Phosphorus-containing flame-retardant polyester ionomer/nanocomposite material and preparation method thereof

A technology of nanocomposite materials and flame-retardant copolyesters, which is applied in the field of phosphorus-containing flame-retardant copolyester ionomer/nanocomposite materials and its preparation, can solve the problems of poor comprehensive properties of materials, and achieve improved crystallization properties and good The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

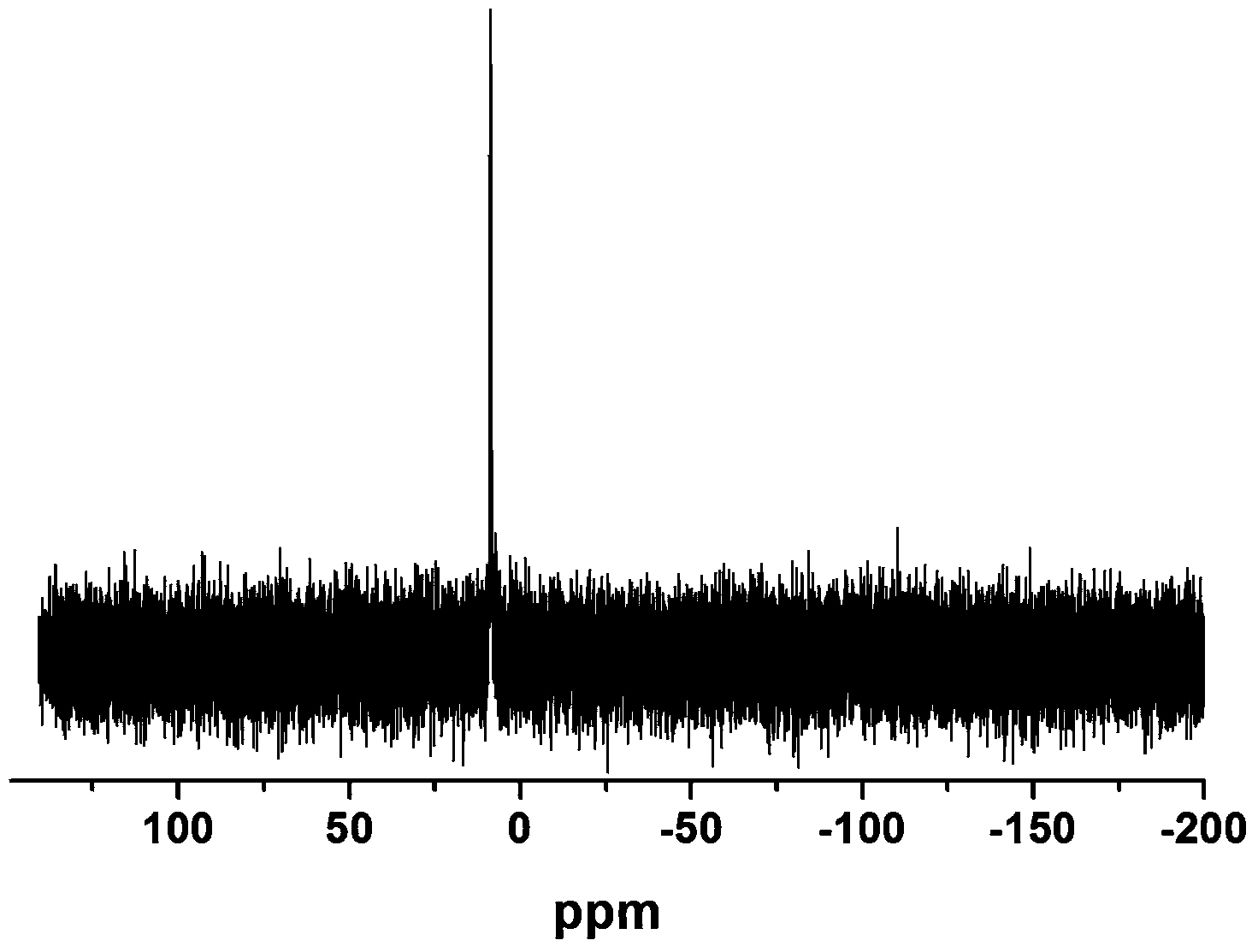

Method used

Image

Examples

Embodiment 1

[0060] First add 830g of terephthalic acid, 434mL of ethylene glycol and 0.46g of tetrabutyl titanate into the reaction kettle, pressurize to 0.1MPa, stir and heat up to 240°C under nitrogen protection to start esterification, control the pressure to 0.3MPa, about 1h After that, raise the temperature to 260°C and continue the esterification until no water is produced, and the pressure drops to normal pressure. After vacuuming at 260°C for about 0.5h, the excess ethylene glycol is pumped out, and then the vacuum is stopped. Nitrogen is introduced into the system, and after returning to normal pressure Into the reaction kettle, add dropwise the ethylene glycol containing 44.6g phosphorus-containing ionic monomer 2,8-(2-hydroxyethoxy)carbonylphenanthreneoxaphosphinate potassium (DHPPO-K) at a rate of 2 to 3 drops / second. Alcohol solution and 20.38g of octadecyltrimethylammonium chloride modified montmorillonite pre-dispersed in 150ml of ethylene glycol, and control the system temp...

Embodiment 2

[0062] First, 830g of terephthalic acid, 434mL of ethylene glycol and 0.46g of tetrabutyl titanate were added to the reactor, and the esterification reaction was carried out according to the method of Example 1 (the difference was that the pressure was controlled at 0.4MPa). After the esterification was completed, , the pressure is reduced to normal pressure, vacuumize at 260°C for about 0.5h, stop the vacuum after pumping out excess ethylene glycol, feed nitrogen into the system, return to normal pressure, and inject it into the reaction kettle at a rate of 2 to 3 drops / second Add dropwise the ethylene glycol solution containing 66.9g phosphorus ion monomer 2,8-(2-hydroxyethoxy) carbonyl phenanthrene oxa hypophosphite potassium and 5.11g pre-dispersed octadecyl in 50ml ethylene glycol Trimethyl ammonium chloride modified montmorillonite, and the temperature of the system is controlled above 220° C. during the dropping process, and the polycondensation can be carried out accord...

Embodiment 3

[0064] First, 830g of terephthalic acid, 434mL of ethylene glycol, 0.46g of tetrabutyl titanate, and 66.9g of phosphorus-containing ionic monomer 2,8-(2-hydroxyethoxy)carbonylphenanthreneoxaphosphinate potassium Diol solution is added in the reactor, carry out esterification reaction by the method for embodiment 1, after esterification finishes, pressure drops to normal pressure, vacuumizes at 260 ℃ for about 0.5h and stops vacuumizing after taking out excess ethylene glycol, to Nitrogen was introduced into the system, and after returning to normal pressure, 10.28g of octadecyltrimethylammonium chloride modified in advance dispersed in 120ml of ethylene glycol was added dropwise at a rate of 2 to 3 drops / second. Montmorillonite, and control the temperature of the system during the dropping process to be above 220° C., and then carry out polycondensation according to the method of Example 1 after adding (the difference is that the high vacuum polycondensation time is 0.5 hours)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com