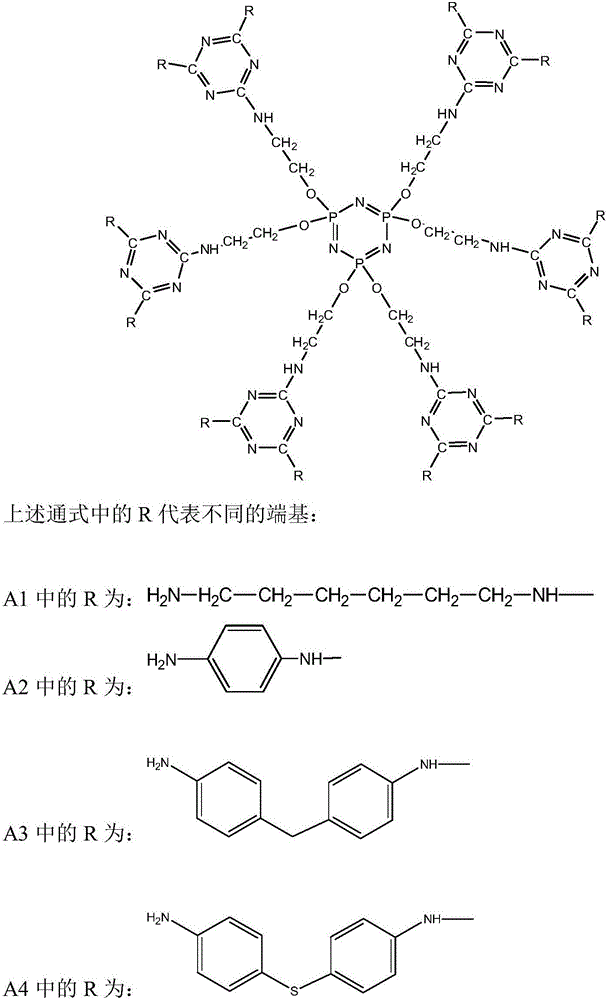

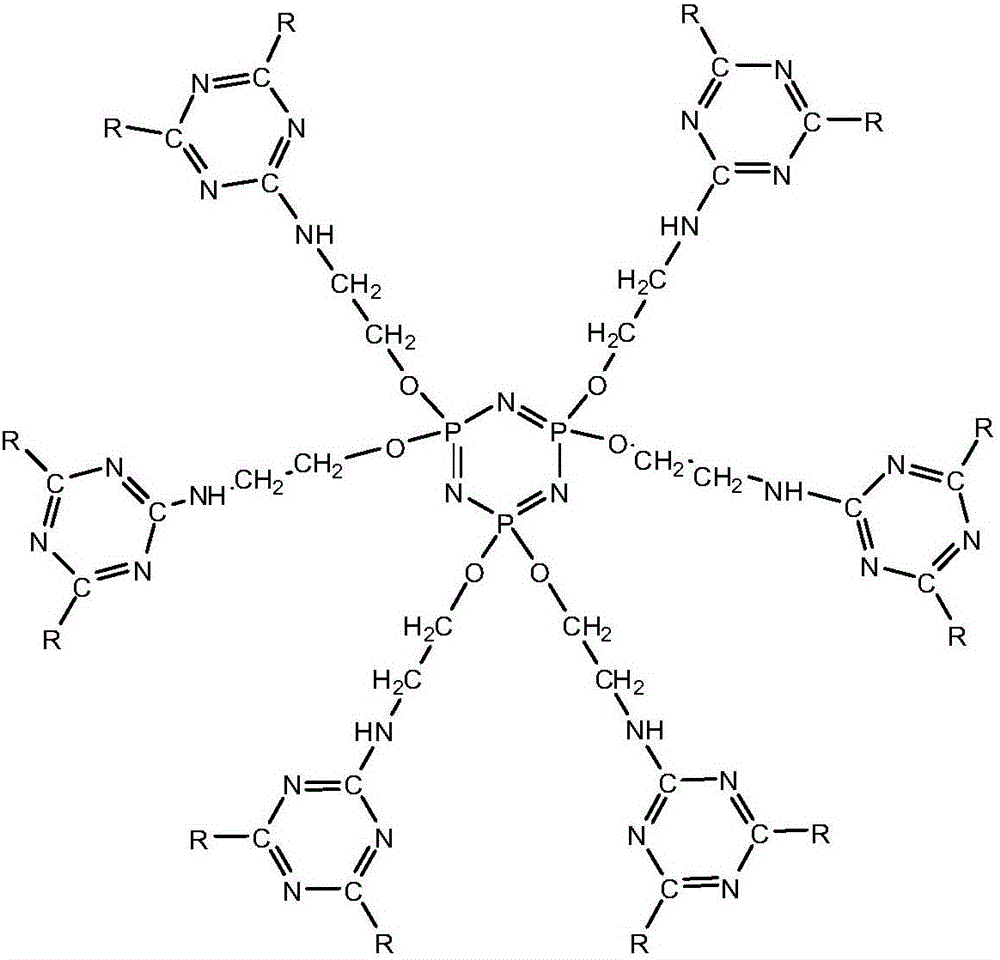

Phosphonitrile/triazine double-group molecular synergistic flame retardation polylactic acid composite material and preparation method thereof

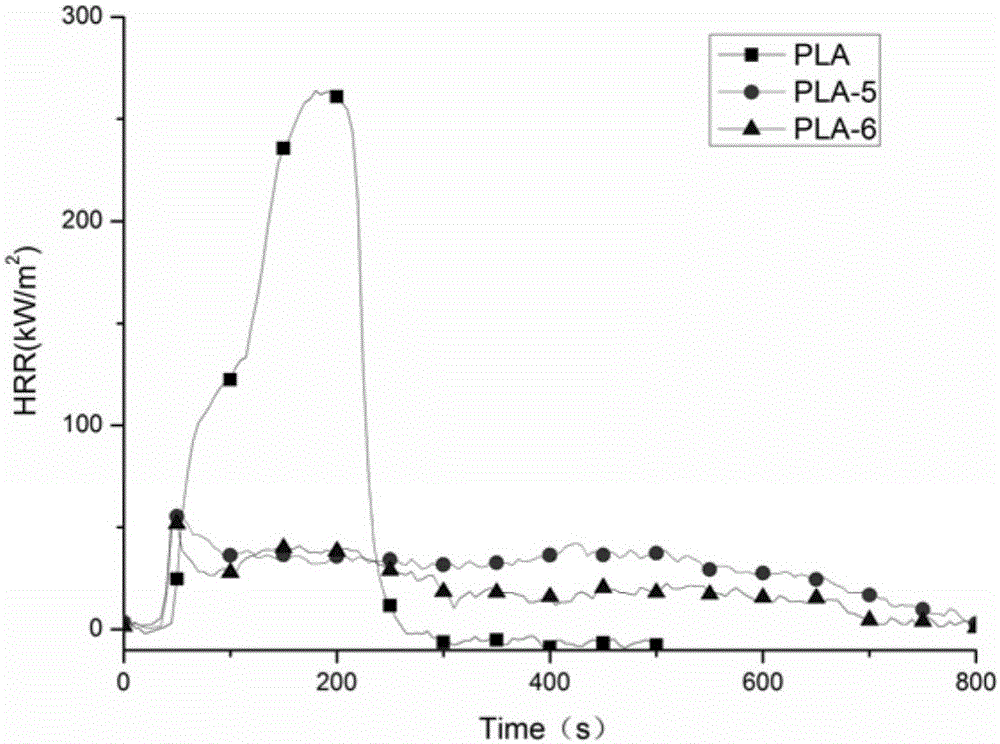

A composite material and synergistic flame-retardant technology, which is applied in the field of phosphazene/triazine biradical molecular synergistic flame-retardant polylactic acid composite materials and its preparation, can solve the problems of rapid degradation of polylactic acid, reduction of mechanical properties of polylactic acid matrix, and limitations Material application fields and other issues, to achieve the effect of high oxygen index and good anti-droplet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 75 parts of high-molecular-weight polylactic acid with a viscosity average molecular weight of more than 100,000, 12.5 parts of phosphazene / triazine double-base molecular synergist A1 (R in the structural formula of A1 is hexamethylenediamine group), 12.5 parts of ammonium polyphosphate (ammonium polyphosphate, abbreviated The word is APP) 12.5 parts, antioxidant 0.03 parts are premixed and placed in a torque rheometer at 170 ° C for mixing to obtain a flame-retardant polylactic acid composite material PLA-1. The flame retardancy of the composite material is as follows: LOI is 40.8%; it passes the UL94V-0 level test.

Embodiment 2

[0023] 75 parts of high-molecular-weight polylactic acid with a viscosity-average molecular weight of more than 100,000, 18.75 parts of phosphazene / triazine double-base molecular synergist A1 (R in the A1 structural formula is a hexamethylenediamine group), 6.25 parts of melamine polyphosphate, and antioxidant After premixing 0.04 parts of the agent, place it in a torque rheometer at 230°C for kneading to obtain the flame-retardant polylactic acid composite material PLA-2. The flame retardancy of the composite material is as follows: LOI is 41.3%; it passes the UL94V-0 level test.

Embodiment 3

[0025] 80 parts of high-molecular-weight polylactic acid with a viscosity-average molecular weight of more than 100,000, 15 parts of phosphazene / triazine double-base molecular synergist A2 (R in the A2 structural formula is p-phenylenediamine group), 5 parts of ammonium polyphosphate (APP) Parts, 0.03 parts of antioxidant pre-mixed and placed in a torque rheometer at 220 ° C for mixing to obtain flame-retardant polylactic acid composite material PLA-3. The flame retardancy of the composite material is: LOI is 39.5%; it passes the UL94V-0 level test. Example 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com