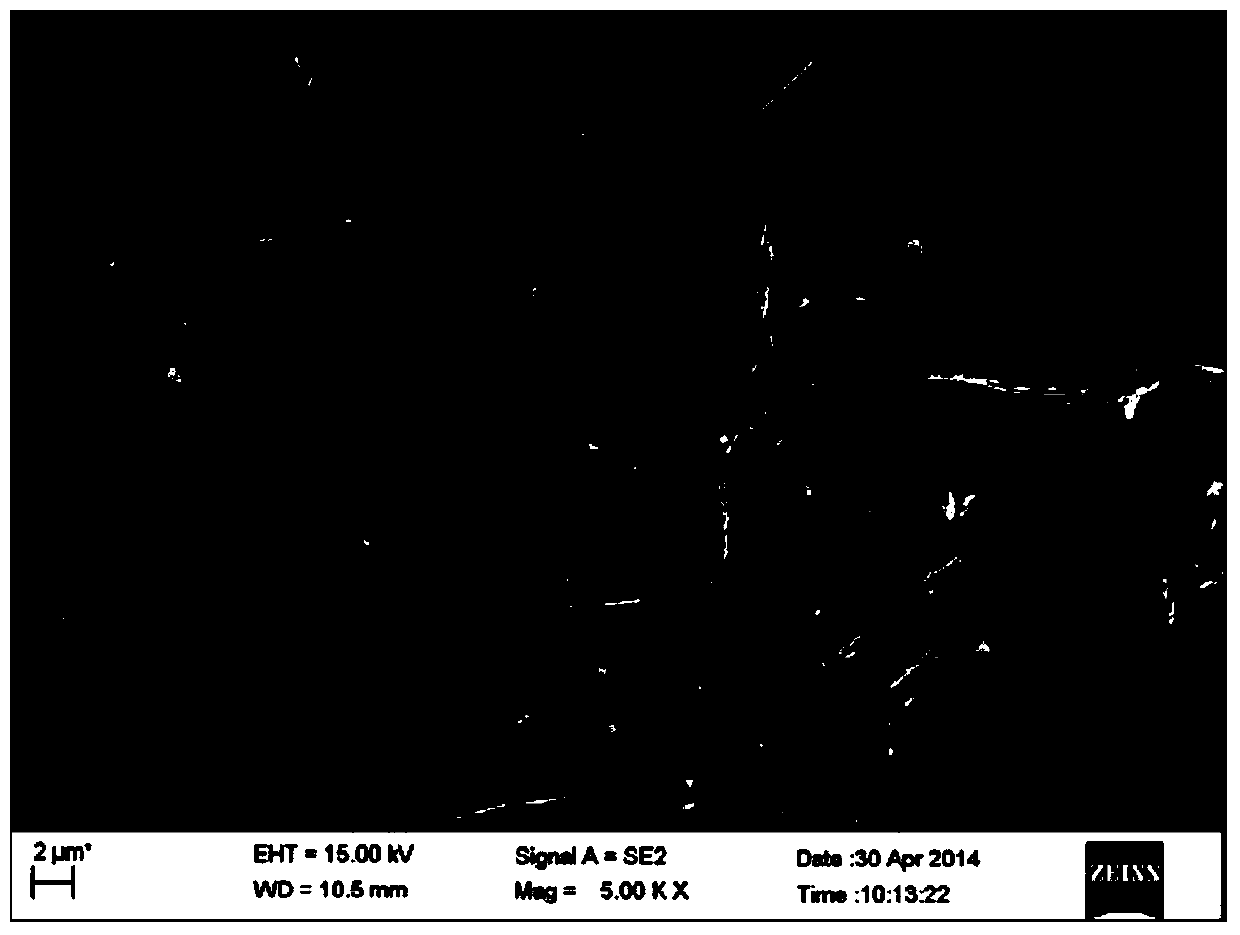

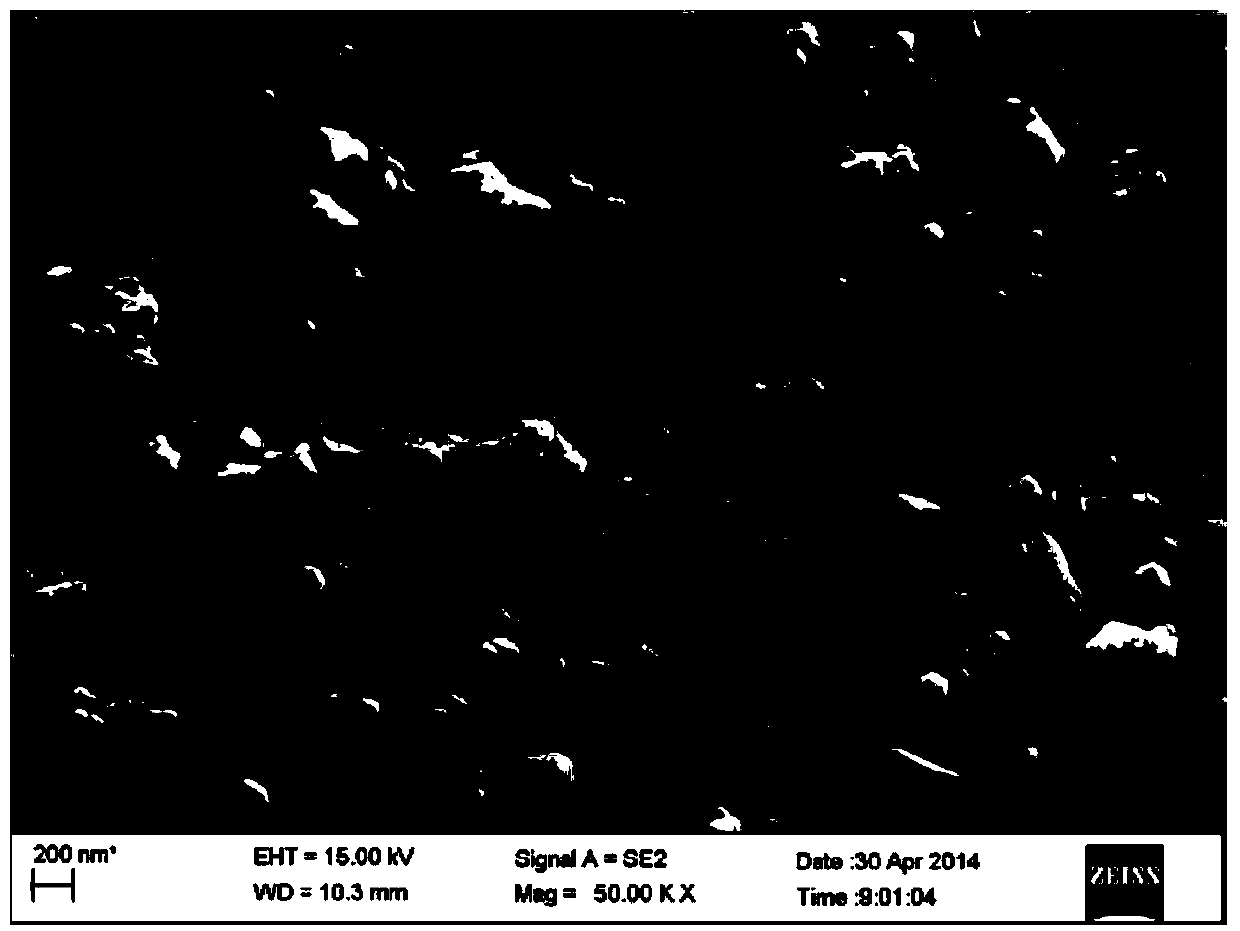

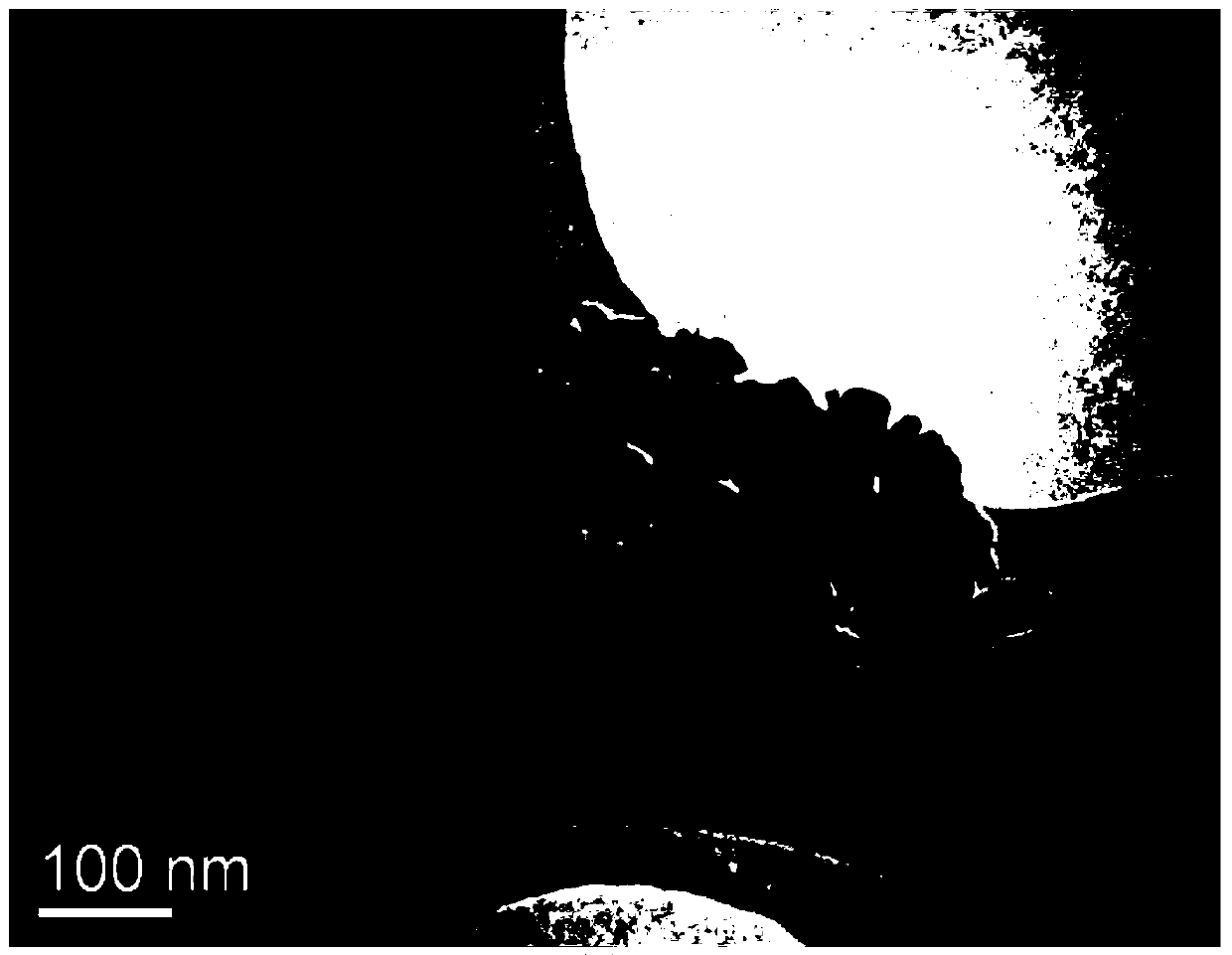

[0035] Observation by scanning electron microscope (see figure 1 ), the powder crystallizes well, the particle morphology is mainly hexagonal flake and plate shape, and the particle size is between 400nm and 10um. The product obtained by measuring XRD is a pure phase pyrrhotite (see Figure 4 ). The hysteresis loop of the prepared sample was measured with a vibrating sample magnetometer ...

Embodiment 2

[0037] Weigh the analytically pure reduced iron powder (Fe) and sublimated sulfur (S) respectively, so that the ratio of Fe to S is 1:1, put them in a mortar and grind them until they are evenly mixed; put the mixed powder in a crucible , sealed and put into a vacuum heating device. Vacuumize the vacuum heating device to 4.5*10 -2 Pa. According to the heating rate of 5 °C / min, the temperature was raised to 350 °C and kept for 22 hours, and then cooled to room temperature according to the cooling rate of 5 °C / min, and the product in the crucible was taken out to obtain gray-black powder particles.

[0038] Observation by scanning electron microscope shows that the crystal morphology of the powder is mainly hexagonal plate shape, and the particle size is between 350nm and 18um. The product obtained by measuring XRD is a pure phase pyrrhotite (see Figure 5 ). The hysteresis loop of the prepared sample was measured with a vibrating sample magnetometer (VSM), such as Figure ...

Embodiment 3

[0040] Weigh the analytically pure reduced iron powder (Fe) and sublimated sulfur (S) respectively, so that the ratio of Fe to S is 1:1, put them in a mortar and grind them until they are evenly mixed; put the mixed powder in a crucible , sealed and put into a vacuum heating device. Vacuumize the vacuum heating device to 3.2*10 -2 Pa. According to the heating rate of 5 °C / min, the temperature was raised to 400 °C for 22 hours, and then cooled to room temperature according to the cooling rate of 5 °C / min, and the product in the crucible was taken out to obtain gray-black powder particles.

[0041] Observation by a scanning electron microscope shows that the powder crystallizes in a hexagonal plate shape with a particle size between 800nm and 30um. The product obtained by measuring XRD is a pure phase pyrrhotite (see Figure 5 ). The hysteresis loop of the prepared sample was measured with a vibrating sample magnetometer (VSM), such as Figure 9 shown. The magnetic perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com