Expanded polyol and its preparation method and application

A polyol, expansion type technology, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., to achieve the effects of mild reaction conditions, good thermal stability, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

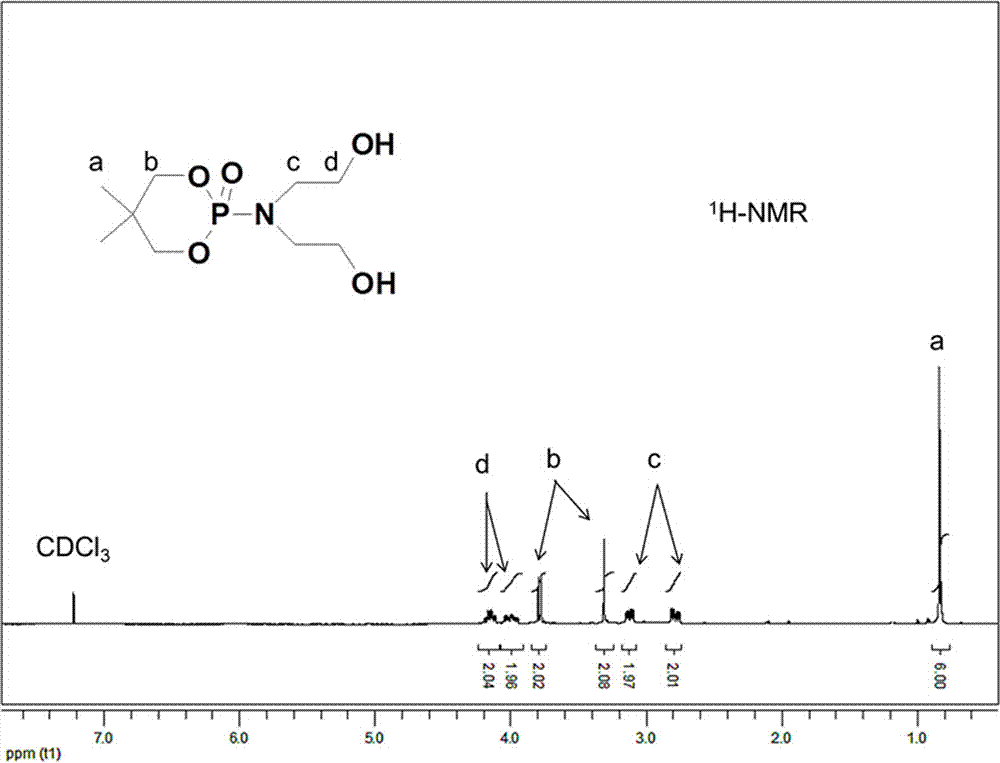

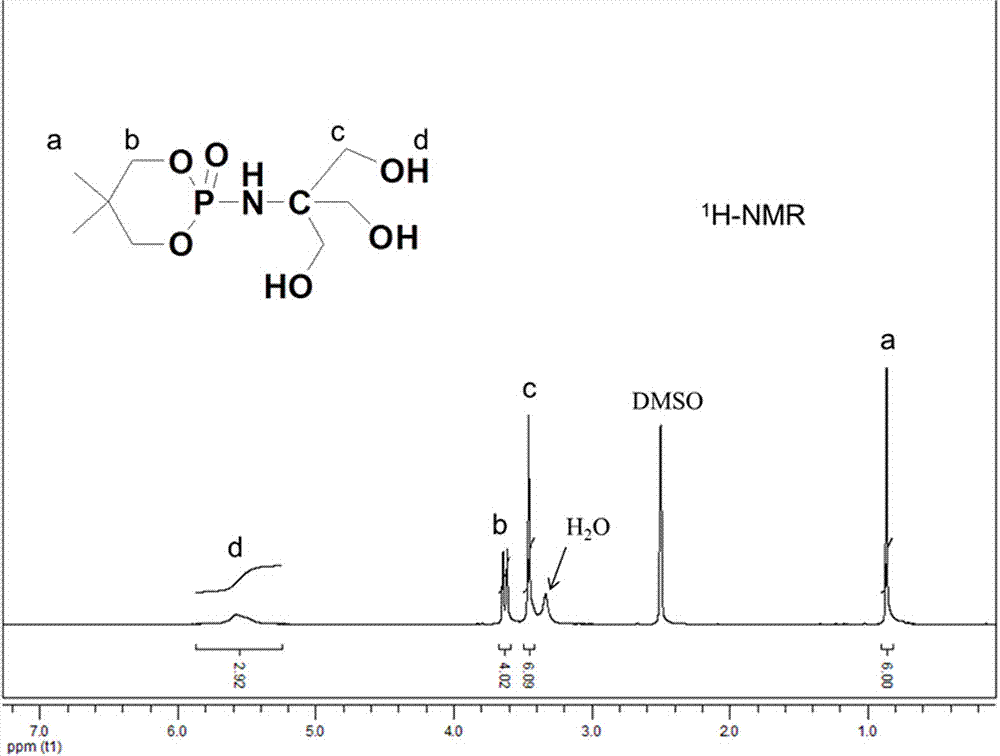

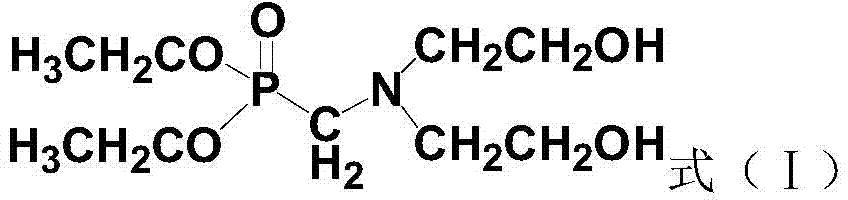

[0029] The preparation method of the expanded polyol DOP-DEA:

[0030] (1) In a 250mL reaction vessel equipped with a stirring and cooling device, add 18.40g of 2,2-dimethyl-1,3-propanediol-phosphonyl chloride (0.1mol) and 50mL of tetrahydrofuran, start stirring to dissolve evenly; Diethanolamine (0.1 mol, 10.51 g), triethylamine (0.3 mol, 30.36 g) and 100 mL of tetrahydrofuran solution were slowly added dropwise while stirring at -10°C, and a white precipitate gradually formed in the system.

[0031] (2) After the dropwise addition of the solution, the system was reacted at 0-10°C for 10 hours, then heated to 20°C for 12 hours, the white precipitate triethylamine hydrochloride was filtered, concentrated under reduced pressure, purified and dried to obtain light Yellow transparent oily liquid product with a yield of 98.5%.

Embodiment 2

[0033] The preparation method of the expanded polyol DOP-DEA:

[0034] (1) In a 250mL reaction vessel equipped with a stirring and cooling device, add 18.40g of 2,2-dimethyl-1,3-propanediol-phosphonyl chloride (0.1mol) and 50mL of tetrahydrofuran, and start stirring to dissolve evenly. Diethanolamine (0.1 mol, 10.51 g), pyridine (0.2 mol, 15.82 g) and 100 mL of tetrahydrofuran solution were slowly added dropwise while stirring at 0-10°C, and a white precipitate gradually formed in the system.

[0035] (2) After the solution is added dropwise, let the system react at 0-10°C for 8 hours, then raise the temperature to 20°C and react for 8 hours, filter the white precipitate pyridine hydrochloride, concentrate under reduced pressure, purify and dry to obtain light yellow transparent Oily liquid product, yield 90.6%.

Embodiment 3

[0037] The preparation method of the expanded polyol DOP-DEA:

[0038](1) In a 250mL reaction vessel equipped with a stirring and cooling device, add 18.40g of 2,2-dimethyl-1,3-propanediol-phosphonyl chloride (0.1mol) and 50mL of dichloromethane, and start stirring to dissolve evenly. Diethanolamine (0.1 mol, 10.51 g), triethylenediamine (0.1 mol, 11.20 g) and 100 mL of dichloromethane solution were slowly added dropwise while stirring at 0-10°C, and a white precipitate gradually formed in the system.

[0039] (2) After the solution was added dropwise, the system was reacted at 0-10°C for 10 hours, then heated to 20°C for 12 hours, the white precipitate was filtered, concentrated under reduced pressure, purified and dried to obtain a light yellow transparent oily liquid product, The yield was 93.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com