Phosphorus heterocycle inflaming retarding copolyester ionomer and preparation method thereof

A copolyester and ionomer technology, applied in the manufacture of fire-resistant and flame-retardant filaments, single-component copolyester artificial filaments, etc., can solve the problems of poor hydrophilicity and dyeability, lack of flame-retardant properties, and fabric costs Higher problems, to achieve the effect of increasing melt viscosity, excellent flame retardancy and anti-dripping, excellent anti-dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

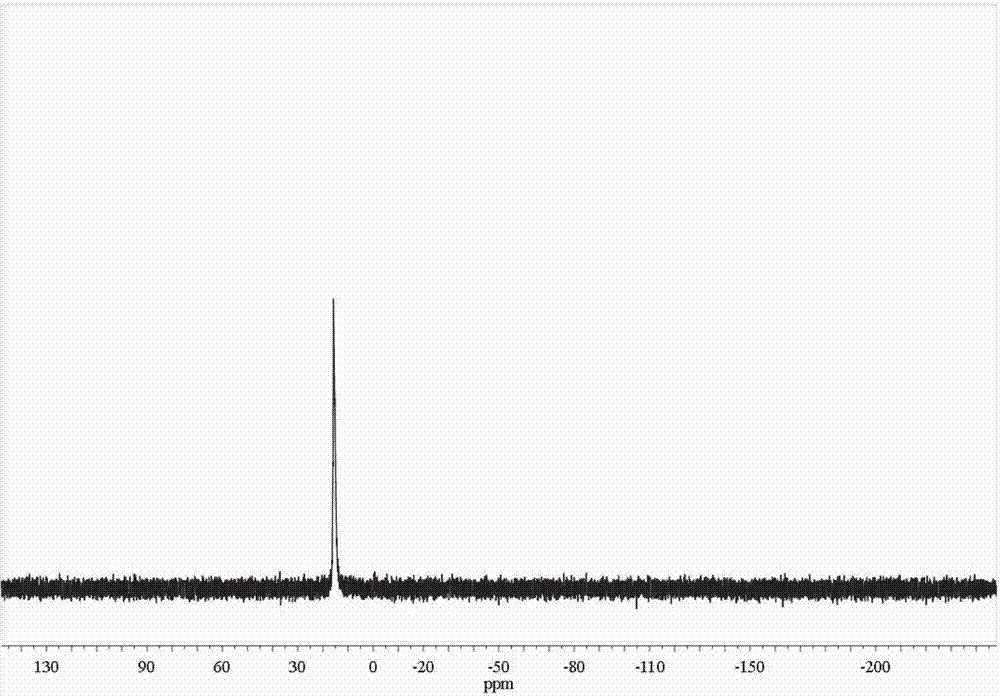

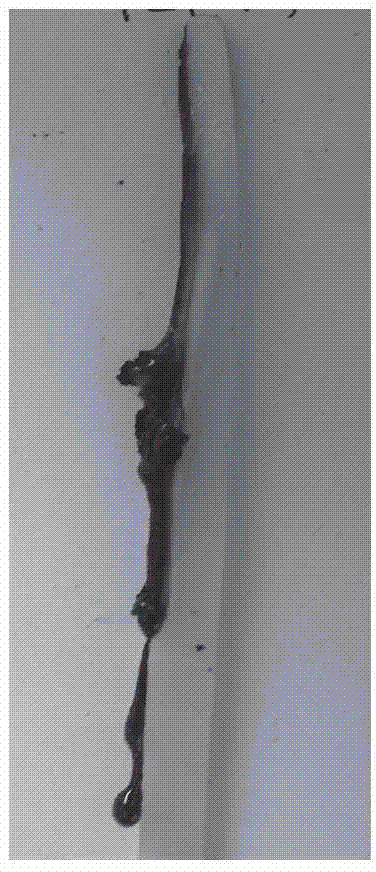

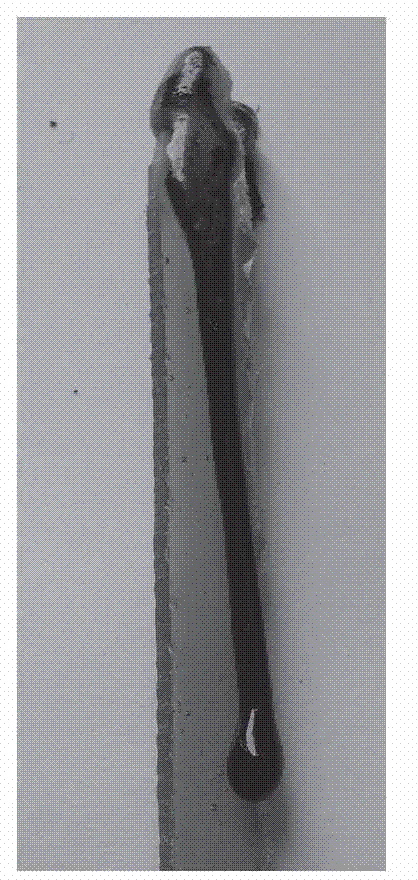

Embodiment 1

[0057] First add 415g of terephthalic acid (TPA), 217mL of ethylene glycol (EG) and 0.23g of tetrabutyl titanate into the reaction kettle, fill with nitrogen to remove the air in the kettle, then pressurize to 0.1MPa, and gradually raise the temperature to 240°C , start esterification, and control the pressure in the kettle to 0.3-0.4MPa. After 1 hour of esterification, the temperature gradually rises to 260°C. When the esterification reaction ends when anhydrous is generated, the pressure drops to normal pressure; Inject nitrogen, slowly add 1.10g of ethylene glycol solution of phosphorus-containing flame retardant ionic monomer 2,8-(2-hydroxyethoxy) carbonylphenanthrene oxaphosphinate (SDHPPO) into the reaction kettle, and control the temperature When the temperature is above 220°C, stop the nitrogen flow after the addition, and start vacuuming. The system is pre-condensed at 260°C for 0.5h in low vacuum, and then enters the high vacuum stage (<100Pa), polycondensates at 280°...

Embodiment 2

[0060] Firstly, 415g of terephthalic acid (TPA), 217mL of ethylene glycol (EG) and 0.23g of tetrabutyl titanate were added to the reaction kettle, and the esterification reaction was carried out according to the method in Example 1. After the esterification, the pressure drop To normal pressure, nitrogen gas is slowly introduced into the reactor, and the ethylene glycol of 10.75g of phosphorus-containing flame-retardant ionic monomer 2,8-(2-hydroxyethoxy)sodium carbonylphenanthreneoxaphosphinate (SDHPPO) The solution was slowly added to the reactor, and then the polycondensation was carried out according to the method of Example 1.

[0061] The intrinsic viscosity [η] of the phosphorus-containing heterocyclic flame-retardant copolyester ionomer is 0.89dL / g, the limiting oxygen index LOI is 25.0, and the peak heat release rate is 442kW / m 2 .

Embodiment 3

[0063] Firstly, 415g of terephthalic acid (TPA), 217mL of ethylene glycol (EG) and 0.23g of tetrabutyl titanate were added to the reaction kettle, and the esterification reaction was carried out according to the method in Example 1. After the esterification, the pressure drop To normal pressure, nitrogen gas is slowly introduced into the reactor, and the ethylene glycol of 32.25g of phosphorus-containing flame-retardant ionic monomer 2,8-(2-hydroxyethoxy)sodium carbonylphenanthreneoxaphosphinate (SDHPPO) The solution was slowly added to the reactor, and then the polycondensation was carried out according to the method of Example 1.

[0064]The intrinsic viscosity [η] of the phosphorus-containing heterocyclic flame-retardant copolyester ionomer is 0.73dL / g, the limiting oxygen index LOI is 25.5, and the peak heat release rate is 367kW / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak heat release rate | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com