Sintered neodymium iron boron magnet

A technology of NdFeB and magnets, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of unreasonable equipment design and manufacture, large product thickness limitations, and no way to produce them, and achieve Effect of improving effective utilization rate, uniformity and smoothness of structure and composition, and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

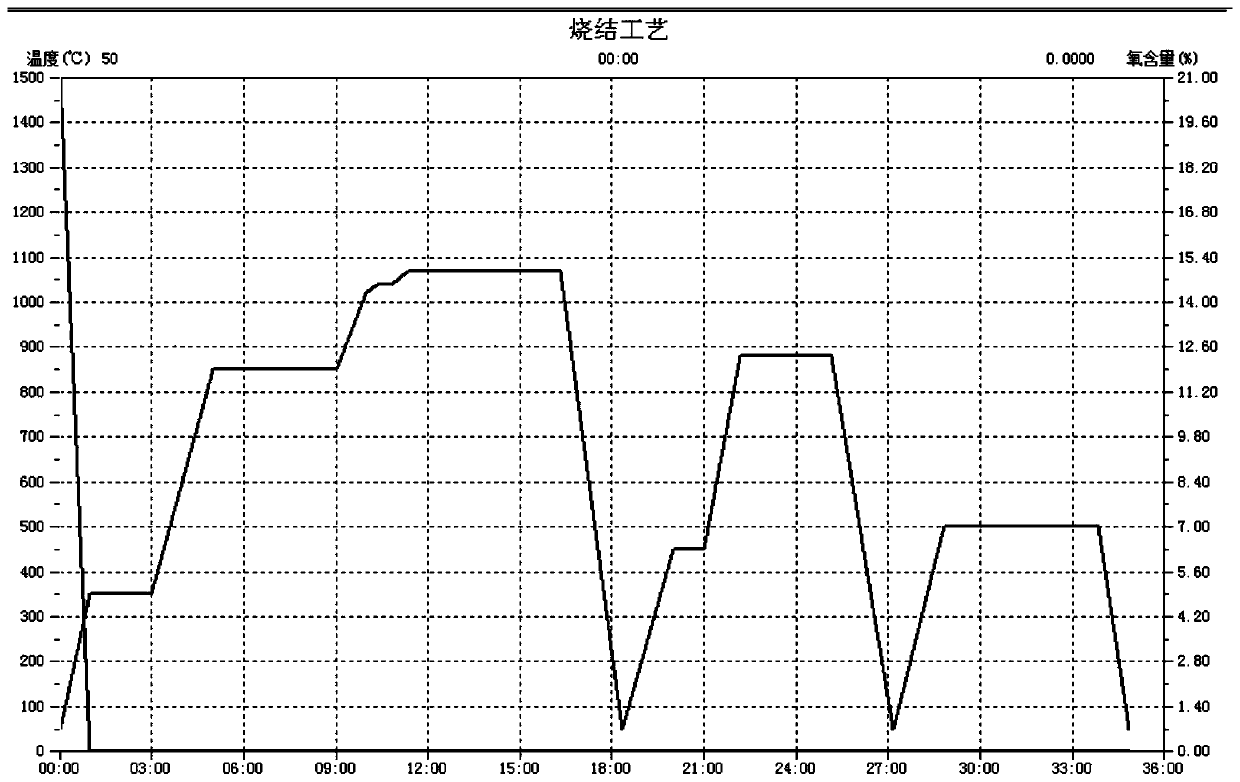

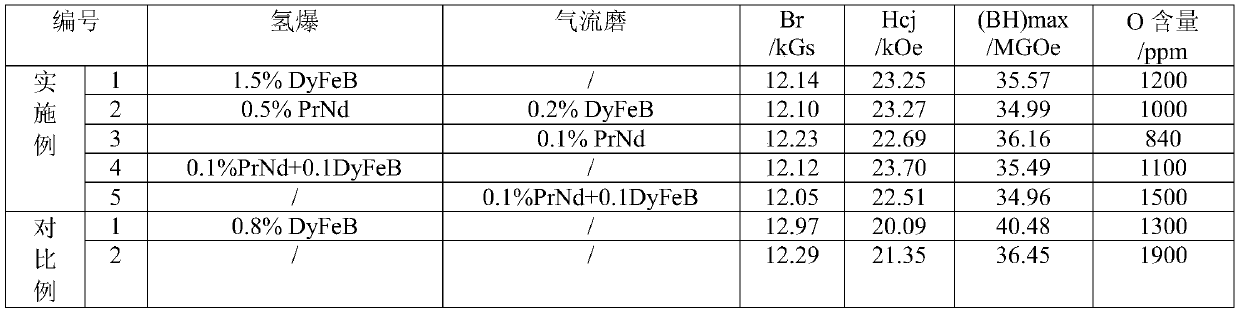

Embodiment 1

[0047] (1) Ingredients: Various industrially pure raw materials are used, according to the nominal formula (PrNd) 31 Ga 0.2 Fe bal B 0.96 Nb 0.1 Zr 0.1 co 1.5 Cu 0.15 Al 1.2 , for batching, bal means that the rest is Fe, and the raw materials are industrially pure;

[0048] (2) Smelting: put the material prepared according to the ratio into a vacuum induction quick-setting furnace, vacuumize, preheat, and then fill it with Ar atmosphere protection for smelting. The melting and casting temperature is 1460 ° C, and the copper roller speed during casting is 2m / s, after the casting is completed, it is filled with argon for blast cooling to obtain NdFeB quick-setting thin strips;

[0049] (3) Hydrogen explosion: add 1.5wt% DyFeB flakes during hydrogen explosion, absorb hydrogen for 1 hour under 0.5MPa hydrogen pressure, and then dehydrogenate at 550°C for 5 hours to obtain NdFeB medium powder;

[0050] (4) jet mill: jet mill powder, obtain NdFeB powder with an average part...

Embodiment 2

[0056] (1) Ingredients: Various industrially pure raw materials are used, according to the nominal formula (PrNd) 31 Dy 1.5 Ga 0.2 Fe bal B 0.97 Nb 0.1 Zr 0.1 co 1.5 Cu 0.15 Al 1.2 , for batching, bal means that the rest is Fe, and the raw materials are industrially pure;

[0057] (2) Smelting: put the material prepared according to the proportion into the vacuum induction quick-setting furnace, vacuumize, preheat, and then fill it with Ar atmosphere protection for smelting. The melting and casting temperature is 1480 ° C, and the copper roller speed during casting is 2.5m / s, filled with argon for blast cooling after casting. After cooling, NdFeB quick-setting thin strips are obtained;

[0058] (3) Hydrogen explosion: add 0.5wt% PrNd small pieces during hydrogen explosion, absorb hydrogen for 2 hours under 0.5MPa hydrogen pressure, and then dehydrogenate at 550°C for 5 hours to obtain hydrogen explosion NdFeB medium powder;

[0059] (4) Jet mill: Add 0.2wt% of DyFeB...

Embodiment 3

[0065] (1) Ingredients: Various industrially pure raw materials are used, according to the nominal formula (PrNd) 31 Dy 1.5 Ga 0.2 Fe bal B 0.96 Nb 0.1 Zr 0.1 co 1.5 Cu 0.15 Al 1.2 , for batching, bal means that the rest is Fe, and the raw materials are industrially pure;

[0066] (2) Smelting: put the material prepared according to the ratio into a vacuum induction quick-setting furnace, vacuumize, preheat, and then fill it with Ar atmosphere protection for smelting. The melting and casting temperature is 1500 ° C, and the copper roller speed during casting is 3m / s, filled with argon for blast cooling after casting. After cooling, NdFeB quick-setting thin strips are obtained;

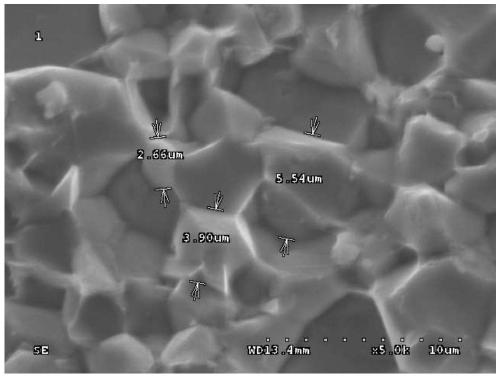

[0067] (3) Hydrogen explosion: Under 0.5MPa hydrogen pressure, absorb hydrogen for 2 hours, then dehydrogenate at 550°C for 5 hours to obtain hydrogen-exploded NdFeB medium powder; (4) Jet mill: add 0.1wt% of PrNd medium powder, jet mill powder, obtain NdFeB powder with an average particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com