A kind of polyamide film layer composite reverse osmosis film and its preparation method and application

A technology of polyamide film and reverse osmosis, which is applied in the fields of chemical instruments and methods, osmosis/dialysis water/sewage treatment, membrane technology, etc., can solve the problems of complex modification steps, unfavorable commercial production, difficult regulation, etc., and achieve Effects of shortening the dissolution-diffusion path, optimizing the interfacial polymerization process, and reducing the intrinsic thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

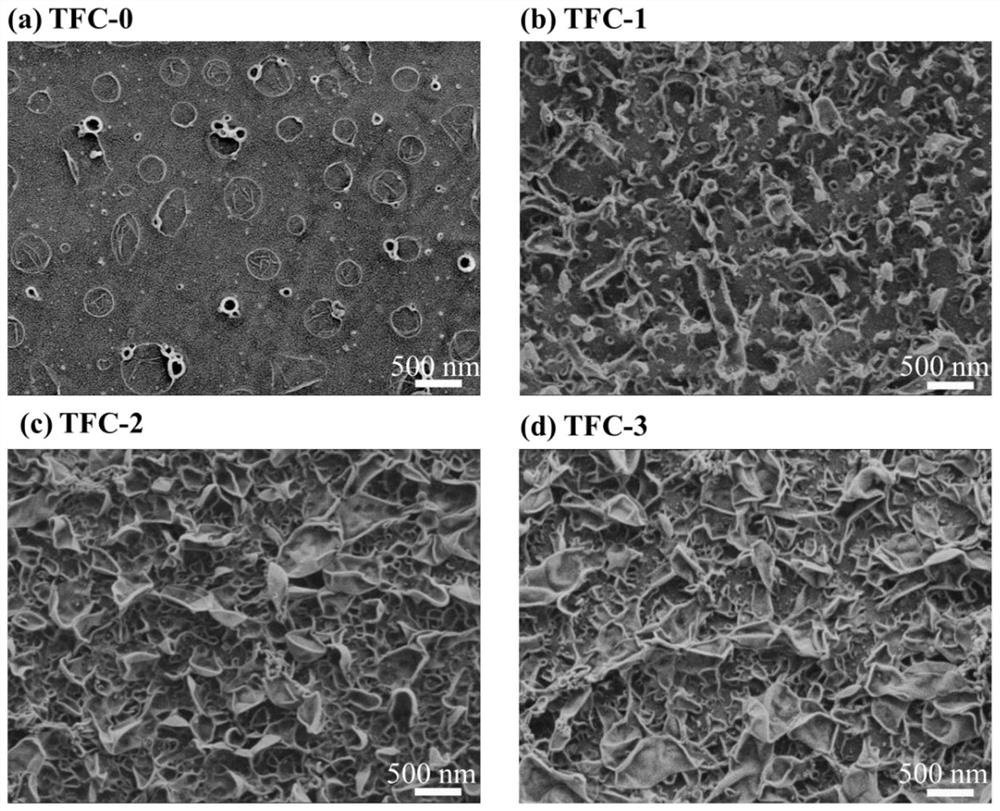

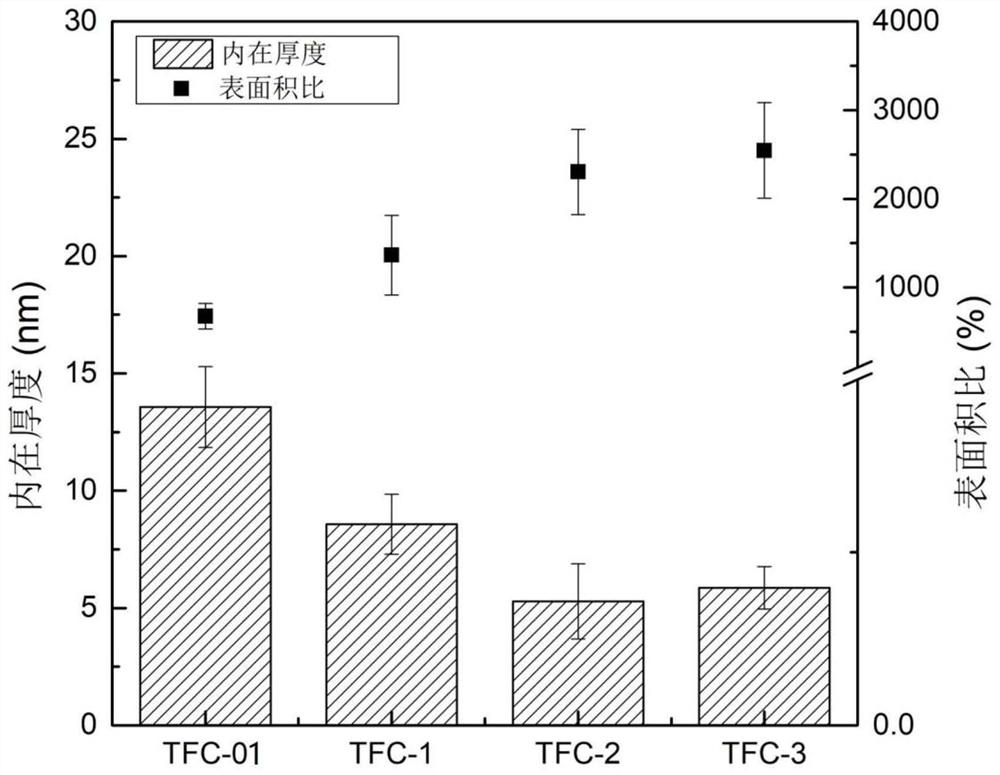

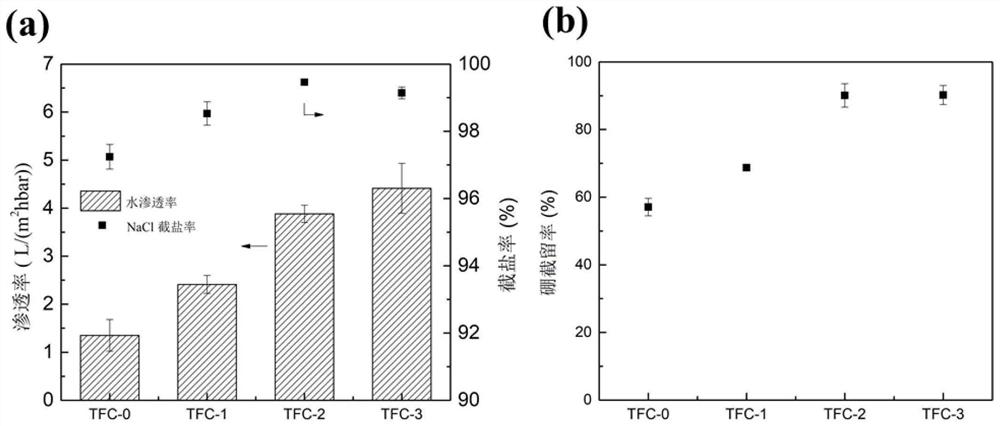

Method used

Image

Examples

Embodiment 1

[0035] 30mg of Cu(NO 3 ) 2 ·3H 2 O, 15mg of terephthalic acid (H 2 BDC), 0.03mL of formic acid and 0.04mL of pyridine were dissolved in 5mL of N,N-dimethylacetamide solution to make solution A; 0.05mL of triethylamine was dissolved in 5mL of n-hexane to make solution B ; Slowly add solution A to the bottom of solution B through a syringe, seal it in a glass jar and react at room temperature for 15 hours, and synthesize ultra-thin metal-organic framework CuBDC through interfacial reaction; centrifuge at 8000rpm for 8 minutes to obtain a blue precipitate, which is washed repeatedly with acetone , remove the organic solvent residue in the metal-organic framework CuBDC, and vacuum-dry at 60°C to obtain the metal-organic framework CuBDC nanosheets for use;

[0036] dissolving the m-phenylenediamine solution in deionized water to form a m-phenylenediamine solution with a mass concentration of 2%;

[0037] Dissolving metal-organic framework CuBDC nanosheets in n-hexane to form Cu...

Embodiment 2

[0042] 40mg of Cu(NO 3 ) 2 ·3H 2 O. 16 mg of terephthalic acid, 0.05 mL of formic acid, and 0.01 mL of pyridine were dissolved in 5 mL of N,N-dimethylacetamide solution to form A solution; 0.05 mL of triethylamine was dissolved in 5 mL of n-hexane Prepare solution B in alkane; slowly add solution A to the bottom of solution B through a syringe, seal it in a glass jar and react at room temperature for 15 hours, and synthesize ultrathin metal organic framework CuBDC through interfacial reaction; centrifuge at 8000rpm for min to obtain a blue color Precipitate, wash repeatedly with acetone, remove the organic solvent residue in the ultra-thin metal-organic framework CuBDC, and dry it in vacuum at 60°C to obtain metal-organic framework CuBDC nanosheets for future use;

[0043] dissolving the m-phenylenediamine solution in deionized water to form a m-phenylenediamine solution with a mass concentration of 2.0%;

[0044] Dissolving metal-organic framework CuBDC nanosheets in n-hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com