Micro-ablation insulating material and preparation method thereof

A technology of thermal insulation materials and composite materials, applied in the field of ablative composite materials with dimensionality and functional gradient and its preparation, can solve the problems of high thermal conductivity, easy to fall off, peel off, unable to further prevent heat flow transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

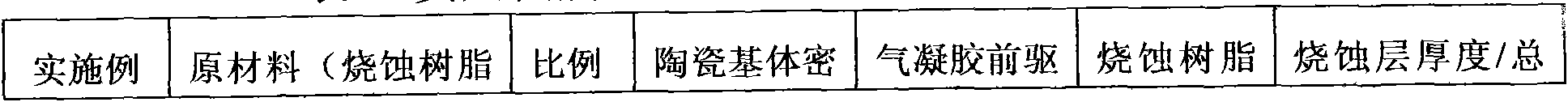

Examples

Embodiment 1

[0145] Example 1: Preparation of Barium Phenolic Resin Composite Rigid Thermal Insulation Material

[0146] (1) Using 3-5μm quartz fiber, borosilicate binder and titanium dioxide anti-radiation agent, blending according to the mass ratio of 100:3:10 to obtain a rigid fiber matrix with a density of 0.2g / cm 3 .

[0147] (2) Place the rigid fiber matrix prepared in step (1) with a size of 100mm×100mm×20mm in a container, vacuumize to remove the gas in the pores of the material, and then vacuum impregnate and composite 20% silica airgel Precursor aqueous solution, the obtained density is 0.40g / cm 3 rigid insulation material.

[0148] (3) Get 200g barium phenolic resin and join in 800g ethanol, add 10g hexamethylenetetramine, stir and dissolve with mechanical stirrer, be made into 20% barium phenolic resin ethanolic solution;

[0149] (4) Open the vacuum valve of the container, automatically inject the prepared phenolic resin solution into the tooling under the action of the int...

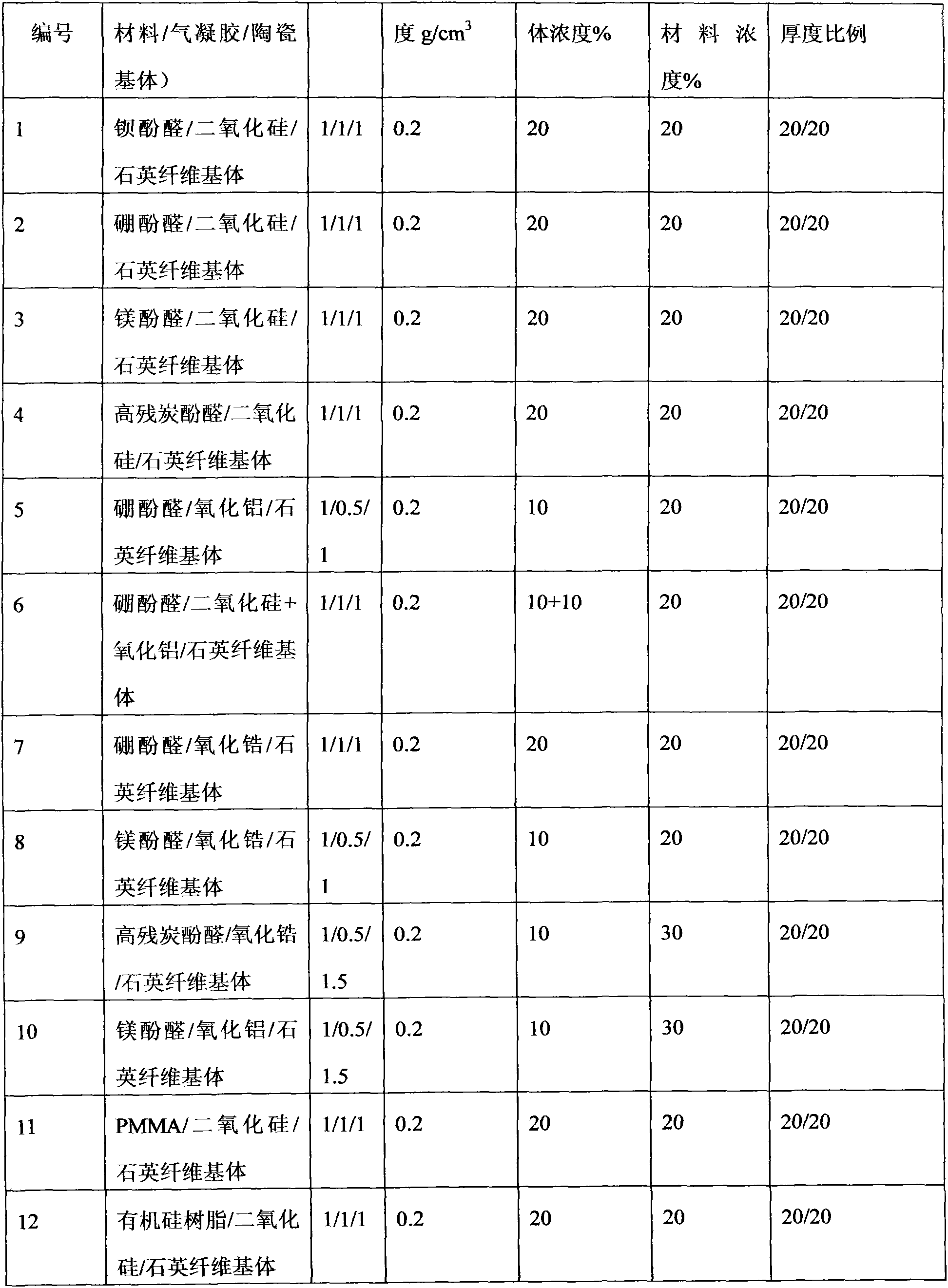

Embodiment 13

[0155] Example 13: boron phenolic resin surface layer composite rigid insulation material

[0156] (1) Using 3-5 μm quartz fiber, alumina fiber, borosilicate binder and potassium titanate whisker anti-radiation agent, blending at a mass ratio of 78:22:3::10 to prepare a rigid fiber matrix, The density is 0.25g / cm 3 .

[0157] (2) Place the rigid fiber matrix with a size of 100mm×100mm×20mm in the container, vacuumize to remove the gas in the pores of the material, and then vacuum impregnate the composite 25% silica airgel precursor body, the obtained density is 0.50g / cm 3 rigid insulation material.

[0158] (3) Get 300g barium phenolic resin and join in 700g ethanol, add the hexamethylenetetramine of 10g, stir and dissolve with mechanical stirrer, be made into 30% barium phenolic resin ethanolic solution;

[0159] (4) Open the vacuum valve of the container, slowly inject the prepared boron phenolic resin solution into the container under the effect of the internal and exte...

Embodiment 19

[0165] Example 19: Boron phenolic resin-PMMA double-surface layer composite rigid heat insulation material

[0166] (1) The size is 150mm×150mm×25mm, the density is 0.3g / cm 3 The quartz substrate is put into a 210mm×210mm×40mm container, vacuumed to remove the gas in the pores of the material, and then vacuum impregnated with 20% silica airgel precursor to obtain a rigid thermal insulation with a density of 0.50g / cm3 Material;

[0167] (2) Get 200g boron phenolic resin and add in 800g ethanol solvent, stir and dissolve with mechanical stirrer, after dissolving completely, add 10g p-toluenesulfonic acid curing agent, be made into 20% boron phenolic ethanol solution, measure 120ml solution;

[0168] (3) Open the vacuum valve of the container, slowly inject the prepared boron phenolic resin solution into the container under the effect of the internal and external pressure difference, and adjust the glue feeding speed by controlling the size of the valve;

[0169] (4) Quickly ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com