High-modulus, high-impact, wear-resistant and heat-resistant intrinsic flame-retardant polydicyclopentadiene engineering material and preparation method thereof

A technology of polydicyclopentadiene and engineering materials, which is applied in the direction of structural parts, battery pack parts, electrical components, etc., can solve the problem that the material cannot achieve high modulus, high impact and wear resistance, and the limiting oxygen index is only 24%. The improvement of flame retardant performance is not obvious, etc., to achieve the effect of improving modulus, high-efficiency intrinsic flame retardant, and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The flame-retardant polydicyclopentadiene material of this embodiment includes the following raw materials: 77.13 wt % of dicyclopentadiene, 6.42 wt % of 5-norbornene-2-carboxamide, and 5-norbornene-2-methanol It is 6.25wt%, the flame retardant is 10wt%, the catalyst is 0.16wt%, and the inhibitor is 0.04wt%. The flame retardant is a norbornene-based reactive flame retardant A containing an amide bond and a cage-like phosphate structure.

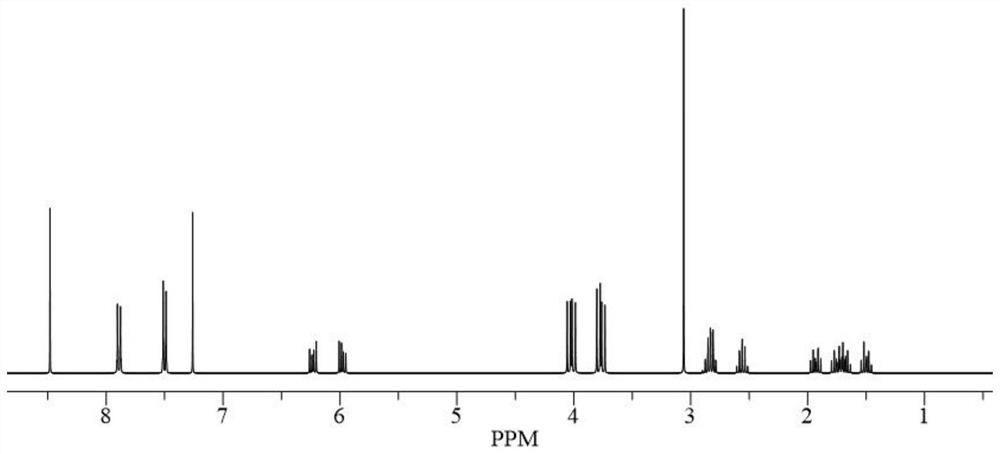

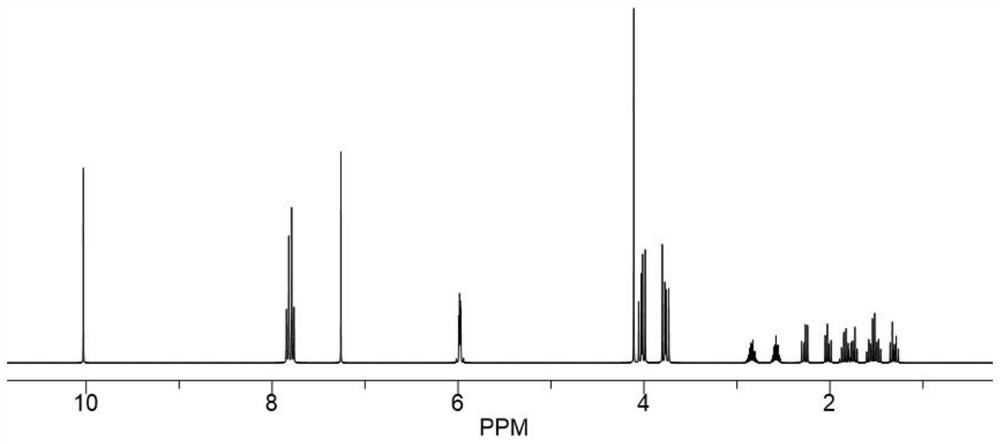

[0055] Its structural formula is:

[0056]

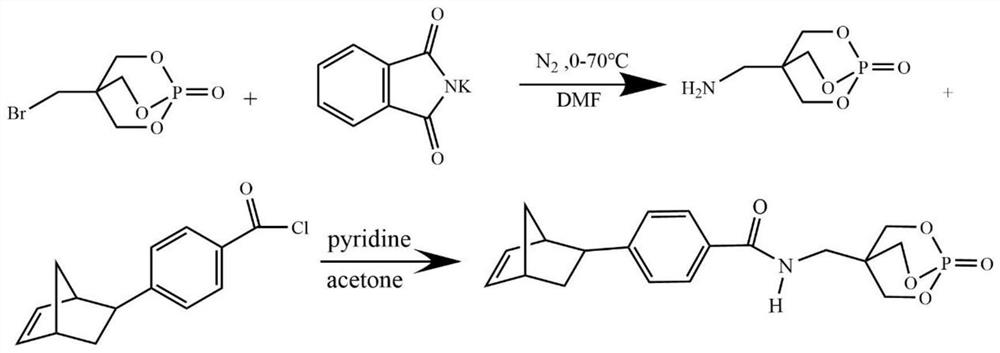

[0057] Flame Retardant A (see attached for the synthetic route map figure 1 ) preparation:

[0058] (1) 0.1mol 2,6,7-trioxa-1-phosphabicyclo[2.2.2]octane-4-bromomethyl-1-oxide, 0.14mol potassium phthalimide and 150 ml of N,N-dimethylformamide was stirred at 0°C for 2 hours under nitrogen protection, then raised to 70°C and reacted for 20 hours. It was then cooled to room temperature and washed with deionized water. The solid was collected by filtration to give the intermediate 2,6,7-...

Embodiment 2

[0066] The flame-retardant polydicyclopentadiene material of this embodiment includes the following raw materials: 67.13 wt % of dicyclopentadiene, 6.42 wt % of 5-norbornene-2-carboxamide, 5-norbornene-2-methanol It is 6.25wt%, the flame retardant is 20wt%, the catalyst is 0.16wt%, and the inhibitor is 0.04wt%. The flame retardant is a norbornene-based reactive flame retardant A containing an amide bond and a cage-like phosphate structure.

[0067] The preparation process of the flame-retardant polydicyclopentadiene engineering material of the present embodiment is the same as that of embodiment 1.

Embodiment 3

[0069] The flame-retardant polydicyclopentadiene material of this embodiment includes the following raw materials: 57.13 wt % of dicyclopentadiene, 6.42 wt % of 5-norbornene-2-carboxamide, and 5-norbornene-2-methanol It is 6.25wt%, the flame retardant is 30wt%, the catalyst is 0.16wt%, and the inhibitor is 0.04wt%. The flame retardant is a norbornene-based reactive flame retardant A containing an amide bond and a cage-like phosphate structure.

[0070] The preparation process of the flame-retardant polydicyclopentadiene engineering material of the present embodiment is the same as that of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com