Ionic monomer containing benzo heterocyclic sulfonate structure, ionomer using same for flame resistance and molten resistance, and preparation method and application thereof

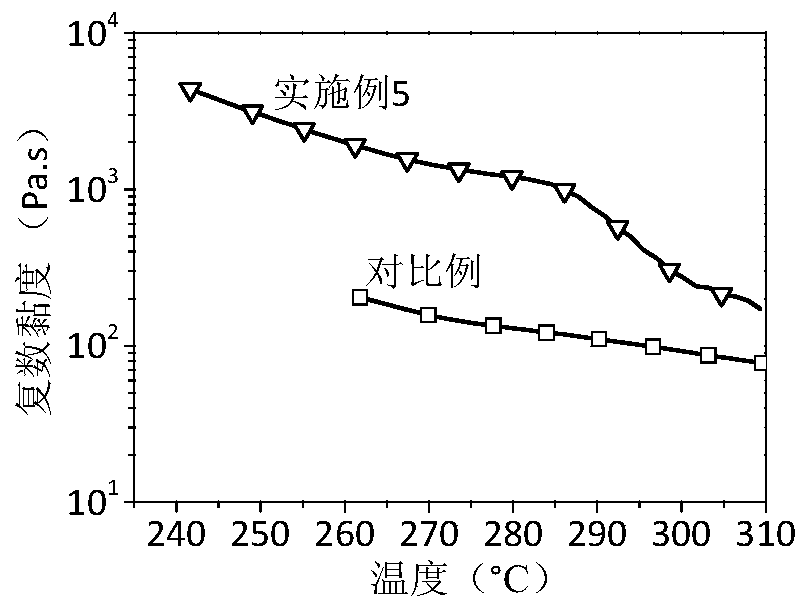

A technology of heterocyclic sulfonates and ionic monomers, applied in the manufacture of fire-retardant and flame-retardant filaments, one-component copolyester rayon, organic chemistry, etc., can solve the problems of affecting the cost and introducing a large amount of monomers, etc. , to achieve the effect of increasing the melt strength, suppressing the droplet phenomenon, and improving the ability to resist the droplet effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In the reaction vessel, add 40g of isophthalic acid-5-sodium sulfonate, 75g of methyl 3,4-diaminobenzoate, 63.5g of EDCI (condensing agent), 45g of HOBT (condensing agent) and 4.500L of DMF, and stir at room temperature for 24h , the obtained clear solution was evaporated to remove the solvent, 2L of glacial acetic acid was added, and a white solid was precipitated under reflux at 140°C, filtered by suction, washed with water, and dried to obtain 1,3-bis(5-(4-methoxy Sodium carbonyl-1H-benzimidazol-2-yl)-5-benzenesulfonate.

Embodiment 2

[0061] In the reaction vessel, add 85g of isophthalic acid-5-potassium sulfonate and disperse it in thionyl chloride and reflux for 3h to prepare the corresponding acid chloride, and then slowly drop it into 150g of 4-amino-3-hydroxybenzoic acid formic acid In the DMF solution of the ester, stir at room temperature for 12 hours, add dehydrating agent p-toluenesulfonic acid, reflux and stir at 120-160°C for 8 hours, pour the solution into a large amount of deionized water while it is hot, and precipitate a large amount of solids, filter with suction, wash with water, and wash with alkali. After washing with water and drying, potassium 1,3-bis(5-(4-methoxycarbonyl-1H-benzoxazol-2-yl)-5-benzenesulfonate can be obtained.

Embodiment 3

[0063] In the reaction vessel, add 40g sodium 2,4-dicarboxybenzenesulfonate, 75g methyl 3,4-diaminobenzoate, 63.5g EDCI (condensing agent), 45g HOBT (condensing agent) and 4.5L DMF, and stir at room temperature for 24h , the obtained clear solution was evaporated to remove the solvent, added 2L glacial acetic acid, refluxed at 140°C, a white solid precipitated, filtered with suction, washed with water, and dried to obtain 1,3-bis(5-(4-methoxy Sodium carbonyl-1H-benzimidazol-2-yl)-4-benzenesulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak heat release rate | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com