High-thermal-conductivity semi-cured adhesive film of metal substrate and preparation method of high-thermal-conductivity semi-cured adhesive film

A metal substrate, semi-curing technology, used in adhesives, epoxy resins, film/sheet adhesives, etc., can solve the problems of easy embrittlement, easy tearing, accelerated embrittlement, etc. Thermal conductivity, strong crosslinking, effect of improving thermal conductivity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

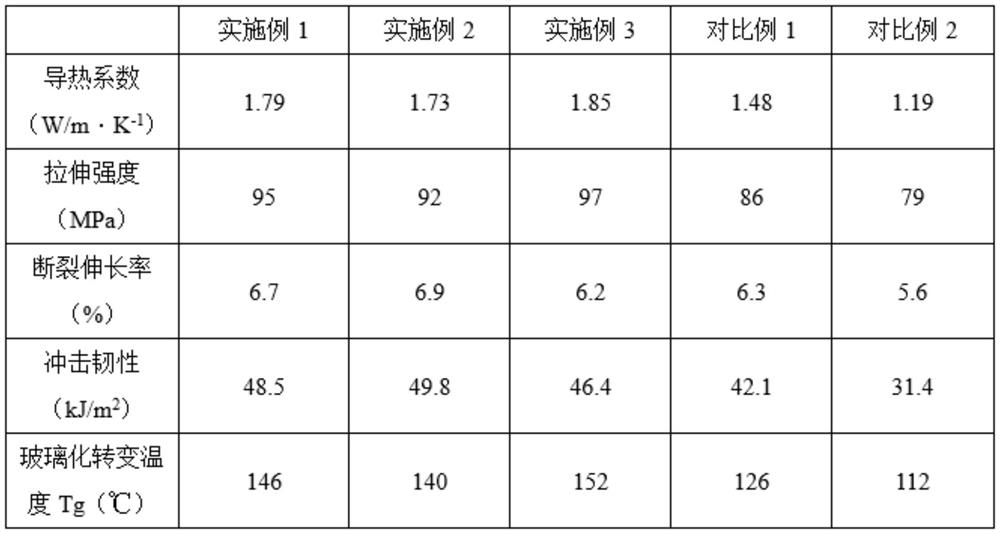

Examples

Embodiment 1

[0041] A high thermal conductivity prepreg film for a metal substrate, calculated in parts by weight, includes the following parts by weight:

[0042] 100 parts of epoxy resin, 20 parts of thermally conductive filler, 35 parts of curing agent and 6 parts of curing agent accelerator;

[0043] Wherein, the thermally conductive filler is modified boron nitride / tantalum disilicide microspheres.

[0044] Described epoxy resin is the mixture of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin, the weight ratio of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin 30:8:15.

[0045] The curing agent is methyl tetrahydrophthalic anhydride.

[0046] The curing agent accelerator is 2,4,6-tris(dimethylaminomethyl)phenol.

[0047] The thermally conductive filler is treated boron nitride, and the treatment method of boron nitride is:

[0048] Step 1, treating boron nitride with acid solution, and then grafting with zinc...

Embodiment 2

[0067] A high thermal conductivity prepreg film for a metal substrate, calculated in parts by weight, includes the following parts by weight:

[0068] 100 parts of epoxy resin, 16 parts of thermally conductive filler, 20 parts of curing agent and 3 parts of curing agent accelerator;

[0069] Wherein, the thermally conductive filler is modified boron nitride / tantalum disilicide microspheres.

[0070] Described epoxy resin is the mixture of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin, the weight ratio of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin It is 25:5:10.

[0071] The curing agent is dimer acid-based polyamide.

[0072] The curing agent accelerator is N,N-dimethylbenzylamine.

[0073] The thermally conductive filler is treated boron nitride, and the treatment method of boron nitride is:

[0074] Step 1, treating boron nitride with acid solution, and then grafting with zinc phenolsulfonate ...

Embodiment 3

[0094] A high thermal conductivity prepreg film for a metal substrate, calculated in parts by weight, includes the following parts by weight:

[0095]100 parts of epoxy resin, 24 parts of thermally conductive filler, 50 parts of curing agent and 9 parts of curing agent accelerator;

[0096] Wherein, the thermally conductive filler is modified boron nitride / tantalum disilicide microspheres.

[0097] Described epoxy resin is the mixture of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin, the weight ratio of bisphenol A type epoxy resin, naphthalene ring epoxy resin and biphenyl epoxy resin It is 45:10:20.

[0098] The curing agent is 4,4-diaminodiphenyl sulfone.

[0099] The curing agent accelerator is N,N-dimethylbenzylamine.

[0100] The thermally conductive filler is treated boron nitride, and the treatment method of boron nitride is:

[0101] Step 1, treating boron nitride with acid solution, and then grafting with zinc phenolsulfonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com