End Tooth Electromagnetic Clutch

An electromagnetic clutch and end tooth technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of low transmission ratio precision, short service life, large coil windings, etc., and achieve high transmission ratio precision and compact structure. , The effect of large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

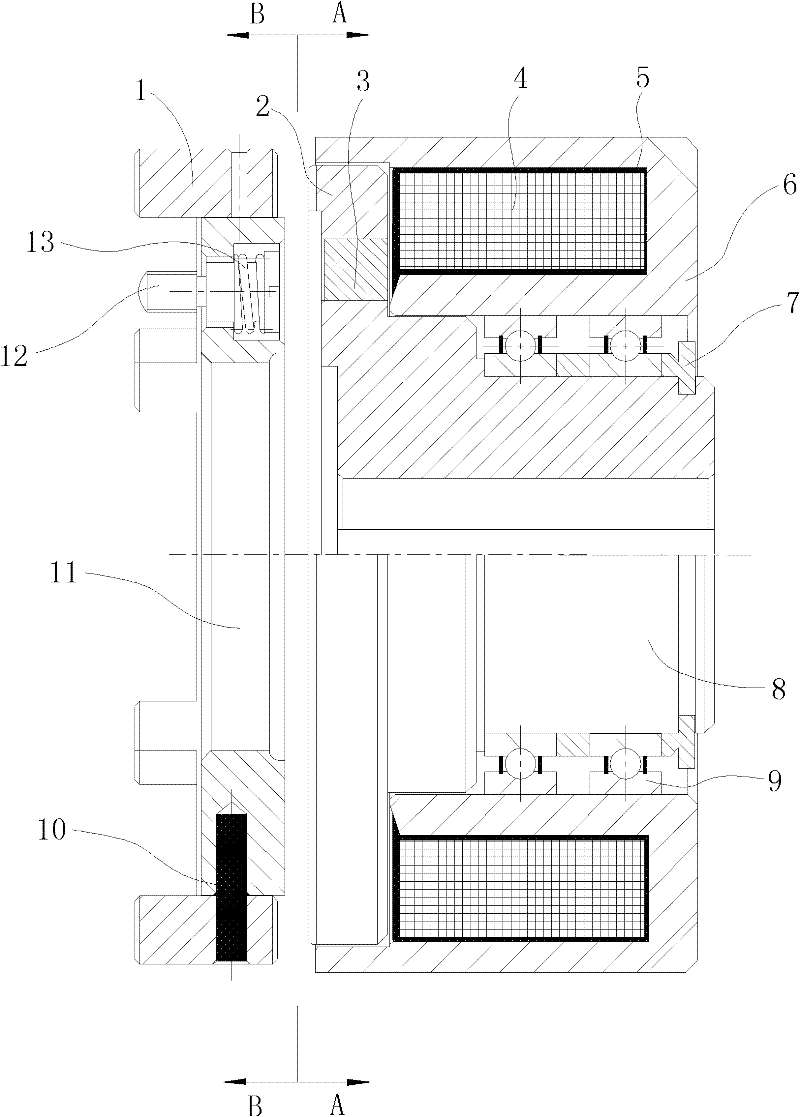

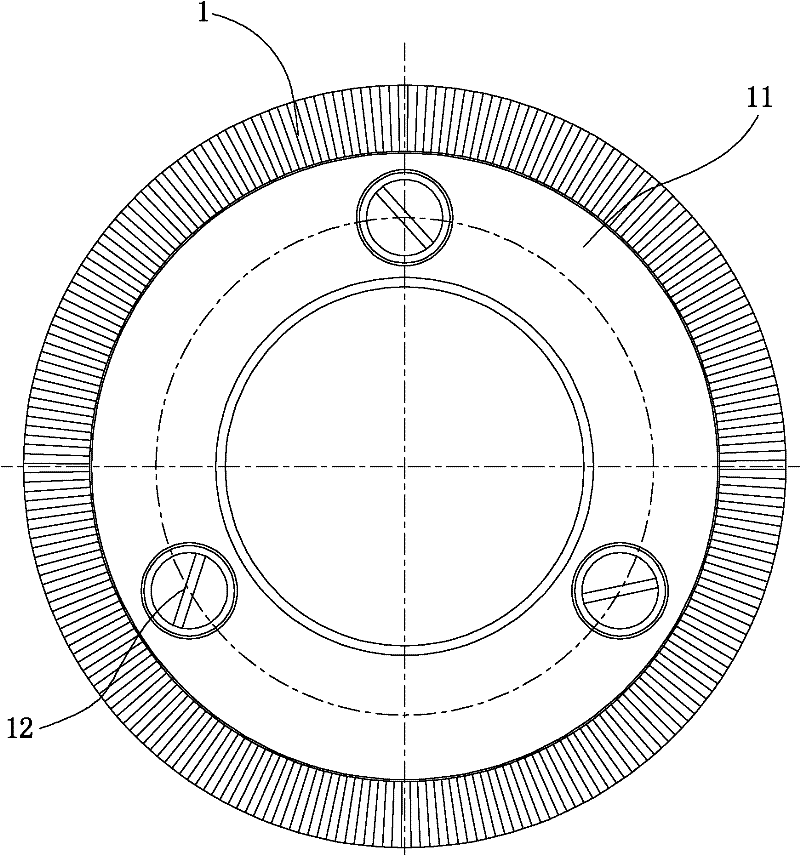

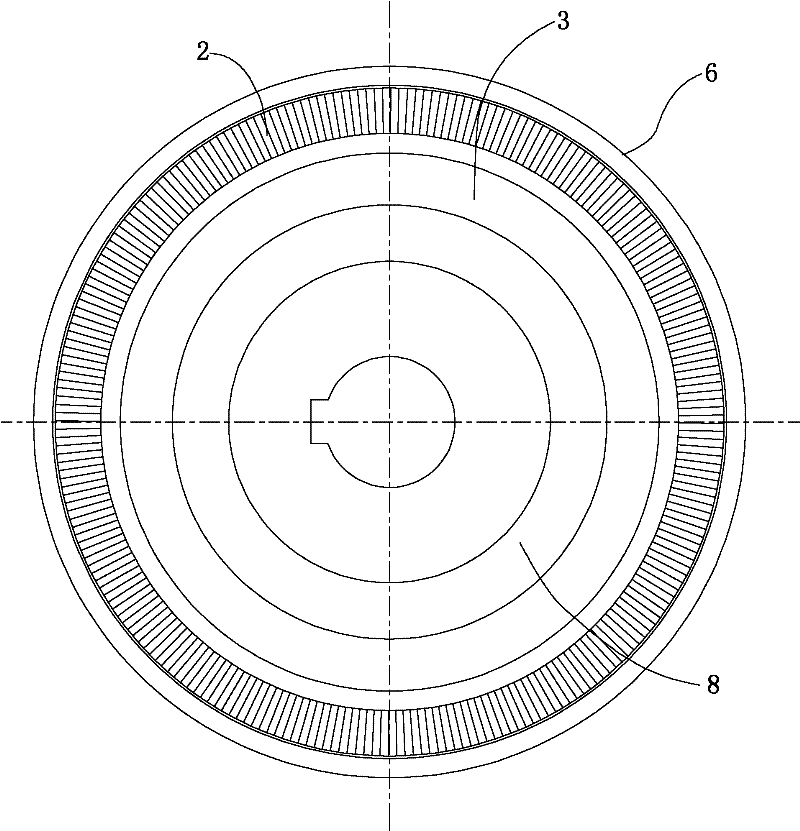

[0020] The implementation of the present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of an embodiment of the end-tooth electromagnetic clutch provided by the present invention, figure 2 , image 3 respectively figure 1 The B-B and A-A orientation views. This embodiment is a clutch used for fast and accurate conversion of electric energy and mechanical energy in industrial production to obtain torque transmission. It can be seen from the figure that the end gear shaft 2, the magnetic isolation ring 3, and the core shaft 8 are assembled into the end gear shaft, which is set in two 6807 bearings 9, positioned axially by the retaining ring 7, and then assembled on the coil wrapped by insulating paper 5. 4. Place it in the yoke 6 as the active part; then rivet the armature flange 11 in the end tooth clutch claw 1 with a hollow pin 10, and set the spring 13 on the M4 screw 12 to fix the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com