Flame-retardant nano composite material and preparation method thereof

A nano-composite material and nano flame retardant technology are applied in the field of flame-retardant nano-composite materials and their preparation, which can solve the problems of affecting the mechanical properties of composite materials, adding a large amount of flame-retardant additives, and a large amount of toxic fumes, so as to achieve enhanced smoke suppression. Good effect, good flame retardant effect, good anti-melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

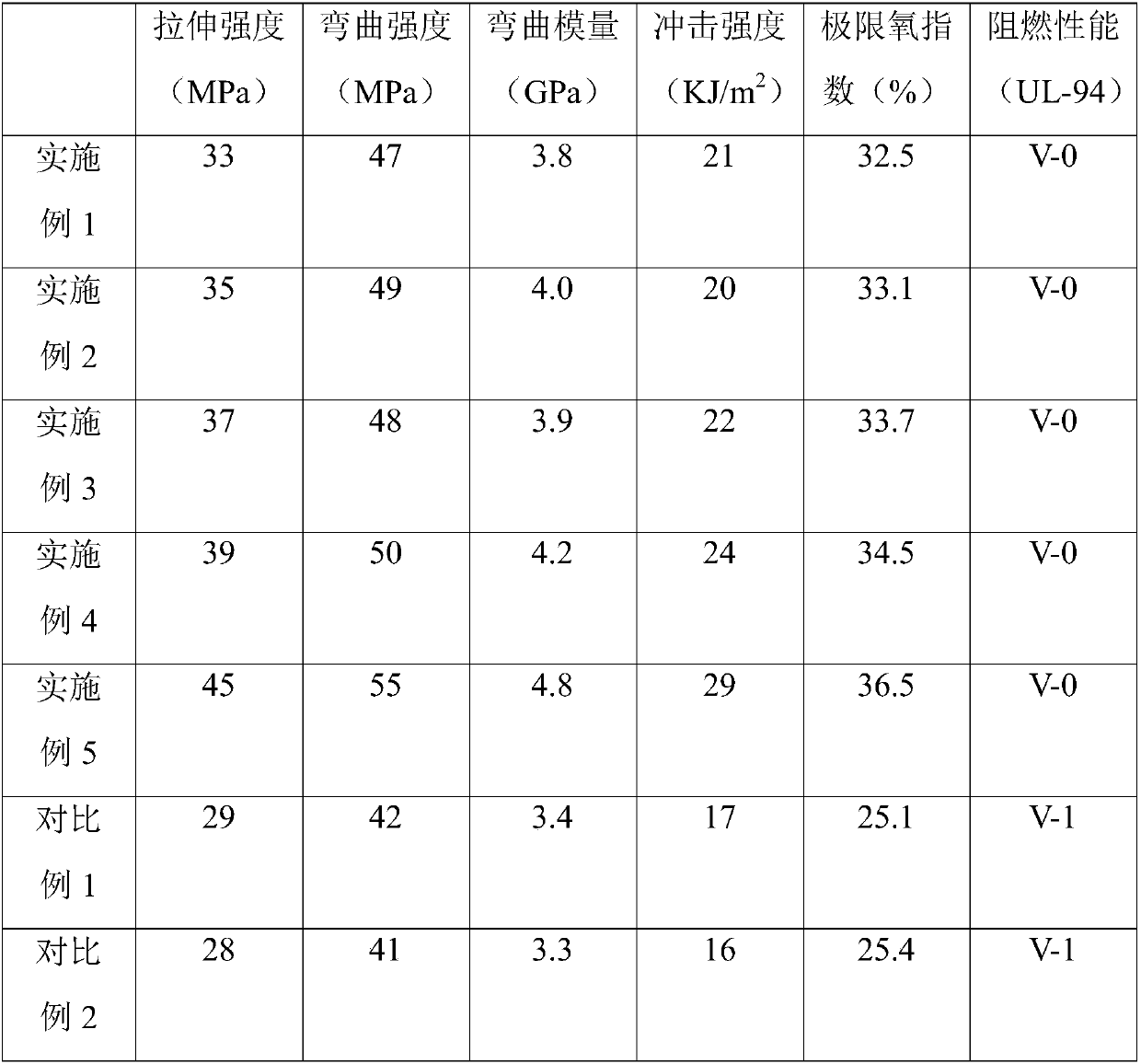

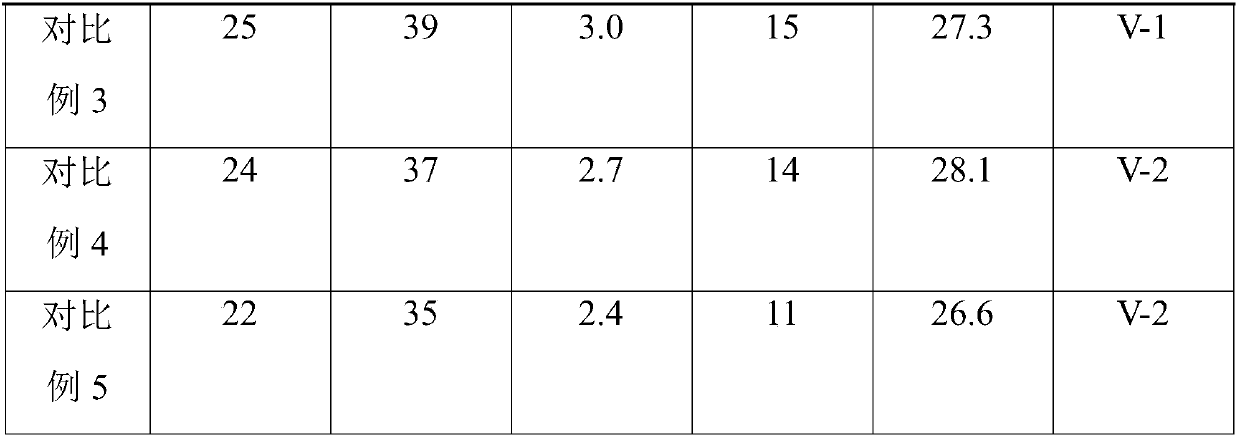

Examples

Embodiment 1

[0027] A flame-retardant nano-composite material, comprising the following components by weight: 80 parts of polypropylene resin, 1 part of composite nano-flame retardant, 5 parts of nano-talc powder, 0.5 parts of flame-retardant synergist, anti-dripping agent 0.1 part, 1 part of compatibilizer, 0.1 part of antioxidant and 0.5 part of reinforcing agent;

[0028] The composite nano-flame retardant includes the following components by weight: 10 parts of modified nano-montmorillonite, 8 parts of nano-aluminum hydroxide, 2 parts of nano-aluminum tripolyphosphate and 1 part of nano-magnesium hydroxide.

[0029] The modified nano-montmorillonite is prepared by the following method: add montmorillonite to 80°C water, disperse ultrasonically for 1 hour to obtain a montmorillonite dispersion with a concentration of 10wt%, then add an intercalation agent and a protonating agent to control the temperature At 80°C, continue ultrasonic dispersion for 1 hour, then filter to obtain the firs...

Embodiment 2

[0040] A flame-retardant nano-composite material, comprising the following components by weight: 100 parts of polypropylene resin, 4 parts of composite nano-flame retardant, 15 parts of nano-talc powder, 1.5 parts of flame-retardant synergist, anti-dripping agent 0.5 parts, 4 parts of compatibilizer, 0.5 parts of antioxidant and 1.5 parts of reinforcing agent;

[0041] The composite nano-flame retardant includes the following components by weight: 20 parts of modified nano-montmorillonite, 15 parts of nano-aluminum hydroxide, 6 parts of nano-aluminum tripolyphosphate and 5 parts of nano-magnesium hydroxide.

[0042] The modified nano-montmorillonite is prepared by the following method: add montmorillonite to 80°C water, disperse ultrasonically for 1 hour to obtain a montmorillonite dispersion with a concentration of 10wt%, then add an intercalation agent and a protonating agent to control the temperature At 80°C, continue ultrasonic dispersion for 1 hour, then filter to obtain...

Embodiment 3

[0053] A flame-retardant nanocomposite material, comprising the following components by weight: 85 parts of polypropylene resin, 2 parts of composite nano-flame retardant, 8 parts of nano-talc powder, 0.8 parts of flame-retardant synergist, anti-dripping agent 0.2 parts, 2 parts of compatibilizer, 0.2 parts of antioxidant and 0.8 parts of strengthening agent;

[0054] The composite nano-flame retardant includes the following components by weight: 13 parts of modified nano-montmorillonite, 10 parts of nano-aluminum hydroxide, 3 parts of nano-aluminum tripolyphosphate and 2 parts of nano-magnesium hydroxide.

[0055] The modified nano-montmorillonite was prepared by the following method: adding montmorillonite to 80°C water and ultrasonically dispersing it for 1 hour to obtain a montmorillonite dispersion with a concentration of 6 wt%, and then adding an intercalation agent and a protonating agent to control the temperature At 80°C, continue ultrasonic dispersion for 1 hour, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com