Application of polymer as anti-dripping flame retardant

A polymer and anti-droplet technology, which is applied in the field of flame retardants, can solve problems such as lack of droplet resistance, and achieve the effects of preventing various hazards, increasing carbon formation, and inhibiting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Heat and dissolve 20 parts by mass of polyvinyl alcohol (the molecular weight of polyvinyl alcohol is 74800 to 79200 g / mol) in 180 parts by mass of deionized water, then add 40 parts by mass of phytic acid and 10 parts by mass of 4-bis Aminopyridine catalyst to obtain a mixed solution.

[0043] Step 2: Place the reaction bottle containing the mixed solution in an oil bath, and stir until it is completely dissolved. Then, the temperature of the obtained reaction liquid was raised to 60° C., stirring was continued, and the reaction was carried out for 4 hours.

[0044] Step 3: After cooling the reaction solution to room temperature, add an appropriate amount of ethanol to precipitate the polymer product, and filter to obtain a white product.

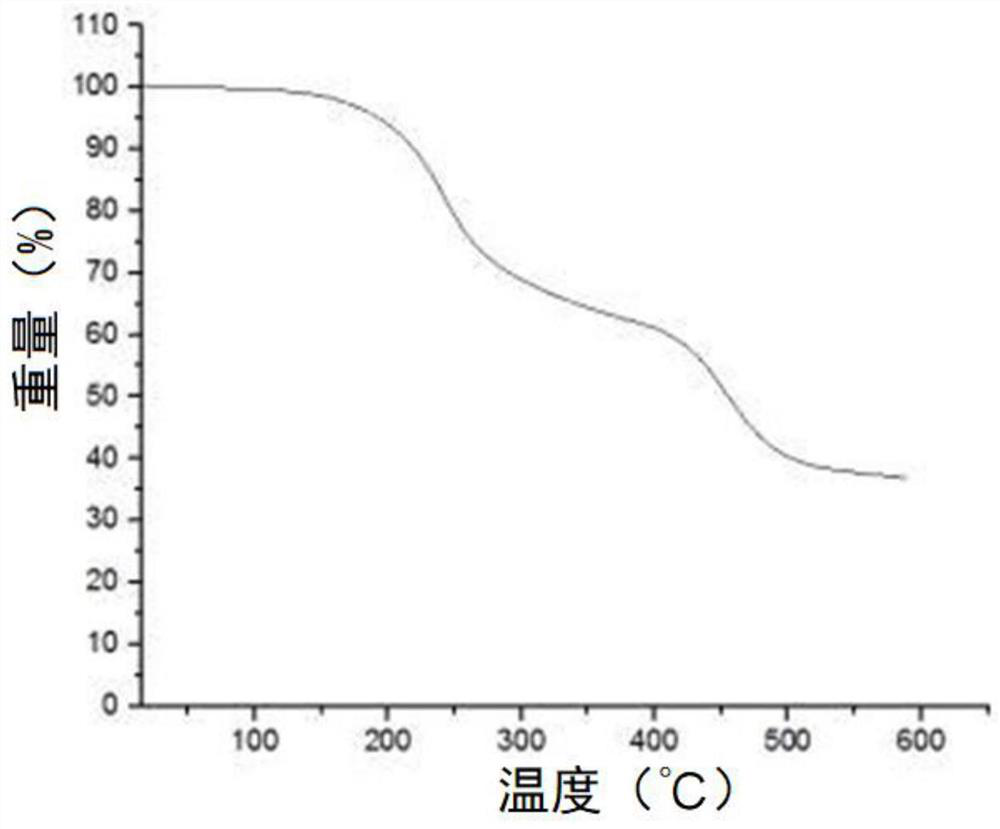

[0045] Step 4: Dissolve the obtained white product in water, and after filtering, dry the filtrate in a freeze dryer to obtain a white three-dimensional structure flame-retardant material, which has several porous structure...

Embodiment 2

[0053] Step 1: Heat and dissolve the flame retardant material prepared in Example 1 in deionized water, and configure it to a concentration of 5g L -1 The solution.

[0054] Step 2: Add graphene oxide into the solution in step 1, and stir until uniform to obtain a flame retardant solution.

[0055] Step 3: apply the flame retardant solution in step 2 on the surface of the fabric, place it in an oven to dry, repeat the preceding steps of step 3 5 times, and obtain a flame retardant fabric. The obtained flame-retardant fabric was weighed to obtain a mass growth rate of 10%.

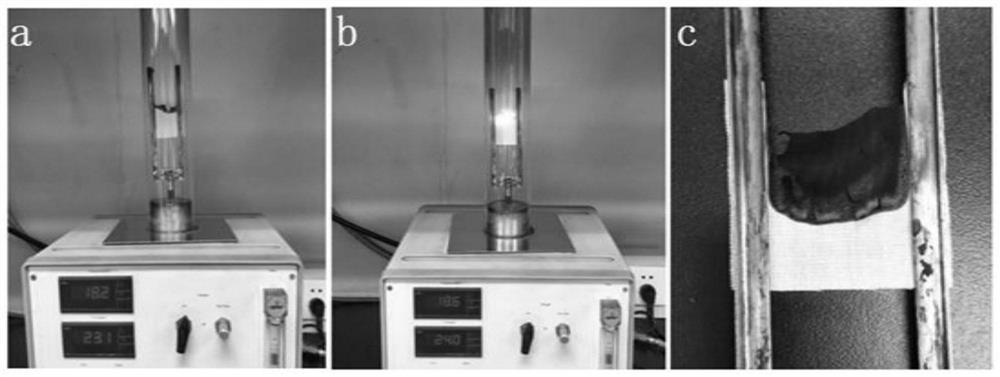

[0056] The limit oxygen test was carried out on the prepared flame-retardant fabric, and the results are shown in Table 2.

[0057] Table 2 Limiting oxygen test results of flame-retardant fabrics

[0058] Oxygen concentration (%) 19.1 20.2 21.2 22.3 23.1 24.0 25.2 26.1 whether to burn no no no no no yes yes yes

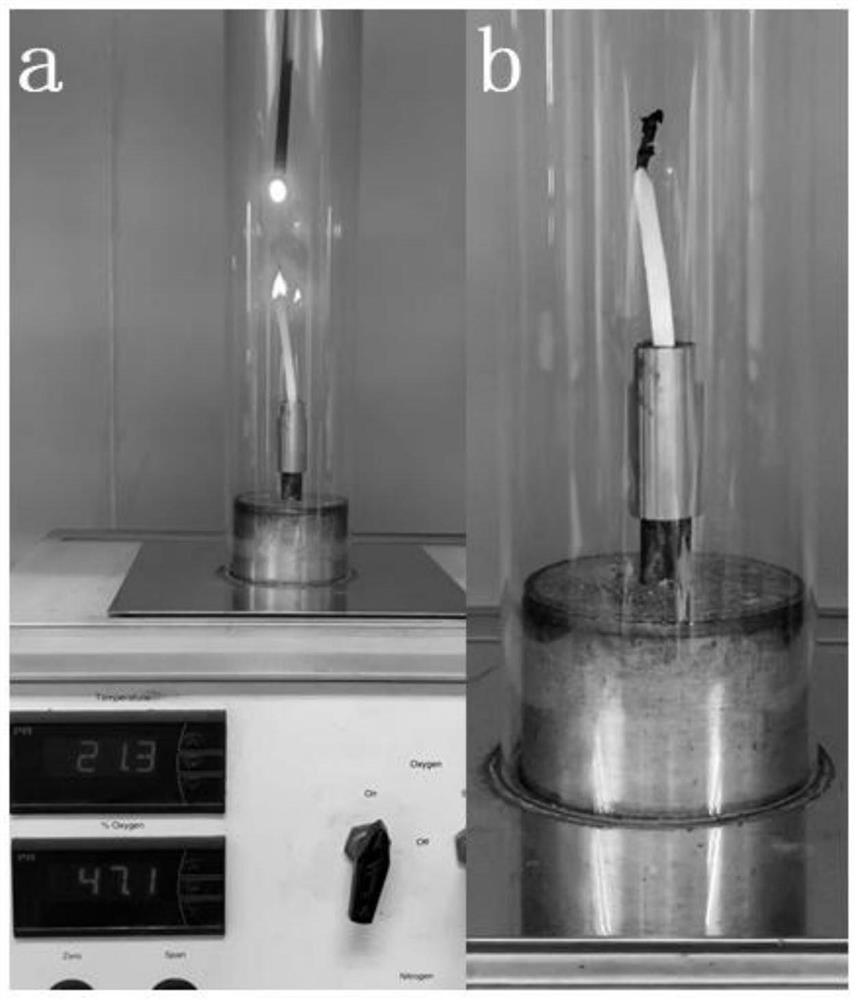

[0059] At the same time, the fabric without flam...

Embodiment 3

[0065] Prepare flame-retardant fabric according to the method of Example 2, the difference is that step 2 is omitted. The prepared flame-retardant fabric still has droplet resistance, and the limiting oxygen index test is almost the same as that without addition, but the smoke emission is higher than that of the flame-retardant fabric in Example 2.

[0066] In summary, the polymer prepared by the present invention has a good flame retardant effect when preparing an anti-dripping flame retardant, and has anti-dripping performance at the same time. After being applied to the fabric, it can effectively increase the limit oxygen index of the fabric and realize the state of self-extinguishing in the air. Controlling the amount of coating can adjust the limiting oxygen index of the fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com