Halogen-free and flame-retardant glass fiber reinforced nylon composite and preparation method thereof

A nylon composite material and glass fiber technology, which is applied in the field of halogen-free flame-retardant glass fiber reinforced nylon composite material and its preparation, can solve the problems of material mechanical property loss and achieve the effect of guaranteed strength and excellent flame-retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

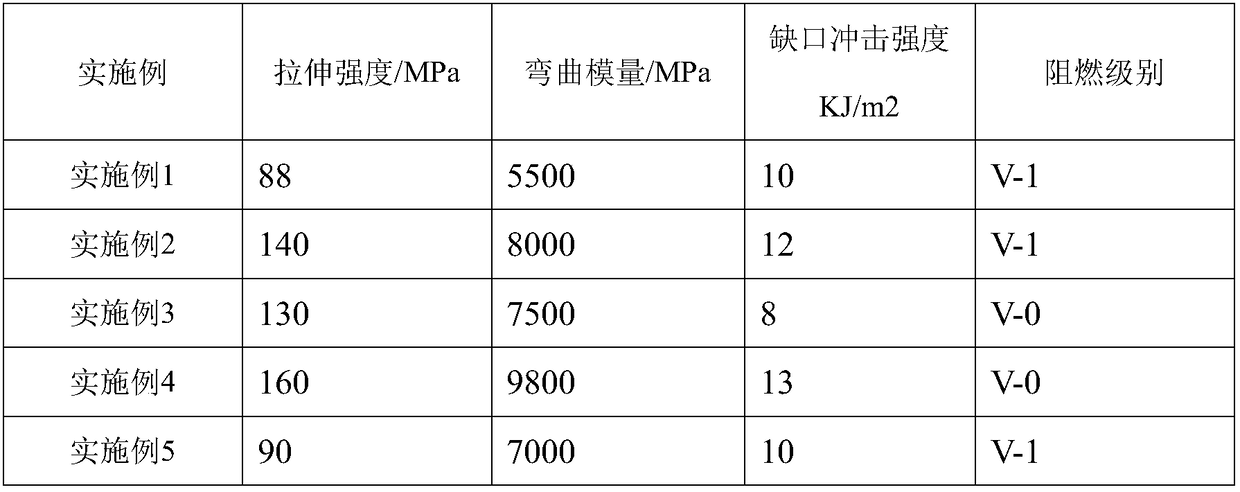

Examples

Embodiment 1

[0027] Weigh 50 parts of dry PA-M1013B, 15 parts of PPS-MT9320C0, 15 parts of halogen-free flame retardant compounding agent (10 parts of red phosphorus flame retardant masterbatch, 2 parts of cyanuric acid melamine salt and organic nano-montmorillonite soil 2 parts), 0.1 part of antioxidant 1098, 0.1 part of antioxidant 168, 5 parts of compatibilizer POE-G, 0.2 part of lubricant EBS, mixed and added to the extruder, and then 15 parts of ER14-1000- 988A is added from the glass fiber port, extruded through the extruder, water-cooled and cut into pellets. Among them, the processing temperature of the extruder is 220°C, 260°C, 270°C, 280°C, 290°C, 295°C from the feeding port to the die port, the main engine speed is 180rpm, and the vacuum degree is -0.03MPa.

Embodiment 2

[0029] Weigh 45 parts of dry PA-M1013B, 5 parts of PPS-MT9320C0, 15 parts of halogen-free flame retardant compounding agent (10 parts of red phosphorus flame retardant masterbatch, 2 parts of cyanuric acid melamine salt and organic nano-membrane 2 parts of soil removal), 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 5 parts of compatibilizer POE-G, 0.5 part of lubricant Lico Wax E, mixed and added to the extruder, and then 30 parts ER14-1000-988A is added from the glass fiber inlet; extruded through the extruder, water-cooled and cut into pellets. Among them, the processing temperature of the extruder is 220°C, 260°C, 270°C, 280°C, 290°C, 295°C from the feeding port to the die port, the speed of the main machine is 200rpm, and the vacuum degree is -0.05MPa.

Embodiment 3

[0031] Weigh 39 parts of dry PA-Alphalon 27, 15 parts of PPS-MT9320C0, 25 parts of halogen-free flame retardant compounding agent (15 parts of red phosphorus flame retardant masterbatch, 5 parts of melamine cyanurate and organic nano 5 parts of montmorillonite), 0.1 part of antioxidant 1098, 0.2 part of antioxidant 168, 1 part of compatibilizer POE-G, 0.3 part of lubricant A-C540A, mixed and added to the extruder, and then 20 parts ER14-1000-988A is added from the glass fiber inlet; extruded through the extruder, water-cooled and cut into pellets. Among them, the processing temperature of the extruder is 220°C, 260°C, 270°C, 280°C, 290°C, 295°C from the feeding port to the die port, the main engine speed is 350rpm, and the vacuum degree is -0.05MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com