Large-current magnetic latching relay, movable contact spring of large-current magnetic latching relay, and contact assembly of large-current magnetic latching relay

A technology of magnetic latching relays and contact components, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problem of affecting the accuracy of smart meter detection values, no improvement in the withstand voltage performance of the medium between contacts, and limiting the gap between dynamic and static contacts To achieve the effect of improving the product withstand voltage range, improving the stability of the action, and reducing the formation of arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0045] The orientations such as up, down, top, and bottom mentioned in the present invention are only used to illustrate the relative positional relationship between the components, and do not limit the specific installation orientations of the components in the present invention.

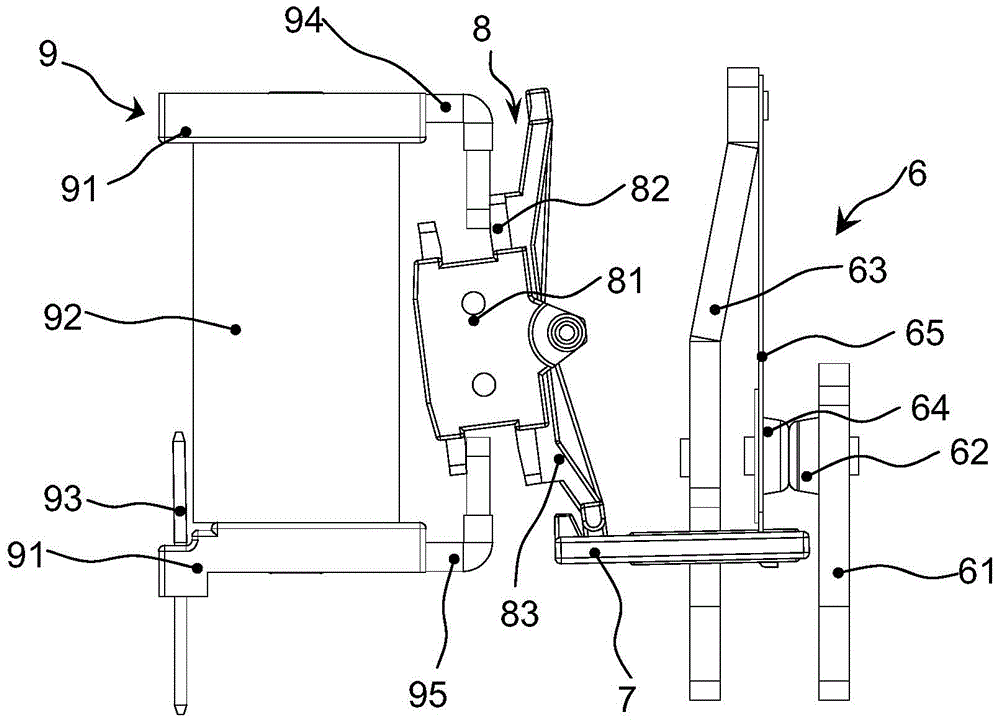

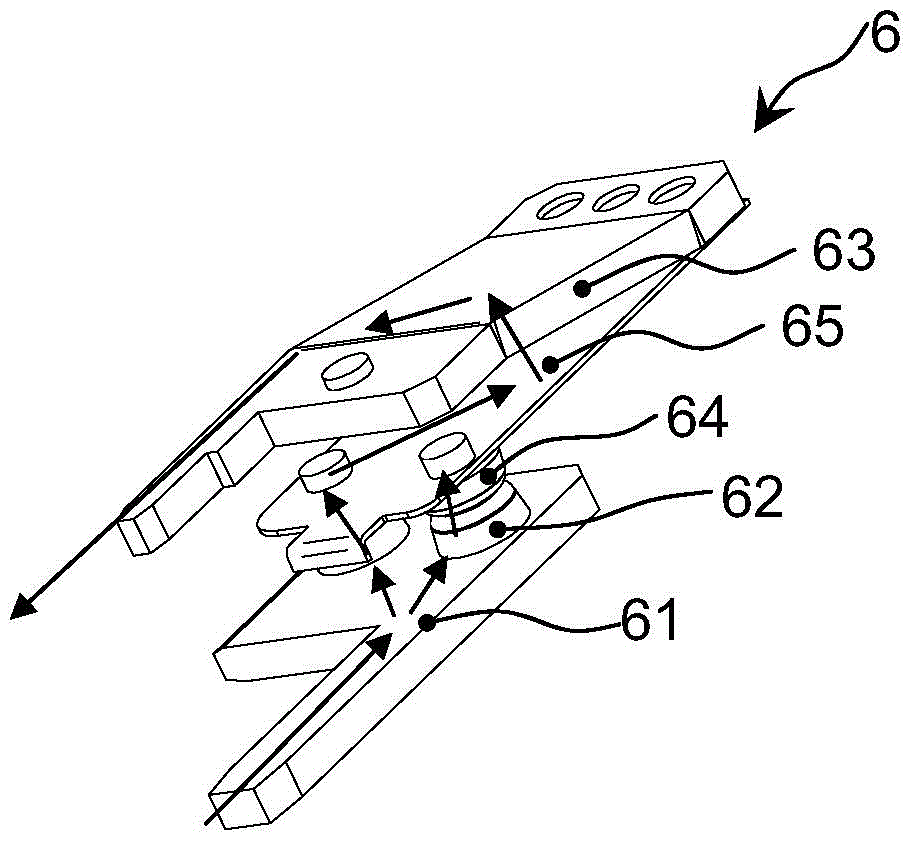

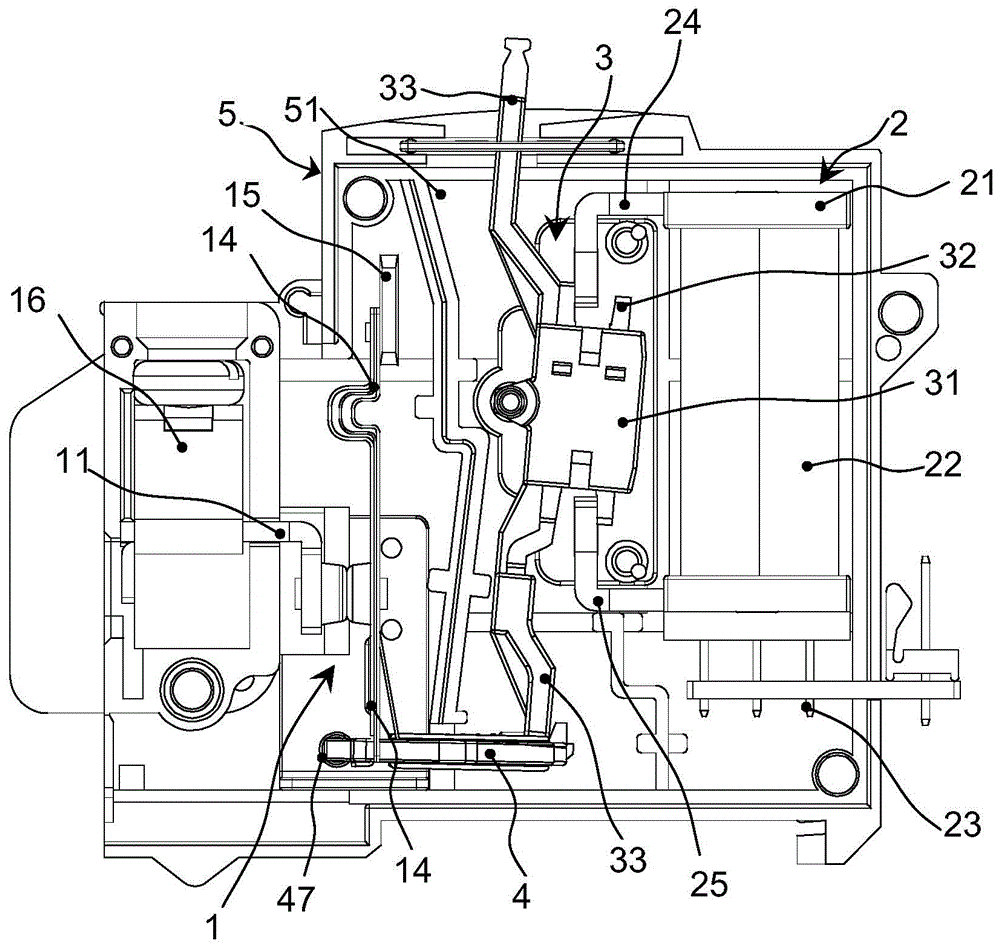

[0046] An embodiment of the present invention provides a large current magnetic latching relay, referring to image 3 , Figure 4 and Figure 5 , The relay mainly includes a contact assembly 1, an electromagnetic assembly 2, an armature assembly 3 and a push card 4, and these components are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com