Irradiation cross-linked thermoplastic polyester elastomer cable material and cable production method

A thermoplastic polyester and elastomer technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems that affect production stability and product quality, low TPEE flame retardant grade, high melting point of polyester hard segment, etc., to achieve Excellent char formation and flame retardancy, improved anti-dripping properties, improved mechanical properties at room temperature and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

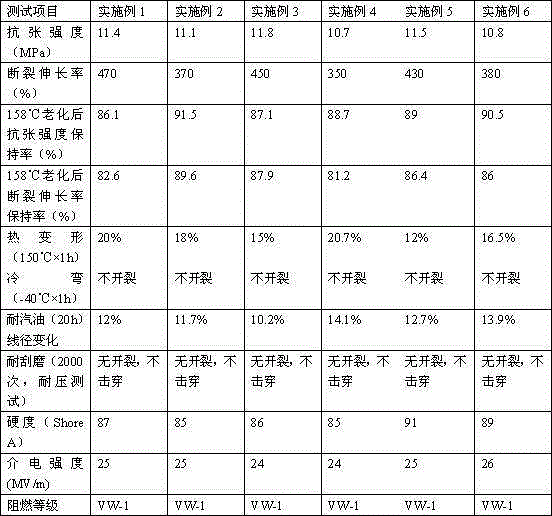

Examples

Embodiment 1

[0028] The formula consists of the following:

[0029] Thermoplastic polyester elastomer (TPEE) 100 parts;

[0030] 30 parts of ethylene-vinyl acetate copolymer (EVA);

[0031] Melamine cyanurate (MCA) 40 parts;

[0032] 25 parts of organic phosphinate;

[0033] 2 parts silicone;

[0034] Antioxidant 10102 parts;

[0035] Anti-ultraviolet agent 7701 parts.

[0036] The preparation steps are as follows:

[0037] Weigh the components according to the above formula, add them into a high-speed mixer, stir evenly, and then discharge to obtain a mixed material. The mixture is melted and extruded at 190-230°C through a twin-screw extruder with a relatively large length and diameter, drawn, cooled, and granulated to obtain a finished masterbatch of radiation crosslinked thermoplastic polyester elastomer cable material. The finished wire and cable material is extruded through a twin-screw extruder and a conductor (metal conductor such as copper or aluminum), and the resulting wi...

Embodiment 2

[0039] The formula consists of the following:

[0040] Thermoplastic polyester elastomer (TPEE) 100 parts;

[0041] 35 parts of ethylene-vinyl acetate copolymer (EVA);

[0042] Melamine cyanurate (MCA) 35 parts;

[0043] 30 parts of organic phosphinate;

[0044] 2 parts silicone;

[0045] Antioxidant 10102 parts;

[0046] Anti-ultraviolet agent 7700.5 parts.

[0047] The preparation steps are as follows:

[0048] Weigh the components according to the above formula, add them into a high-speed mixer, stir evenly, and then discharge to obtain a mixed material. The mixture is melted and extruded at 190-230°C through a twin-screw extruder with a relatively large length and diameter, drawn, cooled, and granulated to obtain a finished masterbatch of radiation crosslinked thermoplastic polyester elastomer cable material. The finished wire and cable material is extruded through a twin-screw extruder and a conductor (metal conductor such as copper or aluminum), and the resulting ...

Embodiment 3

[0050] The formula consists of the following:

[0051] Thermoplastic polyester elastomer (TPEE) 100 parts;

[0052] 20 parts of ethylene-vinyl acetate copolymer (EVA);

[0053] Melamine cyanurate (MCA) 30 parts;

[0054] 25 parts of organic phosphinate;

[0055] 1.5 parts of silicone;

[0056] Antioxidant 10101 parts

[0057] 0.5 parts of antioxidant 412s;

[0058] Anti-ultraviolet agent 7700.5 parts.

[0059] The preparation steps are as follows:

[0060] Weigh the components according to the above formula, add them into a high-speed mixer, stir evenly, and then discharge to obtain a mixed material. The mixture is melted and extruded at 190-230°C through a twin-screw extruder with a relatively large length and diameter, drawn, cooled, and granulated to obtain a finished masterbatch of radiation crosslinked thermoplastic polyester elastomer cable material. The finished wire and cable material is extruded through a twin-screw extruder and a conductor (metal conductor su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com