Patents

Literature

79results about How to "Excellent resistance to dripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

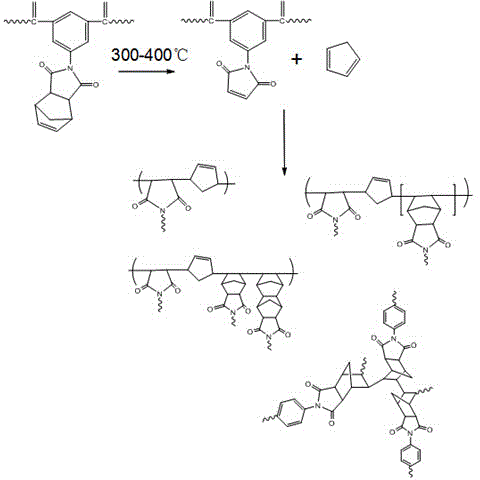

High-temperature self-crosslinking flame-retardant anti-dripping copolyester and preparation method thereof

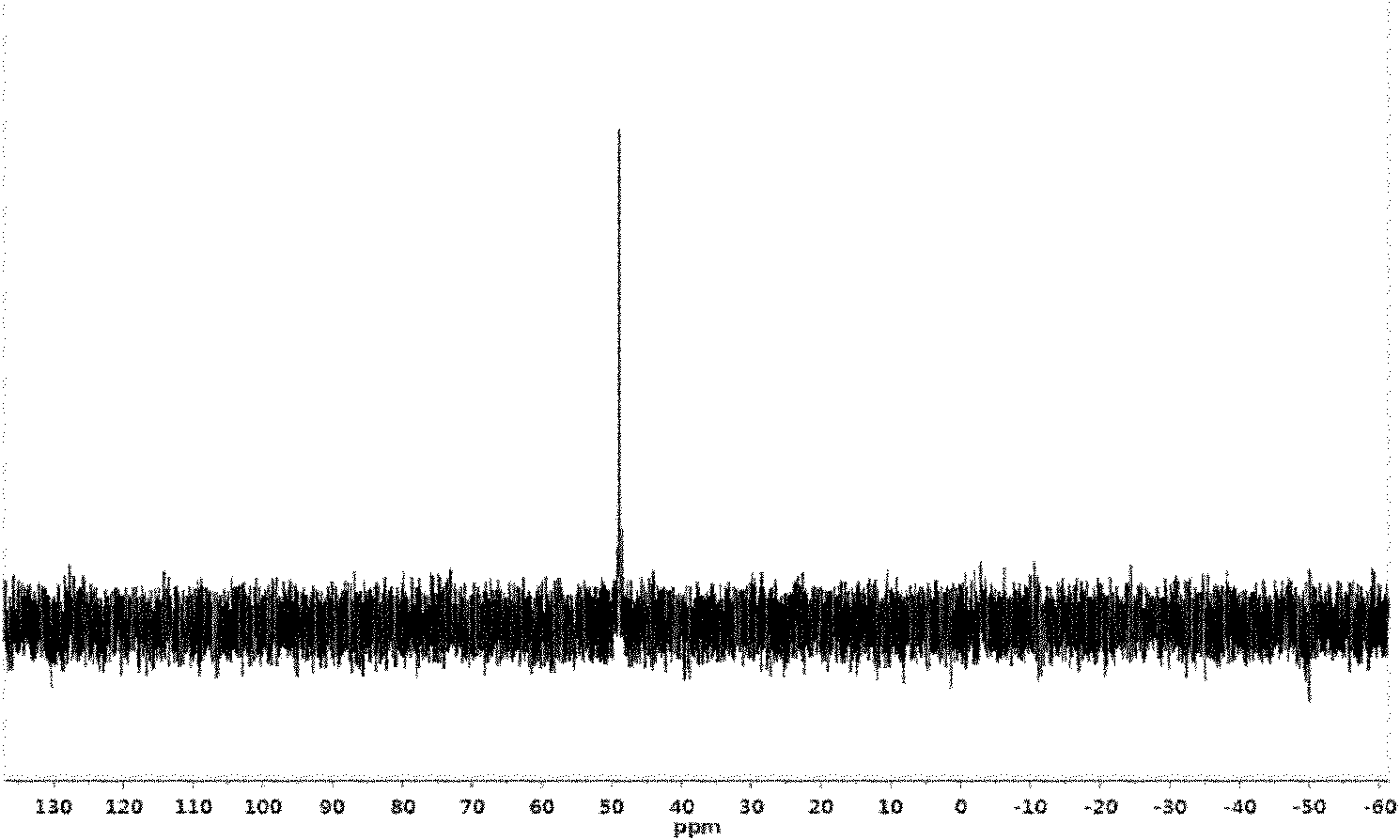

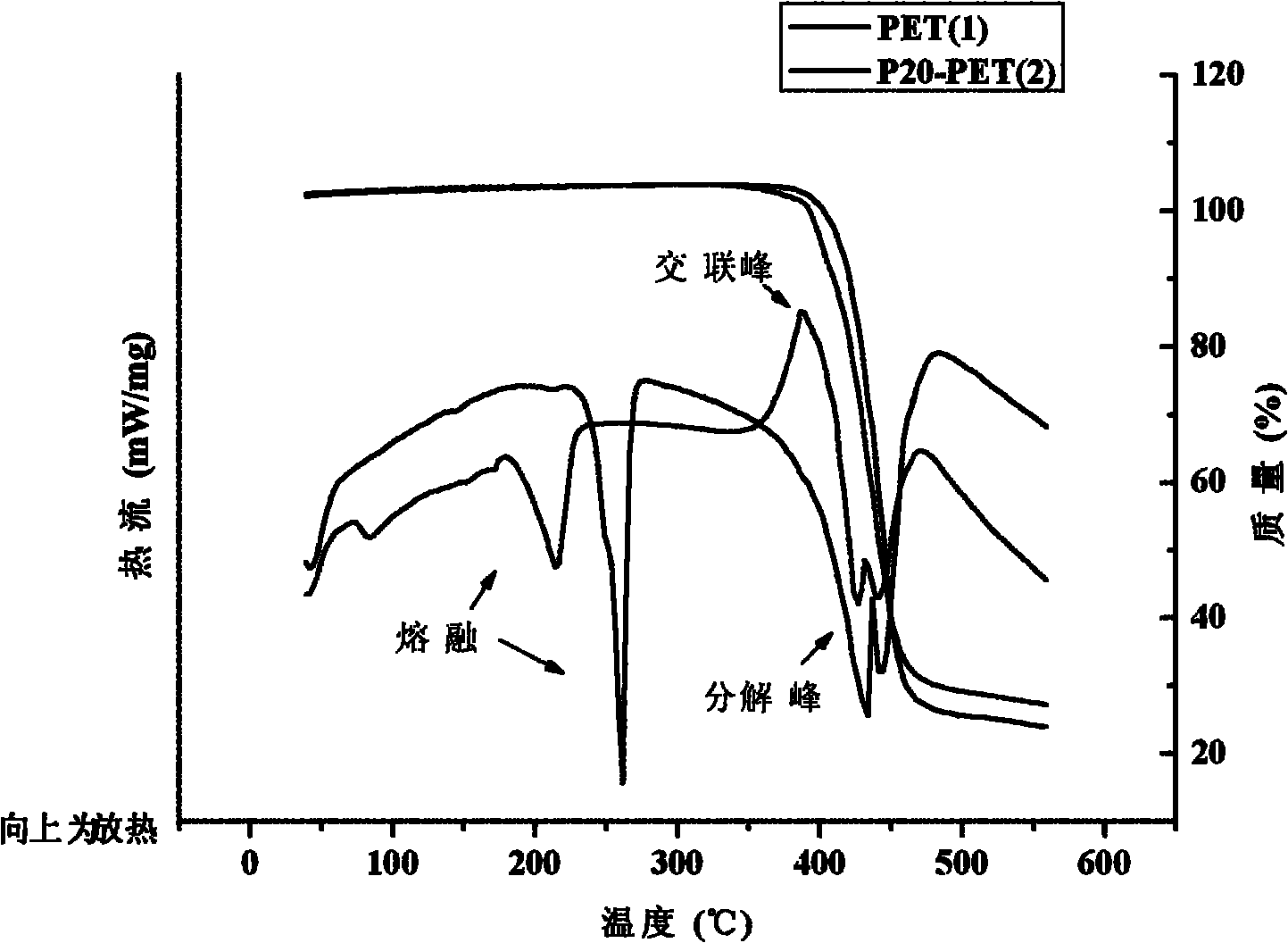

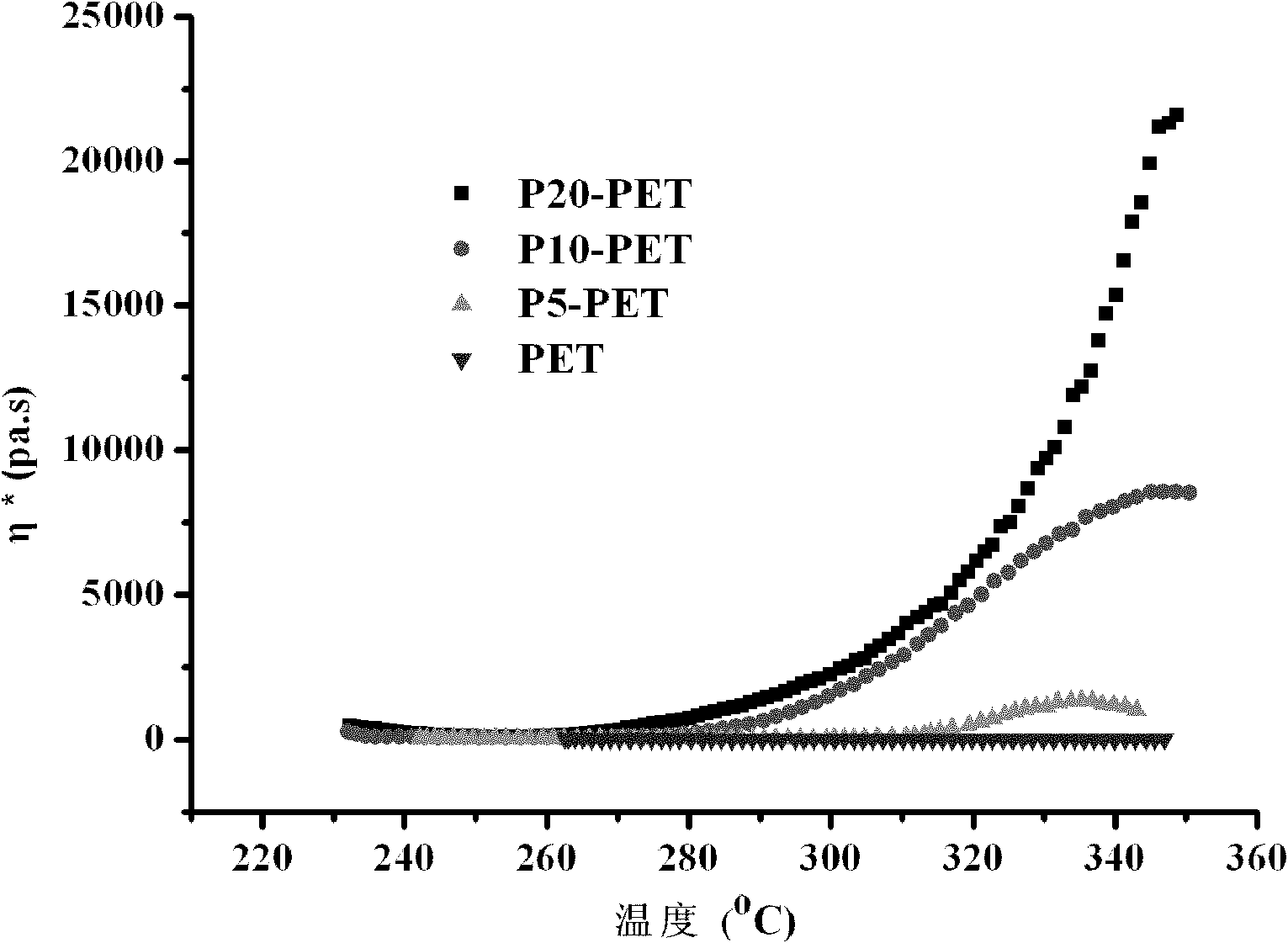

The invention discloses a high-temperature self-crosslinking flame-retardant anti-dripping copolyester which is prepared by introducing a structural unit shown as IV in the specification or introducing structural units shown as III and IV in the specification by random copolymerization on the basis of structural units of synthetic polyester shown as I and II in the specification, and the intrinsic viscosity [eta] of the prepared high-temperature self-crosslinking copolyester is 0.25-1.25dL / g. The invention also discloses the preparation method of the high-temperature self-crosslinking copolyester. Because the crosslinking group introduced in the invention is a high-temperature self-crosslinking group, on the premise of not affecting the preparation and forming of the polyester, self-crosslinking can be realized at higher temperature, and the melt viscosity of the polyester is improved through the char formation effect and stable chemical crosslinking of the self-crosslinking group, thereby performing combined action with the phosphorus-containing flame-retardant structural unit IV and endowing the polyester with better flame-retardant and anti-dripping properties.

Owner:SICHUAN UNIV

A preparation method of flame-retardant anti-melt drop polyester composite fiber

ActiveCN102277653AImprove flame retardant performanceExcellent resistance to drippingFilament/thread formingConjugated synthetic polymer artificial filamentsHeat stabilityPhosphate glass

The invention relates to a preparation method of inflame-retardant anti-dripping polyester composite fibers. The method provided by the invention comprises the following steps of: (1) mixing aromatic dicarboxylic acid, dihydric alcohol and phosphorus-containing fire retardant and adding catalyst and heat stability; reacting to obtain an inflame-retardant copolyester; (2) pre-mixing SNF2, SnO, NH4H2PO4 or P2O5 for 30-60 min and melting at a temperature in a range of 400-500 DEG C for 60-90 min; cooling and carrying out a heat treatment at a temperature in a range of 70-100 DEG C for 90-120 minto obtain phosphate glass; and (3) blending the inflame-retardant copolyester with the phosphate glass and melting and spinning to obtain the inflame-retardant anti-dripping polyester composite fibers. The method provided by the invention has the advantages of simple process and easiness of being implemented; the prepared copolyester and fibers thereof have good inflame-retardant and anti-dripping performances; the limit oxygen index of the textiles is 29.8-33.2% and no melted drops are formed when the product is combusted so that the method provided by the invention has a good application prospect.

Owner:DONGHUA UNIV

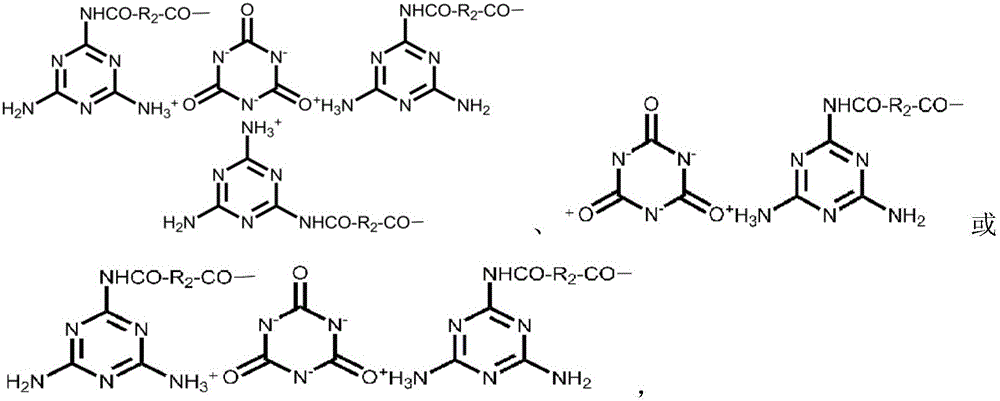

Phosphoric flame-proof copolyester ionomer and preparation method thereof

The invention discloses a phosphorus-containing flame retardant copolyester ionomer and the preparation method, which is characterized in that: based on a plurality of building units synthesizing polyester represented by I and II, a plurality building units represented by IV or a plurality building units represented by III and IV are introduced and the copolyester ionomer is prepared by random copolymerization; wherein, the number of the building units represented by III is 0 to 20 percent of the number of the building units represented by I, the number of the building units represented by IV is 0.1 to 20 percent of the number of the building units represented by I, the number of the building units represented II: the number of the building units represented by [I+III+IV] equals 1, the intrinsic viscosity of the prepared copolyester ionomer [Eta] is in the rang of 0.25 to 0.95dL / g. The phosphorus-containing flame retardant copolyester ionomer has the advantages that: because the ionic groups are phosphorus-containing groups, the flame-retardance modification and the ionization modification of polyester are realized simultaneously; meanwhile, the melt viscosity of polyester is enhanced by the incarbonization produced by the phosphorus-containing ionic groups and the ''physical crosslinking'' produced by the ''ionic aggregate'', thus, the flame retardant and anti-dripping performance is given to polyester.

Owner:SICHUAN UNIV

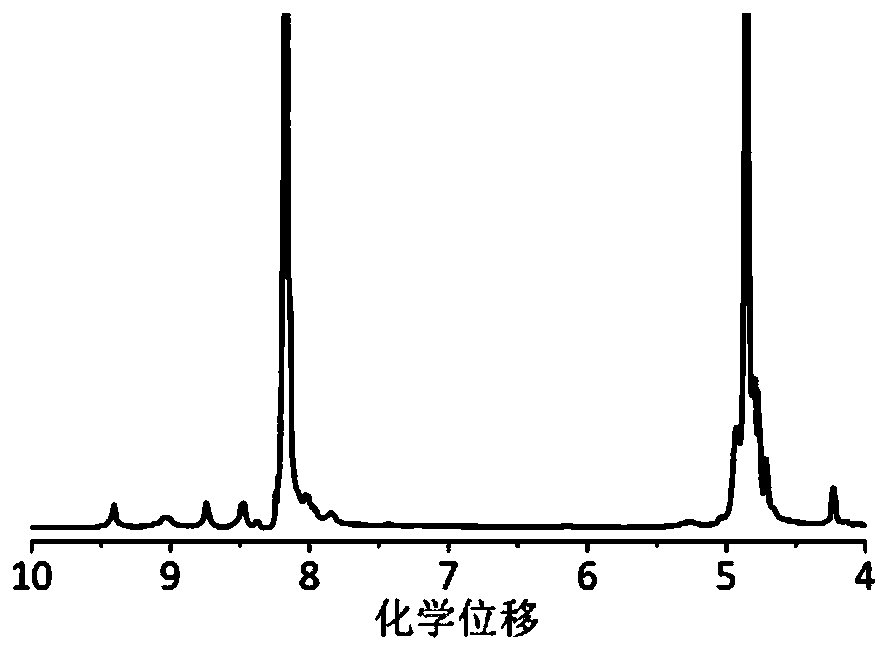

Phosphorus heterocycle inflaming retarding copolyester ionomer and preparation method thereof

ActiveCN102924702AMolecular weight effectIncrease forceFlame-proof filament manufactureMonocomponent copolyesters artificial filamentFiberEngineering plastic

The invention discloses a phosphorus heterocycle inflaming retarding copolyester ionomer which is formed by introducing structure units represented by III and IV on the basis of polyester structure units represented by I and II and conducting random copolymerization. The intrinsic viscosity [eta]of the phosphorus heterocycle inflaming retarding copolyester ionomer is 0.2-1.1 dL / g. A preparation method of the ionomer is further disclosed. Due to the fact that phosphorus ion groups are introduced, inflaming retarding modification and ionization modification can be simultaneously achieved without adding other fire retardants, carbon formation effect and stable 'physical cross-linking' effect produced by 'iron aggregate' of the phosphorus ion groups improve melt viscosity of high polyester, and simultaneously the polyester has excellent inflaming retarding and molten drop resistance. The ionomer can directly serve as raw materials for preparing fibers, engineering plastics, film and the like.

Owner:SICHUAN UNIV

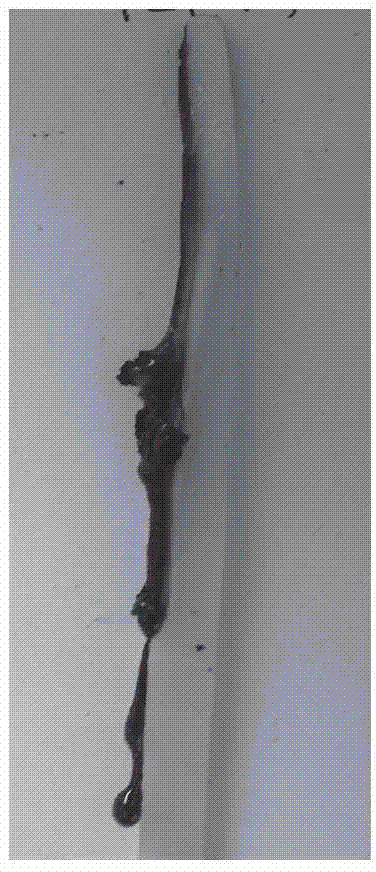

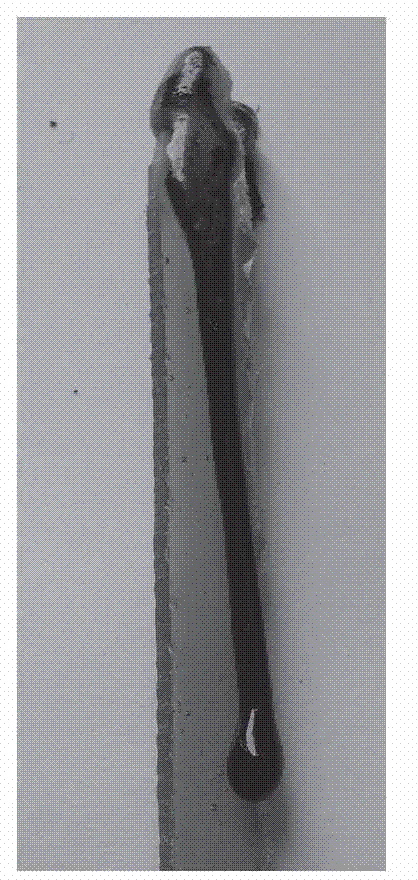

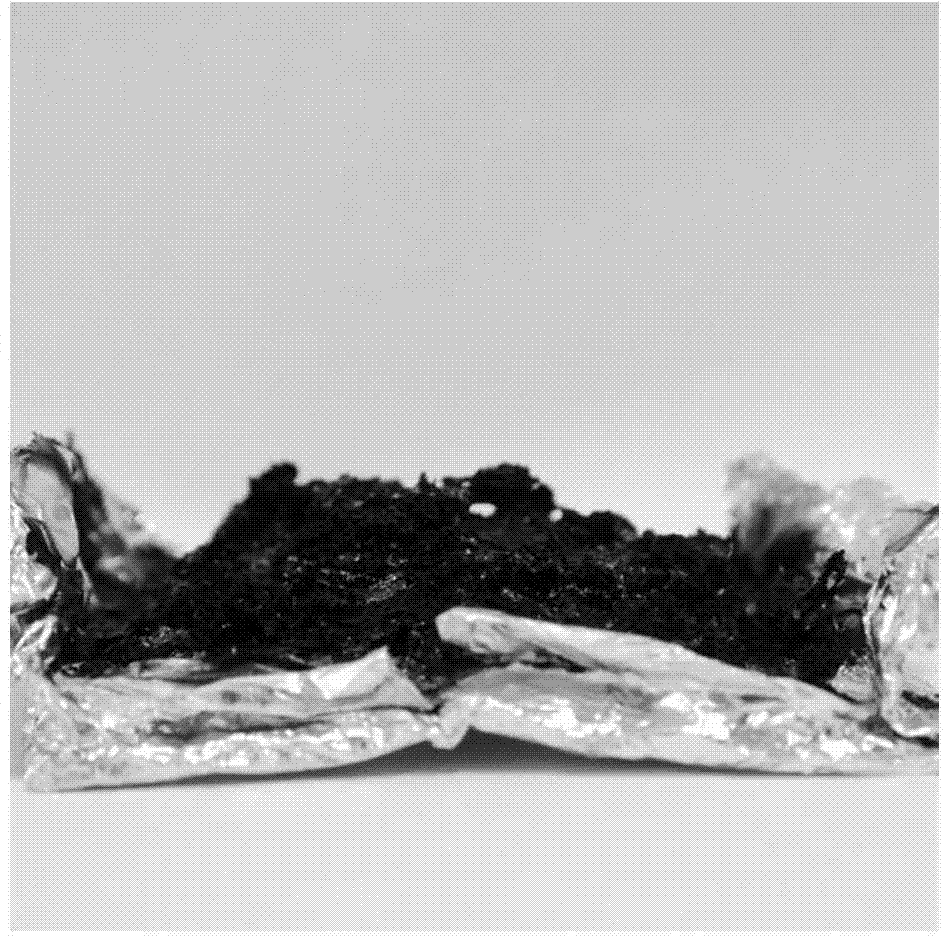

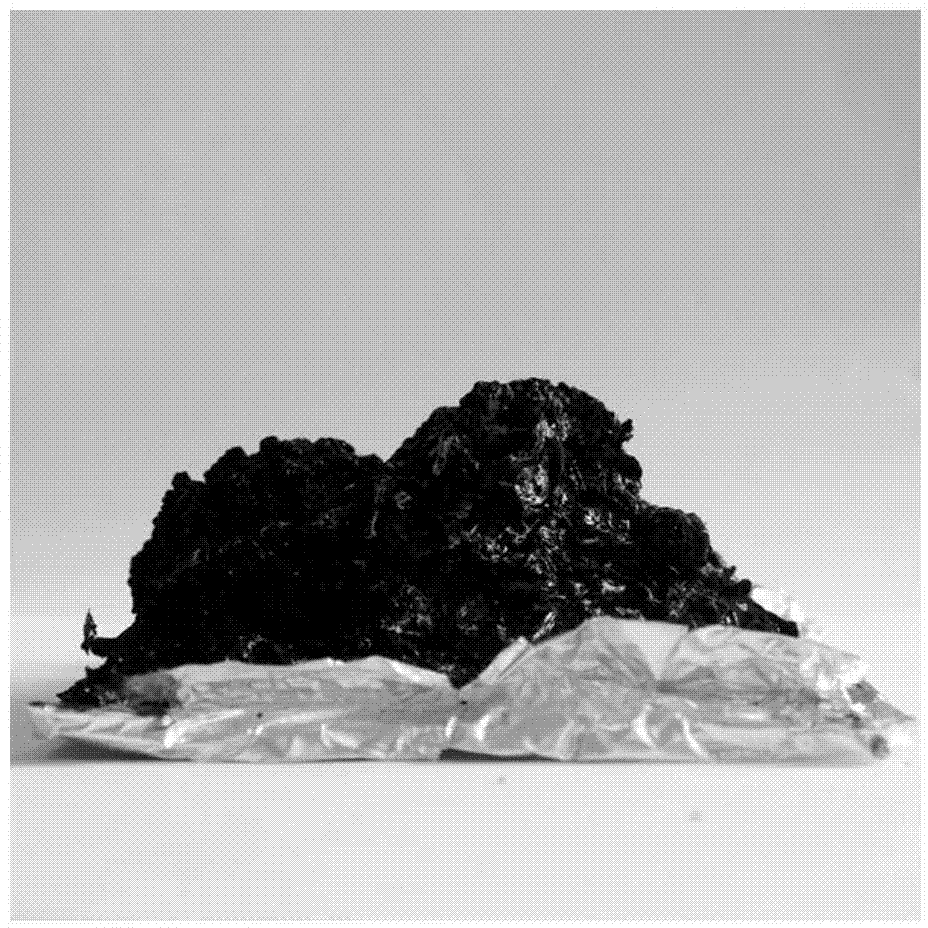

Method for preparing flame-retardant anti-dripping copolyester fibers

InactiveCN102181958AImprove flame retardant performanceExcellent resistance to drippingFlame-proof filament manufactureMelt spinning methodsMilitary UniformsAlcohol

The invention relates to a method for preparing flame-retardant anti-dripping copolyester fibers. The method comprises the following steps: firstly dispersing inorganic clay into nano-size lamellas in water; secondly utilizing dibasic alcohol to further cover the lamellas and enabling the lamellas to carry out condensation polymerization with aromatic dibasic acid, dibasic alcohol and a flame retardant containing phosphorus to obtain flame-retardant anti-dripping copolyester composites; and finally carrying out melt spinning on the flame-retardant anti-dripping copolyester composites to prepare the flame-retardant anti-dripping copolyester fibers. The method has the following beneficial effects: the method has the advantages of simple process and low cost and is suitable for industrialization; and the obtained copolyester fibers have good flame retardant and anti-dripping effects and have a good application prospect in such fields as protective clothing, military uniforms, decorative fabrics for high-rise hotels and the like.

Owner:DONGHUA UNIV

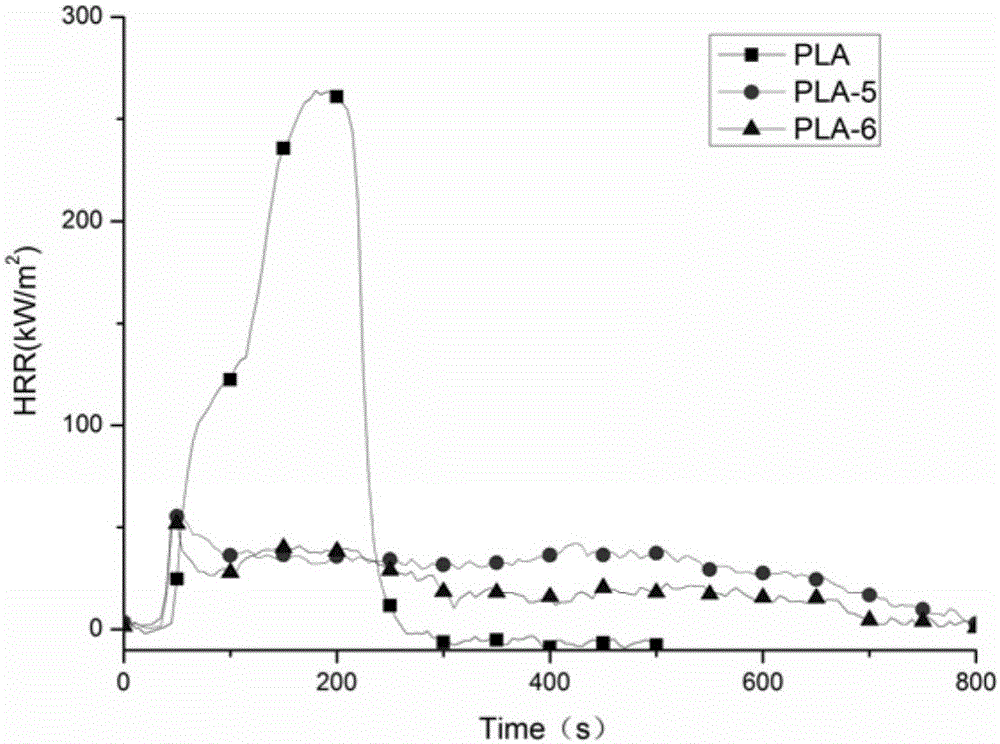

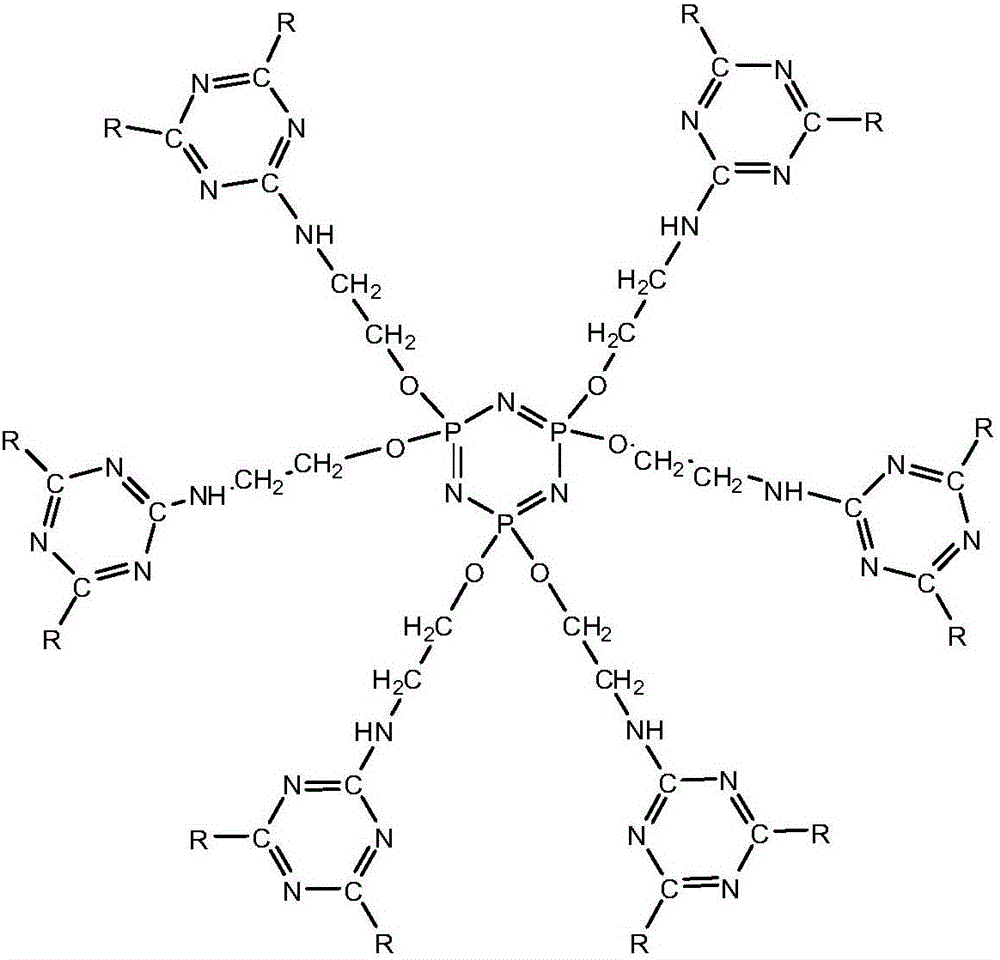

Branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on triazine ring structure and preparation method of copolyester

ActiveCN104710604AIncrease melt viscosityImprove flame retardant performanceNitrogenNetwork structure

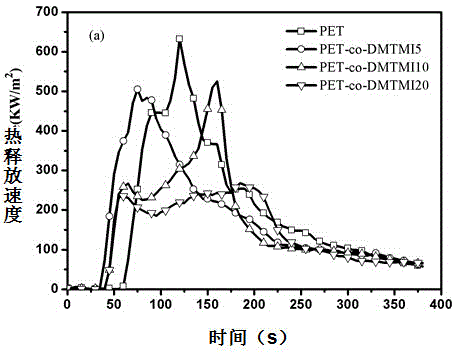

The invention discloses branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on a triazine ring structure. The copolyester is prepared by conducting random copolymerization on structure units expressed as formulae I, II and III or structure units expressed as formulae I, II, III and IV according to a conventional method. The intrinsic viscosity [eta] of the prepared branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester is 0.41-1.10 dL / g; the extreme oxygen index is 24.5-38.0%; the vertical combustion grade is between V-2 and V-0; the peak heat release rate p-HRR in a cone heat test is 247-643 kW / m<2>. According to the copolyester, a modified monomer of the triazine ring structure is introduced, and then copolymerized with polyester to form a unique ternary branched cross-linking network structure; the modified monomer of the triazine ring structure contains the flame-retardant element nitrogen, so that the melt viscosity of the copolyester in combustion can be improved; the copolyester is capable of releasing nitrogen and quickly forming an expanded char layer with excellent heat and oxygen insulation effects; especially, a phosphorus-nitrogen synergism effect can be generated when the copolyester is used together with the conventional phosphorus-containing flame-retardant agent; the flame-retardant performance and the melt-dropping-resistant effects can be more excellent; the selected monomer is low in price; the preparation process is mature; the operation is simple and convenient; the industrialized large-scale production is liable to implement.

Owner:SICHUAN UNIV

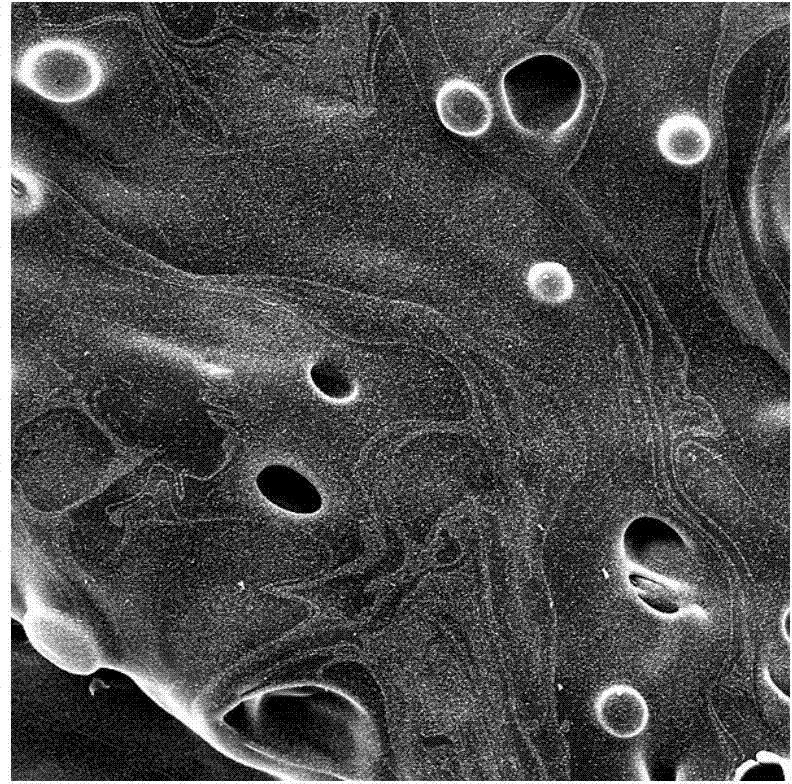

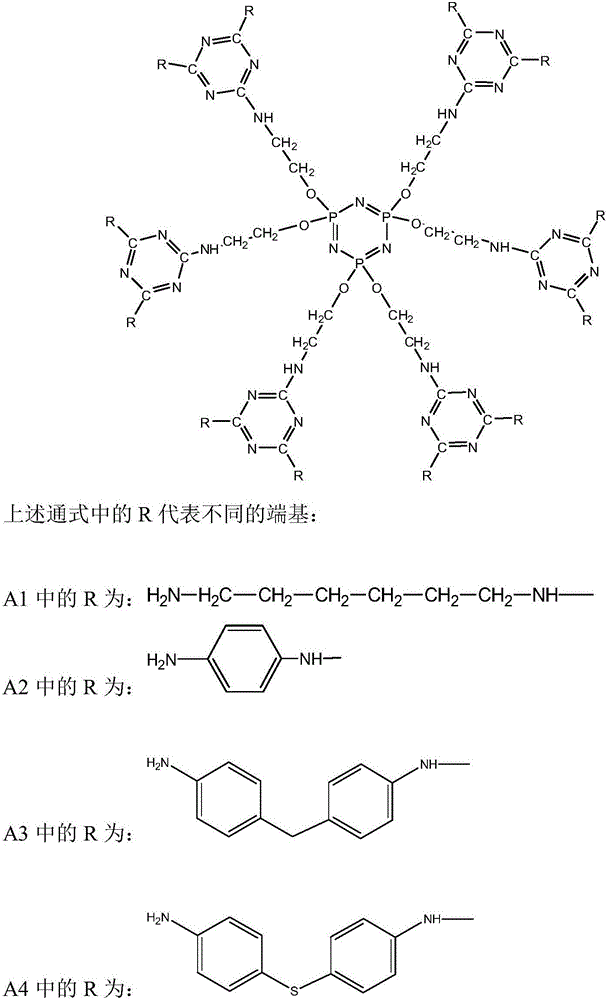

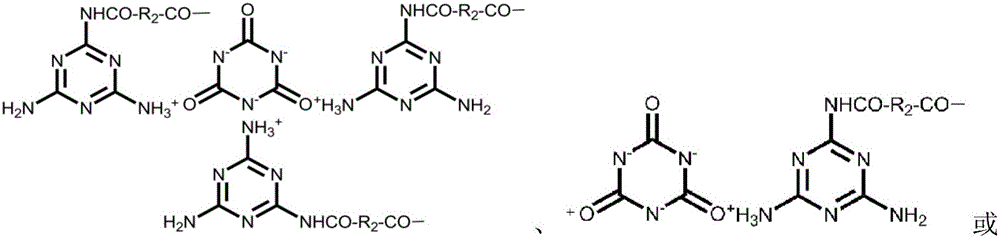

Phosphonitrile/triazine double-group molecular synergistic flame retardation polylactic acid composite material and preparation method thereof

The invention discloses a phosphonitrile / triazine double-group molecular synergistic flame retardation polylactic acid composite material. The phosphonitrile / triazine double-group molecular synergistic flame retardation polylactic acid composite material comprises, by weight, 75-90 parts of polylactic acid resin, 25-10 parts of a phosphorus flame retardant and a phosphonitrile / triazine double-group molecular synergist, and 0.03-0.1 parts of an antioxidant, wherein a weight ratio of the phosphorus flame retardant to the phosphonitrile / triazine double-group molecular synergist is 1-3:3-1. The phosphonitrile / triazine double-group molecular synergistic flame retardation polylactic acid composite material is obtained through the following steps: pre-mixing above components in proportion, and carrying out melt blending at 170-230DEG C. The flame retardation polylactic acid composite material has the characteristics of high anti-droplet effect and high oxygen index; and when the addition amount of the flame retardant is low (10%), the oxygen index still keeps at 30% or above and the composite material can reach vertical burning UL94V0 grade.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Expansive type dripping-resistant flame retardant and preparation method thereof

ActiveCN104262620AImprove flame retardant performanceLittle impact on mechanical propertiesFiberPolyester

The invention relates to a method for preparing an expansive type dripping-resistant flame retardant. The method is characterized by comprising the following steps: mixing phosphorus-containing copolymerization type flame retardant and dihydric alcohol, reacting under the conditions of the temperature of 70-170 DEG C and the pressure of 0.01MPa below zero to 0.096MPa below zero for 4-10 hours, thereby preparing a flame-retardant esterification fluid; and enabling the flame-retardant esterification fluid to react with diamine and ethanol under the conditions of the temperature of 60-140 DEG C and the pressure of 0.01MPa below zero to 0.096MPa below zero for 4-10 hours, adding a dripping-resistant agent and an inorganic flame retardant, thereby preparing the expansive type dripping-resistant flame retardant. The expansive type dripping-resistant flame retardant prepared by the invention has the advantages of high flame retardant efficiency, high temperature resistance, dripping resistance, smoke suppression and small influence on mechanical properties of materials, the flame retardant grade reaches the V-0 level in the UL-94 standard, and the limit oxygen index is over 32 percent. The expansive type dripping-resistant flame retardant can be used for flame-retardant nylon, polyesters and other engineering plastics, also can be applied to the field of fiber textiles and has wide market prospects.

Owner:CHENGDU TALY TECH CO LTD

Flame-retardant anti-dripping polyester fiber and preparation method thereof

InactiveCN107557901AReduce acidityReduce the impactFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolymer scienceIn situ polymerization

The invention relates to flame-retardant anti-dripping polyester fiber and a preparation method thereof. A phosphorus-based flame retardant and graphene oxide react under a certain condition to prepare a flame-retardant anti-dripping agent, then terephthalic acid and ethylene glycol are utilized as raw materials, the flame-retardant anti-dripping agent is introduced into a polyester matrix by an in-situ polymerization method to prepare flame-retardant anti-dripping polyester, and then the flame-retardant anti-dripping polyester fiber is prepared by a melt spinning assembly. A technology designed by the invention not only reduces an effect of the phosphorus-based flame retardant in a polyester polymerization process, but also utilizes excellent dispersing performance and anti-dripping performance effects of the graphene oxide to make a final product have flame-retardant anti-dripping performance. The flame retardance of the prepared flame-retardant anti-dripping polyester fiber is obviously improved, and the prepared flame-retardant anti-dripping polyester fiber can be widely applied to the fields of home textiles, clothes, sports, leisure and the like.

Owner:HUIZHOU DHOMA IND CO LTD

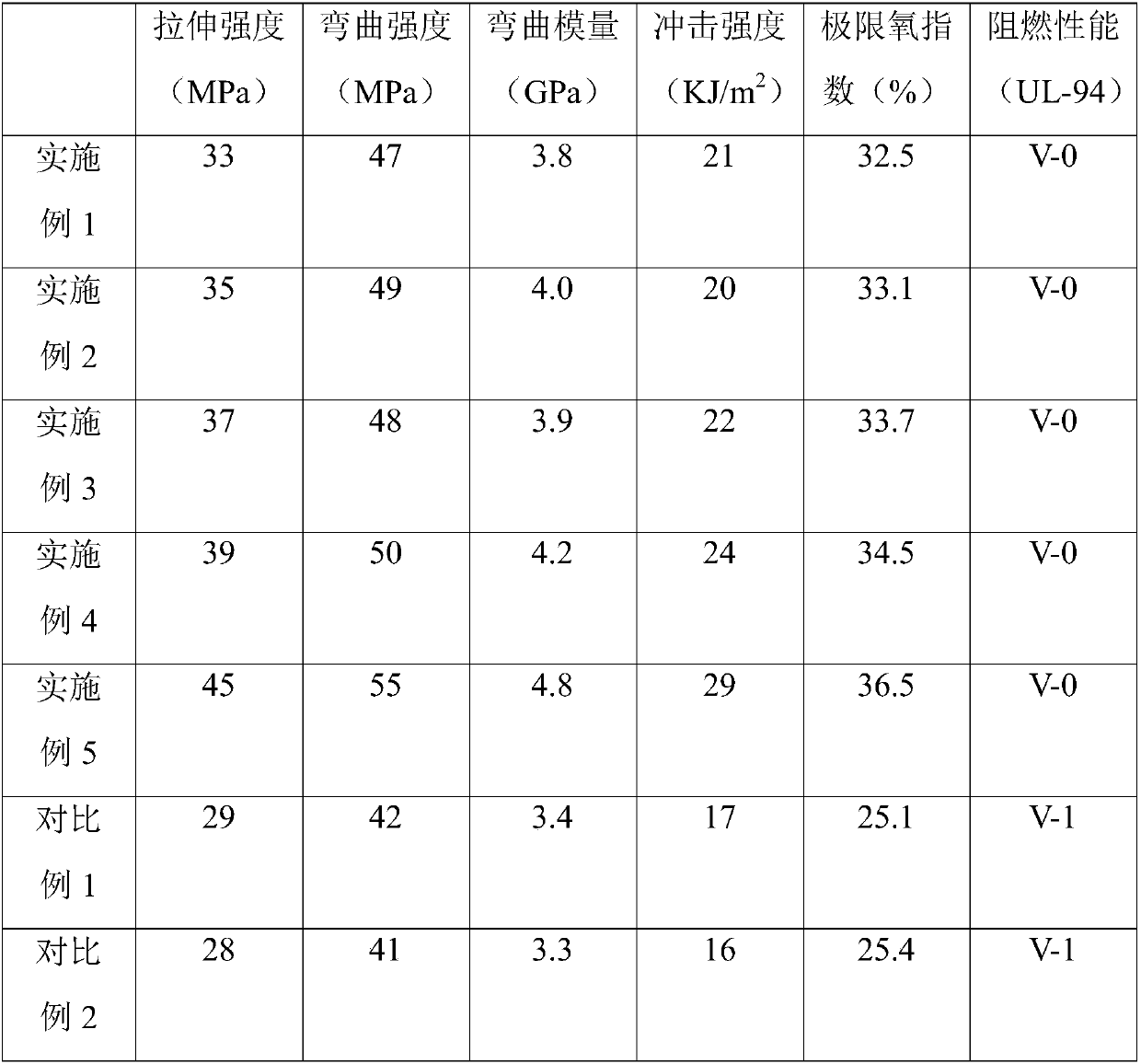

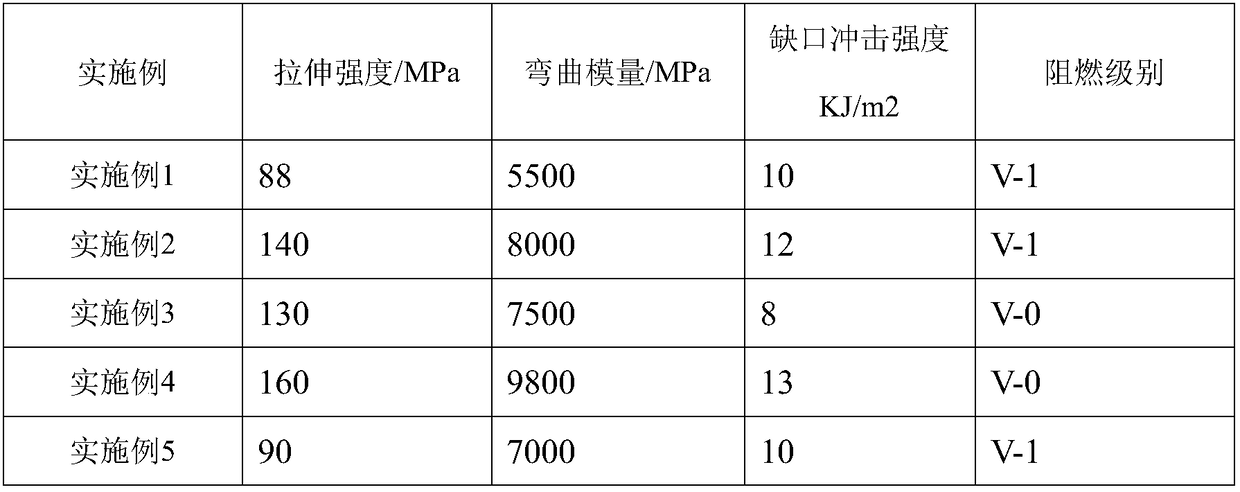

Novel halogen-free flame-retardant composition, halogen-free flame-retardant PBT engineering plastic composite material and preparation method thereof

The invention relates to the field of flame-retardant polymer materials and particularly relates to a novel halogen-free flame-retardant composition, halogen-free flame-retardant PBT engineering plastic composite material and a preparation method thereof. The halogen-free flame retardant FRs is mainly obtained by mixing FR1, FR2, FR3, FR4 and FR5 at a specified ratio and the substances are used in combination so that the halogen-free flame-retardant system has higher heat-resistant stability and good fire-retardant property. The halogen-free flame-retardant PBT engineering plastic composite material is mainly prepared from PBT, alkali-free glass fiber, the halogen-free flame retardant FRs, a CTI synergist, an antioxidant, a lubricant, a coupling agent, a compatibilizer and a toughener; by the cooperation of each component, the prepared halogen-free flame-retardant PBT engineering plastic composite material has excellent comprehensive properties such as flame retardant property, electrical property, heat resistance, mechanical property and coloring property; the preparation method of the composite material is simple and feasible and the prepared composite material has excellent comprehensive properties.

Owner:XIHUA UNIV

Preparation method of PPS fibers with self-extinguishment and free of molten drops

ActiveCN105113209AHigh glass transition temperatureImprove creep resistanceFibre typesFiberTemperature resistance

The invention discloses a preparation method of PPS fibers with self-extinguishment and free of molten drops. The preparation method comprises the following steps: soaking a pure polyphenylene sulfide fiber serving as a raw material into an oxidant solution, controlling the soaking temperature and the soaking time by selecting the type of an oxidant, adjusting the oxidization degree of sulfur atoms on the surface of the fiber, performing solvent separation after an reaction, and washing and drying the PPS fibers. The preparation method is simple and feasible, and a complicated fiber modification method is eliminated; the performances, such as oxidization resistance, high-temperature resistance, creep resistance and molten drop resistance, of the prepared PPS fibers are greatly improved.

Owner:TIANJIN POLYTECHNIC UNIV

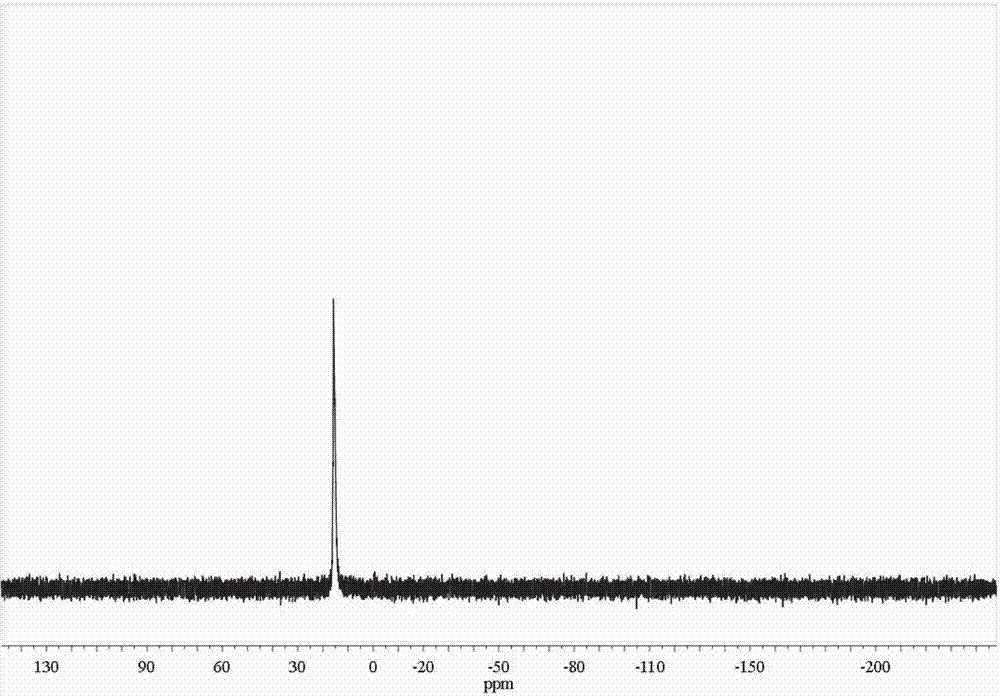

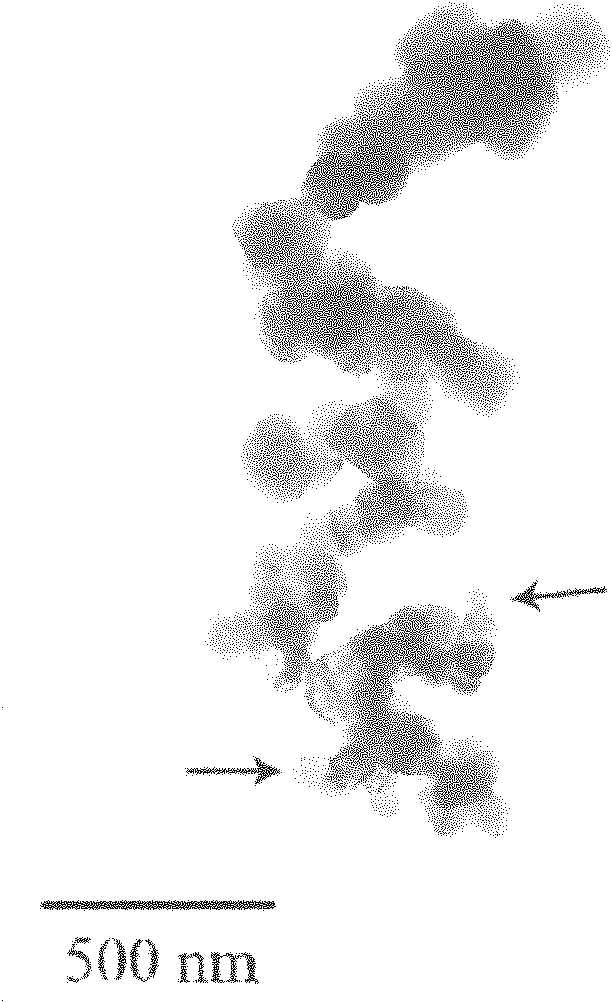

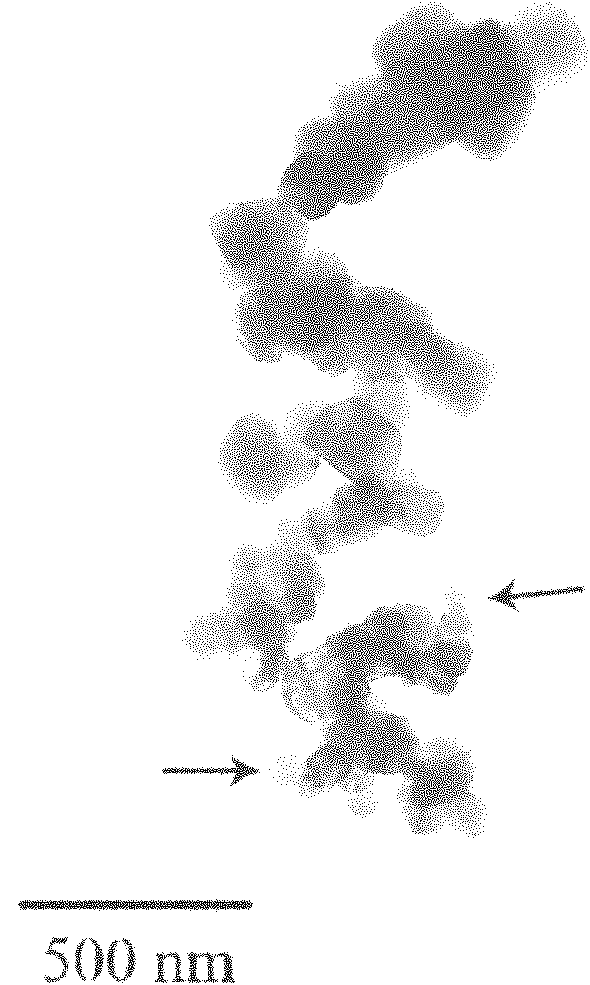

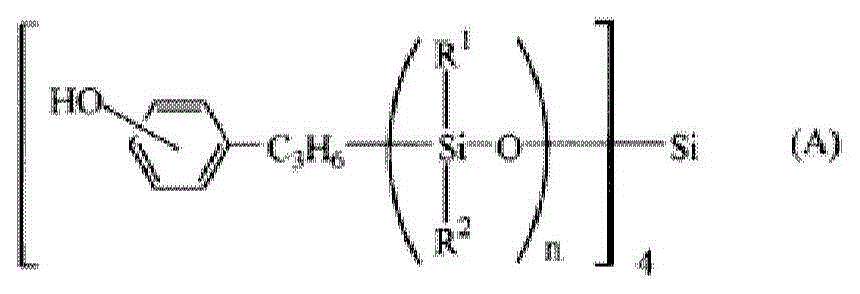

Phosphorus-containing flame-retardant polyester ionomer/nanocomposite material and preparation method thereof

The invention discloses a phosphorus-containing flame-retardant polyester ionomer / nanocomposite material and a preparation method thereof. The phosphorus-containing flame-retardant polyester ionomer / nanocomposite material is prepared by in-situ polymerization of terephthalic acid or dimethyl terephthalate, ethylene glycol, phosphorus-containing ion monomers (i) or phosphorus-containing ion monomers (ii), inorganic nanoparticles or / and organic modified inorganic nanoparticles. The numbers of phosphorus-containing ion group structure units in the composite material account for 2% to 5% of the numbers of structure units of the terephthalic acid or the dimethyl terephthalate in the composite material. The content of the inorganic nanoparticles or / and organic modified inorganic nanoparticles accounts for 0.5 to 10% of the total mass of the composite material. Meanwhile, the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material is excellent in flame retardance, melt drip resistance and crystallization resistance. The intrinsic viscosity of the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material can reach 0.6dL / g to 1.0dL / g. Thus, the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material can be directly taken as a raw material used for preparing fibers, engineering plastics, thin films and the like.

Owner:SICHUAN UNIV

Preparation method of inflame-retardant anti-dripping polyester composite fibers

ActiveCN102277653BImprove flame retardant performanceExcellent resistance to drippingFilament/thread formingConjugated synthetic polymer artificial filamentsHeat stabilityPhosphate glass

The invention relates to a preparation method of inflame-retardant anti-dripping polyester composite fibers. The method provided by the invention comprises the following steps of: (1) mixing aromatic dicarboxylic acid, dihydric alcohol and phosphorus-containing fire retardant and adding catalyst and heat stability; reacting to obtain an inflame-retardant copolyester; (2) pre-mixing SNF2, SnO, NH4H2PO4 or P2O5 for 30-60 min and melting at a temperature in a range of 400-500 DEG C for 60-90 min; cooling and carrying out a heat treatment at a temperature in a range of 70-100 DEG C for 90-120 minto obtain phosphate glass; and (3) blending the inflame-retardant copolyester with the phosphate glass and melting and spinning to obtain the inflame-retardant anti-dripping polyester composite fibers. The method provided by the invention has the advantages of simple process and easiness of being implemented; the prepared copolyester and fibers thereof have good inflame-retardant and anti-dripping performances; the limit oxygen index of the textiles is 29.8-33.2% and no melted drops are formed when the product is combusted so that the method provided by the invention has a good application prospect.

Owner:DONGHUA UNIV

Flame-retardant nano composite material and preparation method thereof

InactiveCN107936370AImprove mechanical propertiesImprove flame retardant performanceCombustionPolypropylene

The invention discloses a flame-retardant nano composite material and a preparation method thereof. The flame-retardant nano composite material comprises the following components in parts by weight: 80-100 parts of polypropylene resin, 1-4 parts of a compounded nano flame retardant, 5-15 parts of nano talcum powder, 0.5-1.5 parts of a flame-retardant synergist, 0.1-0.5 part of anti-dripping agent,1-4 parts of a compatilizer, 0.1-0.5 part of an antioxidant and 0.5-1.5 parts of a reinforcing agent. The composite material prepared by combining specific components has the advantages of good mechanical property, good flame-retardant effect, less smoke generated during combustion, good anti-dripping effect, no harm to human body and no environmental pollution; meanwhile, the preparation processis simple and convenient, the cost is low, and the composite material is suitable for industrial production.

Owner:XIHUA UNIV

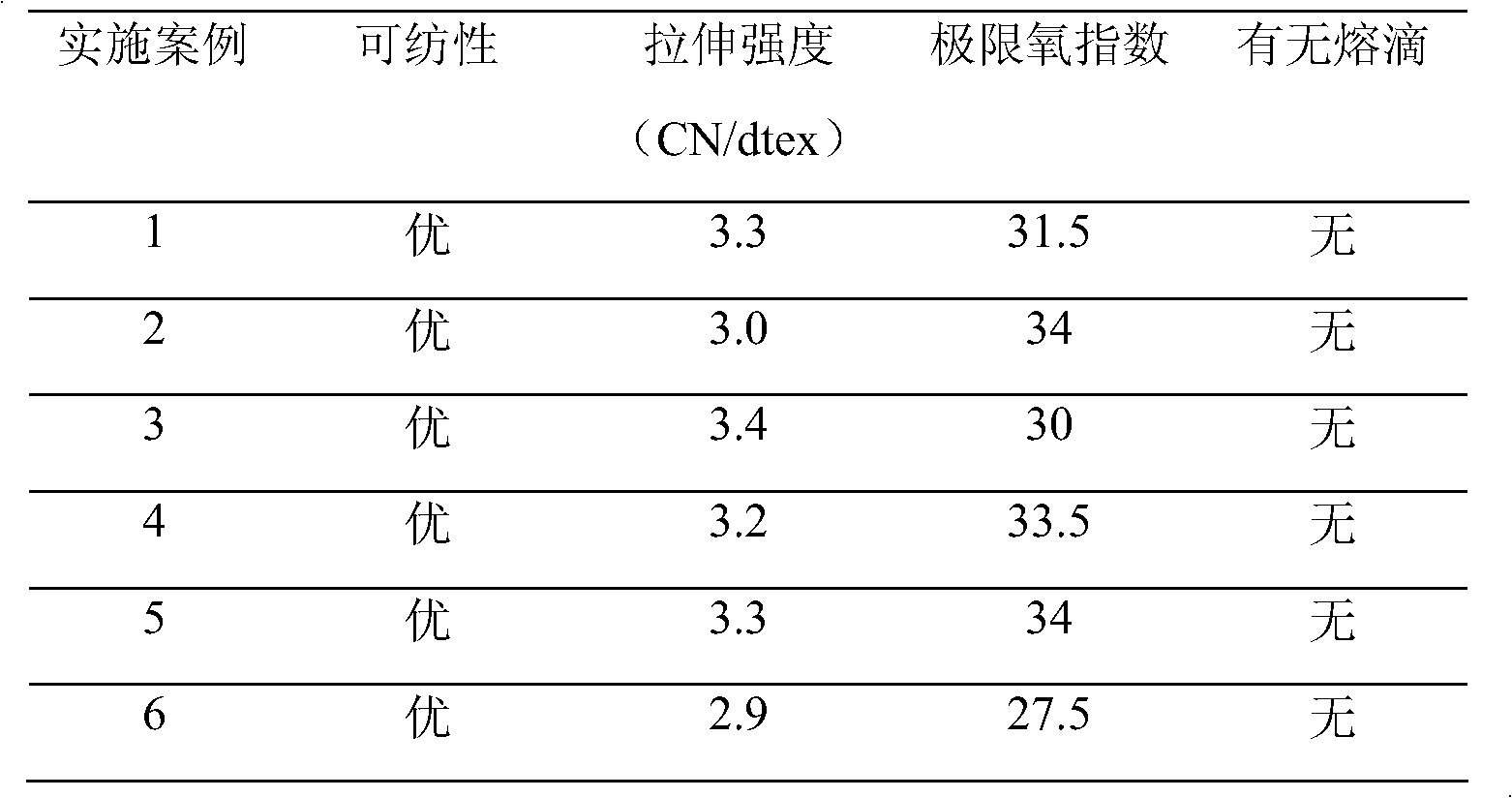

Uses of fluorine-containing sulfonate salt as flame retardant in polyester PET, and flame retardant composition comprising same

PendingCN111138648APlay a synergistic flame retardant effectExcellent resistance to drippingFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterSulfonate

The invention provides applications of fluorine-containing sulfonate as a flame retardant in polyester PET, and a flame-retardant composition containing the fluorine-containing sulfonate. According tothe invention, a compound containing fluorine and sulfur (preferably perfluorosulfonate) and a DOPO flame retardant take a synergistic effect on fire retardation of PET; and the flame-retardant composition comprises a compound containing fluorine and sulfur and a DOPO flame retardant, can be used as a PET flame retardant, and enables flame-retardant PET to have excellent molten drop resistance and excellent flame retardance under the condition of maintaining good spinning capability.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

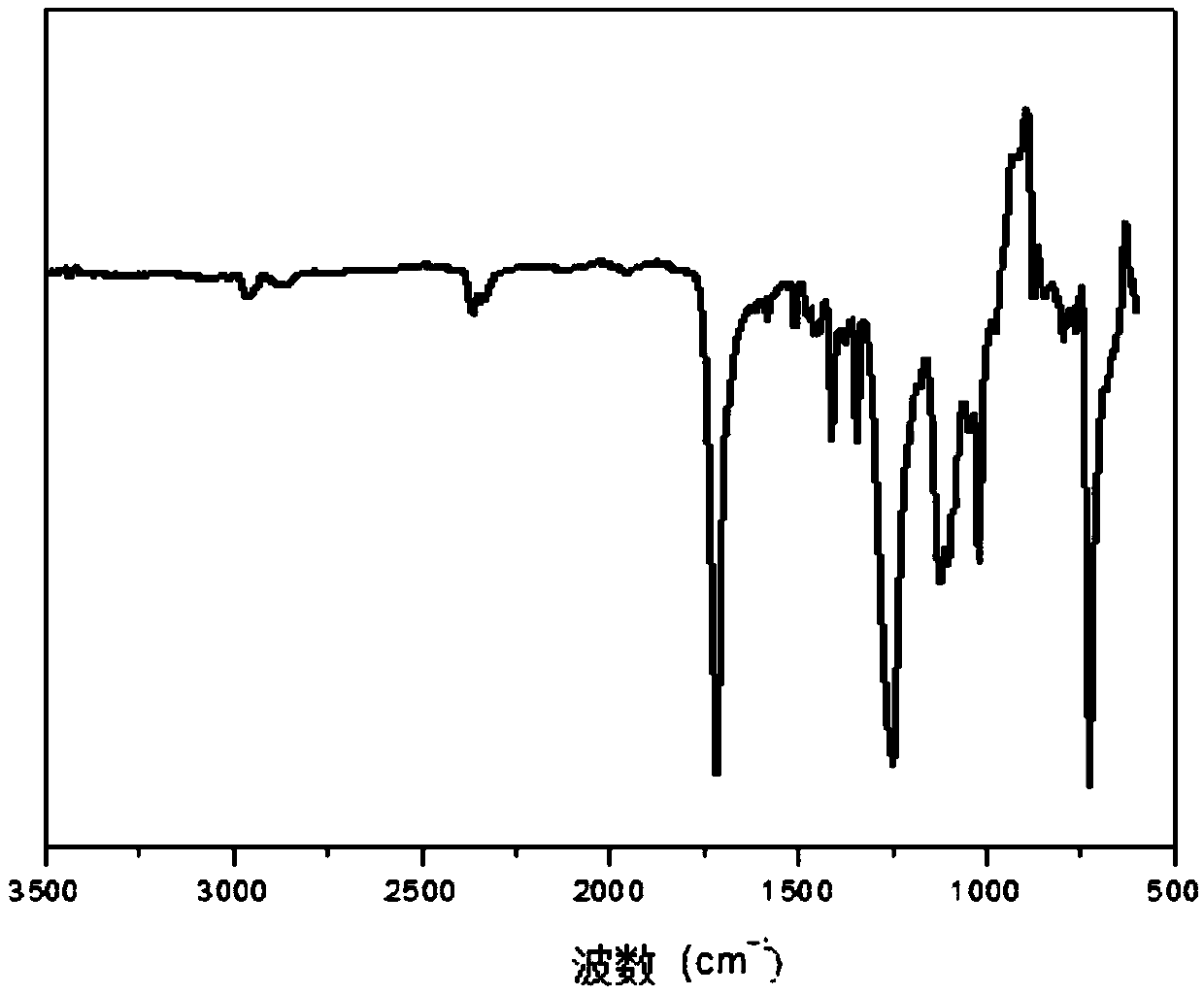

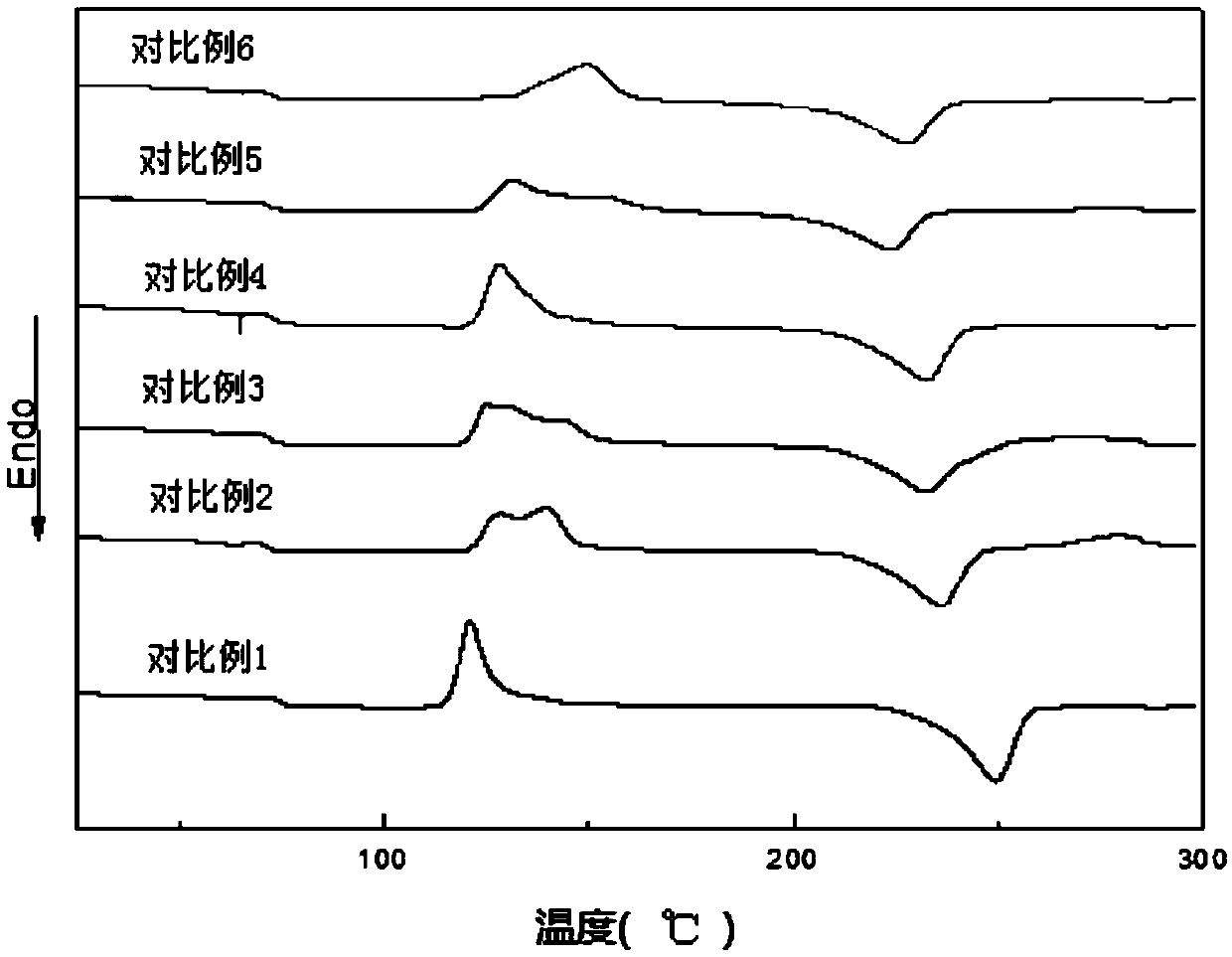

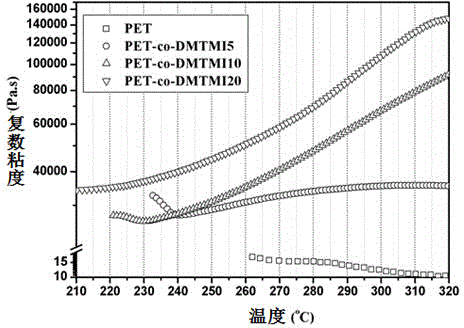

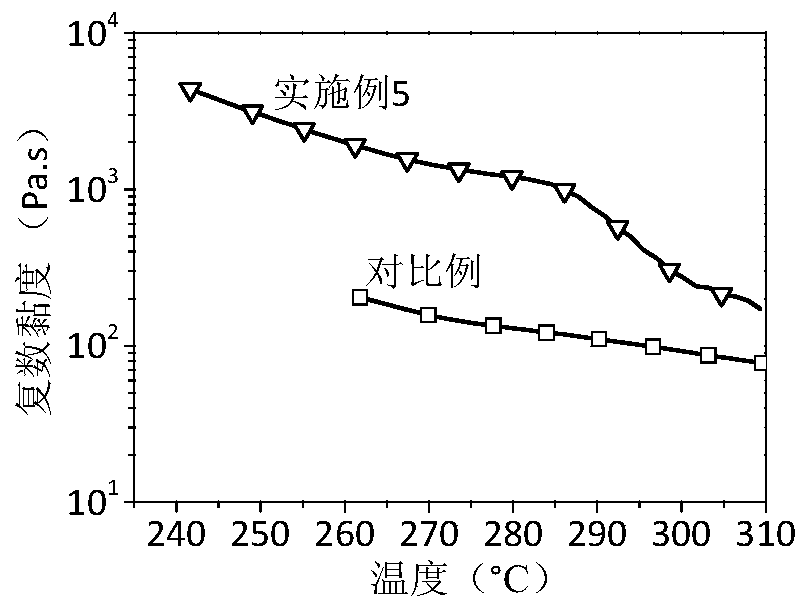

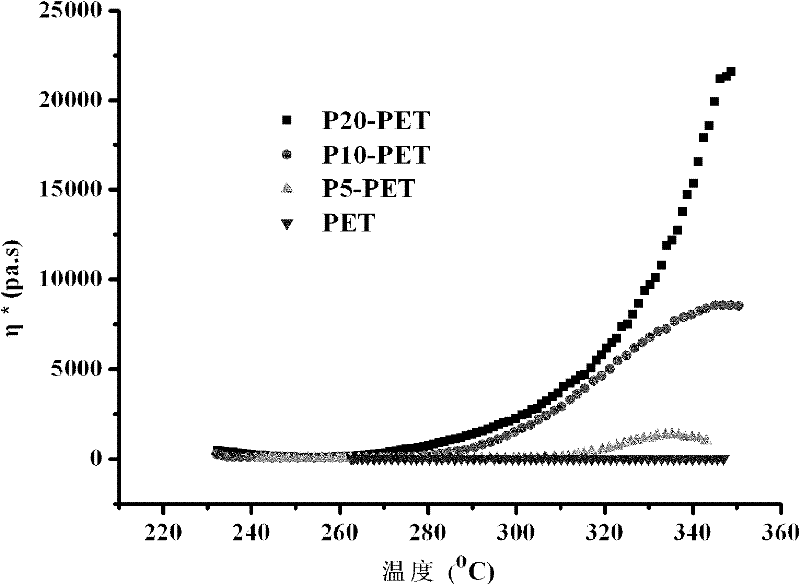

Copolyester crosslinking monomer, copolyester based on monomer and preparation method thereof

The invention discloses a copolyester crosslinking monomer, a copolyester based on the monomer and a preparation method thereof. The copolyester is prepared by carrying out random copolymerization on structural units disclosed as I, II and III. The intrinsic viscosity number [eta] of the copolyester is 0.20-0.94 dL / g. The invention also discloses a preparation method of the copolyester. The introduced crosslinking group is a cyclic olefin structure which has a unique structure and can be subjected to chemical decomposition rearrangement with double bond at high temperature, causing crosslinking, thereby greatly enhancing the complex viscosity of the copolyester in the combustion process; and thus, the carbonization capacity is enhanced, so the copolyester has excellent flame retardancy and molten drop resistance, and the glass transition temperature of the copolyester can be obviously enhanced. The structure is simple to synthesize and low in cost; and the structure is free of the volatilizable halogen, phosphorus and other toxic substance elements in the traditional flame retardant, and thus, belongs to a green flame-retardant copolyester.

Owner:SICHUAN UNIV

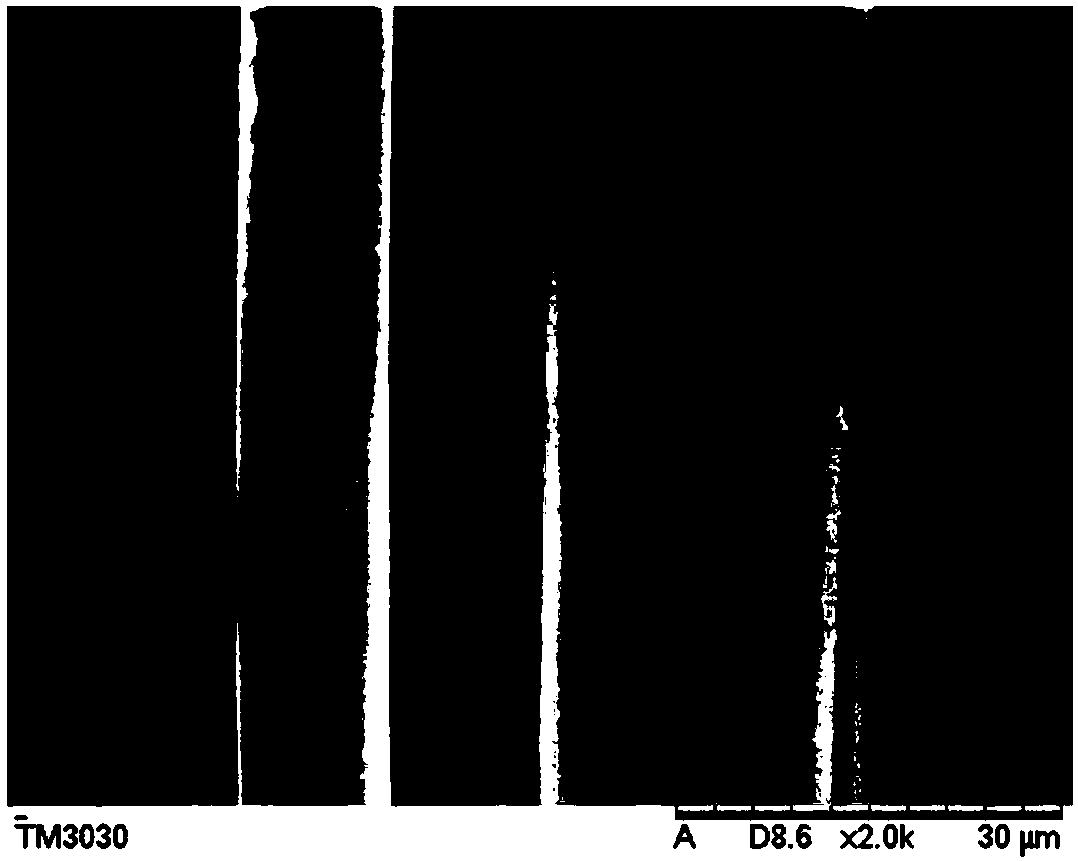

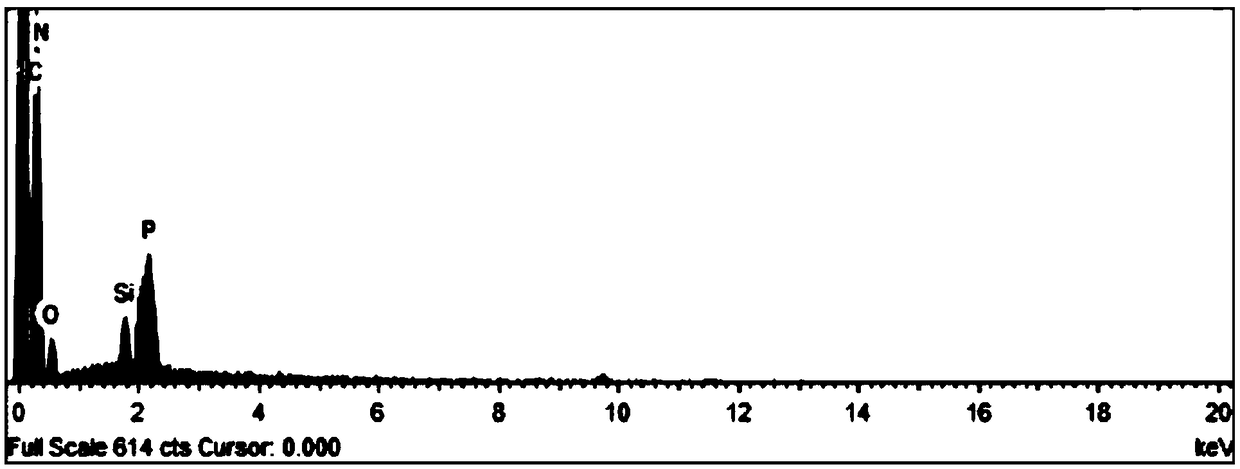

Flame-retardant and anti-ultraviolet nylon fabric and preparation method thereof

ActiveCN108755125AIncreased UPF valueImprove anti-ultraviolet and anti-aging performanceLight resistant fibresHeat resistant fibresPolymer scienceAqueous solution

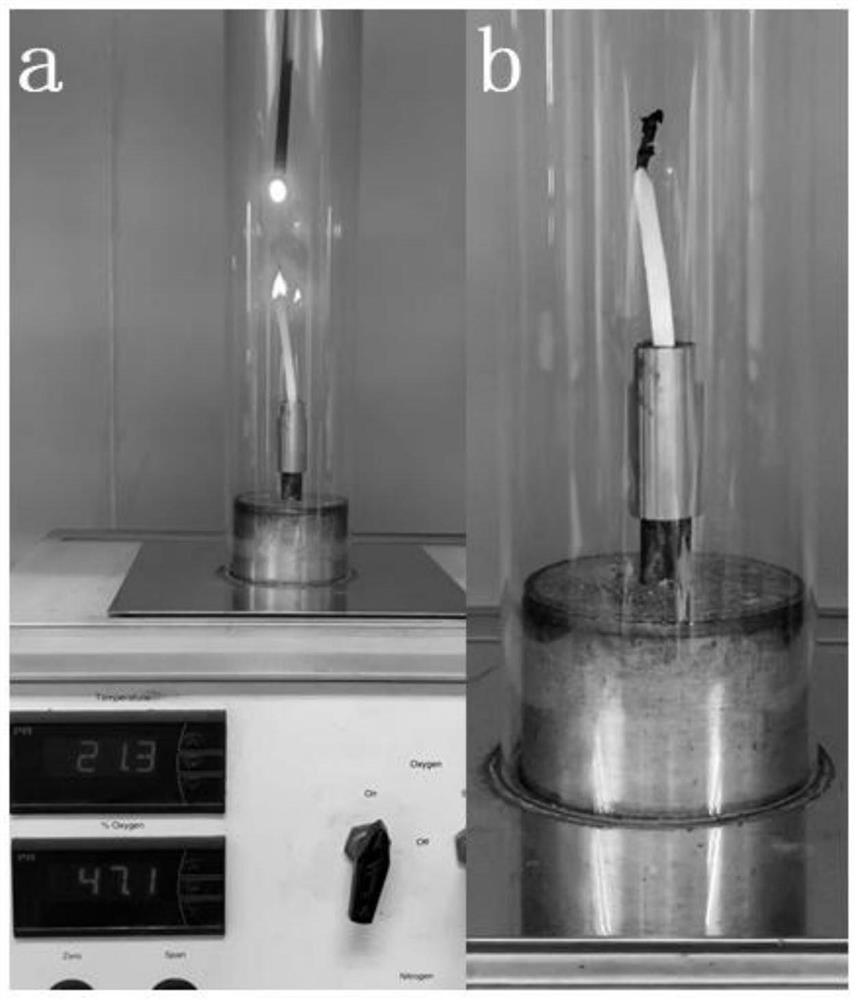

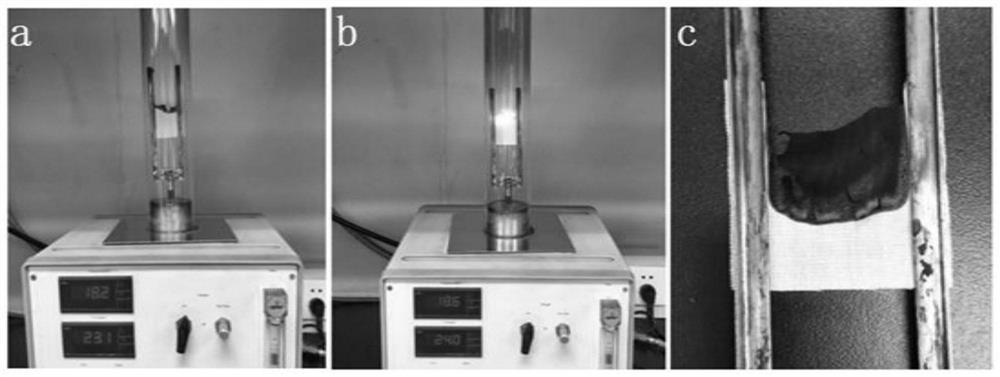

The invention relates to a preparation method of flame-retardant and anti-ultraviolet nylon fabric. The method comprises steps as follows: the nylon fabric with a clean surface is soaked in an aqueousdopamine solution, and dopamine modified nylon fabric is obtained; the dopamine modified nylon fabric is soaked in a silane coupling agent solution containing amino groups or sulfydryl groups and dried, and nylon fabric modified with the silane coupling agent is obtained; finally, the nylon fabric modified with the silane coupling agent is subjected to padding and finishing by a phosphorus-containing flame retardant solution with carboxyl groups. The flame-retardant and anti-ultraviolet nylon fabric prepared with the method is required to be protected, phosphorus content of the fabric is higher than or equal to 2.0wt%, nitrogen content is higher than or equal to 8.6wt%, silicon content is higher than or equal to 2.4wt%, and sulfur content is higher than or equal to 0wt%. The preparation method is simple and easy and has low requirement for equipment, the raw materials are environmentally friendly, the finally prepared fabric has excellent flame-retardant and anti-ultraviolet properties, the appearing time of first molten drop is longer than or equal to 23.1s, and the UPF value is larger than or equal to 200.

Owner:SUZHOU UNIV

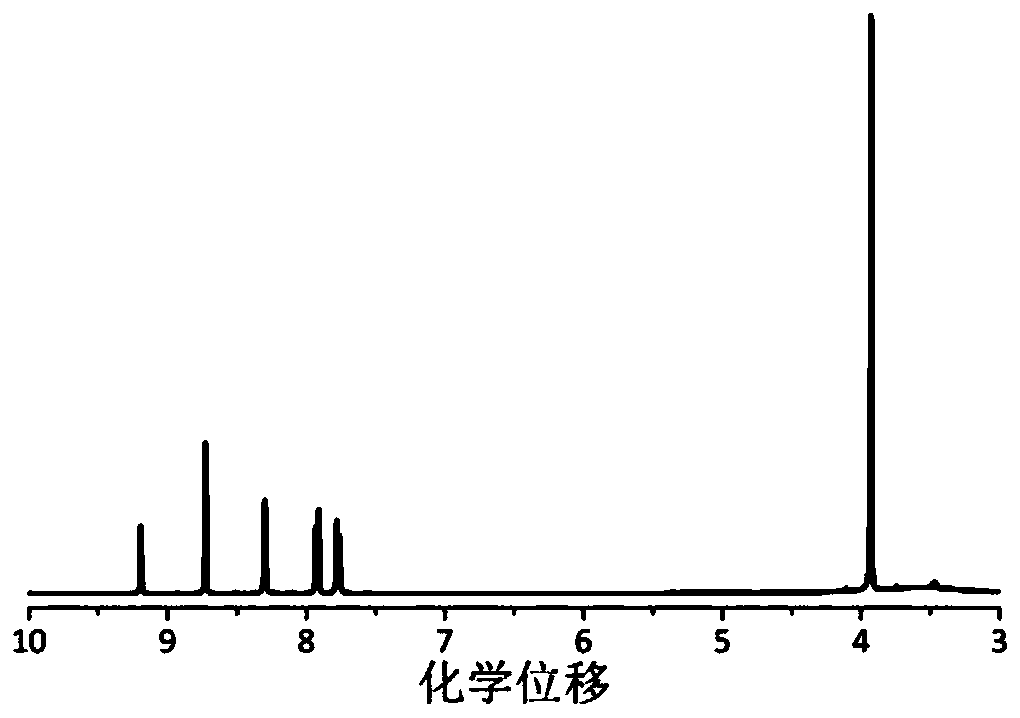

Ionic monomer containing benzo heterocyclic sulfonate structure, ionomer using same for flame resistance and molten resistance, and preparation method and application thereof

ActiveCN110066389AImprove melt strengthInhibition of droplet phenomenonOrganic chemistryFlame-proof filament manufacturePolyesterCarbon layer

The invention discloses an ionic monomer containing a benzo heterocyclic sulfonate structure, an ionomer using the same for flame resistance and molten resistance, and a preparation method and application thereof. The ionomer for flame resistance and molten resistance is prepared by esterifying a copolyester monomer of dibasic acid or ester thereof and C2-C8 polyol, a catalyst and the ionic monomer containing the benzo heterocyclic sulfonate structure with a structural general formula as shown in the specification by a direct esterification method or an ester exchange method through a polycondensation reaction, wherein the ionic monomer containing the benzo heterocyclic sulfonate structure can form an ionic cluster in a molecular chain of the ionomer to form a stable physical crosslinkingnetwork; In addition, the ionomer has good carbon-forming property, when the ionomer is introduced with a low content, not only can the melt strength of the polymer be increased, but also stable and compact carbon layer can be formed to restrain the molten drop phenomenon, so that the ionomer can be used to prepare textile fibers and cationic dyeable polyester textiles, engineering plastics and packaging materials at room temperature. The preparation method is mature, simple and convenient, and industrial production can be easily achieved.

Owner:SICHUAN UNIV

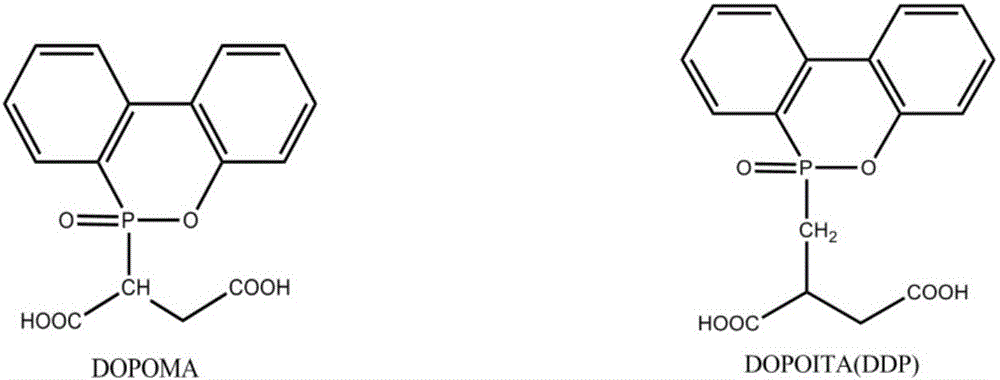

N-P synergetic flame retardant nylon 66 and preparation method thereof

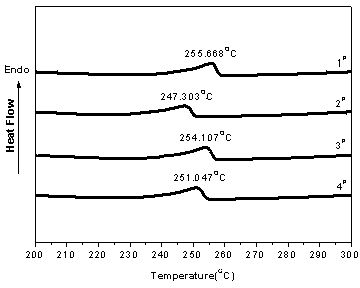

The invention discloses N-P synergetic flame retardant nylon 66 and a preparation method thereof. The N-P synergetic flame retardant nylon 66 is characterized in that a derivative of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide react with diamine to prepare a flame retardant A containing P; a binary acid melamine salt and a cyanuric acid diamine salt which are equal in molar mass are mixed to prepare a flame retardant B containing N; the flame retardant A and the flame retardant B react with a nylon 66 salt to prepare the N-P synergetic flame retardant nylon 66, wherein the flame retardant A and the nylon 66 are subjected to copolymerization, and the flame retardant B and the nylon 66 are subjected to in-situ polymerization. The N-P synergetic flame retardant nylon 66 has a melting point range of 255-265 DEG C, a relative viscosity range of 2.0-3.0, a flame retardant rating of V0, tensile strength of 70.0-82.0 MPa, notch impact strength of 3.5-5.0 KJ / m<2>, bending strength of 100-120 MPa and smoke density of 10-15%. The N-P synergetic flame retardant nylon 66 can be used for spinning and manufacture of engineering plastics.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

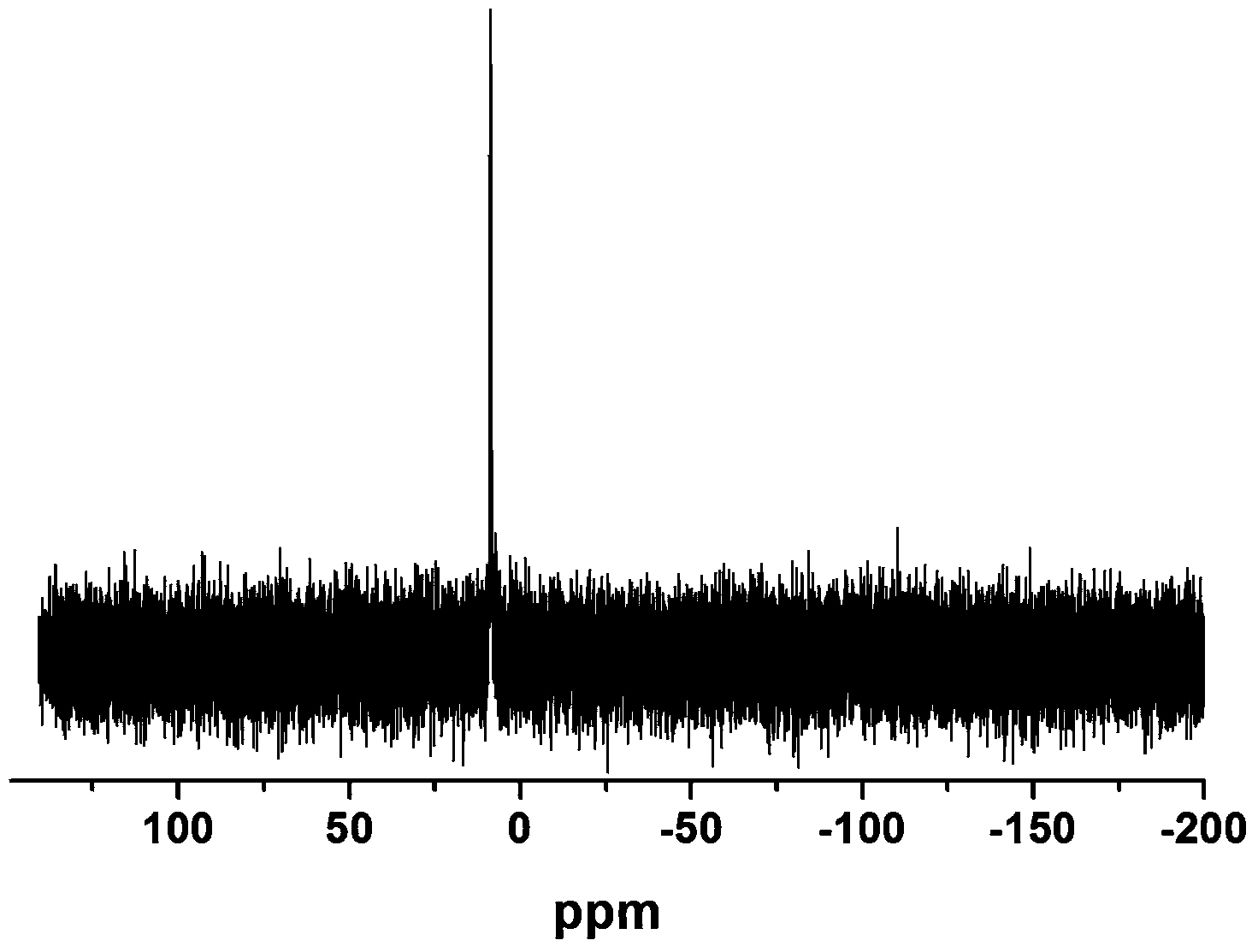

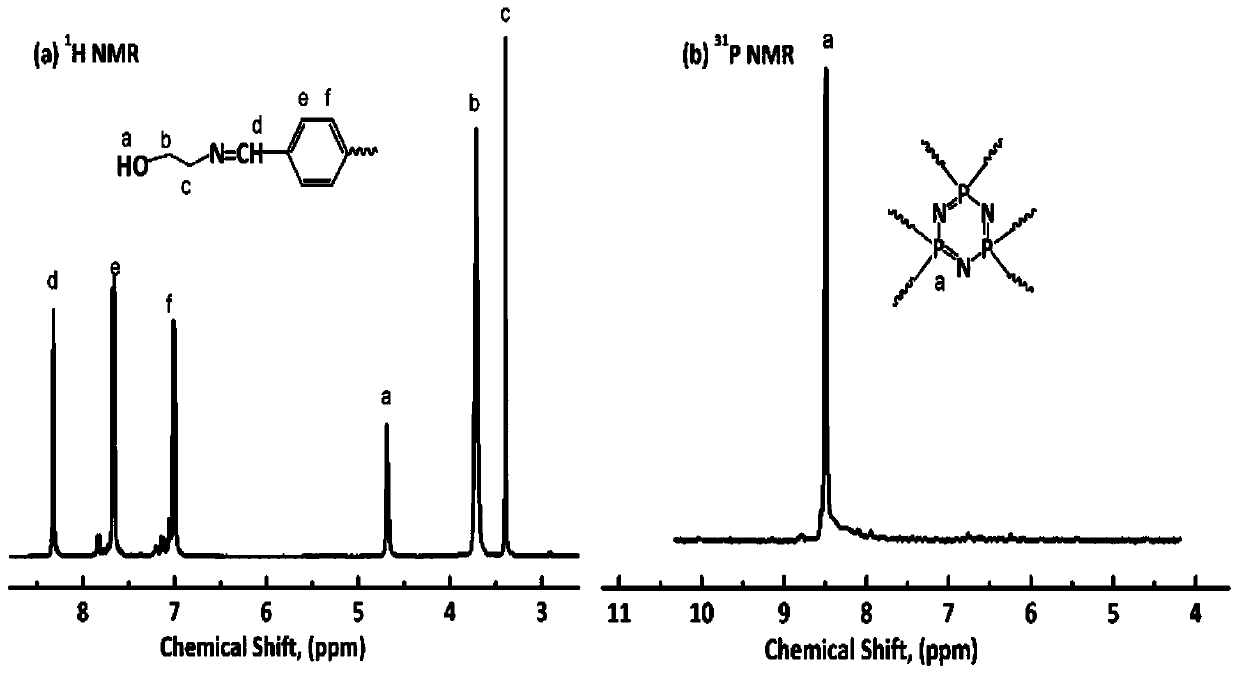

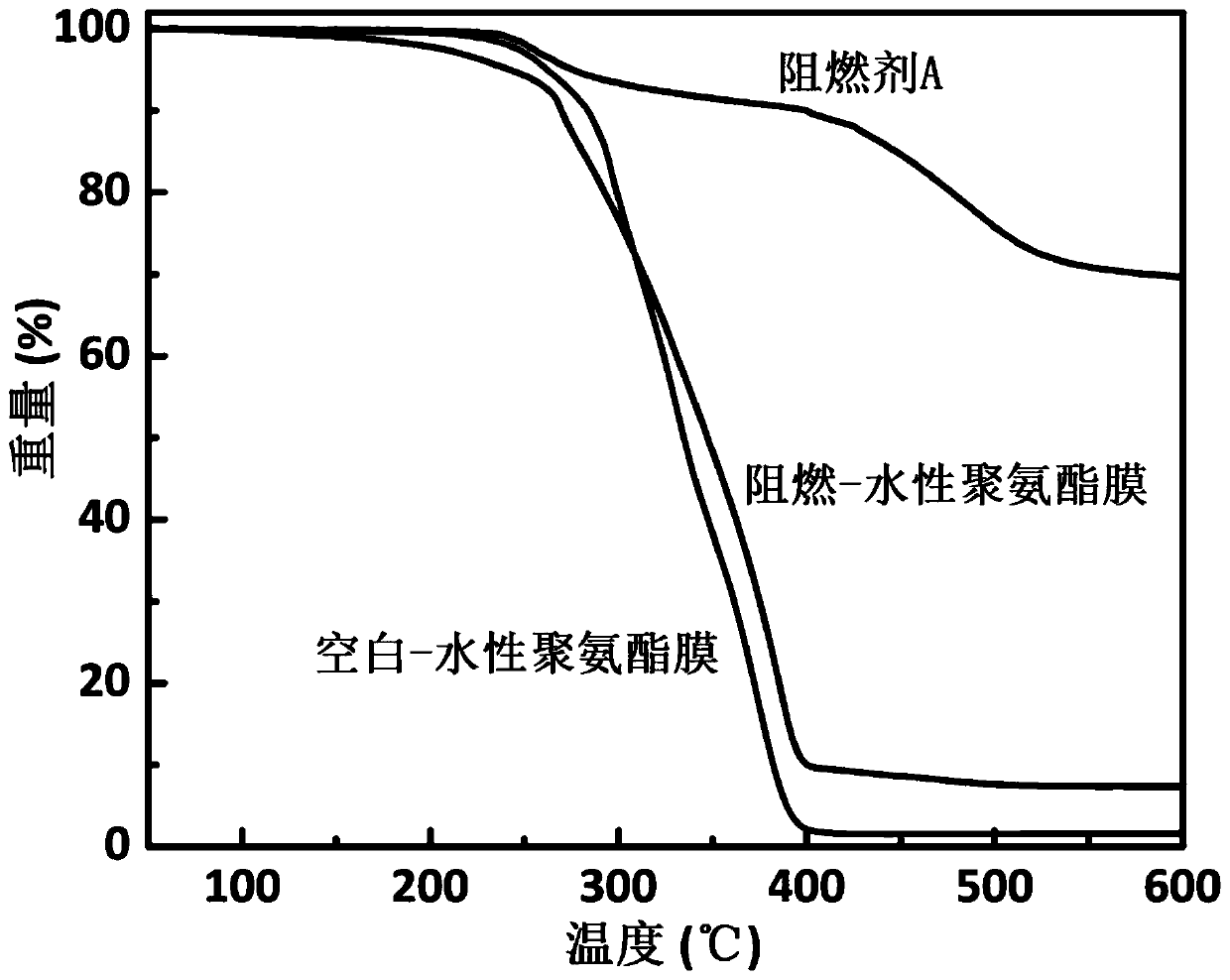

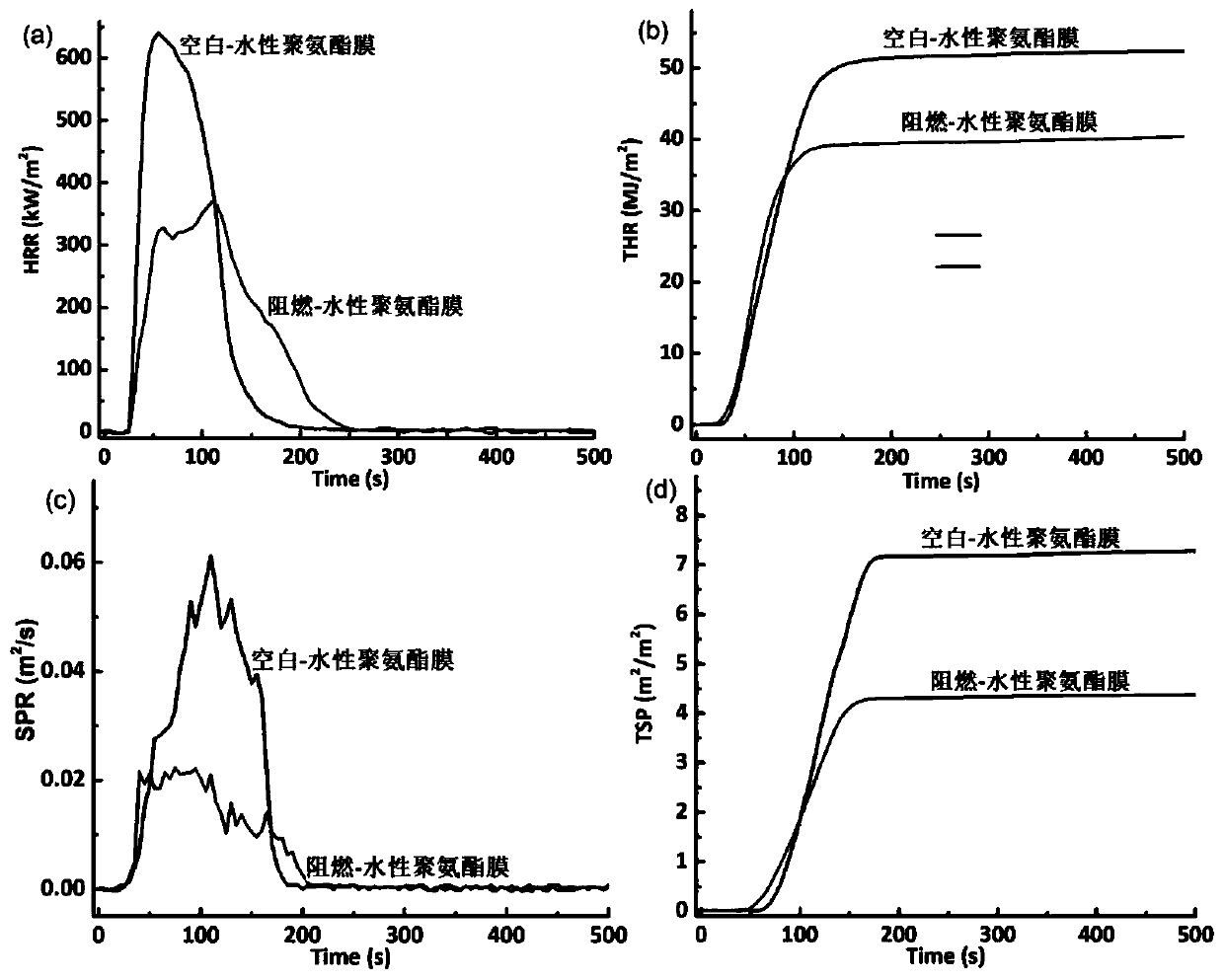

Synthesis methods of Schiff base phosphazene double-base structure flame retardant and modified polyurethane flame retardant

ActiveCN110563765AImprove flame retardant performanceImprove anti-dripping performanceGroup 5/15 element organic compoundsSynthesis methodsResidual carbon

The invention discloses a synthesis method of a Schiff base phosphazene double-base structure flame retardant. The synthesis method comprises the following steps: S1, reacting phosphonitrilic chloridetrimer with a compound containing hydroxyl and active carbonyl, a strong alkali and weak acid salt and a solvent to prepare a phosphazene-containing intermediate; S2, reacting the phosphazene-containing intermediate prepared in the step S1 with an alcohol amine compound and a solvent to prepare the Schiff base phosphazene double-base structure flame retardant. A synthesis method of a modified polyurethane flame retardant comprises the step of applying the prepared Schiff base phosphazene double-base structure flame retardant to waterborne polyurethane to prepare a waterborne polyurethane flame retardant containing the hydroxyl-terminated Schiff base phosphazene double-base structure. The Schiff base phosphazene double-base structure flame retardant can effectively improve the flame retardancy and molten drop resistance of a base material; a Schiff base structure contained in the structure of the modified polyurethane flame retardant has certain stability, crosslinking of melt and formation of residual carbon can be promoted, the molten drop resistance of a prepared flame-retardant material is improved, two elements including nitrogen and phosphorus in a phosphazene ring can achieve synergistic flame retardance, and a good flame-retardant effect is achieved.

Owner:青岛玉城科技有限公司

Halogen-free and flame-retardant glass fiber reinforced nylon composite and preparation method thereof

The invention discloses a halogen-free and flame-retardant glass fiber reinforced nylon composite and a preparation method thereof, and belongs to the field of production of halogen-free and flame-retardant reinforced nylon and polyphenylene sulfide composites. The halogen-free and flame-retardant glass fiber reinforced nylon composite is prepared from 25-50 parts of nylon, 5-15 parts of polyphenylene sulfide, 10-30 parts of glass fiber, 15-25 parts of a halogen-free and flame-retardant mixture, 1-5 parts of a compatilizer, 0.1-0.3 parts of an antioxidant and 0.1-0.5 parts of a lubricant by mixing and extruding. The halogen-free and flame-retardant mixture is prepared from flame-retardant red phosphorus masterbatch, melamine cyanurate and organic nano-montmorillonite in a mass ratio being5:1:1-5:3:3 by compounding. By compounding polyphenylene sulfide and nylon, hardness, wear resistance and creep resistance of the material are improved; meanwhile, flame retardance of the composite isimproved by the halogen-free and flame-retardant mixture, oxygen index reaches 28 or higher, and finally, the halogen-free and flame-retardant glass fiber reinforced nylon composite product with excellent combination property is obtained.

Owner:HEFEI GENIUS NEW MATERIALS

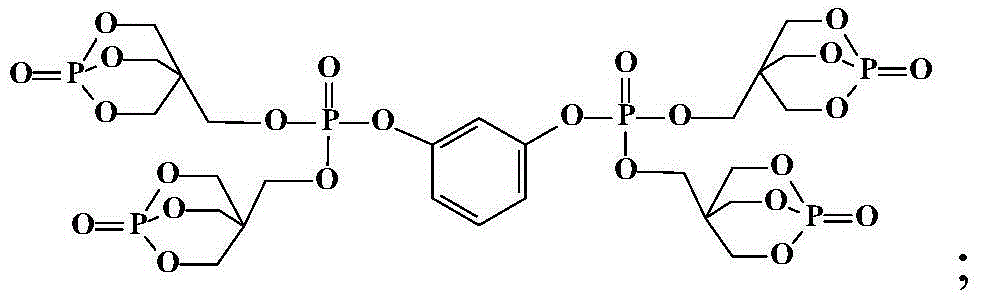

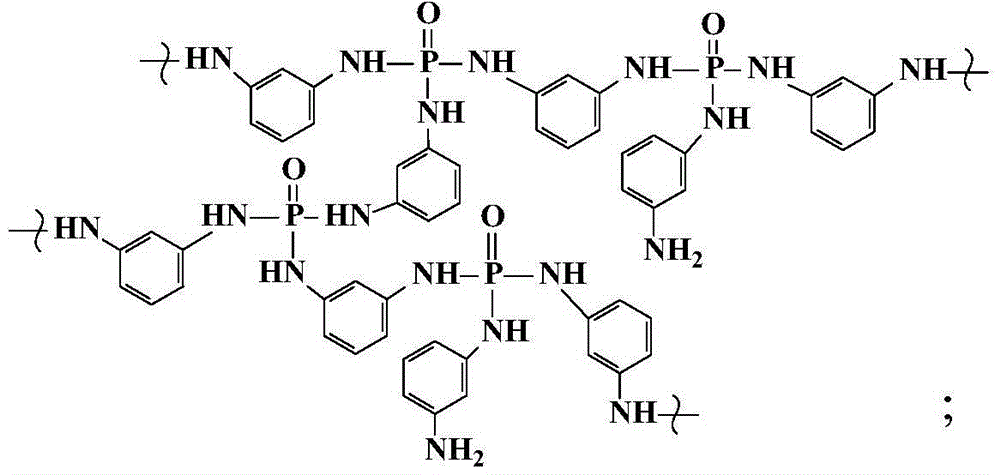

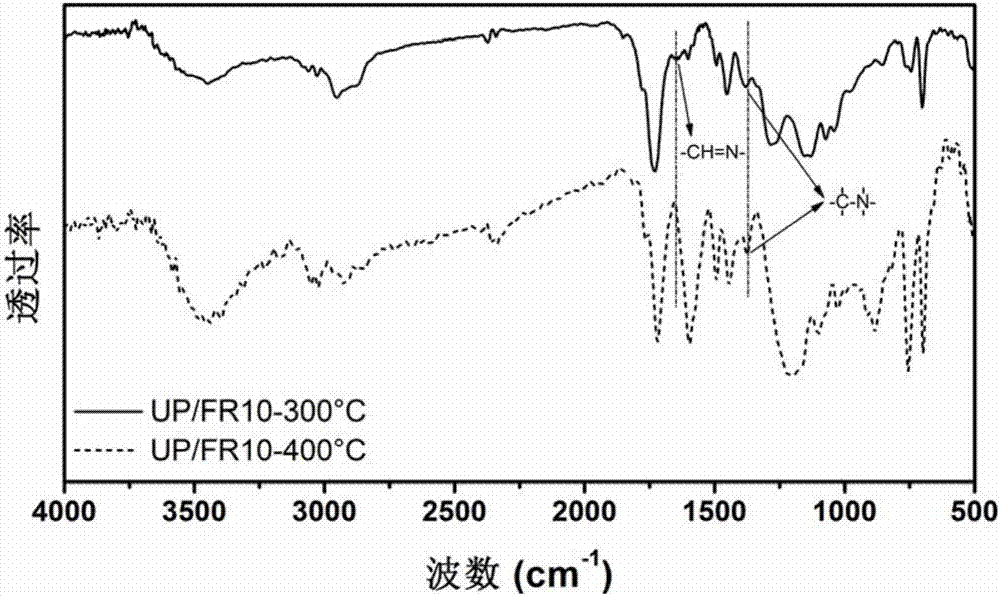

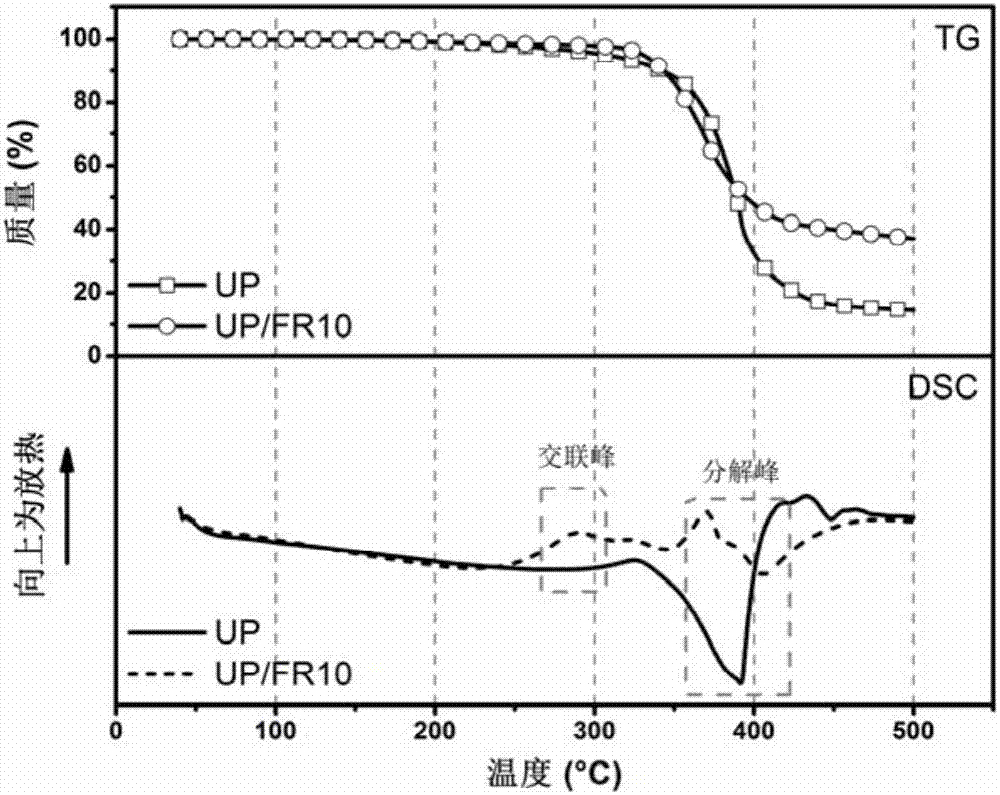

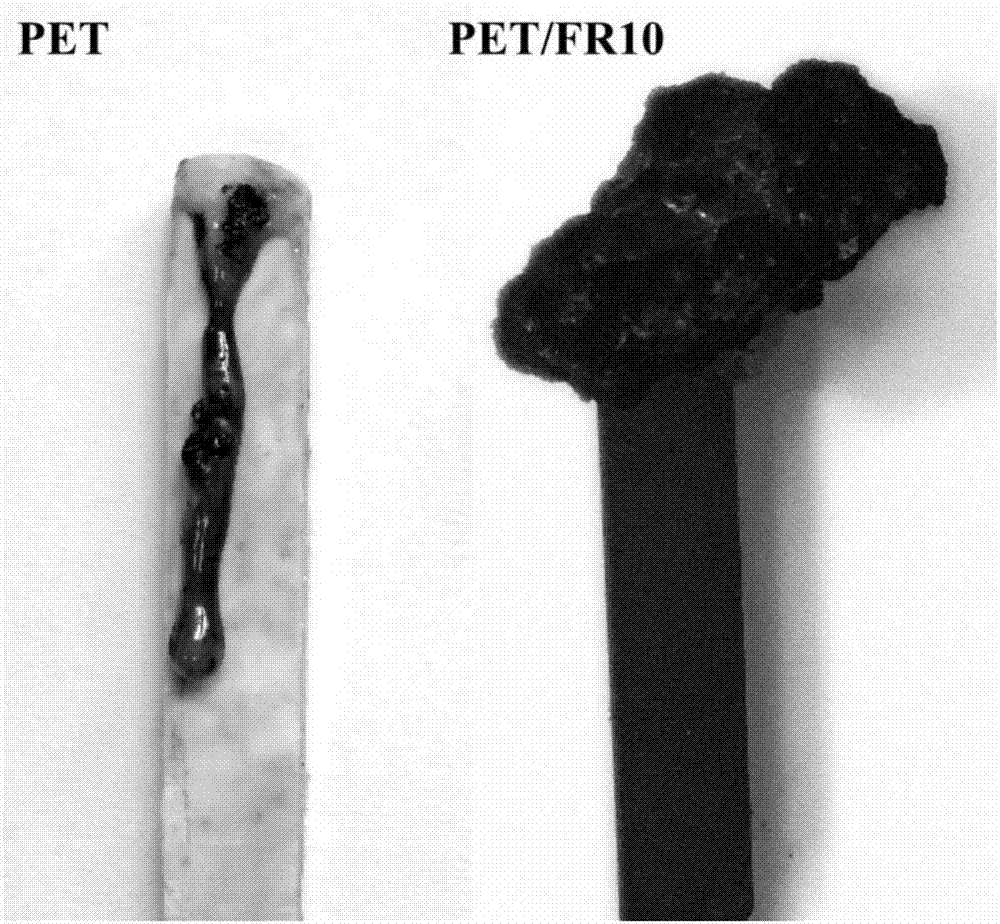

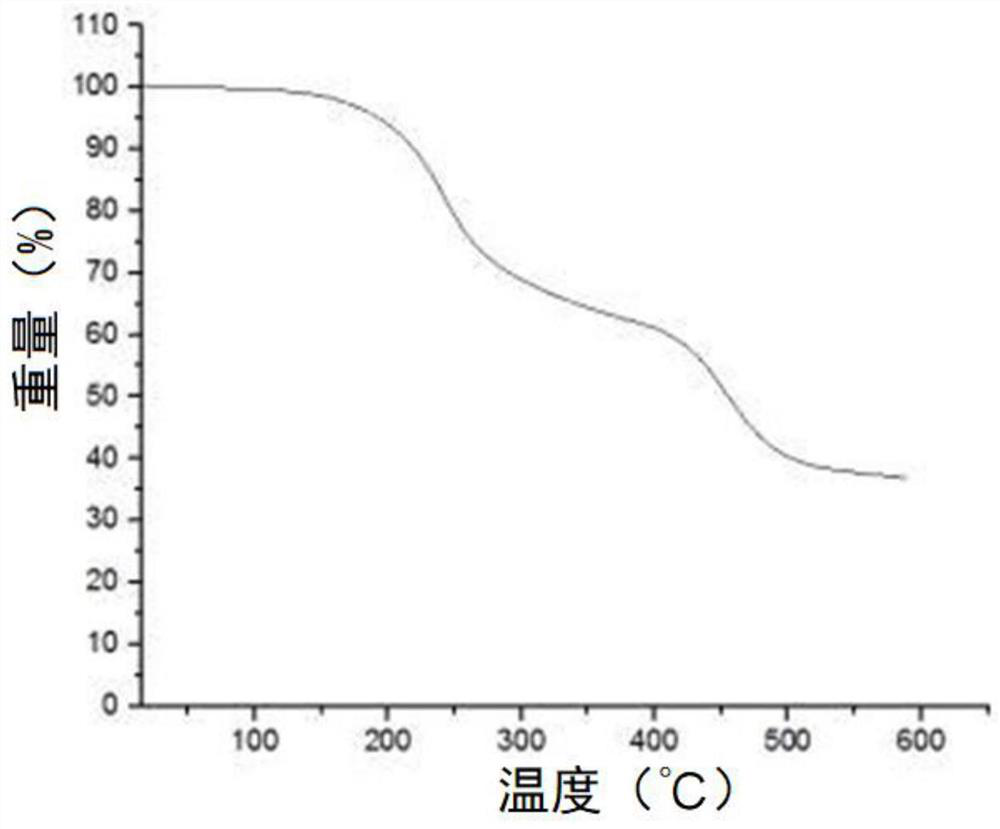

High temperature crosslinked flame retardant with Schiff base and phosphoryl (phosphonyl) structure, preparation method and application thereof

The invention discloses a high temperature crosslinked anti-dripping flame retardant with Schiff base and phosphoryl (phosphonyl) structure. The flame retardant has the following repeating structure unit shown as the specification. The flame retardant is obtained by subjecting a monomer I with a Schiff base structure and a monomer II with a phosphoryl (phosphonyl) structure to melting reaction or solution reaction under nitrogen protection. The flame retardant disclosed by the invention simultaneously introduces the Schiff base high temperature chemical crosslinking structure and the phosphoryl (phosphonyl) high efficiency flame retardant group, not only can produce a synergistic flame retardant effect of phosphorus and nitrogen, endows the polymer with excellent flame retardant and anti-dripping effects, but also can significantly reduce the heat release rate and total heat release of the material, and can be used for flame retardation of unsaturated polyester resin, epoxy resin, polyester, polyolefin and other materials. The preparation method provided by the invention is simple and easy for control, and is suitable for industrial production.

Owner:SICHUAN UNIV

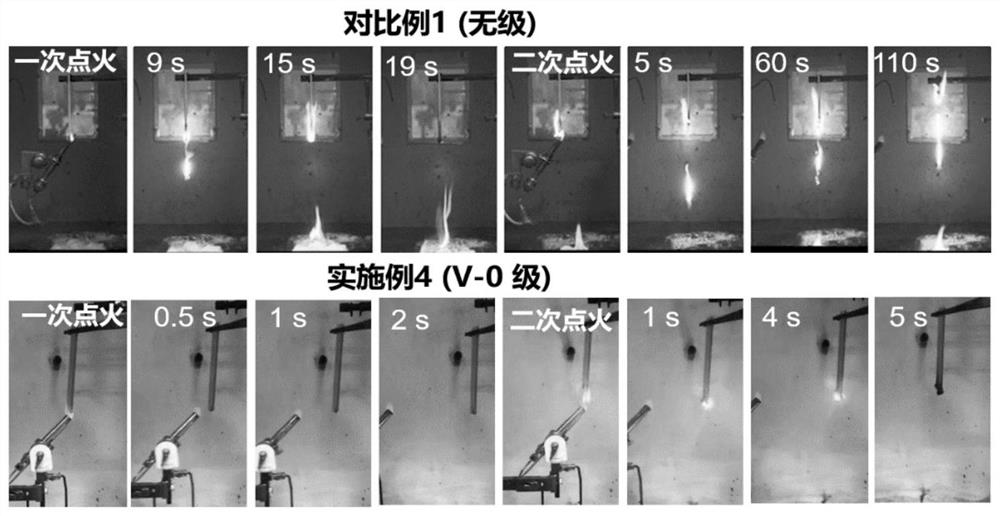

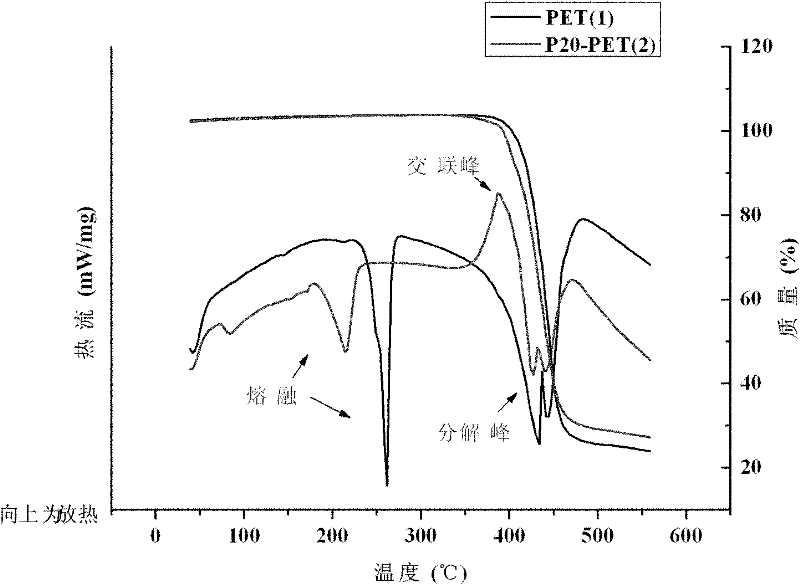

Flame-retardant anti-dripping copolyester based on high-temperature self-crosslinking as well as preparation method and application of flame-retardant anti-dripping copolyester

ActiveCN113817152AInhibitionImprove flame retardant performanceFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolymer scienceCombustion

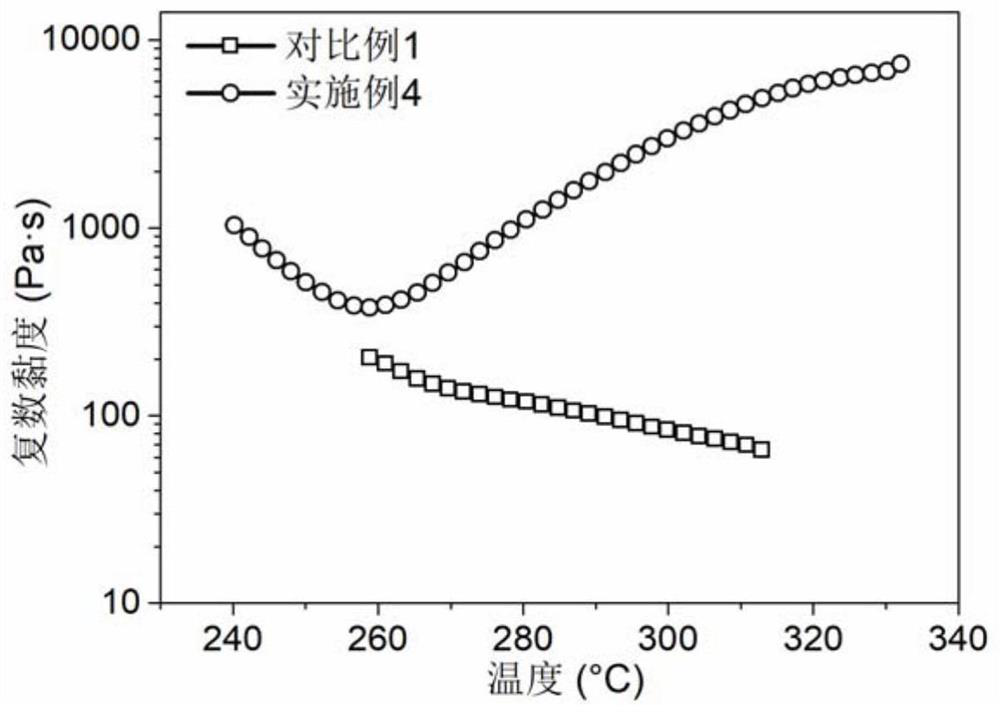

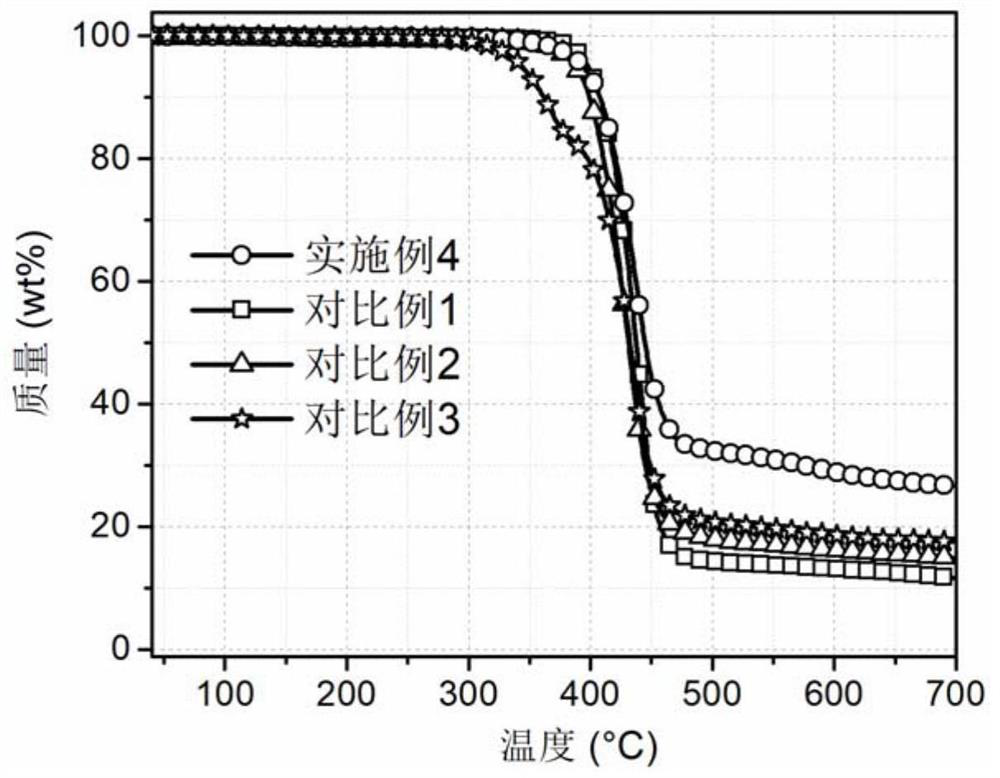

The flame-retardant anti-dripping copolyester based on high-temperature self-crosslinking disclosed by the invention is composed of structural units represented by I, II, III and IV, the intrinsic viscosity [eta] of the copolyester is 0.20-3.50 dL / g, the limit oxygen index is 23.0-60.0%, and the vertical burning grade is V-2 to V-0 grade. The invention also discloses a preparation method and application of the flame-retardant anti-dripping copolyester. Due to the introduced high-temperature self-crosslinking group and ionic group, the melt viscosity and the melt strength of the copolyester during combustion are improved, and meanwhile, the charring capacity of the copolyester is effectively enhanced, so that the copolyester disclosed by the invention shows excellent flame retardance and molten drop resistance. The preparation process of the copolyester is mature, simple and convenient to operate, easy to control and suitable for industrial production.

Owner:SICHUAN UNIV

Application of polymer as anti-dripping flame retardant

The invention relates to an application of a polymer as an anti-dripping flame retardant. The polymer comprises esterification products of polyvinyl alcohol and a phosphorus-based flame retardant containing a phosphate group. The preparation method of the polymer comprises the following steps: carrying out esterification reaction on polyvinyl alcohol and a phosphorus-based flame retardant containing a phosphate group in water at 55-65 DEG C under the action of a catalyst, thereby preparingthe polymer after the reaction is completed. According to the molten-drop-resistant flame retardant disclosed by the invention, the polymer of the polyvinyl alcohol and the phosphorus-based flame retardant containing the phosphate group is utilized, the polymer has the characteristics of flame retardanceand molten drop resistance, and the surface of a fabric can be more stably coated with the polymer through a cross-linking structure between the polymer and the fabric, so that the internal fabric iseffectively protected while combustion is carried out, and the safety is improved.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

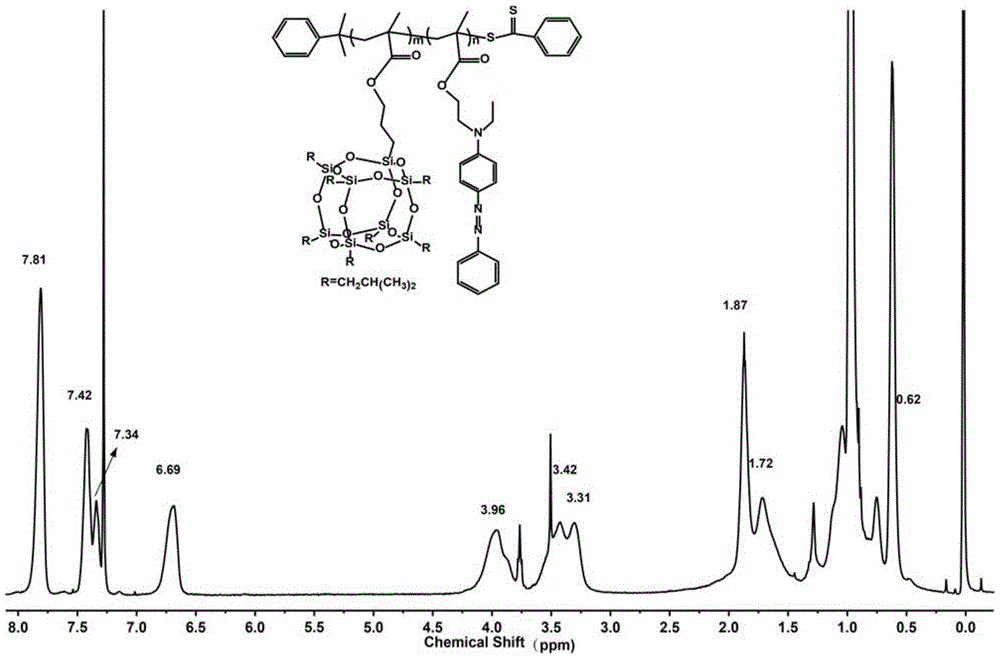

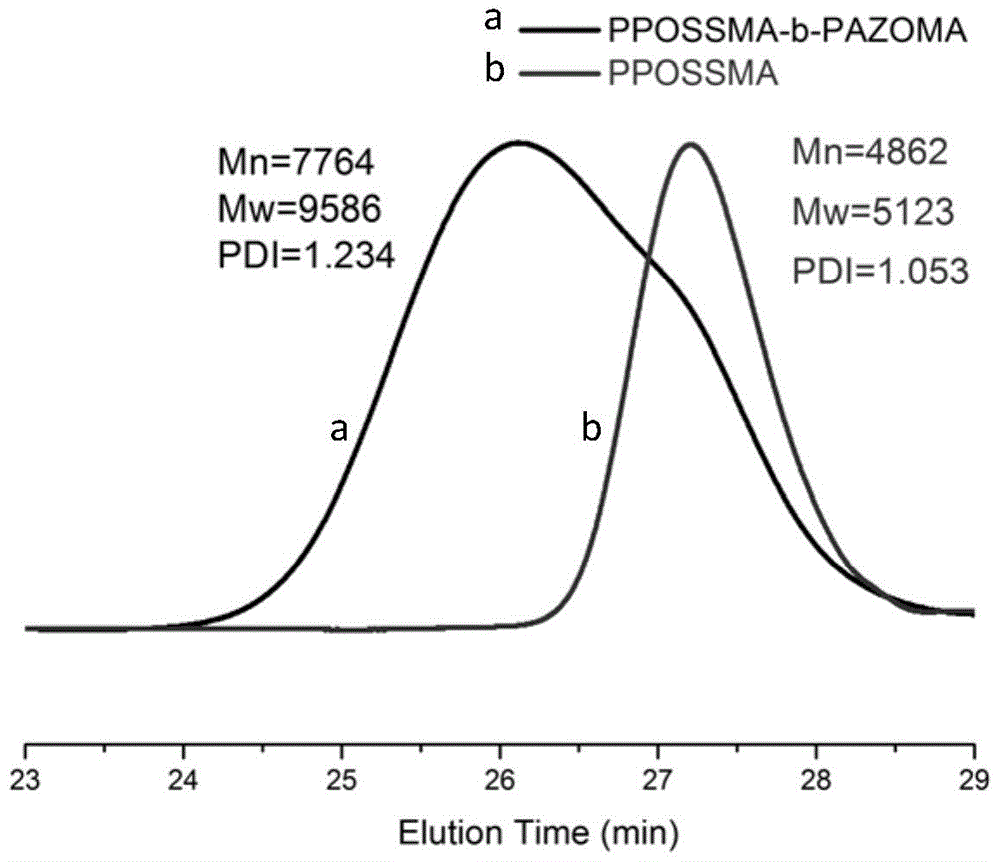

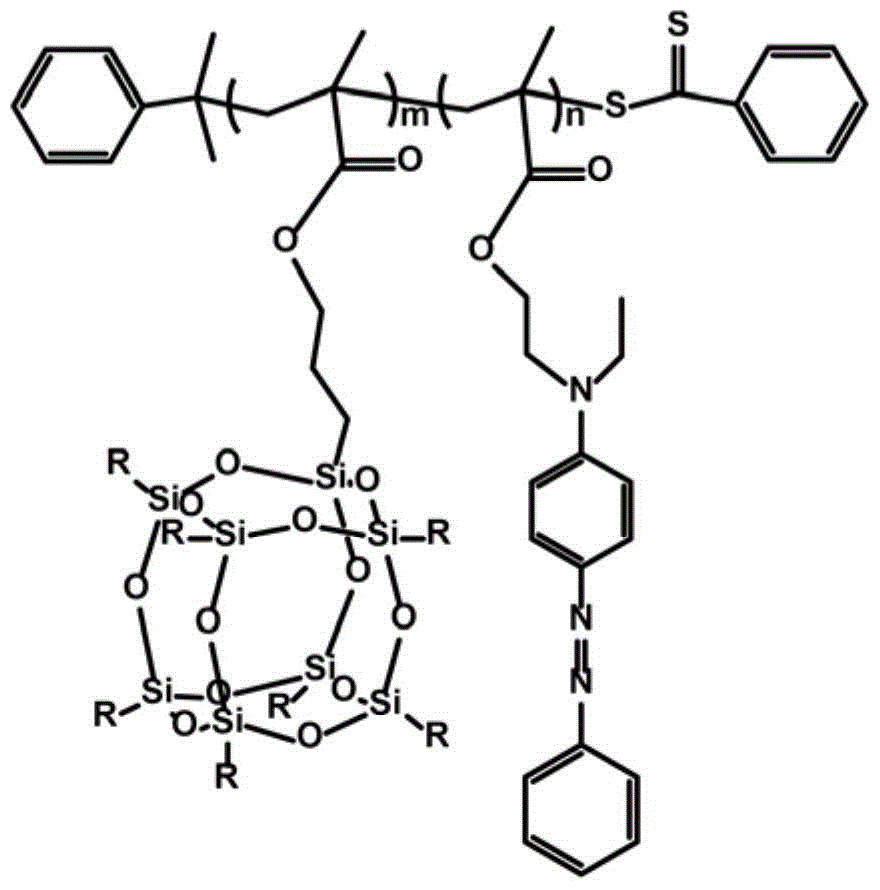

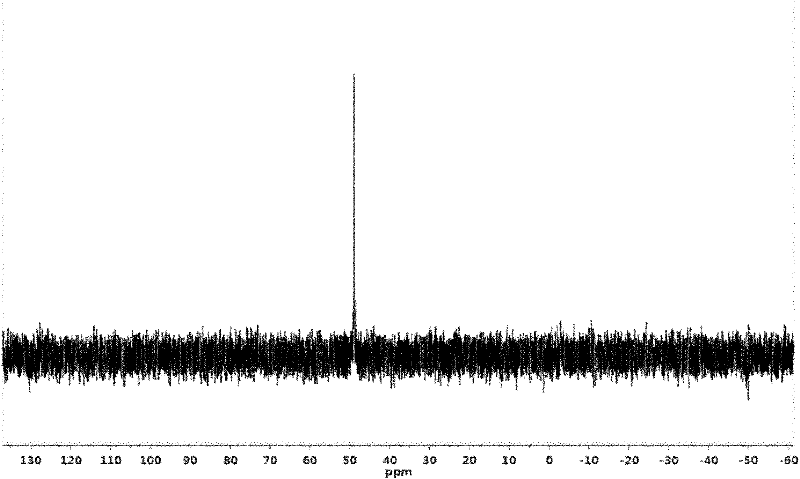

Silicon nitrogen containing flame retardant type polymer dye and preparation method thereof

Relating to a block copolymer dye, the invention provides a silicon nitrogen containing flame retardant type polymer dye and a preparation method thereof. Polymethacryloxypropyl polyhedron oligomeric silsesquioxane is adopted as a first block, and polymethacrylate azobenzene is taken as a second blocker to prepare a halogen-free flame retardant block copolymer dye by means of reversible addition-fragmentation chain transfer. The self-assembly effect of a POSS group in the dye molecule can significantly improve the dye molecule fastness and reduce dye molecule migration, and through introduction of an azo group (-N=N-) and the POSS group, the material can be endowed with good flame-retardant and anti-dripping performance. By adjusting the feeding proportion of the two monomers, the content of silicon and nitrogen flame retardant elements in the polymer dye molecules can be controlled, and the method has the advantages of simple synthesis process, mild reaction conditions, easy control of reaction, and is suitable for mass production.

Owner:XIAMEN UNIV

A method for anti-melt drop flame retardant finishing of high-strength polyester

The invention relates to an anti-dripping flame-retardant finishing method for high-tenacity polyester, which comprises the following steps: adding a compound flame retardant, an adhesive and an anti-dripping agent into a solvent at 100-160 DEG C, and stirring to obtain a flame-retardant solution; and adding polyester fabrics into the flame-retardant solution for soaking and rolling twice respectively, then pre-baking at 80-120 DEG C for 3-6min, baking at 140-180 DEG C for 2-4min, taking out, and cooling to obtain the high-tenacity polyester. The polyester fabrics finished by the finishing process provided by the invention have the characteristics of flame resistance, smoke suppression, high tenacity and anti-dripping capability so as to meet the high-tenacity requirement for polyester and have broad market prospects. The polyester fabrics obtained by the finishing method provided by the invention have the tenacity of 6.6-8.0cN / dtex, the limited oxygen index of 28-40% and the breaking elongation of 13-16%.

Owner:DONGHUA UNIV +1

Production method of blended yarn containing flame-retardant polyester fibers and polyarylate fibers

The invention relates to a production method of a blended yarn containing flame-retardant polyester fibers and polyarylate fibers, which comprises the following steps of: respectively carrying out siro spinning on the flame-retardant polyester fiber roving and polyarylate fiber roving to obtain the blended yarn; wherein the flame-retardant polyester fiber roving is prepared from flame-retardant polyester fibers through a pretreatment process, an opening and picking process, a cotton carding process, a second drawing process and a roving process; the polyarylate fiber roving is prepared from polyarylate fibers through a pretreatment process, an opening and picking process, a cotton carding process, a combing process, a drawing process and a roving process. According to the production methodof the blended yarn containing the flame-retardant polyester fibers and the polyarylate fibers, the combing process parameters are adjusted, the cylinder needle number is reduced, the cylinder toothdensity is reduced, the cylinder carding dead zone length is increased, the combing effect of the flame-retardant polyester fibers is ensured, meanwhile, the condition that the hook part of the flame-retardant polyester fiber is combed by the combing needle is reduced, the fiber damage is avoided, the combing cotton drop is reduced, and the prepared blended yarn has excellent mechanical property and flame retardant property.

Owner:DONGHUA UNIV

Phosphorus heterocycle inflaming retarding copolyester ionomer and preparation method thereof

ActiveCN102924702BMolecular weight effectIncrease forceFlame-proof filament manufactureMonocomponent copolyesters artificial filamentFiberEngineering plastic

The invention discloses a phosphorus heterocycle inflaming retarding copolyester ionomer which is formed by introducing structure units represented by III and IV on the basis of polyester structure units represented by I and II and conducting random copolymerization. The intrinsic viscosity [eta]of the phosphorus heterocycle inflaming retarding copolyester ionomer is 0.2-1.1 dL / g. A preparation method of the ionomer is further disclosed. Due to the fact that phosphorus ion groups are introduced, inflaming retarding modification and ionization modification can be simultaneously achieved without adding other fire retardants, carbon formation effect and stable 'physical cross-linking' effect produced by 'iron aggregate' of the phosphorus ion groups improve melt viscosity of high polyester, and simultaneously the polyester has excellent inflaming retarding and molten drop resistance. The ionomer can directly serve as raw materials for preparing fibers, engineering plastics, film and the like.

Owner:SICHUAN UNIV

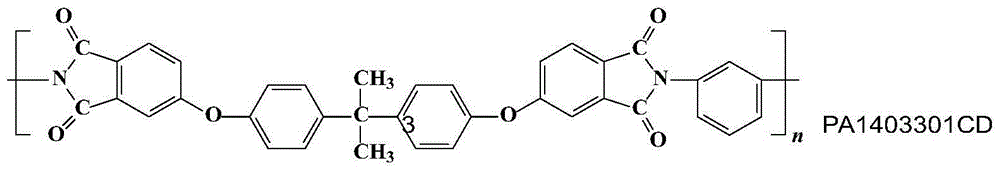

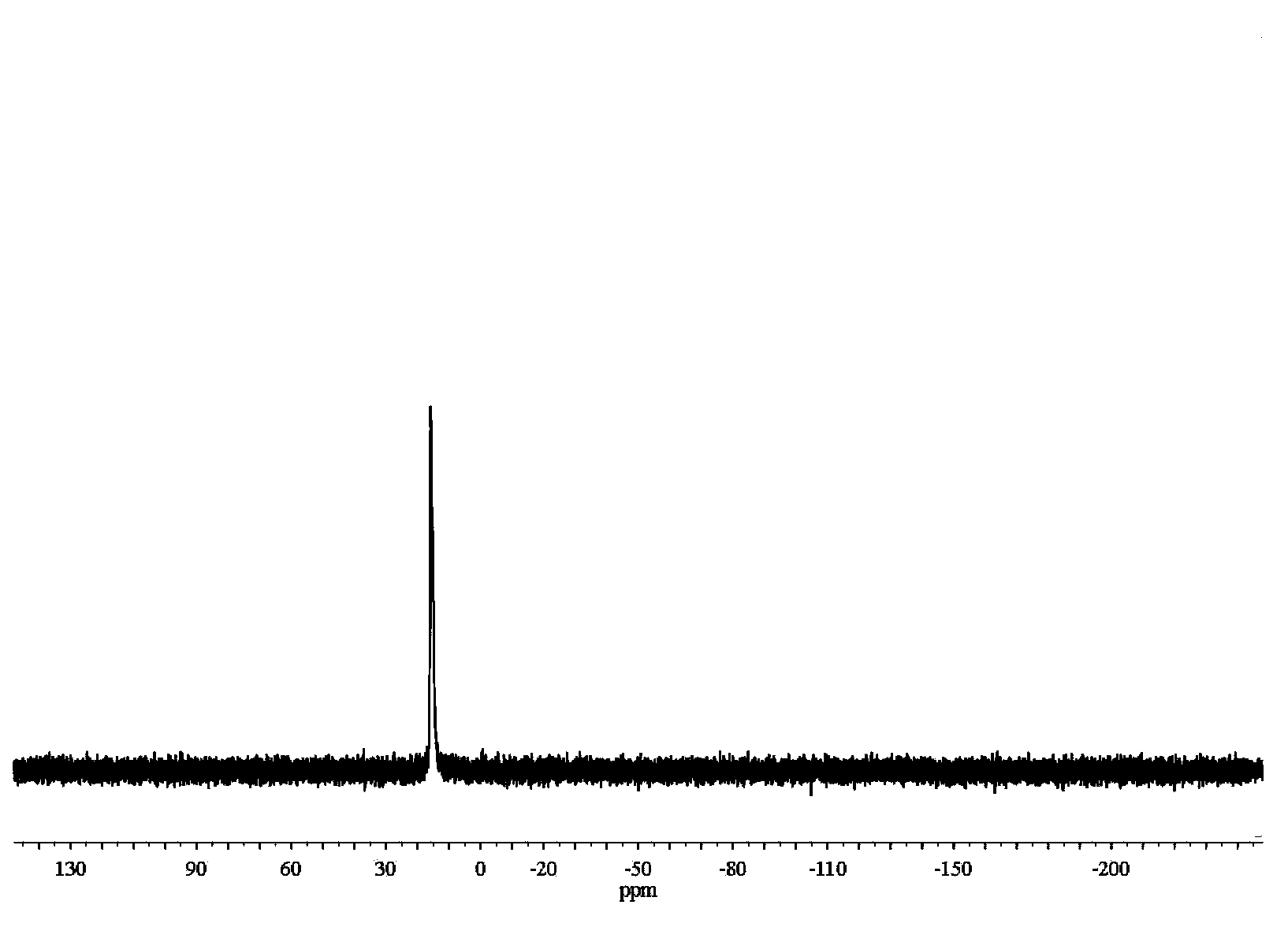

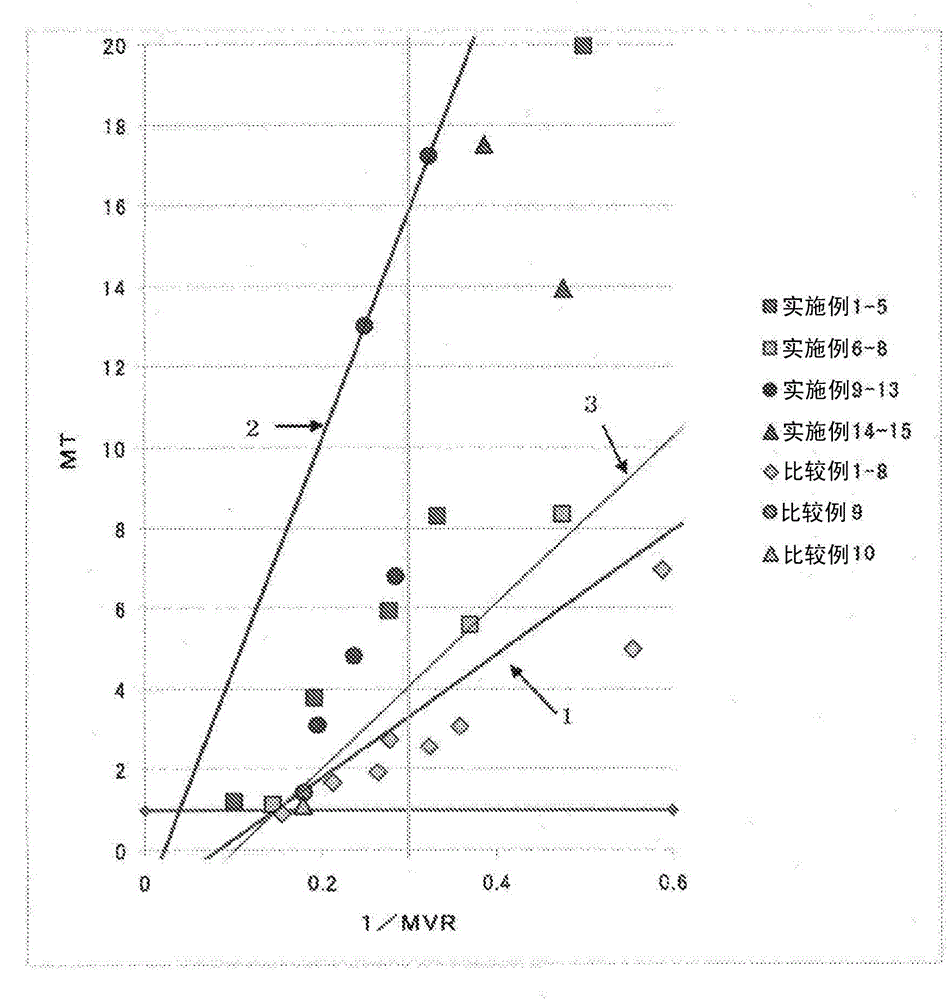

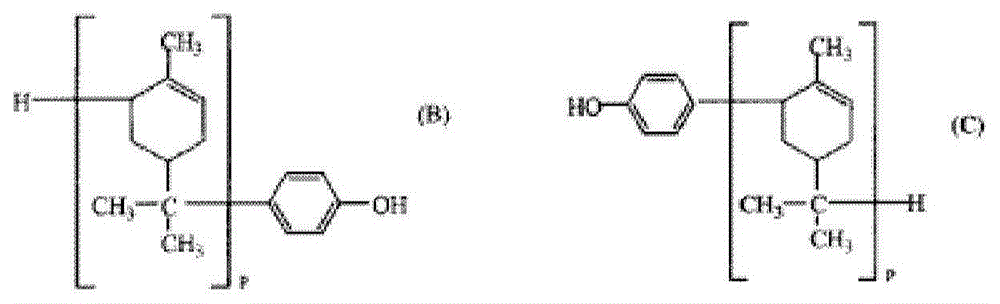

Polycarbonate resin, polycarbonate resin composition and molded article

ActiveCN104812796AHigh melt tensionExcellent resistance to drippingPolymer scienceBisphenol-A-polycarbonate

A polycarbonate resin wherein a relation between the melt tension [MT (g)] at 280°C and melt volume rate [MVR (cm3 / 10 min)] at 280°C satisfies the requirements represented by formulae (1) to (3), and a polycarbonate resin composition and a molded article containing the same. Formula (1): MT≥(15.4 / MVR)-1.3 Formula (2): MT≤(57.4 / MVR)-1.3 Formula (3): MT≥1

Owner:IDEMITSU KOSAN CO LTD

High-temperature self-crosslinking flame-retardant anti-dripping copolyester and preparation method thereof

The invention discloses a high-temperature self-crosslinking flame-retardant anti-dripping copolyester which is prepared by introducing a structural unit shown as IV in the specification or introducing structural units shown as III and IV in the specification by random copolymerization on the basis of structural units of synthetic polyester shown as I and II in the specification, and the intrinsic viscosity [eta] of the prepared high-temperature self-crosslinking copolyester is 0.25-1.25dL / g. The invention also discloses the preparation method of the high-temperature self-crosslinking copolyester. Because the crosslinking group introduced in the invention is a high-temperature self-crosslinking group, on the premise of not affecting the preparation and forming of the polyester, self-crosslinking can be realized at higher temperature, and the melt viscosity of the polyester is improved through the char formation effect and stable chemical crosslinking of the self-crosslinking group, thereby performing combined action with the phosphorus-containing flame-retardant structural unit IV and endowing the polyester with better flame-retardant and anti-dripping properties.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com