Preparation method of continuous cellulose-carbon nanomaterial composite aerogel fibers

A carbon nanomaterial, composite aerogel technology, applied in the chemical characteristics of fibers, man-made filaments made of viscose, wet spinning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 The preparation method 1 of continuous cellulose / carbon nanotube composite airgel fiber

[0029] making process:

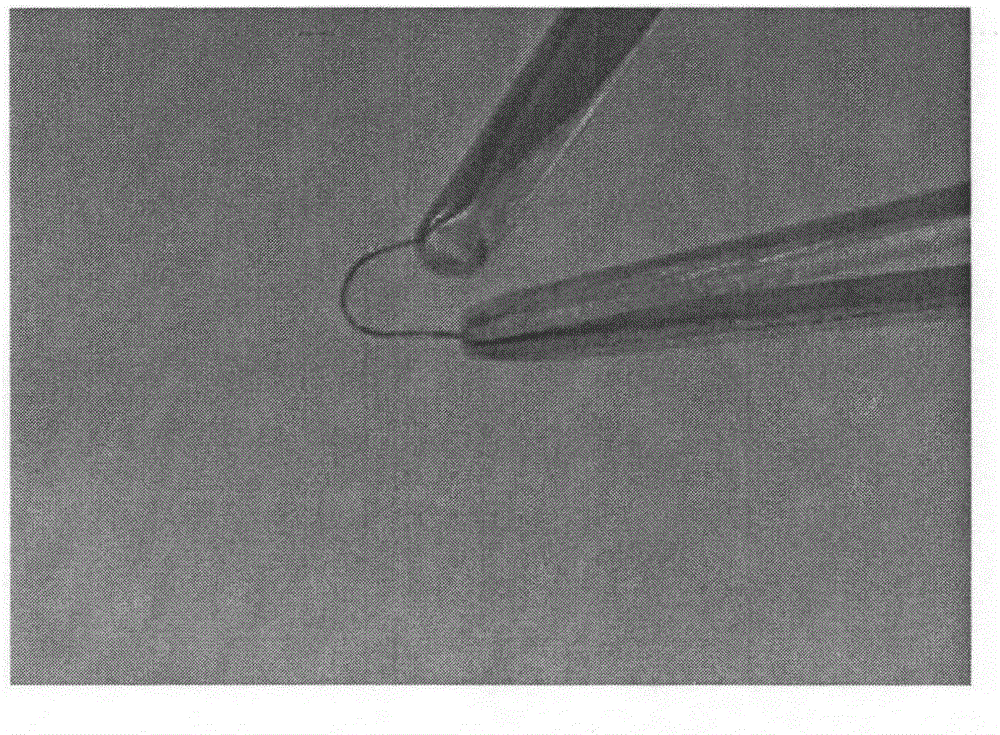

[0030] Disperse bacterial cellulose in a low-temperature solvent system with a mass fraction of 7% NaOH / 8% urea / 10% thiourea, wherein the mass fraction of bacterial cellulose is 2%, and the mass fraction is 0.5% of hydroxylated multi-walled carbon nano Tube, mechanically stirred for 30 minutes, degassed with a centrifuge at 10,000r / min for 20 minutes, and wet-spun with a volume fraction of 10% ethanol aqueous solution as a coagulation bath, and the extrusion speed of the spinning stock solution was 0.6m / min . The cellulose gel fiber containing hydroxylated multi-walled carbon nanotubes formed in the coagulation bath was wound at a winding speed of 0.6 m / min. The wound fibers were immersed in pure ethanol solution and aged for 1 h to make them completely gelled. After aging, the fiber is washed with deionized water to neutrality, then the dei...

Embodiment 2

[0034] Embodiment 2 Preparation method 2 of continuous cellulose-carbon nanomaterial composite airgel fiber

[0035] making process:

[0036] Disperse the treated cotton pulp cellulose (the cellulose cotton pulp is mechanically crushed, washed with water and ethanol several times and then dried in a vacuum oven at 50°C) in a mass fraction of 8% NaOH / 8% urea / 6.5% thiourea In the low-temperature solvent system, wherein the mass fraction of cotton pulp cellulose is 7%, the hydroxylated multi-walled carbon nanotubes with a mass fraction of 1% are added, mechanically vigorously stirred for 30min, and degassed with a centrifuge at 10000r / min for 20min, to The aqueous ethanol solution with a volume fraction of 50% was used as a coagulation bath for wet spinning, and the extrusion speed of the spinning stock solution was 3 m / min. The cellulose gel fiber containing hydroxylated multi-walled carbon nanotubes formed in the coagulation bath was wound at a winding speed of 6 m / min. The wou...

Embodiment 3

[0039] Embodiment 3 The preparation method 3 of continuous cellulose / graphene composite airgel fiber

[0040] making process:

[0041] Disperse bacterial cellulose in a low-temperature solvent system with a mass fraction of 9.5% NaOH / 4.5% thiourea, wherein the mass fraction of bacterial cellulose is 7%, add graphene with a mass fraction of 0.5%, stir mechanically for 30 minutes, and centrifuge Machine 10000r / min for defoaming treatment 20min, volume fraction of 10% acetone aqueous solution as coagulation bath, wet spinning, the extrusion speed of spinning stock solution is 2.4m / min. The graphene-containing cellulose gel fibers formed in the coagulation bath were wound at a winding speed of 6 m / min. The wound fiber was immersed in pure acetone solution for 20min to make it completely gelled. After aging, the fibers are washed with deionized water until neutral, and freeze-dried to obtain cellulose / graphene composite airgel fibers.

[0042] Result detection:

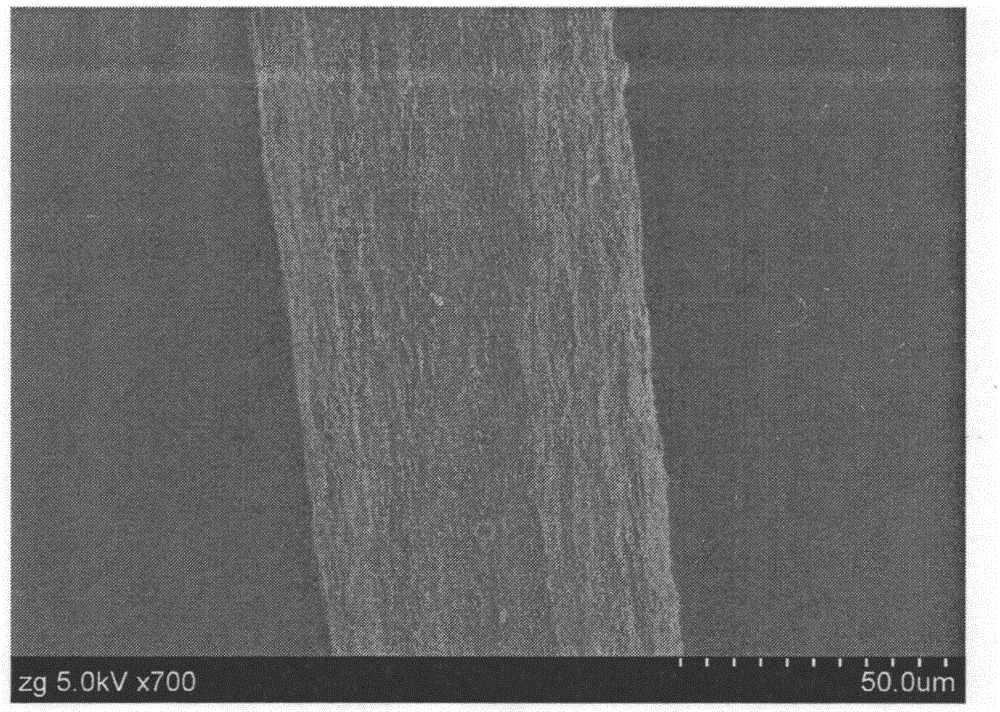

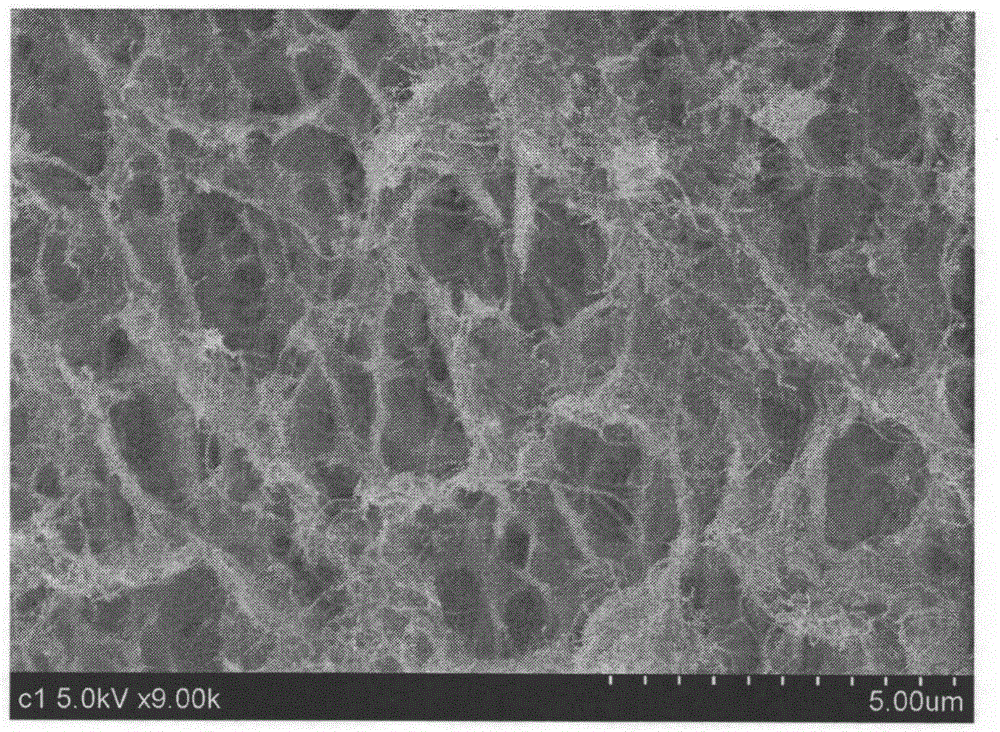

[0043] The spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com