Patents

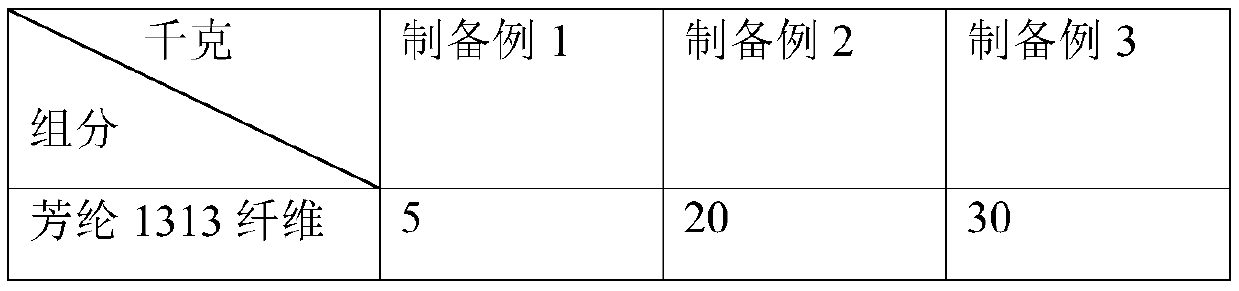

Literature

51results about How to "High char formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-containing macromolecular intumescent flame-retardant charring agent with cross-linked structure as well as preparation method and application thereof

ActiveCN104559204ASolve the problems caused by poor water resistanceImprove solubilityEpoxyCross-link

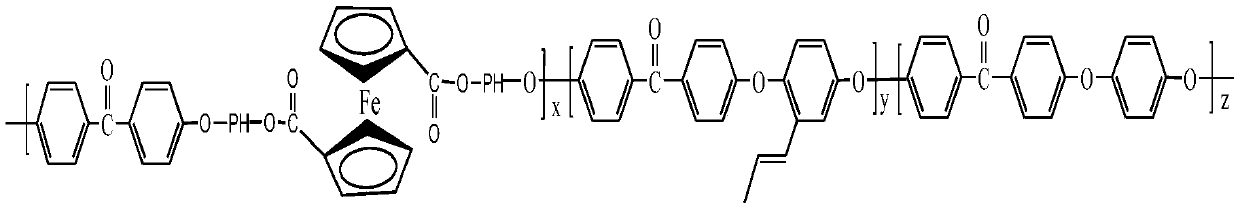

The invention discloses a phosphorus-containing macromolecular intumescent flame-retardant charring agent with a cross-linked structure as well as a preparation method and an application thereof. A structural general formula of the phosphorus-containing macromolecular intumescent flame-retardant charring agent is as shown in the specification, wherein X, Y and Z are any one of diamine, diol group, alkylol amine or diphenol, and can be the same, and can also be different. The invention further relates to a preparation method of the flame-retardant charring agent, and an application of the flame-retardant charring agent as a carbon source of a novel intumescent flame-retardant system, and an application of novel intumescent flame-retardant system in polyolefin, polyurethane, polylactic acid, polyamide and epoxy resin. The intumescent flame-retardant charring agent prepared by the method has good charring property, and is free of halogen, low in toxicity and high in water resistance, good in compatibility with a plurality of flame-retardant high polymers, relatively small in effects on mechanical property, simple in synthesis process, easy to control, and easy to put into industrial production.

Owner:SICHUAN UNIV

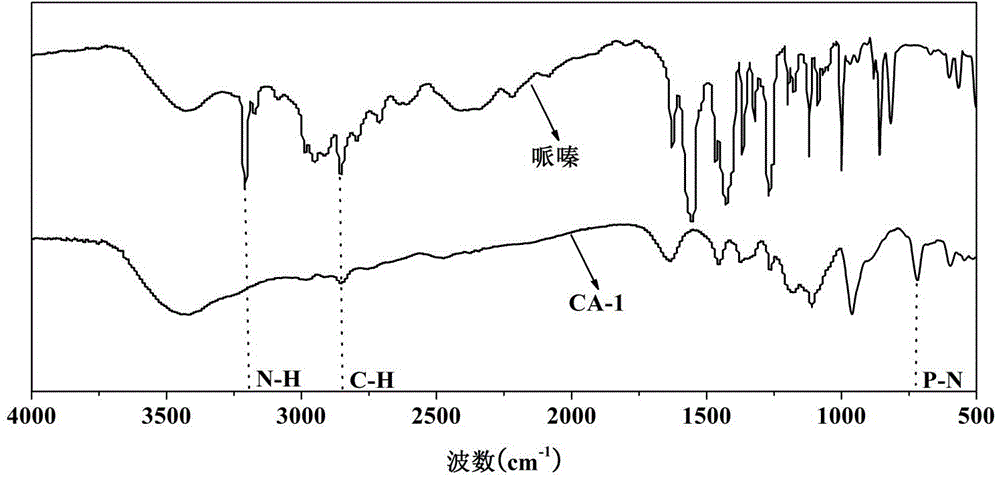

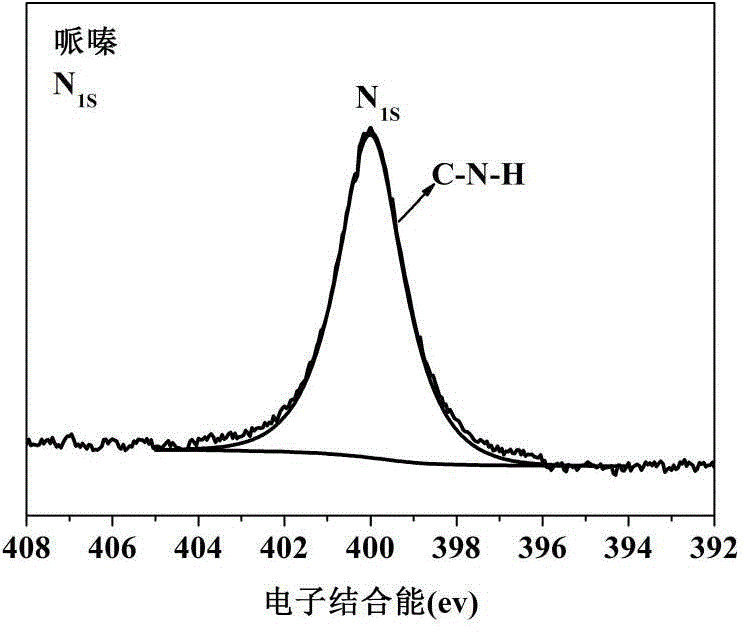

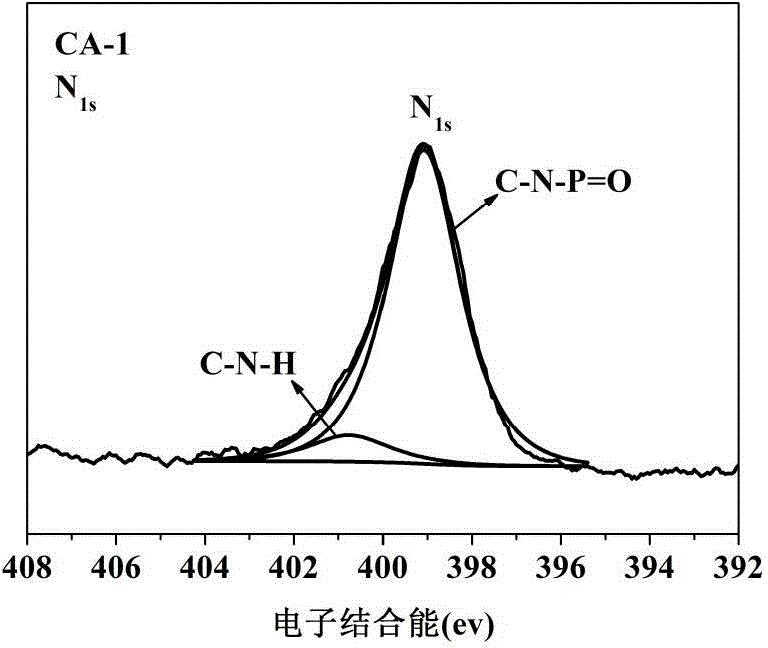

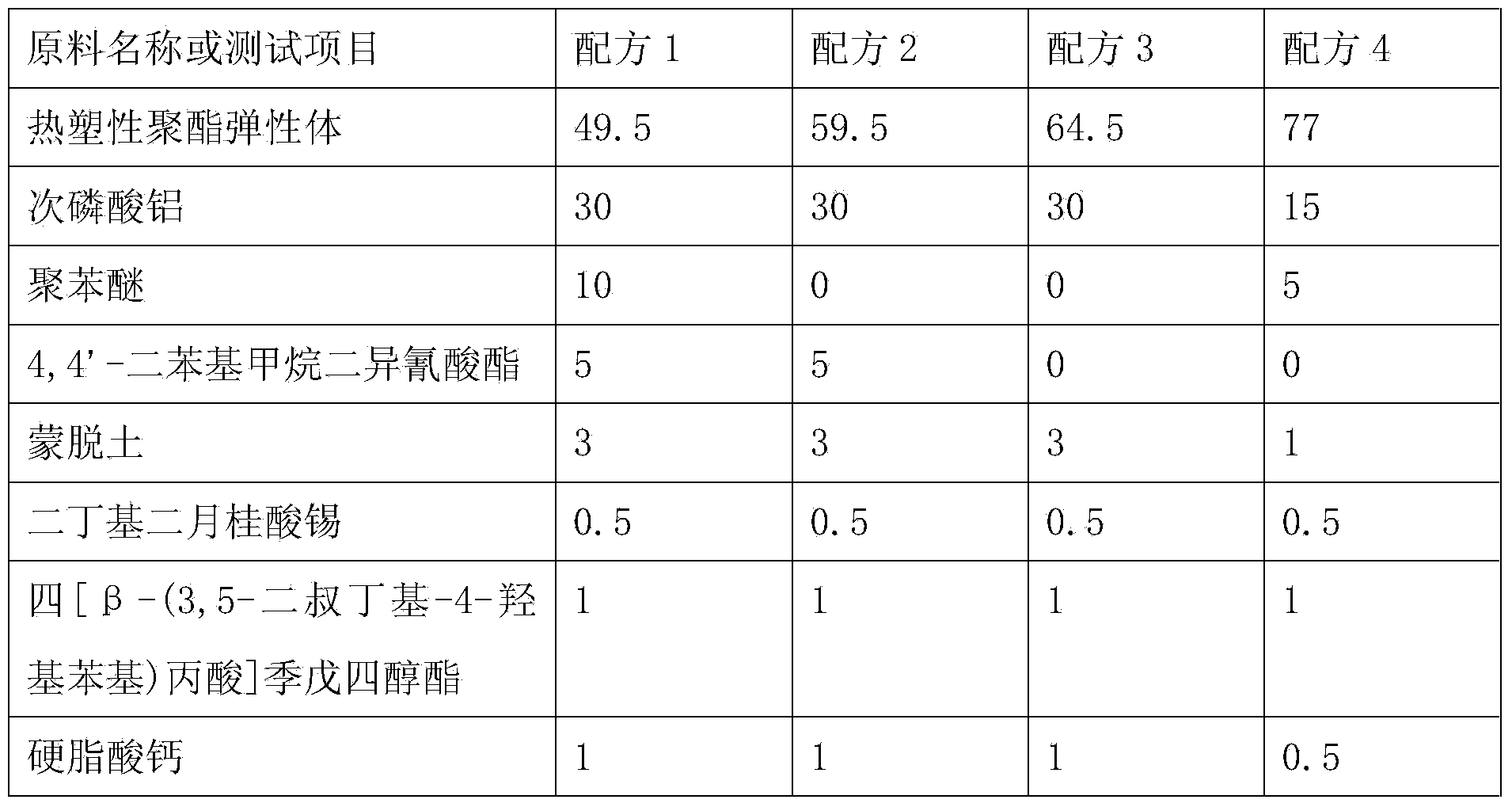

Halogen-free flame-retardant thermoplastic polyester elastomer nano composite material and preparation method thereof

ActiveCN103642178AImprove flame retardant performanceImprove mechanical propertiesElastomerPolyester

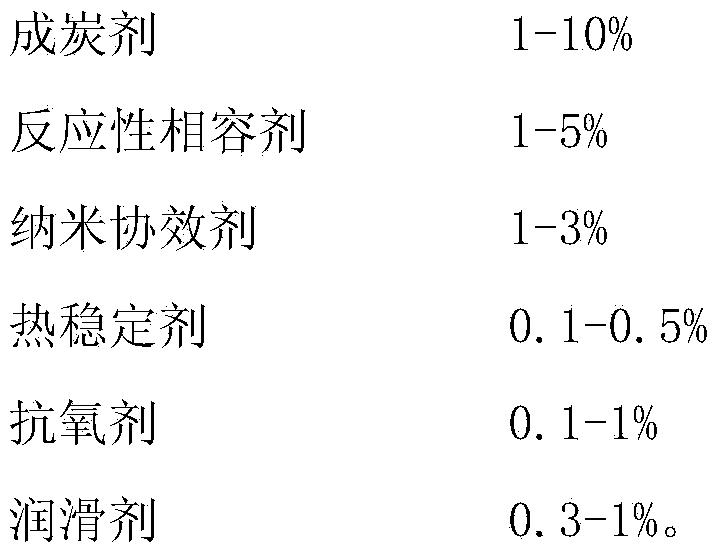

The invention discloses a halogen-free flame-retardant thermoplastic polyester elastomer nano composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing 50.5-81.5 percent of thermoplastic polyester elastomer, 15-30 percent of halogen-free flame retardant, 1-10 percent of charring agent, 1-5 percent of reactive compatibilizer, 1-3 percent of nucleating agent, 0.1-0.5 percent of heat stabilizer, 0.1-1 percent of antioxidant and 0.3-1 percent of lubricating agent according to the total mass percentage of the composite material, heating to the temperature of 210-225 DEG C, performing melt blending, extruding, bracing, cooling, sized dicing and drying to obtain the halogen-free flame-retardant thermoplastic polyester elastomer nano composite material. The nano composite material has excellent flame-retardant property and physical performance, the defects that a halogen-containing flame retardant is high in environmental hazard, the addition amount of an inorganic flame retardant is high, the physical performance of the material is poor and the like in the conventional composite material modification technology are overcome, and the composite material has high application prospects.

Owner:合肥安聚达新材料科技有限公司

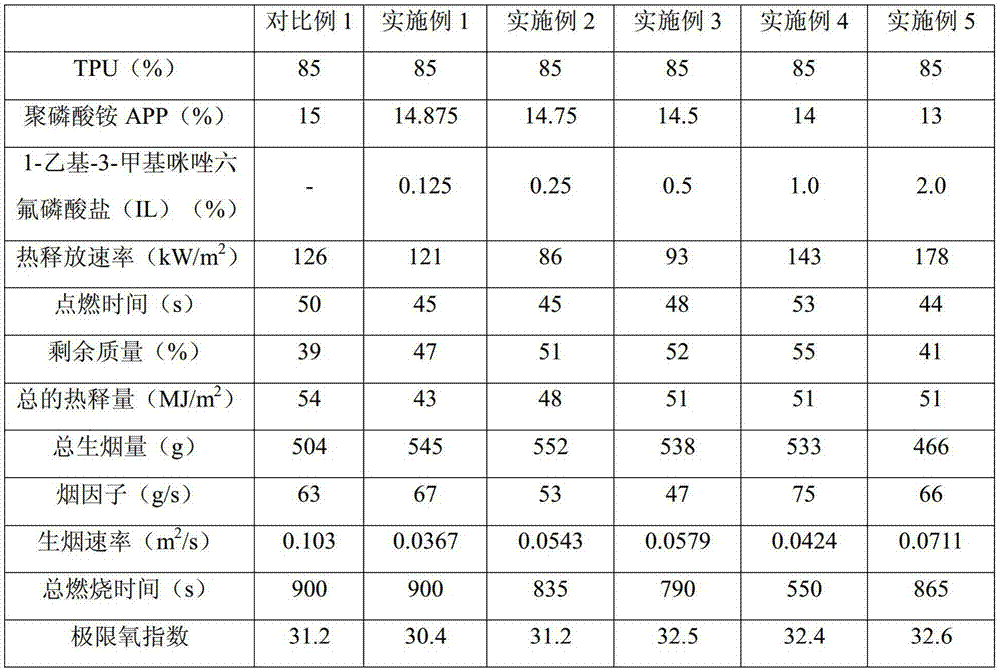

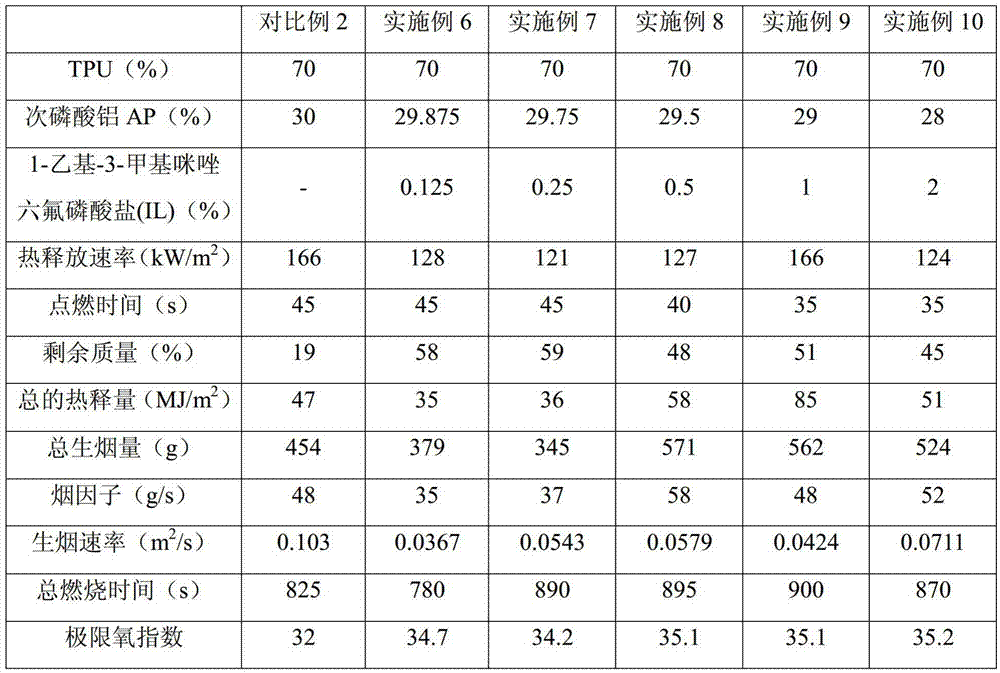

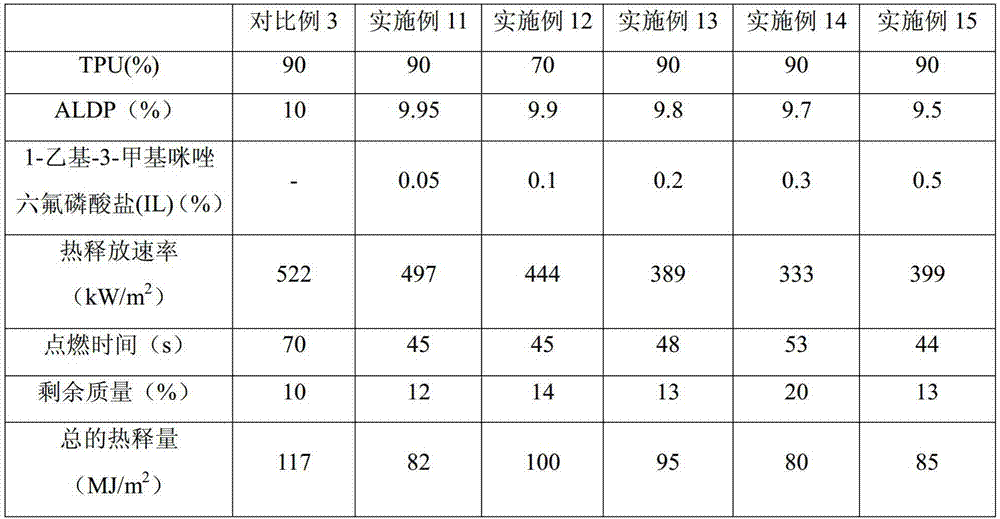

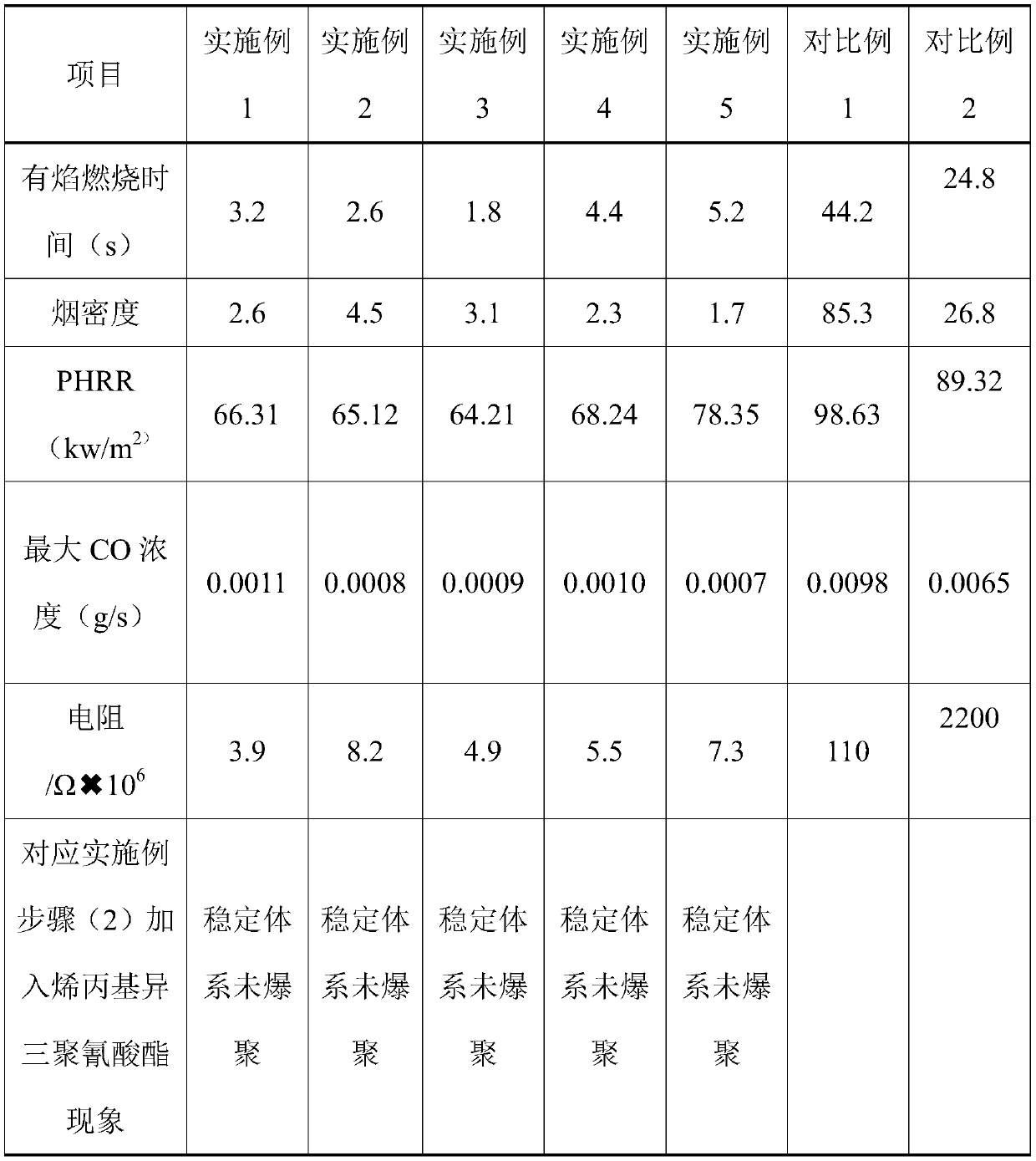

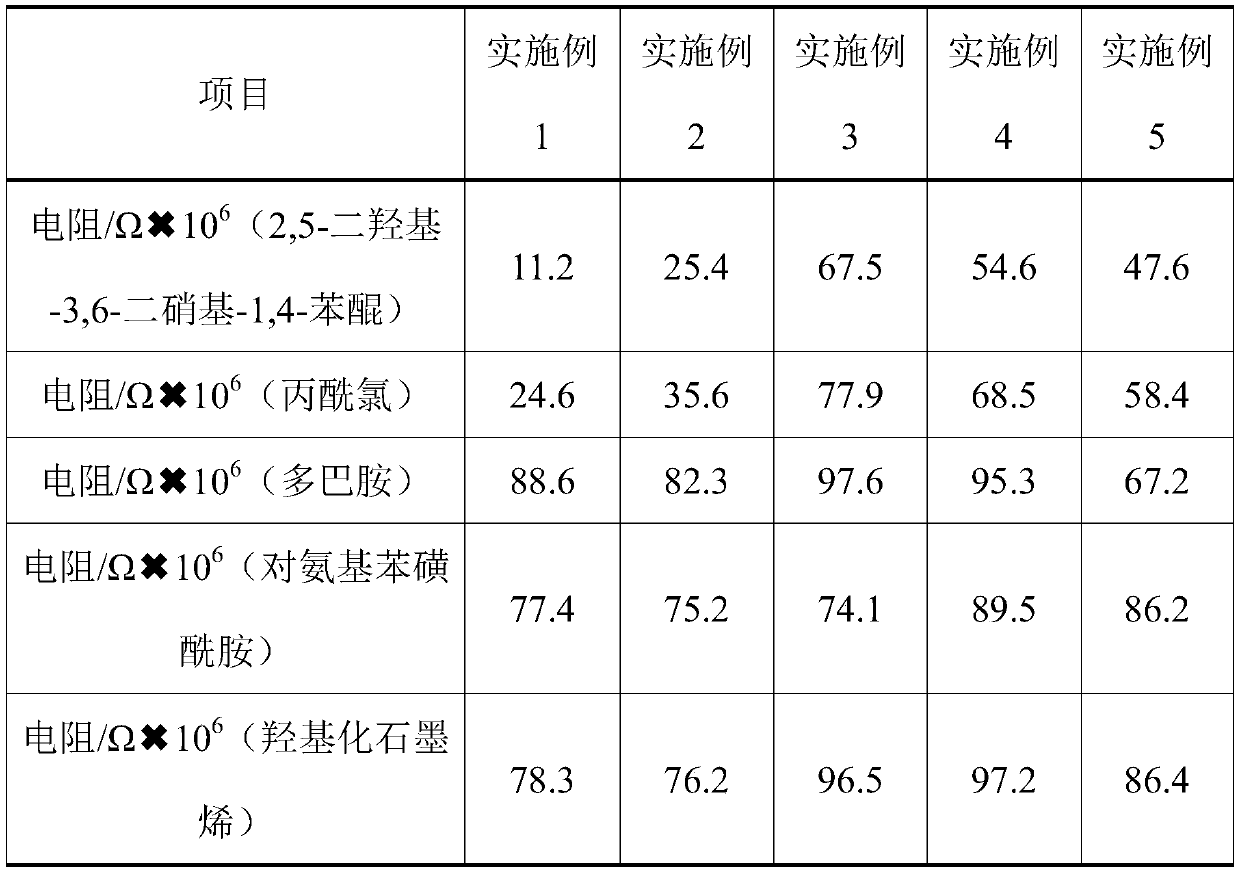

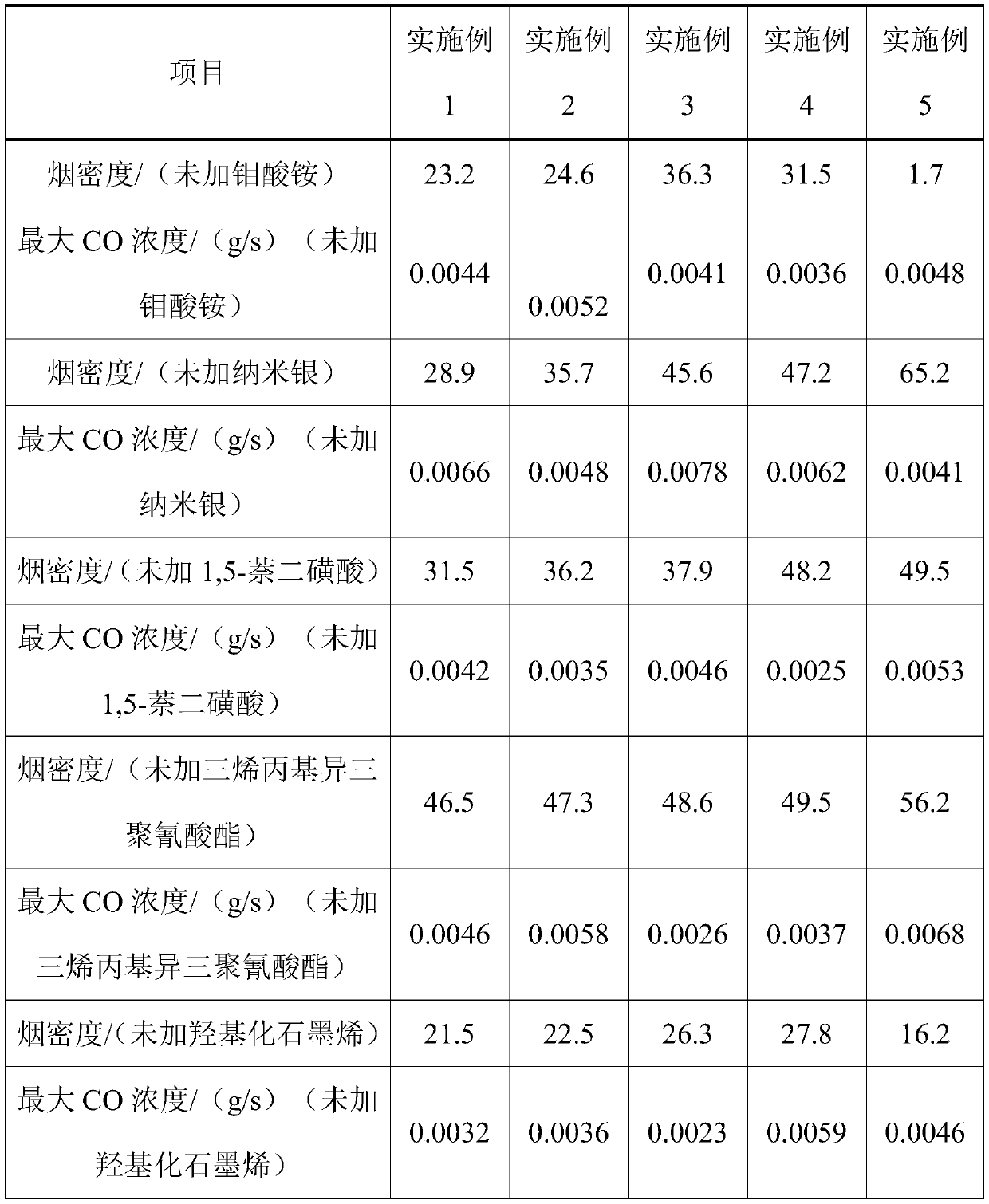

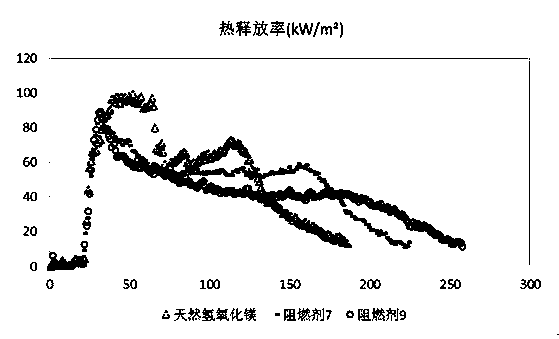

Flame retardant thermoplastic polyurethane elastomer (TPU) and preparation method thereof

ActiveCN105440652AHigh oxygen indexIncreased vertical burn test levelThermoplastic polyurethaneOxygen

The invention relates to a flame retardant thermoplastic polyurethane elastomer (TPU) and a preparation method thereof. The flame retardant TPU comprises the following components in parts by mass: 70-90 parts of TPU, 9.7-29.875 parts of intumescent flame retardants and 0.025-3.75 parts of ionic liquids. The intumescent flame retardant TPU composite material is prepared by adopting the composite intumescent flame retardant. The vertical flame test level of the composite material is increased to V-0. A dense intumescent char layer is formed on the specimen surface of the composite material, so that the composite material has good flame retardant effects. Under the condition of small additive amount of the ionic liquids, the oxygen index of the ionic liquid and intumescent flame retardant synergistic flame retardant TPU composite material is increased, so that the vertical flame performance embodying molten drop resistance is obviously improved, the heat release rate and total heat release can be well reduced, the charring performance during flaming is improved and the composite material has certain effects on smoke suppression.

Owner:盛鼎高新材料有限公司

Preparation method of graphene modified flame-retardant waterborne polyurethane coating and adhesive

ActiveCN111117467ALarge specific surface areaImprove flame retardant propertiesFireproof paintsNon-macromolecular adhesive additivesDibutyl tin dilaurateCyanate ester

The invention relates to a preparation method of a graphene modified flame-retardant waterborne polyurethane coating and adhesive. The preparation method comprises the following steps: preparing a flame-retardant MOFs compound from MOFs, preparing a flame-retardant MOFs dispersion liquid from the flame-retardant MOFs compound, and finally preparing the polyurethane coating and adhesive from polymer polyol, isocyanate, dibutyltin dilaurate and the flame-retardant MOFs dispersion liquid. The effect of improving the two important indexes of flame retardance and static prevention of the polyurethane coating and the adhesive is outstanding.

Owner:中炬高新材料股份有限公司

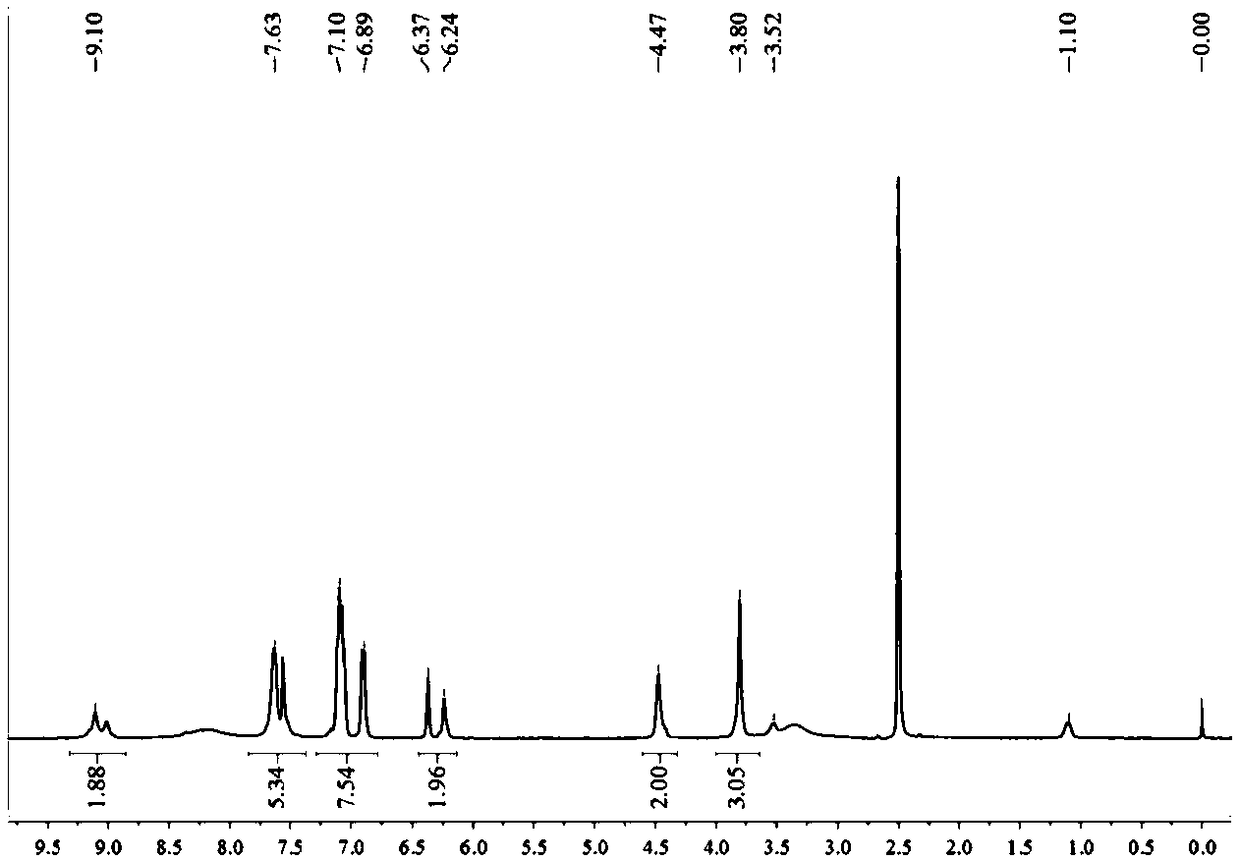

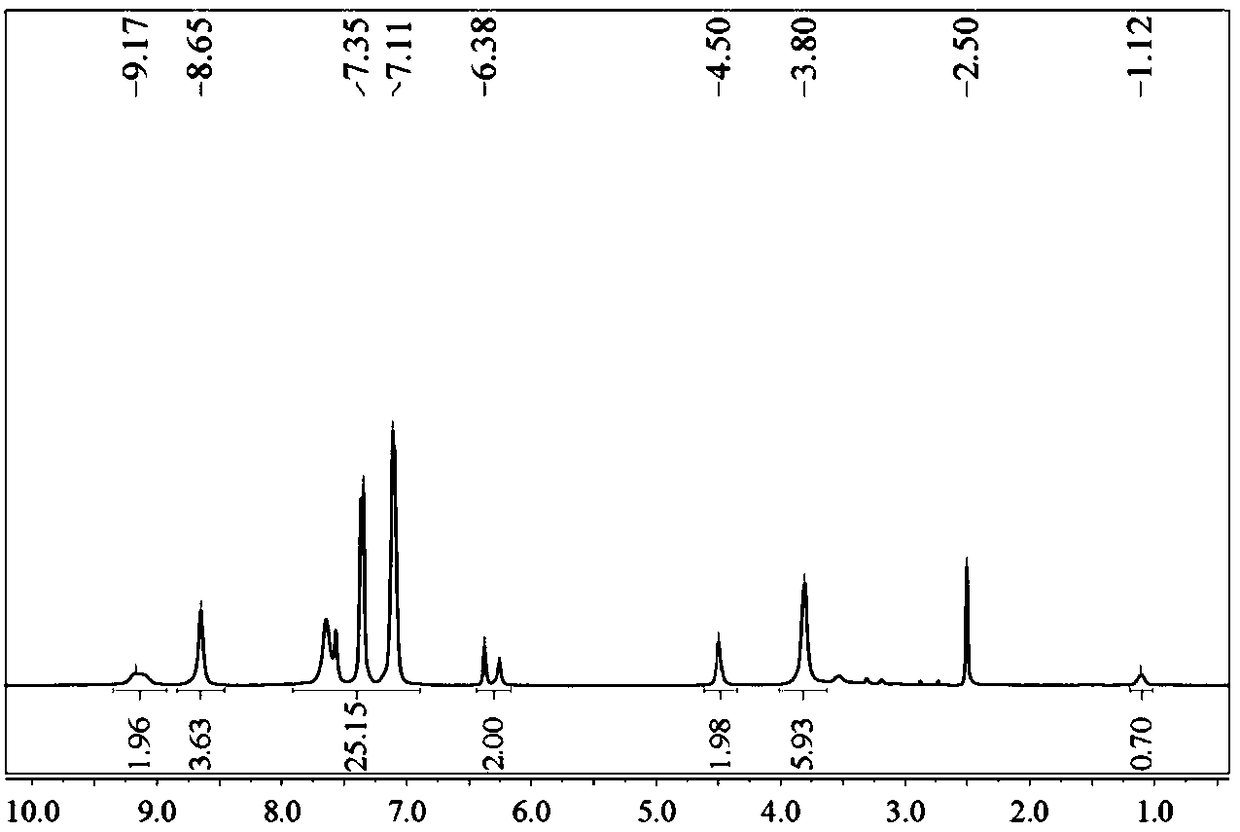

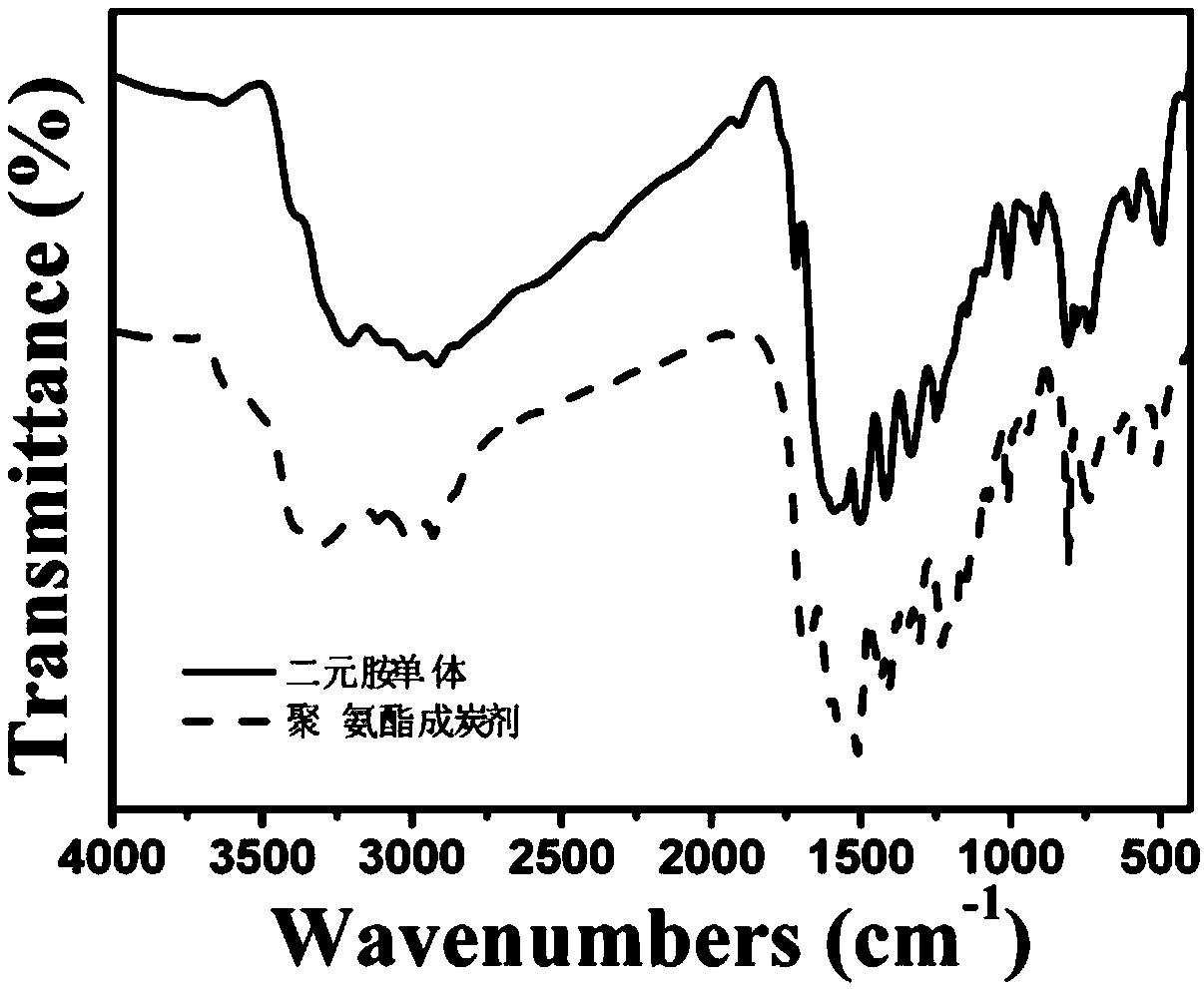

Triazine polyurethane carbon-forming agent containing furan ring side group and synthesis method thereof

ActiveCN109251293AHigh char formationPromote degradationBulk chemical productionFuranSynthesis methods

The invention discloses a triazine polyurethane carbon-forming agent containing a furan ring side group and a synthesis method thereof. According to the invention, a diamine or diol compound containing a furan ring side group and a triazine ring is firstly prepared; the diamine or diol compound and diisocyanate are subjected to prepolymerization under the action of a catalyst; and a chain extenderis added for polymerization to form the polyurethane material. The polyurethane material has excellent carbon forming performance. The method for preparing the polyurethane carbon-forming agent has the advantages of less side effect, high yield and simple operation, the introduced bio-based furan compound can help improve degradability of the polyurethane, and the introduction of the furan ring and the triazine ring can significantly improve the carbon forming performance of the polyurethane. Thereby, the polyurethane carbon-forming agent with good thermal stability, excellent carbon formingperformance and high residual carbon content is obtained, and the polyurethane carbon-forming agent has a good development prospect in the polymer intumescent flame retardant system.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

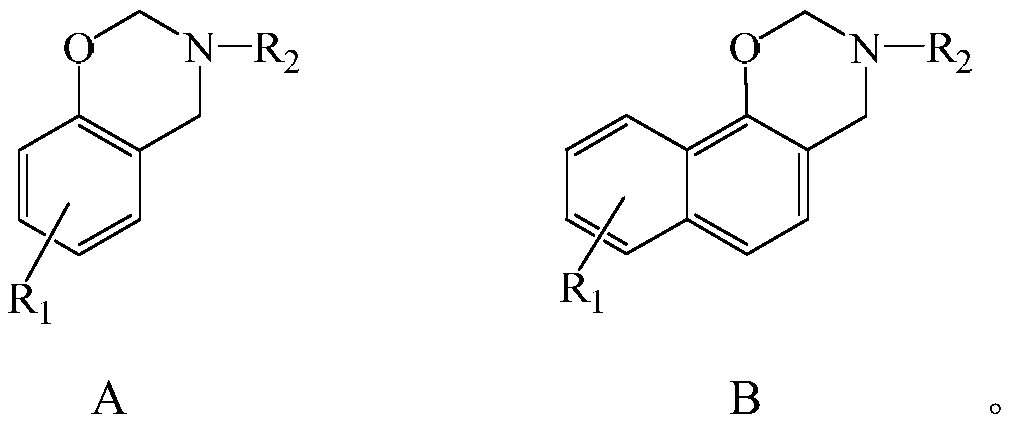

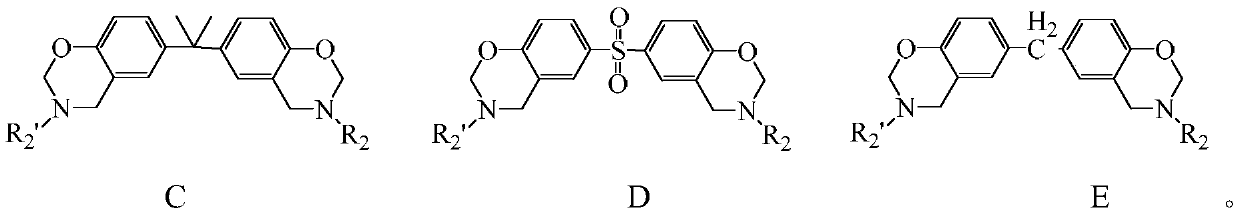

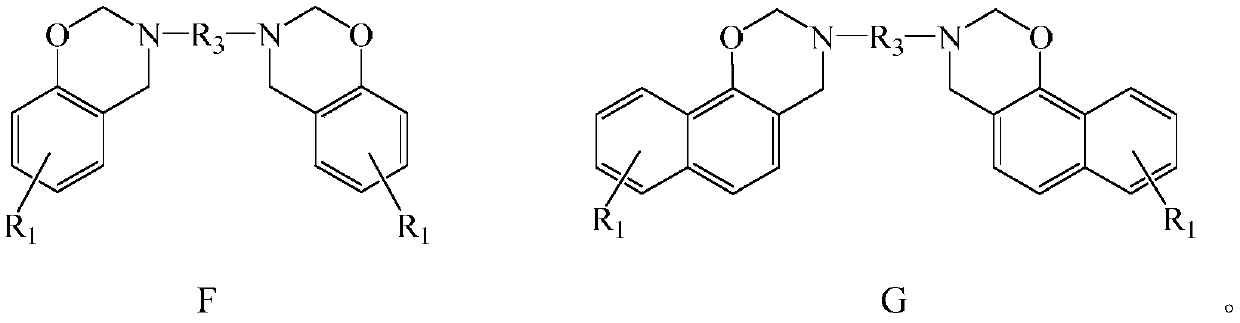

Halogen-free swelling flame-retardant system containing benzoxazine charcoal forming agent and flame-retardant thermoplastic resin of halogen-free swelling flame-retardant system

The invention relates to a halogen-free swelling flame-retardant system containing a benzoxazine charcoal forming agent and flame-retardant thermoplastic resin of the halogen-free swelling flame-retardant system. The halogen-free swelling flame-retardant system is prepared from the following raw materials in percentage by weight: 40%-95% of a phosphorus-nitrogen flame retardant, 2%-50% of the benzoxazine charcoal forming agent, 0-30% of a nitrogen-containing compound and 0-15% of a synergist, wherein the benzoxazine charcoal forming agent is one or more of single-oxazine-ring benzoxazine, bisphenol benzoxazine or diamine double-oxazine-ring benzoxazine. By virtue of the benzoxazine charcoal forming agent in the flame-retardant system, the dispersion of the added flame-retardant system in apolymer base material is promoted, the separation and migration of small-molecular flame-retardant components are inhibited, more stable charcoal layers can be generated in the combustion process, and the thermal insulation and the oxygen insulation are realized, so that the flame-retardant system has relatively high flame-retardant efficiency. Besides, a proper amount of silane structures are introduced into benzoxazine molecules, so that the flame-retardant system has the phosphorus-nitrogen-silicon ternary synergetic flame-retardant effect and can play a role of a silane coupling agent, and the comprehensive performance of a composite material is further improved.

Owner:HENAN UNIVERSITY

Preparation method of compound microcapsule-coated ammonium polyphosphate master batch

InactiveCN105086455AHigh char formation rateImprove flame retardant performanceEpoxyFORMALDEHYDE SOLUTION

The invention discloses a preparation method of a compound microcapsule-coated ammonium polyphosphate master batch. The preparation method comprises that melamine and a formaldehyde solution form a performed polymer, the performed polymer is coated with ammonium polyphosphate in an ethanol aqueous solution, the ammonium polyphosphate-coated performed polymer and epoxy-modified organic silicone resin are mixed and pressed to form the master batch by polymerization. The preparation method improves a processing temperature, widens an application range, utilizes organosilicon to improve a char yield and promotes flame retardation effects.

Owner:ZIBO FUEN CHEM TECH CO LTD

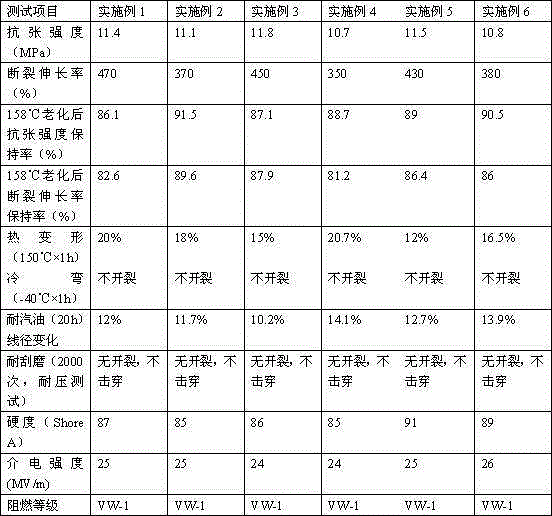

Irradiation cross-linked thermoplastic polyester elastomer cable material and cable production method

InactiveCN105199329AImproved drip resistanceHigh char formationPlastic/resin/waxes insulatorsPolyesterVinyl acetate

The invention discloses an irradiation cross-linked thermoplastic polyester elastomer cable material. The irradiation cross-linked thermoplastic polyester elastomer cable material comprises, by weight, 100 parts of thermoplastic polyester elastomer (TPEE), 15-40 parts of ethylene-vinyl acetate copolymer (EVA), 50-80 parts of a fire retardant, 0.3-2 parts of a lubricant, 0.3-3 parts of an antioxidant and 0.1-1 part of an ultraviolet light stabilizer. The invention also discloses a method for producing cables through using the cable material. Cable products produced by using the cable material have excellent room temperature and high temperature mechanical performances; irradiation crosslinking realizes good flame retardation performance on the premise of meeting environmental protection, and also realizes cost reduction; and the cable material can reach 125DEG C temperature resistance level, has excellent scratch and wear resistance, and can be widely used in the fields of automobile wires and high and low temperature resistant cables.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

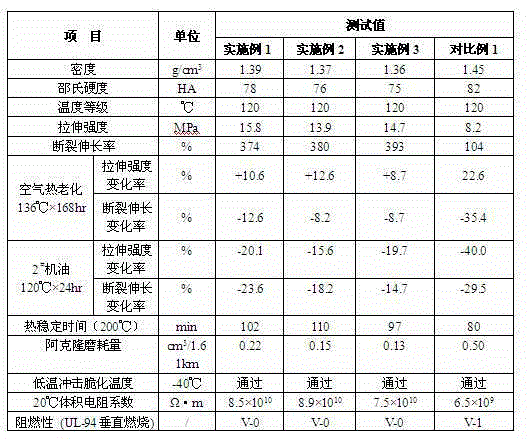

Environment-friendly high and low temperature resistant and oil resistant flame-retardant nano-composite thermoplastic elastomer and preparation process thereof

The invention provides an environment-friendly high and low temperature resistant and oil resistant flame-retardant nano-composite thermoplastic elastomer and a preparation process thereof. The nano-composite thermoplastic elastomer is prepared from the following components in parts by weight: 60 to 75 parts of NBR (Nitrile-Butadiene Rubber) nano-composite particles, 25 to 40 parts of PVC (polyvinyl chloride) premolding powder, 10 to 15 parts of modifier ABS (Acrylonitrile Butadiene Styrene), 10 to 15 parts of first flame retardant, 5.0 to 10 parts of second flame retardant, 0.8 to 1.2 parts of activating agent, 0.2 to 0.4 part of vulcanizing agent, 0.8 to 1.2 parts of anti-aging agent, 0.5 to 1.0 part of accelerator, 0.3 to 0.5 part of ultraviolet light absorber and 1.0 to 2.0 parts of processing aid. The thermoplastic elastomer provided by the invention is green and environment-friendly, resistant to ozone and excellent in mechanical property, high and low temperature resistance, oil immersion resistance and flame retardance and can be used for sheaths and shoes of flame-resistant, oil-resistant and heat-resistant flexible wires, elastomer cables, oil-resistant heavy flexible wires, movable cables and the like, as well as oil pipes and the like.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

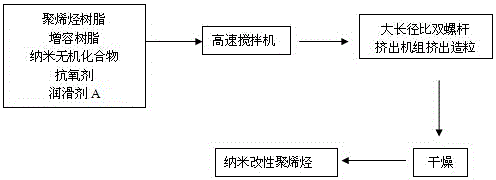

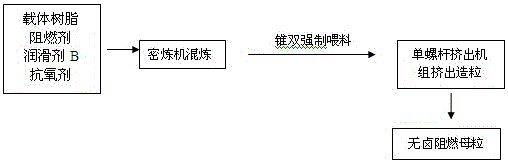

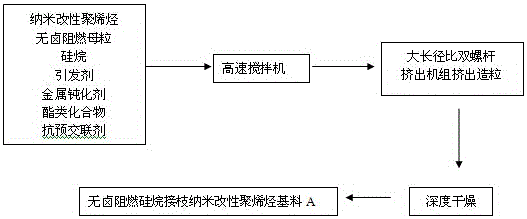

Anti-pre-crosslinking rapid-solidification low-smoke zero-halogen flame-retardant silane crosslinking nano-modified polyolefin composition

ActiveCN105153621AImprove dispersion uniformityGood dispersionPlastic/resin/waxes insulatorsLow smoke zero halogenMasterbatch

The invention relates to an anti-pre-crosslinking rapid-solidification low-smoke zero-halogen flame-retardant silane crosslinking nano-modified polyolefin composition. The composition is prepared from, by weight, 100 parts of zero-halogen flame-retardant silane grafted nano-modified polyolefin matrixes A and 4-6 parts of catalyst master batches B. By the adoption of a fractional step method, a preparation method includes the steps that the zero-halogen flame-retardant silane grafted nano-modified polyolefin matrixes A and the catalyst master batches B are prepared and then mixed evenly, wherein the zero-halogen flame-retardant silane grafted nano-modified polyolefin matrixes A are formed by mixing nano-modified polyolefin, zero-halogen flame-retardant master batches, a silane grafted system and anti-pre-crosslinking agents, and the catalyst master batches B are formed by mixing carrier resin polyolefin and a rapid catalyst system. By the application of the method, the anti-pre-crosslinking low-smoke zero-halogen flame-retardant silane crosslinking nano-modified polyolefin composition capable of achieving rapid crosslinking under natural conditions can be prepared, the performance of the composition meets using requirements, and particularly, the composition can also be used for producing heat-resistant flame-retardant pipes when serving as a low-smoke zero-halogen flame-retardant silane crosslinking polyolefin cable material.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Special anti-wrinkle flame retardant finishing agent of wool hat

InactiveCN107938356AGuaranteed StrengthAvoid yellowingBiochemical fibre treatmentAnimal fibresWrinkle skinRare earth

The invention discloses a special anti-wrinkle flame retardant finishing agent of a wool hat. The finishing agent comprises the following raw materials in parts by weight: 20-38 parts of waterborne polyurethane emulsion, 2-10 parts of organic silicon emulsion, 1-5 parts of sodium cyanate, 3-8 parts of hydrogen peroxide, 1-5 parts of dicyandiamide, 2-10 parts of chitosan, 3-10 parts of mixed plantextracting solution, 2-10 parts of beta-cyclodextrin, 0.1-0.8 parts of cyclodextrin, 1-5 parts of organic acid, 1-4 parts of oxidized alginate, 2-10 parts of oxidized sodium carboxymethyl cellulose, 2-10 parts of rare earth oxide sol, 1-4 parts of hexa(4-aminophenoxy)cyclotriphosphazene and 1-5 parts of a hydrophilic surfactant. The special anti-wrinkle flame retardant finishing agent provided bythe invention has the advantage that the wool hat can be endowed with excellent wrinkle resistance and fire retardance.

Owner:安徽中福毛纺制帽有限公司

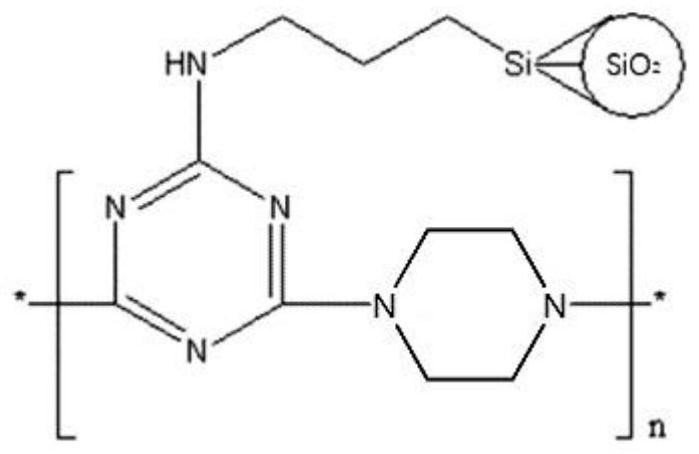

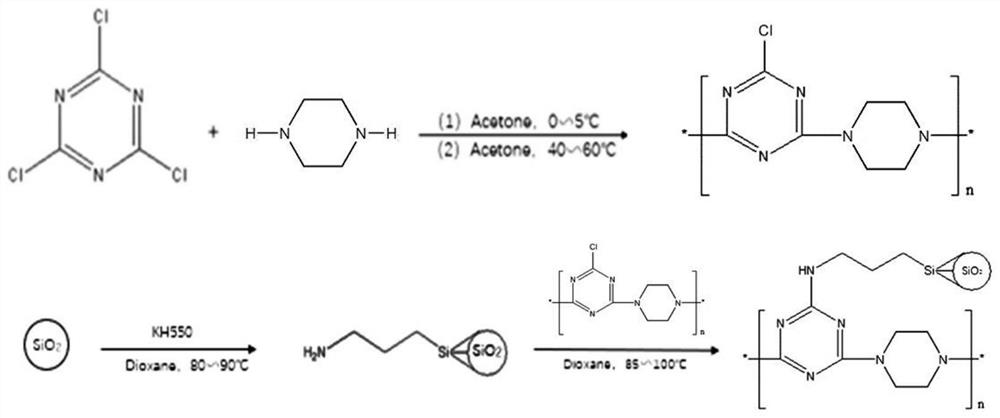

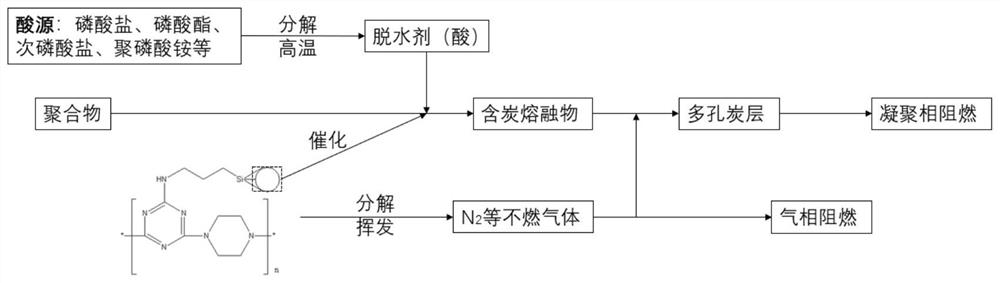

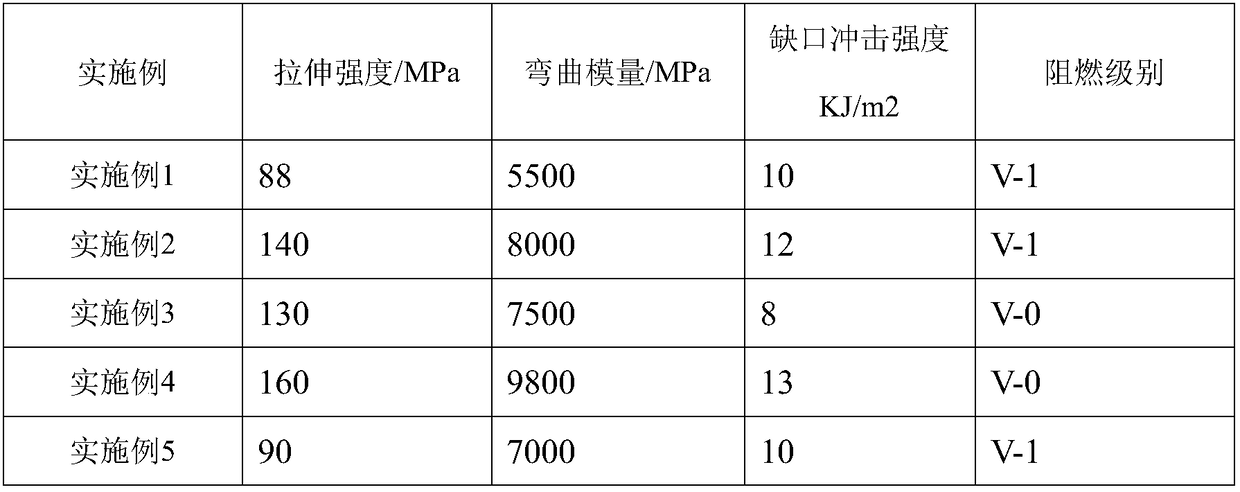

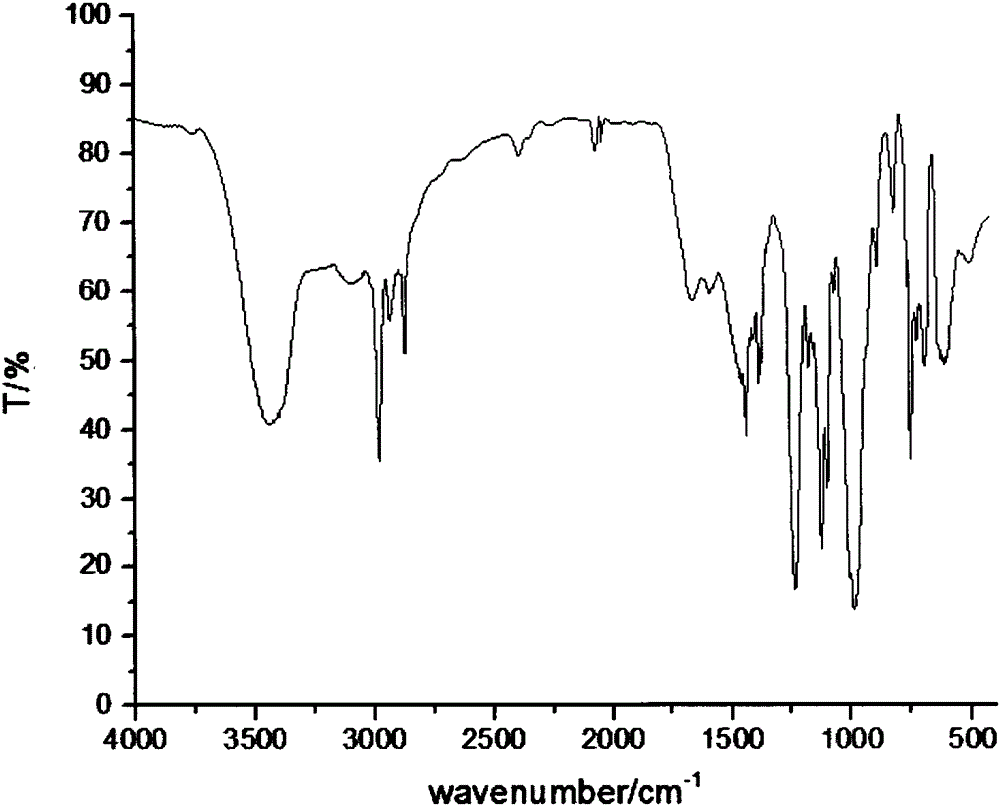

Nano-silica modified macromolecular flame-retardant charring agent and preparation method thereof

InactiveCN112321895AWith flame retardant efficiencyMigration resistantPolymer scienceTriazine derivative

The invention relates to the technical field of macromolecular flame-retardant charring agents applied to polymer materials, and discloses a nano-silica modified efficient charring agent and a preparation method thereof. According to the charring agent, through nucleophilic substitution, two chlorine atoms on cyanuric chloride are sequentially substituted by piperazine at different temperatures toform a linear macromolecular triazine intermediate with piperazine as a chain extender; and then a temperature is raised, and chlorine on the side group of the intermediate is substituted by substituting piperazine and cyanuric chloride with nano-silica and gamma-aminopropyltriethoxysilane which are connected through a hydroxyl group. The charring agent has the characteristics of good charring properties, high molecular weight, migration resistance, high temperature resistance, no influence on the mechanical properties of a matrix material and the like, solves the problem that a carbon layerwith good compactness and complete morphology cannot be formed due to weak migration resistance of a triazine derivative serving as the charring agent, and can be applied to thermoplastic polyurethaneand polypropylene.

Owner:OECHSLER PLASTIC PROD TAICANG +1

Halogen-free and flame-retardant glass fiber reinforced nylon composite and preparation method thereof

The invention discloses a halogen-free and flame-retardant glass fiber reinforced nylon composite and a preparation method thereof, and belongs to the field of production of halogen-free and flame-retardant reinforced nylon and polyphenylene sulfide composites. The halogen-free and flame-retardant glass fiber reinforced nylon composite is prepared from 25-50 parts of nylon, 5-15 parts of polyphenylene sulfide, 10-30 parts of glass fiber, 15-25 parts of a halogen-free and flame-retardant mixture, 1-5 parts of a compatilizer, 0.1-0.3 parts of an antioxidant and 0.1-0.5 parts of a lubricant by mixing and extruding. The halogen-free and flame-retardant mixture is prepared from flame-retardant red phosphorus masterbatch, melamine cyanurate and organic nano-montmorillonite in a mass ratio being5:1:1-5:3:3 by compounding. By compounding polyphenylene sulfide and nylon, hardness, wear resistance and creep resistance of the material are improved; meanwhile, flame retardance of the composite isimproved by the halogen-free and flame-retardant mixture, oxygen index reaches 28 or higher, and finally, the halogen-free and flame-retardant glass fiber reinforced nylon composite product with excellent combination property is obtained.

Owner:HEFEI GENIUS NEW MATERIALS

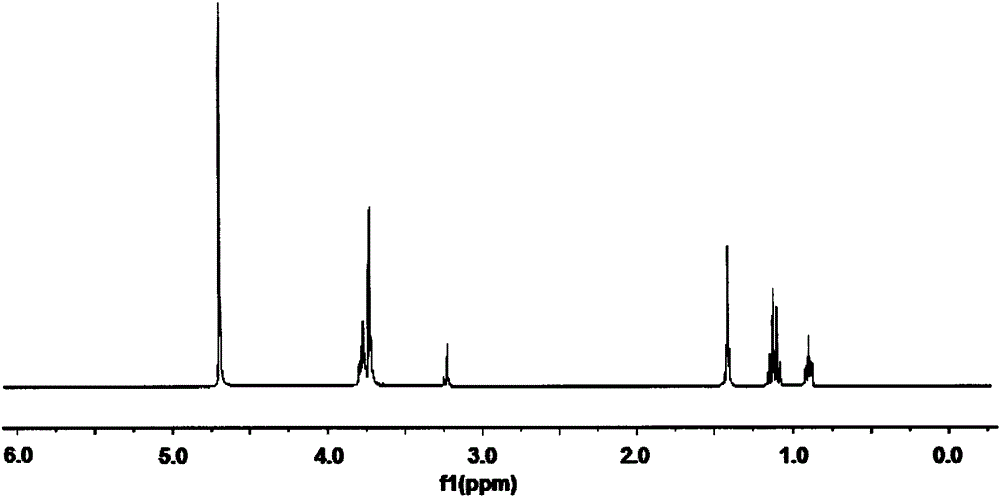

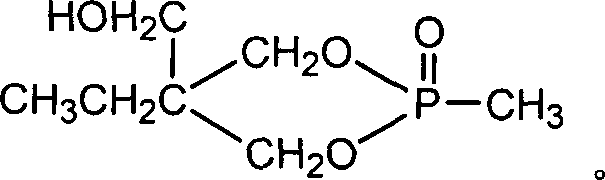

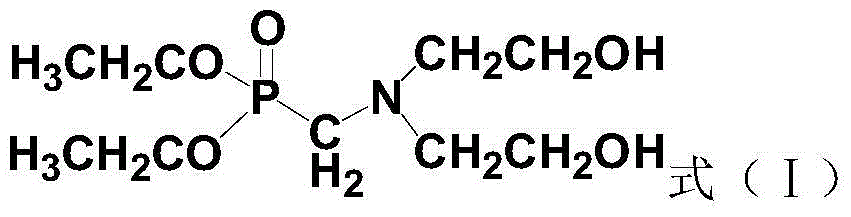

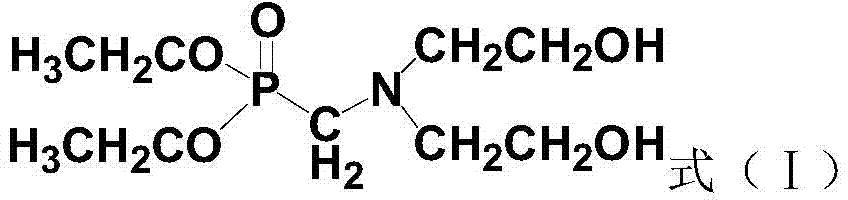

Reactive flame-retardant organic phosphonate compound and preparation method thereof

ActiveCN105218859AHigh char formationStable C-P bondGroup 5/15 element organic compoundsEpoxyPolyester

The invention relates to a reactive flame-retardant organic phosphonate compound and a preparation method thereof. Please see the formula of the structure of the compound in the specification. The preparation method includes the steps that air in a reactor with a fractional device is replaced with nitrogen, the molecular ratio of tri-methylol propane to dimethyl methylphosphonate is controlled to be 1:1-1:1.3, then organic solvents and catalysts are added, temperature is raised to 80-140 DEG C, the temperature of the top of a fractional column is controlled to be not higher than 65 DEG C, generated methyl alcohol is fractionated, a fractional reaction is carried out for 5-10 h until no methyl alcohol is generated, and reactive flame retardant organic phosphonate is obtained through purification. The reactive flame-retardant organic phosphonate compound has good plasticity, good in macro-molecular compatibility, suitable for flame retardants of polyester PBT, polyurethane, epoxy resin, unsaturated resin and other materials, low in production cost, small in equipment investment and very good in application and development prospect, raw materials are easy to obtain, and large-scale production is easy.

Owner:SUZHOU UNIV OF SCI & TECH

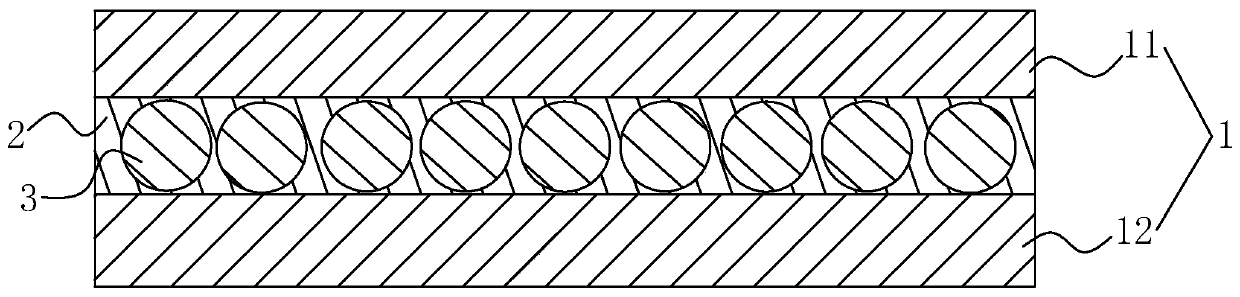

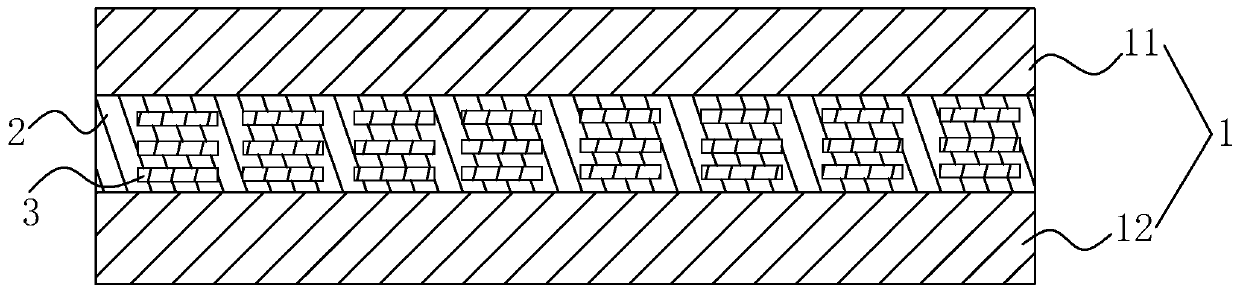

Wear-resistant flame-retardant conveying belt and preparation process thereof

The invention discloses a wear-resistant flame-retardant conveying belt and a preparation process thereof. The wear-resistant flame-retardant conveying belt comprises a cover glue, an adhesive intermediate glue and a framework material, wherein the cover glue comprises an upper cover glue and a lower cover glue; the framework material is a steel wire rope or a flame-retardant polyester fabric; thecover glue comprises the following components: a matrix rubber, sulfur, flame retardant, 10-15 parts of stearic acid, an anti-aging agent, a vulcanization accelerator, a reinforcing filler, paraffinwax, metal oxides, a wear-resistant filler and a dispersing agent. A preparation process of the wear-resistant flame-retardant conveying belt comprises the steps of S1, preparation of the cover glue:(1) preliminary plastication and (2) mixed granulation; S2, preparation of the adhesive intermediate glue: I, preliminary plastication; II, stirring and mixing; III, grinding and defoaming; S3, impregnation and plasticizing of an aggregate material; and S4, extrusion and gluing of the cover glue. The wear-resistant flame-retardant conveying belt disclosed by the invention has the advantages of good wear resistance and excellent flame-retardant effect; in addition, the preparation method disclosed by the invention has the advantages of simple process, low production cost and high work efficiency.

Owner:青岛环球输送带有限公司

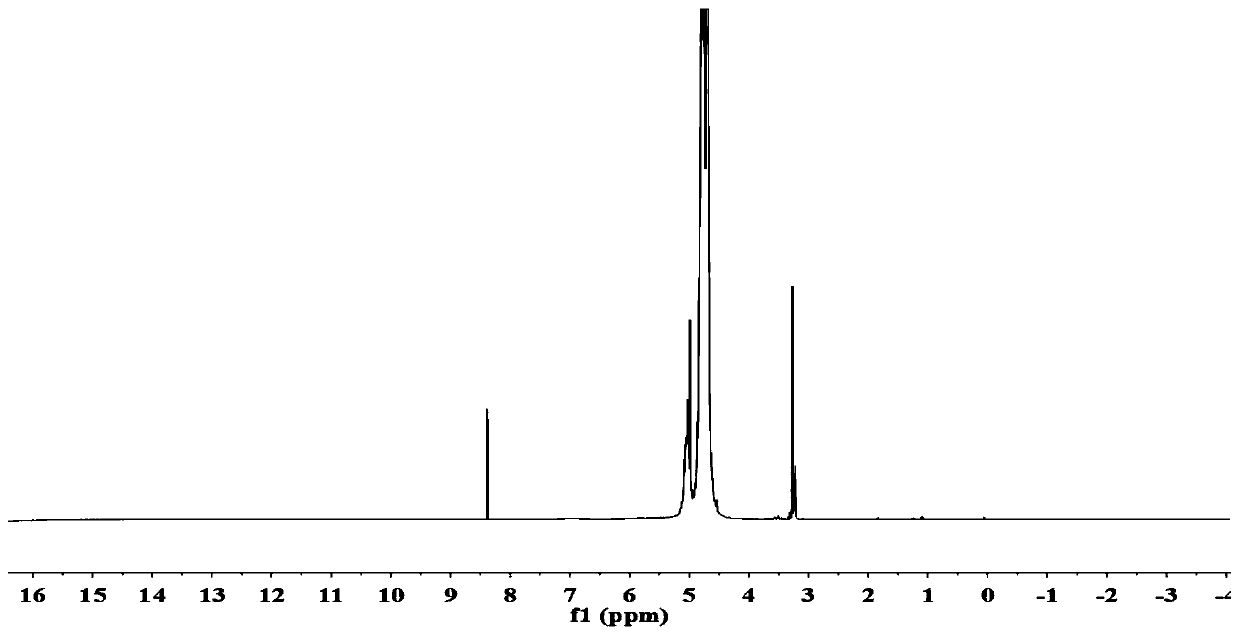

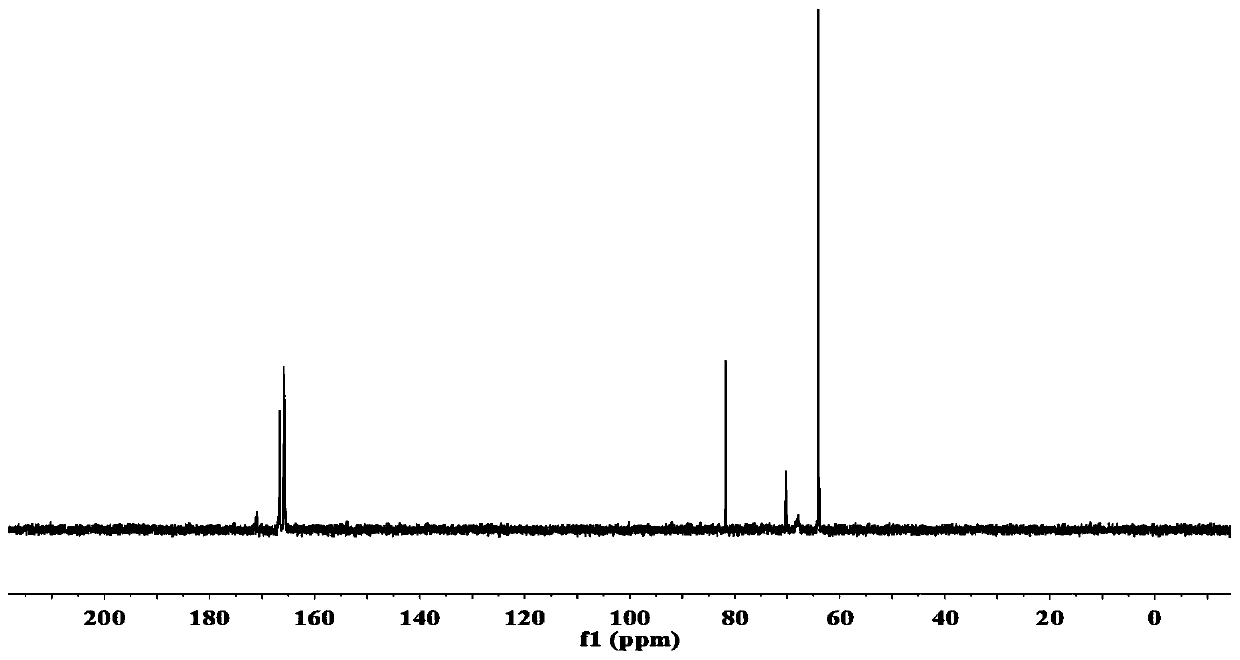

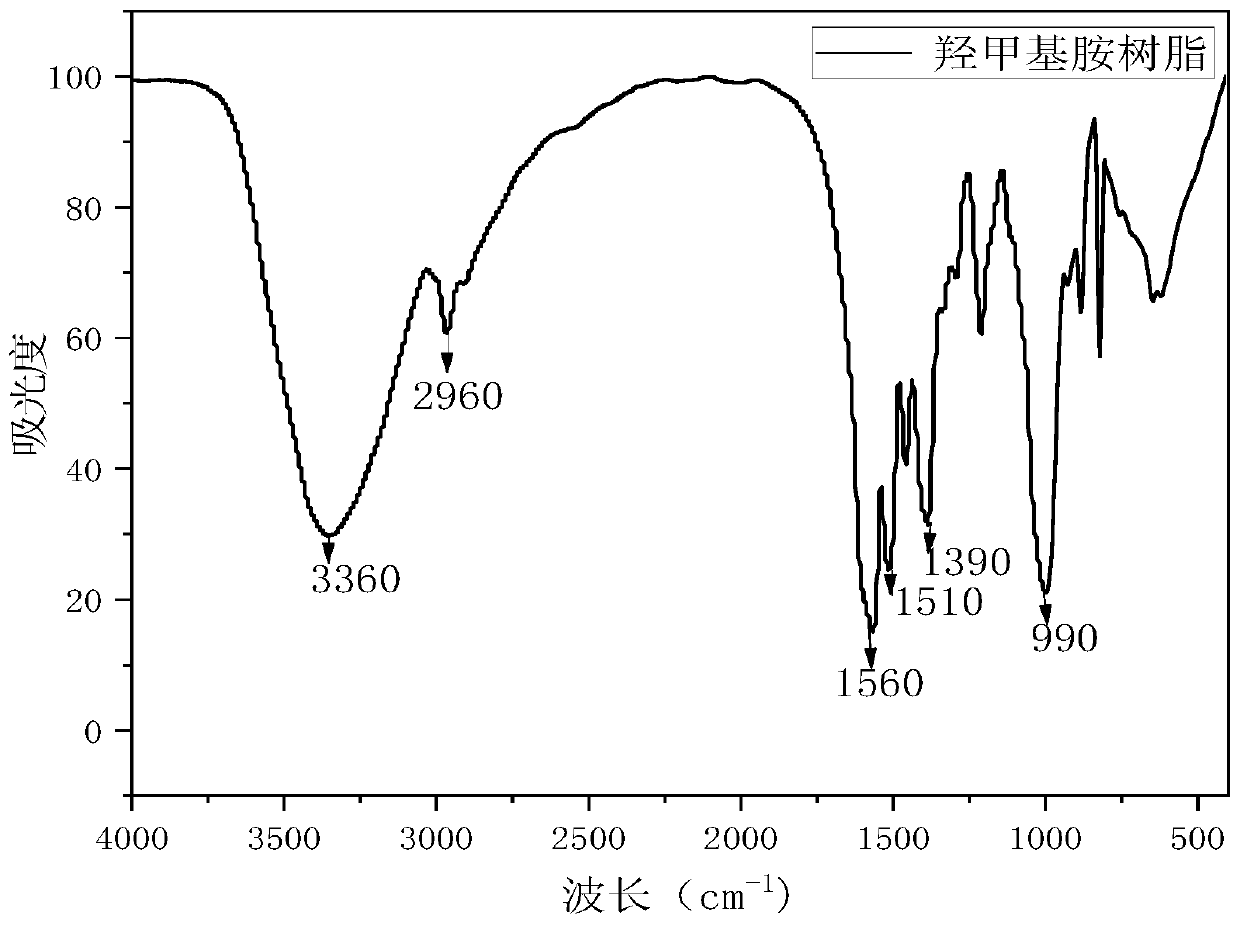

Hydroxymethylated melamino-formaldehyde resin, preparation method and application thereof

InactiveCN110627979AHigh yieldImprove flame retardant performanceReaction temperatureDistilled water

The invention relates to the technical field of fine chemicals and flame-retardant materials, in particular to a preparation method and application of hydroxymethylated melamino-formaldehyde resin powder. The preparation method of the hydroxymethylated melamino-formaldehyde resin includes the steps of: (1) firstly adding melamine and a formaldehyde solution into a reaction container, then adding distilled water to keep the solid content of the system at 10-50%, then controlling the reaction temperature at 40DEG C-95DEG C, and carrying out stirring reaction for 0.5-6h; (2) at the end of the reaction, freezing the reaction container containing the reaction solution to convert the reaction solution into a solid reactant; and (3) finally, drying the obtained solid reactant to obtain the hydroxymethylated melamino-formaldehyde resin powder. The hydroxymethylated melamino-formaldehyde resin prepared by the preparation method of the hydroxymethylated melamino-formaldehyde resin provided by the invention has the characteristics of high hydroxyl content and high yield.

Owner:XIHUA UNIV

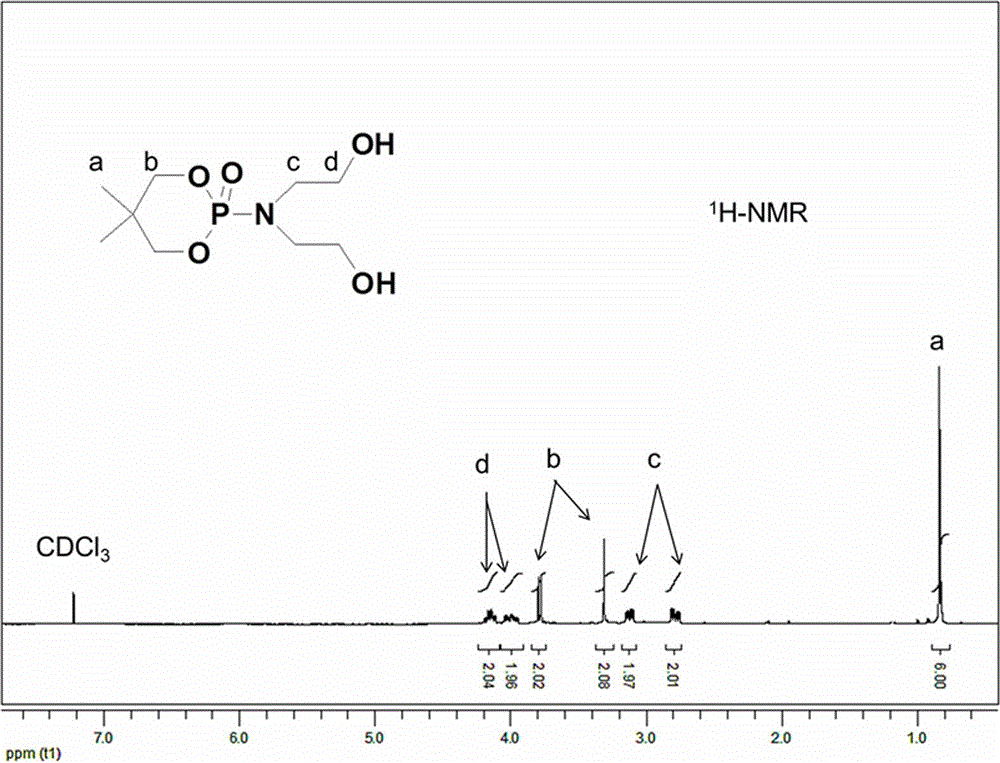

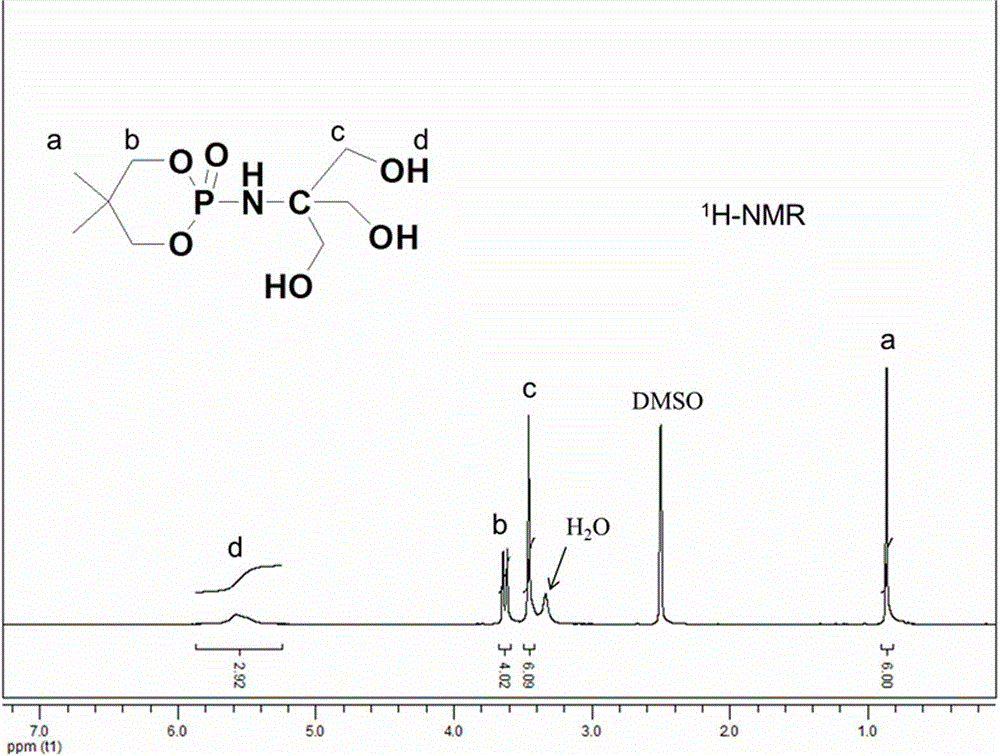

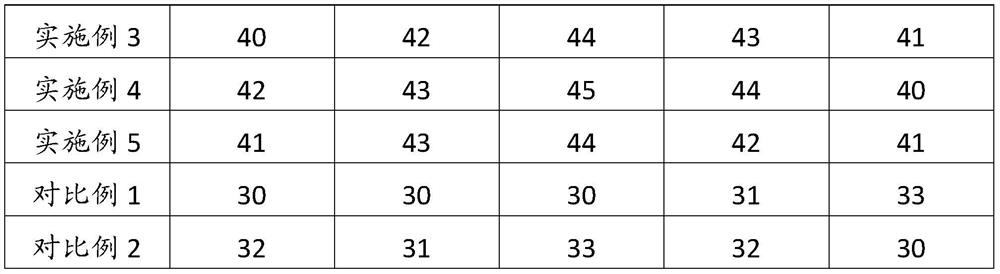

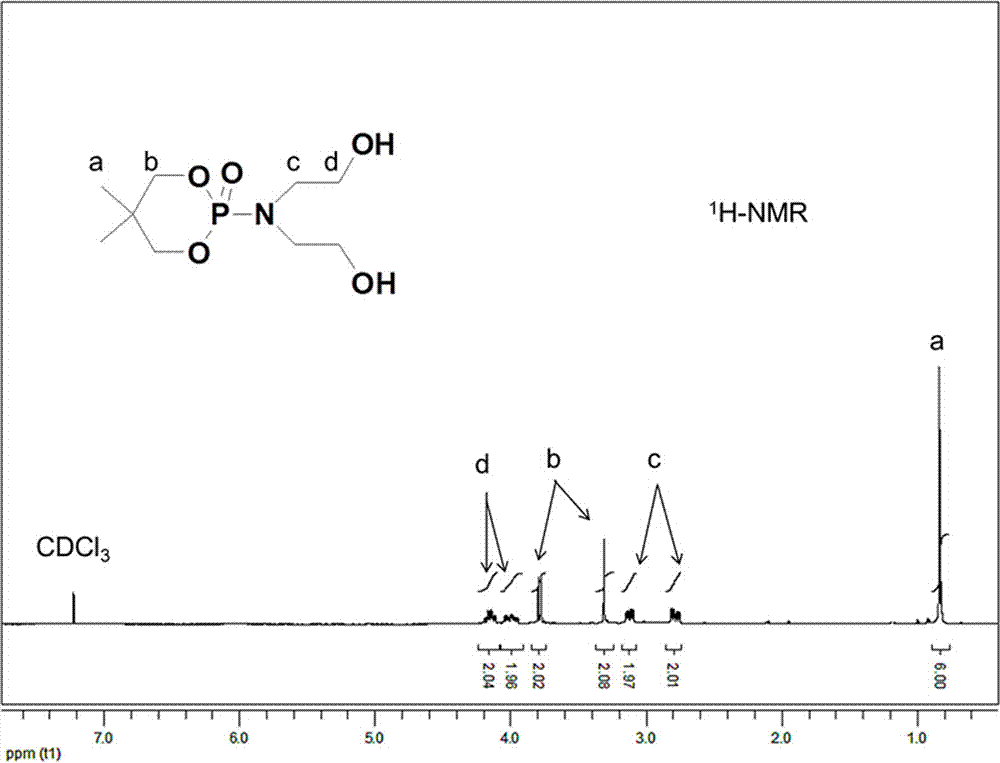

Intumescent polyols as well as preparation method and application thereof

InactiveCN104892676AImprove thermal stabilityHigh char formationGroup 5/15 element organic compoundsMechanical propertyCompatibilization

The invention relates to the field of flame retardants for rigid polyurethane foams and in particular relates to intumescent polyols as well as a preparation method and application thereof. Compared with the prior art, the invention has the following beneficial effects: (1) the two types of novel intumescent polyols integrate an acid source, a carbon source and a gas source, are very good in thermal stability and higher in carbon forming property, have very high phosphorus and nitrogen contents, and can endow a matrix with good flame retardant property; (2) the two types of novel intumescent polyols contain polyhydroxyl active groups, and can react with a raw material namely isocyanate for preparing polyurethane foams to become a part of macromolecule chains of the polyurethane foams, so that the problem that a common flame retardant causes damages to the mechanical properties of a material due to poor compatibility with the matrix can be solved, and the matrix material can keep the flame retardant property for a long time; and (3) the intumescent polyols provided by the invention are simple in preparation process, mild in reaction condition and suitable for industrial production.

Owner:ZHONGBEI UNIV

Halogen-free flame-retardant heat-resistant weather-resistant polypropylene nano composite insulating material for automobile wire and preparation method thereof

ActiveCN105219006AHigh strengthImprove wear resistancePlastic/resin/waxes insulatorsInsulated cablesPolypropyleneExtrusion Granulation

The invention relates to a halogen-free heat-resistant weather-resistant polypropylene nano composite insulating material for an automobile wire and a preparation method thereof. The composite insulating material is prepared from 50-60 parts of polypropylene nano compounds and 50-60 parts of halogen-free flame-retardant master batches. The polypropylene nano compounds are prepared from, by weight, 100 parts of polypropylene, 10-15 parts of polypropylene polar monomer grafts, 4.0-8.0 parts of nano inorganic compounds and the like. The halogen-free flame-retardant master batches are prepared from, by weight, 100 parts of organic hydroxide, 20-30 parts of carrier resin and the like. By the adoption of the binary technology, the polypropylene nano compounds and the halogen-free flame-retardant master batches high in flame-retardant agent content are prepared, the polypropylene nano compounds and the halogen-free flame-retardant master batches are mixed, extruded and granulated through a double-screw extruding machine, and the nano composite insulating material is obtained. The material is low in cost and environmentally friendly, integrates excellent physical and mechanical performance and electric performance and good extruding processability, is suitable for insulating processing of the automobile original wire, and can be used for insulating wrapping of communication cables, logging cables and oil-submerged pump cables.

Owner:TONGJI UNIV

Flame-retardant PTT

The present invention discloses a flame-retardant PTT, which comprises the following components in mass percentage: 80% to 95% of PTT, 2% to 8% of phosphorus-containing monomers, 1% to 5% of organic montmorillonite, 2% to 6% of aliphatic polyether, 0.1% to 0.5% of trimethyl phosphate, and 0.1% to 0.5% of antioxidant. The phosphorus-containing monomers are composed of 2-carboxyl ethyl alkyl phosphonic acid or 2-carboxyl ethyl phenyl phosphinic acid. The aliphatic polyether is composed of one component selected from polyethylene glycol, polytetrahydrofuran and polypropylene oxide, wherein the molecular weight of the aliphatic polyether is 1000-5000. According to the invention, the phosphorus-containing monomers are added for realizing the flame-retardant modification, and the organic montmorillonite is added for synergistically improving the char-forming characteristics and enhancing the droplet-proof performance. Therefore, the flame-retardant PTT is excellent in halogen-free, droplet-proof and flame-retardant performance, good in spinnability, excellent in mechanical property, simple in preparation process, low in cost and easy in popularization and application.

Owner:王妮娜

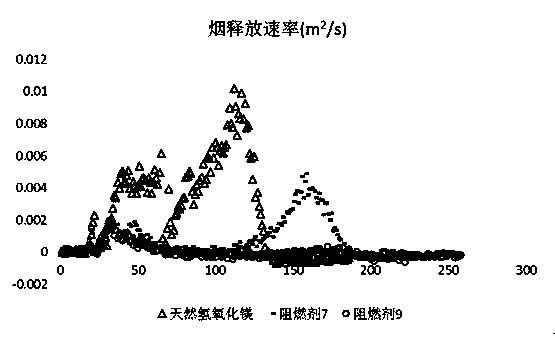

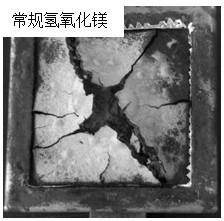

Composite hydroxide smoke suppression type flame retardant as well as preparation method and application thereof

The invention discloses a composite hydroxide smoke suppression type flame retardant as well as a preparation method and application thereof. Calcium hydroxide is used as a synergistic flame retardantto be chemically bonded and coupled with magnesium hydroxide to form a stable chemical structure, the flame retardant can be used in polymer products, the smoke density of the flame-retardant polymeris obviously reduced, and the flame retardance and smoke suppression performance of the flame-retardant polymer are improved.

Owner:江苏艾特克阻燃材料有限公司

Composite flame retardant for low-density polyethylene

The invention discloses a composite flame retardant for low-density polyethylene. The composite flame retardant is prepared from the following raw materials in parts by weight: 12-17 parts of antimonytrioxide, 37-50 parts of decabromodiphenyl ethane and 33-50 parts of titanate coupling agent NDZ-201 (modified bentonite). A preparation method of the titanate coupling agent NDZ-201 (modified bentonite) comprises the following steps of: according to the weight parts, adding 20 parts of sodium-based bentonite into distilled water, wherein the liquid-solid ratio is 20-30; rising the temperature to80-100 DEG C, then stirring and dispersing uniformly, adding 0.8-1.2 parts of titanate coupling agent NDZ-201, stirring for 100-140 minutes at constant temperature, after reaction is ended, filteringwhile being hot, placing in a drying oven to dry at temperature of 95 DEG C, cooling, crushing, treating by a 200-mesh sieve, and obtaining the titanate coupling agent NDZ-201 (modified bentonite). The composite flame retardant disclosed by the invention has the beneficial effects that under the condition guaranteeing the tensile strength and the impact strength of a low-density polyethylene substrate, the problems of serious melt dripping and large smoke generation amount when in burning of the low-density polyethylene are solved.

Owner:GUANGXI UNIV +1

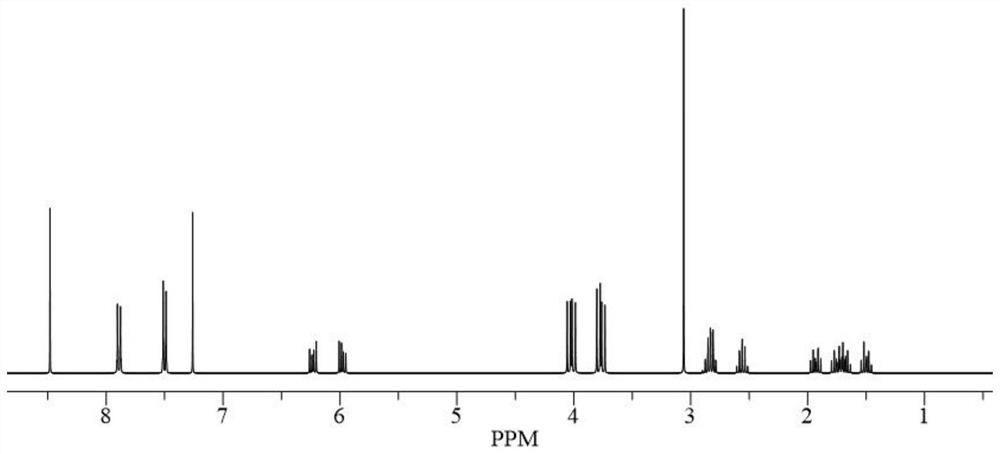

Preparation method of poly(ether-ether-ketone) resin containing ferrocene/DOPO group and crosslinked alkenyl

InactiveCN109851729AAvoid cross-linking reactionsHigh glass transition temperaturePoly ether ether ketoneOrganic solvent

The invention relates to a preparation method of a poly(ether-ether-ketone) resin containing a ferrocene / DOPO group and crosslinked alkenyl. The preparation method comprises following steps: adding acompound liquid containing ferrocene, difluorobenzophenone (DFBP), and a catalyst (I) into an organic solvent (I) according to a certain mole ratio, carrying out secondary reactions under the action of N2 flow; then adding a mixed solution of allyl containing bisphenol and DFBP, raising the temperature to carry out reactions, pouring the reaction liquid into water, carrying out precipitation, filtering, and drying to obtain the poly(ether-ether-ketone) resin. A bisphenol unit containing ferrocene and a DOPO group into the poly(ether-ether-ketone) resin to overcome the problems that the productof industrial NaOH salt forming reactions can be degraded easily, the reactions are difficult to control, and alkali pollution happens. An allyl bisphenol monomer is introduced into the resin to avoid crosslinking reactions of double bonds after long time high temperature reactions. A new approach and a new method are provided for obtaining a flame retardant resin system having a strong flame retardant performance and excellent properties.

Owner:FUJIAN NORMAL UNIV

Preparation method of superacid flame-retardant PET resin master batch

The invention discloses a preparation method of superacid flame-retardant PET resin master batch. The preparation method comprises the following steps: (1) adding talcum powder into water, mixing, stirring to obtain talcum powder suspension, continuously adding ammonia water and sodium polyacrylate to obtain modified talcum powder; (2) adding the modified talcum powder, samarium nitrate and iron nitrate into water to obtain metal ion modified talcum powder; (3) then slowly adding sulfuric acid into the metal ion modified talcum powder to obtain a superacid flame-retardant agent; and (4) mixingthe superacid flame-retardant agent, PET resin and a lubricating agent, adding into a high-speed mixer, uniformly mixing, extruding and granulating by adopting a double-screw extruder to obtain the superacid flame-retardant PET resin master batch. The preparation method of the superacid flame-retardant PET resin master batch provided by the invention is easy in obtaining raw materials and low incost; and the prepared superacid flame-retardant PET resin master batch is excellent in various mechanical performance and good in flame-retardant effect.

Owner:浙江龙泉泓业新材料有限公司

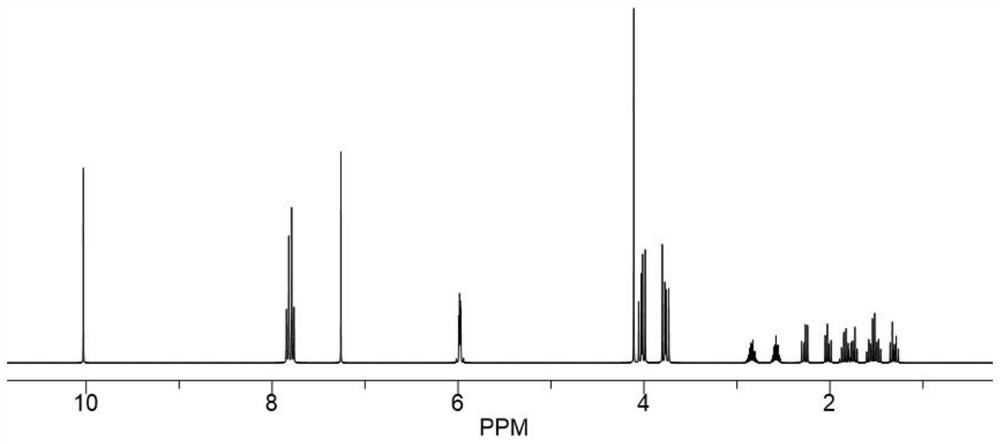

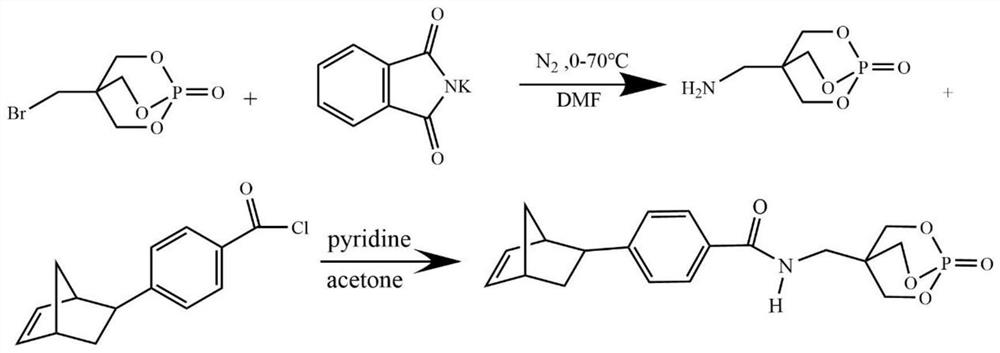

High-modulus, high-impact, wear-resistant and heat-resistant intrinsic flame-retardant polydicyclopentadiene engineering material and preparation method thereof

ActiveCN114790260AImprove flame retardant performancePromote charcoalCell component detailsPolymer sciencePtru catalyst

The invention discloses a high-modulus, high-impact, wear-resistant and heat-resistant intrinsic flame-retardant polydicyclopentadiene engineering material and a preparation method thereof. The polydicyclopentadiene engineering material is prepared by taking dicyclopentadiene, 5-norbornene-2-formamide, 5-norbornene-2-methanol, a norbornene reactive flame retardant containing amido bonds and a caged phosphate structure, a catalyst and an inhibitor as raw materials through a thermally driven self-propagating technology. Wherein the synthesis method of the norbornene reactive flame retardant containing the amido bond and the caged phosphate structure is simple, the yield is high, and the flame retardant property and the mechanical property of a polydicyclopentadiene material can be improved. The limit oxygen index of the prepared polydicyclopentadiene material reaches 42%, the flame retardant rating can reach UL94V-0 level, the impact strength reaches 90kJ / m < 2 >, the shore hardness exceeds 92HD, the tensile strength reaches 120MPa, the heat distortion temperature reaches 197 DEG C, the abrasion loss is reduced by 92%, and the polydicyclopentadiene material has excellent flame retardant property and mechanical property.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

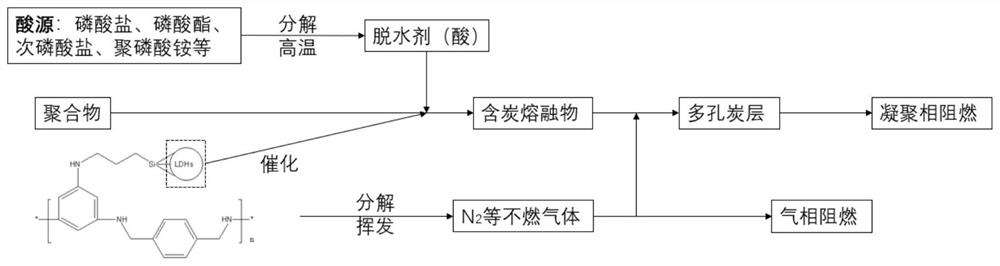

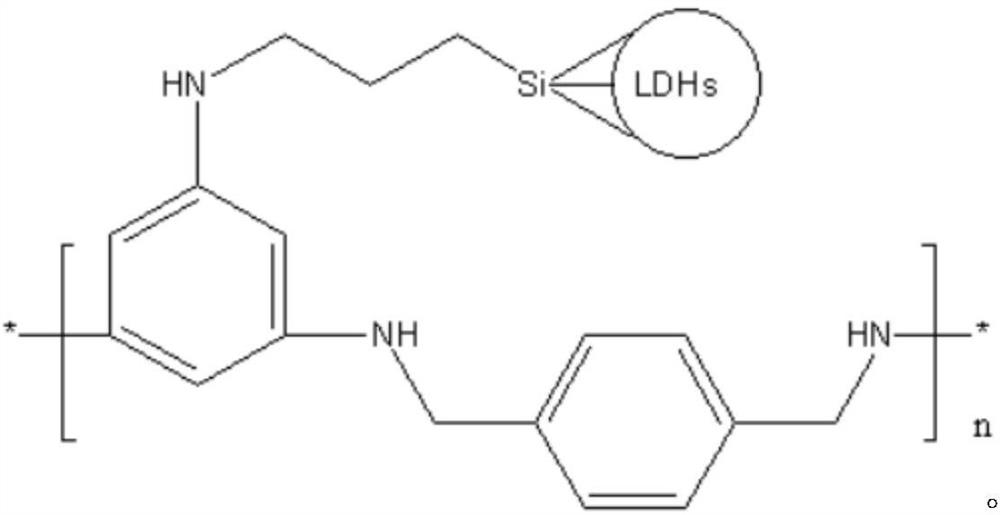

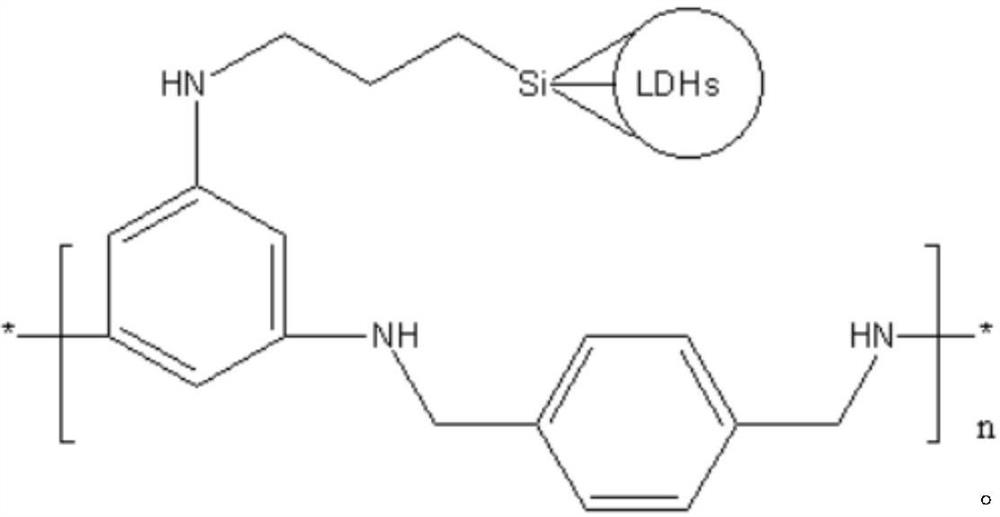

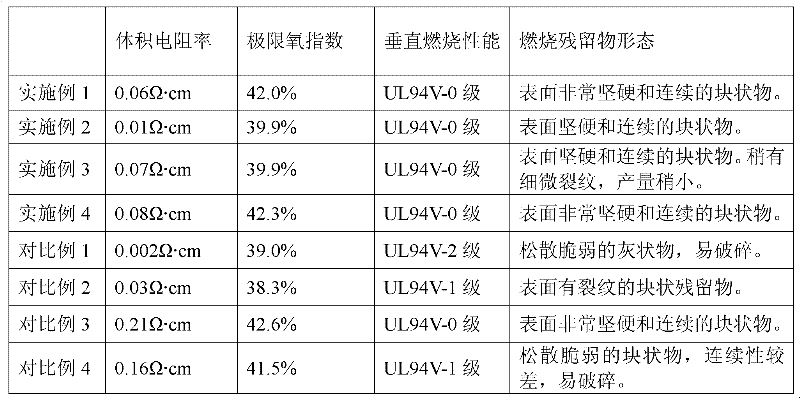

Organic-inorganic hybrid efficient synergistic flame-retardant charring agent and preparation method thereof

The invention relates to the technical field of macromolecular flame-retardant charring agents applied to polymer materials, and discloses an organic-inorganic hybrid efficient synergistic charring agent and a preparation method thereof, and the structural formula of the organic-inorganic hybrid efficient synergistic charring agent is shown in the specification. According to the charring agent, through nucleophilic substitution, two chlorine atoms on cyanuric chloride are sequentially substituted by p-xylylenediamine at different temperatures to form a linear macromolecular triazine intermediate taking p-xylylenediamine as a chain extender, then the temperature is increased, and the step of substituting chlorine on an upper side group of an intermediate is carried out by nano hydrotalcite and gamma aminopropyltriethoxysilane which are connected through hydroxyl according to the same principle as p-xylylenediamine and cyanuric chloride substitution modes. The charring agent has the characteristics of good charring property, high molecular weight, migration resistance, high temperature resistance and no influence on the mechanical properties of a matrix material, solves the problem that the charring property with good compactness and complete morphology cannot be formed due to the anti-migration property of a triazine derivative as the charring agent, and is applied to thermoplastic polyester elastomers.

Owner:EAST CHINA UNIV OF SCI & TECH

Environmental-protection heatproof flame-retardation silicone rubber and preparation method thereof

The invention discloses an environmental-protection heatproof flame-retardation silicone rubber. The heatproof flame-retardation silicone rubber comprises the following components: methyl vinyl silicone rubber, carbon black, carboxyethyl phenyl hypophosphorous acid metal salt, melamine cyanurate, zinc borate, a silane coupling agent, zinc stearate, a plasticizer, sulfur powder, a promoter, and anantioxidant. The invention also provides a preparation method of the environmental-protection heatproof flame-retardation silicone rubber. The method comprises the following steps: adding methyl vinylsilicone rubber, carbon black, carboxyethyl phenyl hypophosphorous acid metal salt, melamine cyanurate, zinc borate, the silane coupling agent, the plasticizer, and the antioxidant in a mixing machine and uniformly mixing the raw materials, adding zinc stearate, sulphur and the promoter and uniformly mixing the materials to prepare a mother material, and adding the mother material in a vulcanizerfor sulfuration to prepare the environmental-protection heatproof flame-retardation silicone rubber. The silicon material of the heatproof flame-retardation silicone rubber has the advantages of highoxygen index, no halogen, safety, environmental protection, and wide application prospect.

Owner:天长市荣盛有机硅科技有限公司

Flaming retarding highly conductive silicon rubber composite material and preparation method thereof

Owner:BEIJING UNIV OF CHEM TECH +1

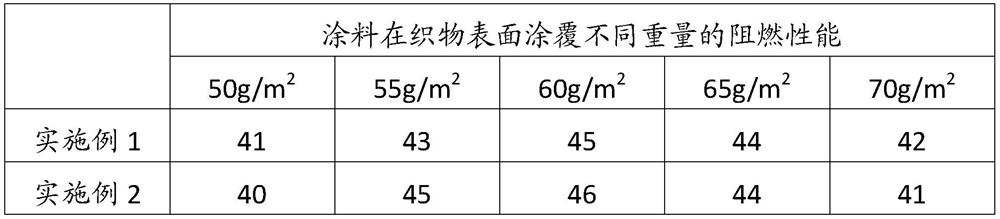

Environment-friendly flame-retardant textile printing coating and preparation method thereof

PendingCN113818257AHigh oxygen indexImprovement intensity is not highTextiles and paperFlame resistanceEnvironmentally friendly

The invention discloses an environment-friendly flame-retardant textile printing coating and a preparation method thereof. The coating comprises an adhesive, a cross-linking agent, a flame retardant and a catalyst; and the coating is prepared from the following components in parts by weight: 45 to 55 parts of the adhesive, 20 to 25 parts of the cross-linking agent, 15 to 20 parts of the flame retardant, 1 to 5 parts of reinforced fibers and 8 to 12 parts of the catalyst. The environment-friendly flame-retardant textile printing coating provided by the invention is simple in composition, environmentally friendly and good in flame retardant property, the oxygen index is remarkably improved, and after the coating is coated on the surface of a fabric, the fabric can have excellent self-extinguishing property, and is low in smoke amount and non-toxic in the combustion process.

Owner:JIANGMEN CAIGE ENVIRONMENTAL PROTECTION TECH IND

Expanded polyol and its preparation method and application

InactiveCN104892676BImprove thermal stabilityHigh char formationGroup 5/15 element organic compoundsFire retardantMechanical property

The present invention relates to the field of flame retardants for rigid polyurethane foams, in particular to an intumescent polyol and its preparation method and application. Compared with the prior art, it has the following beneficial effects: (1) two novel intumescent Type polyol, which integrates acid source, carbon source and gas source, has good thermal stability and higher char-forming performance, and has high phosphorus and nitrogen content, which can endow the matrix with good flame retardant performance; (2) Two kinds of expansion type polyols described in the present invention contain polyhydric active group, can react with the raw material isocyanate of polyurethane foam, become a part in the macromolecular chain of polyurethane foam, not only can solve general flame retardant because of The problem of poor matrix compatibility and damage to the mechanical properties of the material, and the long-term maintenance of flame retardancy of the matrix material; (3) the expansion polyol of the present invention has a simple preparation process and mild reaction conditions, and is suitable for industrial production.

Owner:ZHONGBEI UNIV

Cross-linked phosphorus-containing macromolecular expansion flame-retardant char-forming agent and its preparation method and application

ActiveCN104559204BSolve the problems caused by poor water resistanceImprove solubilityEpoxyPolymer science

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com