Environment-friendly flame-retardant textile printing coating and preparation method thereof

A printing coating and flame retardant technology, which is applied in the field of environmentally friendly flame retardant textile printing coatings, can solve the problems of large smoke generation, thick smoke suffocation, poor flame retardant performance, etc., and achieves increased absorption of small molecules and no emission of harmful substances. , Improve the effect of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

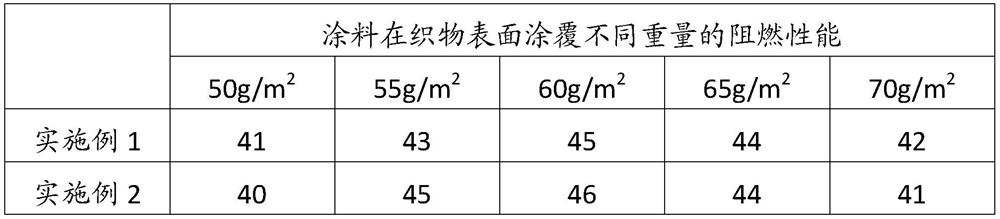

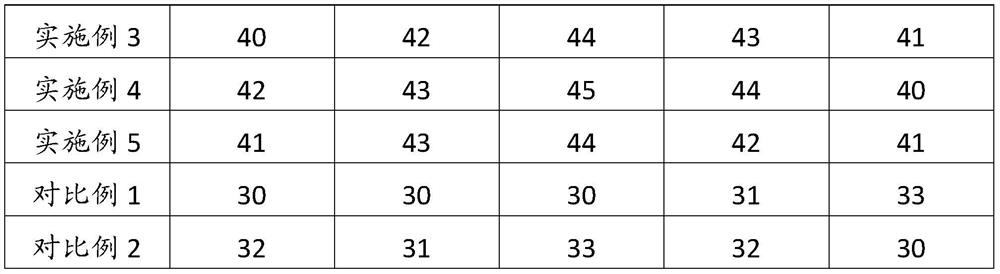

Examples

Embodiment 1

[0024] The coating of the present embodiment comprises 50 parts of polyurethane, 22.5 parts of sodium nitrite, 17.5 parts of ammonium polyphosphate, 10 parts of dibutyl tin oxide, and 2 parts of glass fiber, and the above-mentioned components are uniformly mixed by weight to make the coating of the present invention. coating.

Embodiment 2

[0026] The coating of the present embodiment comprises 55 parts of polyurethane, 20 parts of trisodium phosphate, 20 parts of ammonium polyphosphate, 8 parts of dibutyltin dilaurate, and 4 parts of mineral fiber, and the above-mentioned components are uniformly mixed by weight to make the coating of the present invention. coating.

Embodiment 3

[0028] The coating of the present embodiment comprises 45 parts of polyurethane, 25 parts of disodium hydrogen phosphate, 15 parts of ammonium polyphosphate, 12 parts of tributyltin oxide, and 1 part of carbon fiber, and the above-mentioned components are uniformly mixed by weight to make the coating of the present invention. coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com