Ultrasound wave auxiliary hydrothermal synthesis technique for magnetic magnetic iron oxide nano ultra-tiny grain

A technology of ferroferric oxide and hydrothermal synthesis, which is applied in the direction of iron oxide/iron hydroxide, ferrous iron oxide, etc., can solve the problems of large particle size, application limitation, and difficult control of organic compounds, and achieve remanence The effect of very little, low preparation cost, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

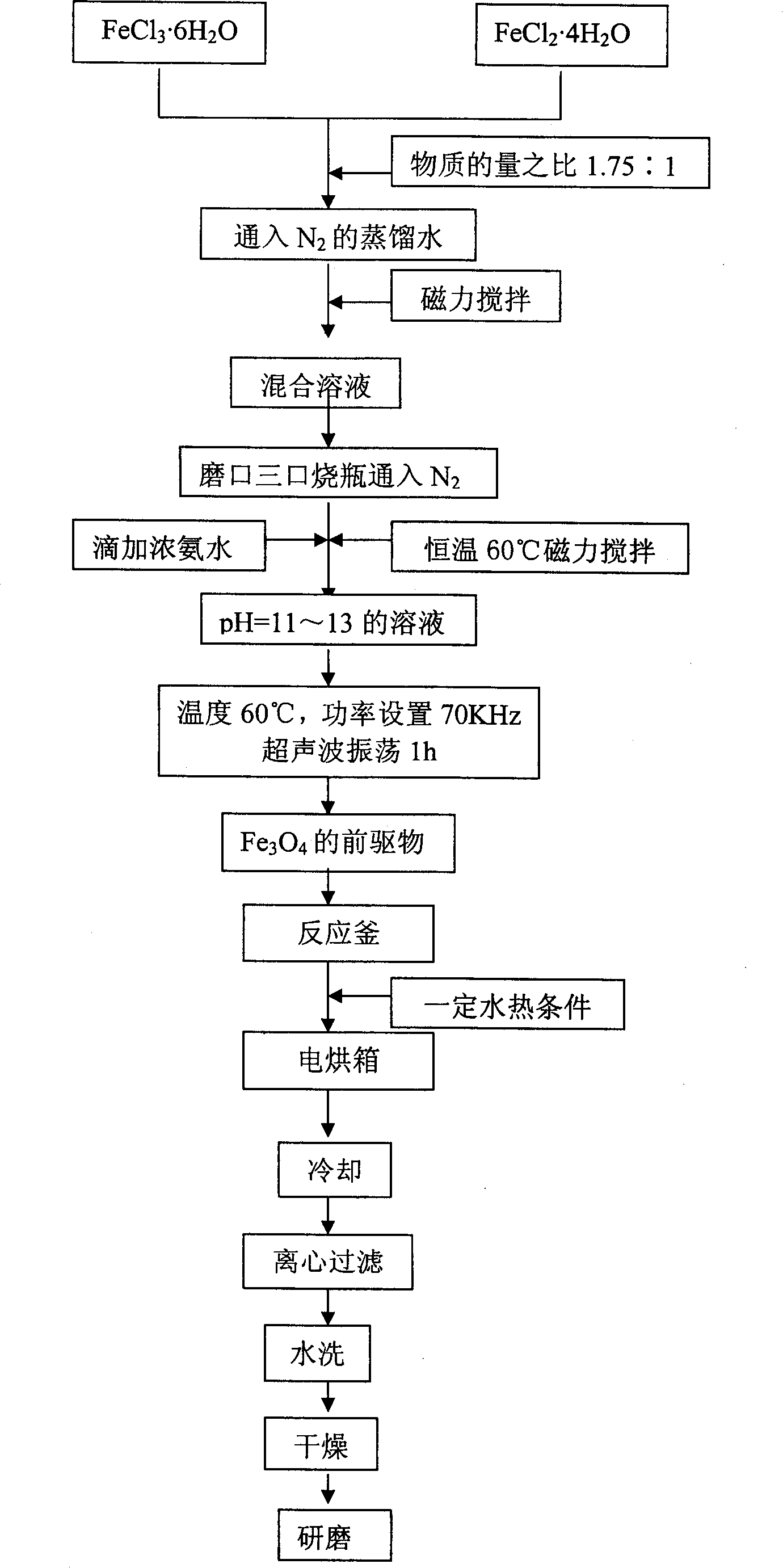

[0015] as per figure 1 The process flow shown makes the product.

[0016] The first step: the FeCl 3 ·6H 2 O and FeCl 2 4H 2 O is dissolved in distilled water at a ratio of 1.75:1, and N 2 The air is passed into distilled water, the air in the water is removed, and the mixed solution is obtained under magnetic stirring;

[0017] The second step: the resulting mixed solution is transferred to a 250ml ground-mouthed three-neck flask, and N 2 The other mouth is equipped with a dropping funnel filled with concentrated ammonia water, and the remaining mouth is plugged with a ground plug. In a constant temperature magnetic stirring electric heating mantle, under constant temperature 60°C magnetic stirring, slowly add concentrated ammonia water to adjust the pH of the solution to 11, and then Put it in a digitally controlled ultrasonic oscillator (setting temperature 60°C, power setting 70KHz), and ultrasonically oscillate for 1 hour to obtain Fe 3 o 4 precursors of

[0018]...

Embodiment 2

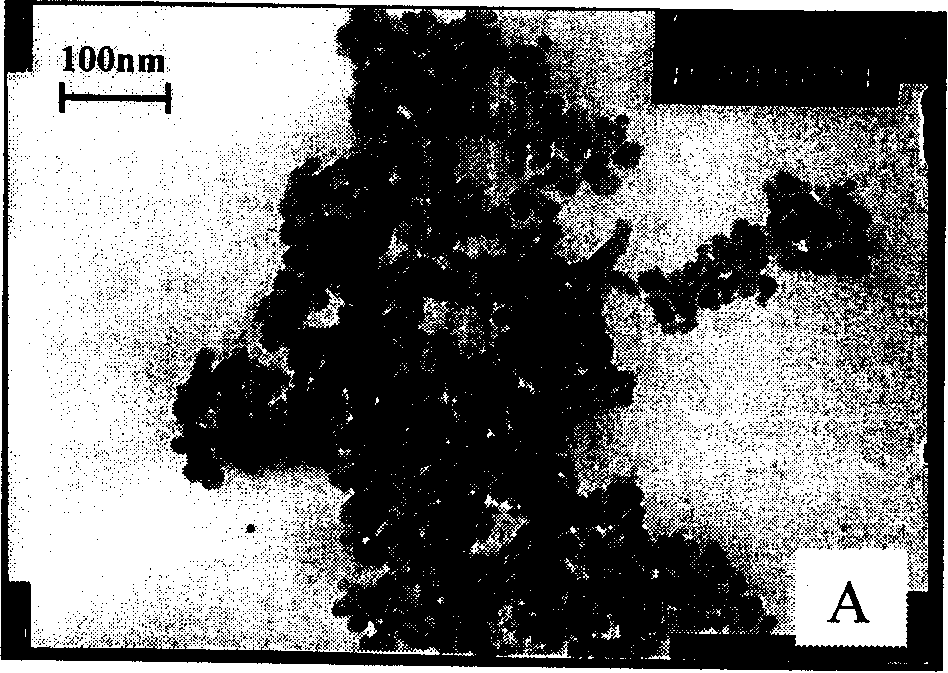

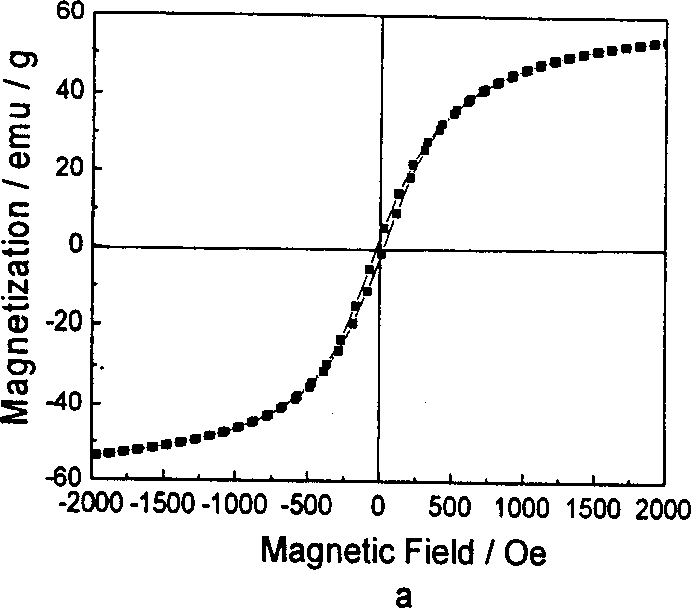

[0022] Concentrated ammonia water was added to adjust the pH of the solution to 12; the reaction temperature of hydrothermal synthesis was 150° C. for 4 hours. All the other are the same as Example 1, finally obtain the black magnetic ferric oxide nano-powder product, the average grain size of the grain is 20.2nm, the specific saturation magnetization is 63emu / g, the coercive force is 27.8Oe, and the remanence is 2.8emu / g, it can be confirmed that the prepared black magnetic ferric oxide nanopowder is a better superparamagnetic material. Its TEM photo and hysteresis loop as Figure 2B , shown in b.

Embodiment 3

[0024] Concentrated ammonia water was added to adjust the pH of the solution to 13; the reaction temperature of hydrothermal synthesis was 140° C. for 4 hours. All the other are the same as in Example 1, finally obtain the black magnetic iron ferric oxide nano powder product, the average grain size of the grain is 12.4nm, the specific saturation magnetization is 64emu / g, the coercive force is 20.4Oe, and the remanence is 1.8emu / g, it can be confirmed that the prepared black magnetic ferric oxide nanopowder is a better superparamagnetic material. Its TEM photo and hysteresis loop as Figure 2C , as shown in c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com