Method for preparing high-magnetic energy product high-coercive force low-cost sintered neodymium iron boron

A technology with high coercive force and high magnetic energy product, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of the decrease of magnetic flux Bs and remanence Br of NdFeB magnets, the reduction of coercive force, and the reduction of iron atom magnetic moment and other problems, to achieve the effect of reducing the average particle size of the surface area, reducing the average grain size, and increasing the coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

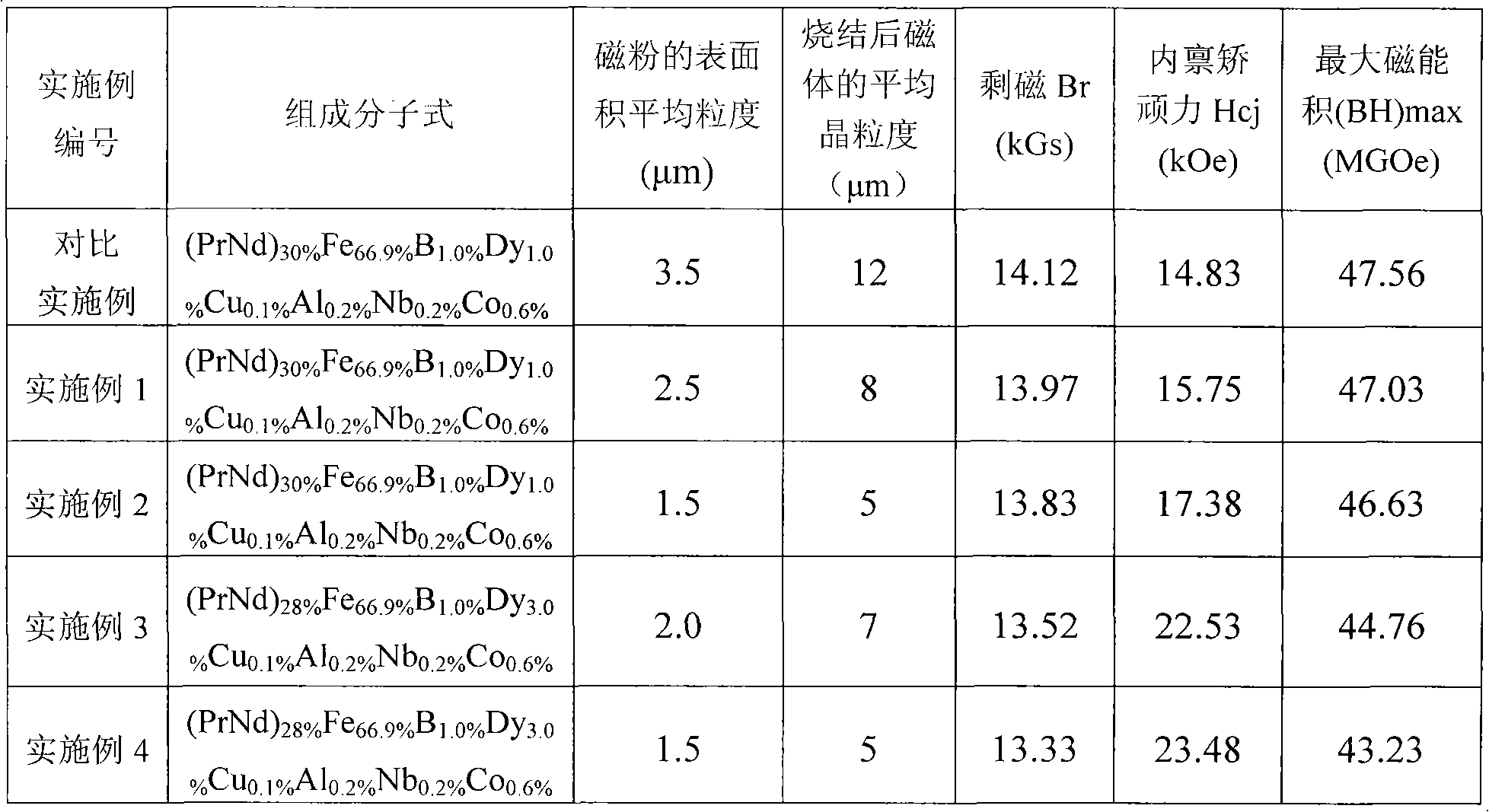

Examples

Embodiment 1

[0032] Embodiment 1: the NdFeB permanent magnet material in the present embodiment is produced according to the following steps:

[0033] Step 1: according to the composition molecular formula representing the composition and mass percentage content of NdFeB alloy: (PrNd) 30% Fe 66.9% B 1.0% Dy 1.0% Cu 0.1% Al 0.2% Nb 0.2% co 0.6% preparation of raw materials;

[0034] Step 2: Put the prepared raw materials into the quick-setting furnace, in a vacuum of 2×10 -2 Heating the oven under a vacuum of Pa, then filling it with Ar gas for smelting, pouring the molten steel onto a copper roll with a roll speed of 2.5m / s after refining, and throwing it into a quick-setting thin strip with an average thickness of 0.25mm;

[0035] Step 3: Put the quick-setting thin strip into the hydrogenation furnace for hydrogen crushing process. The powder after hydrogen crushing is jet milled. During the jet mill, the average particle size of the surface area of the magnetic powder is contro...

Embodiment 2

[0037] Embodiment 2: the NdFeB permanent magnet material in the present embodiment is produced according to the following steps:

[0038] Step 1: according to the composition molecular formula representing the composition and mass percentage content of NdFeB alloy: (PrNd) 30% Fe 66.9% B 1.0% Dy 1.0% Cu 0.1% Al 0.2% Nb 0.2% co 0.6% preparation of raw materials;

[0039] Step 2: Put the prepared raw materials into the quick-setting furnace, in a vacuum of 2×10 -2 Heating the oven under a vacuum of Pa, then filling it with Ar gas for smelting, pouring the molten steel onto a copper roll with a roll speed of 4.0m / s after refining, and throwing it into a quick-setting thin strip with an average thickness of 0.16mm;

[0040] Step 3: Put the quick-setting thin strip into the hydrogenation furnace for hydrogen crushing process. The powder after hydrogen crushing is jet milled. During the jet mill, the average particle size of the surface area of the magnetic powder is contro...

Embodiment 3

[0042] Embodiment 3: the NdFeB permanent magnet material in the present embodiment is produced according to the following steps:

[0043] Step 1: according to the composition molecular formula representing the composition and mass percentage content of NdFeB alloy: (PrNd) 28% Fe 66.9% B 1.0% Dy 3.0% Cu 0.1% Al 0.2% Nb 0.2% co 0.6% preparation of raw materials;

[0044] Step 2: Put the prepared raw materials into the quick-setting furnace, in a vacuum of 2×10 -2 Heating the oven under a vacuum of Pa, then filling it with Ar gas for smelting, pouring the molten steel onto a copper roll with a roll speed of 3.0m / s after refining, and throwing it into a quick-setting thin strip with an average thickness of 0.20mm;

[0045] Step 3: Put the quick-setting thin strip into the hydrogenation furnace for hydrogen crushing process. The powder after hydrogen crushing is jet milled. During the jet mill, the average surface area of the magnetic powder is controlled at 2.0 μm, and it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com