Flaming retarding highly conductive silicon rubber composite material and preparation method thereof

A composite material and silicone rubber technology, which is applied in the field of flame-retardant high-conductivity silicone rubber composite materials and their preparation, can solve problems such as inability to guarantee char formation, achieve good conductivity, improve thermal stability, and improve flame-retardant effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

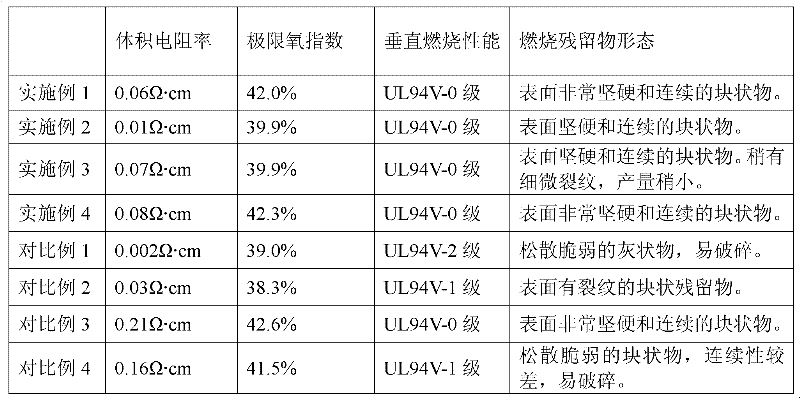

Examples

Embodiment 1

[0036] (1) 100 parts (refer to parts by mass, the same below) vinyl molar content is 0.25%, molar mass 50×10 4 g / mol polymethylvinylsiloxane (110-2 methylvinyl silicone rubber, produced by Zhongwu Chenguang Chemical Research Institute) is wrapped on a double-roll mill, and 18 parts of specific surface area is added to be 300m 2 / g of fumed silica reinforced filler, evenly mixed.

[0037] (2) Then add 20 parts of superfine calcium carbonate (OMYACARB1T-NJ, produced by Nanjing Omiya Fine Chemical Co., Ltd.) with an average particle size of 1 μm, 13 parts of glass powder with a softening point of 450 ° C and a particle size of 18 μm, 3 parts Cerium oxide powder and 230 parts of nickel-plated graphite (product of NOVAMET company) with a particle size of 20-30 μm and a nickel content of 60% and an average particle size of 20 μm were kneaded uniformly.

[0038] (3) Then add 4 parts of hydrogen-containing silicone oil with a viscosity of 500mP·s at 25°C and at least 5 Si-H bonds per...

Embodiment 2

[0044] The amount of nickel-plated graphite is 150 parts, and 120 parts of silver-coated glass powder with an average particle size of 12 μm are added, and 0.6 parts of platinum double-headed (unsaturated siloxane solution of platinum, that is: platinum and unsaturated siloxane complex) solution (corresponding to 55ppm), and other conditions are the same as in Example 1 to obtain a silicone rubber composite. Its volume resistivity reaches 0.01Ω·cm, the limiting oxygen index reaches 41.1%, and reaches the V-0 level of UL94. When the material is burned, the amount of smoke is small, and the burning residue forms a continuous and hard ceramic layer on the surface.

Embodiment 3

[0046] The amount of hydrogen-containing silicone oil was 0.8 parts, and other conditions were the same as in Example 1 to obtain a silicone rubber composite material. Its volume resistivity reaches 0.07Ω·cm, the limiting oxygen index reaches 39.9%, and the flame retardant grade is V-0 of UL94. When the material is burned, the amount of smoke is less, and the burning residue forms a continuous ceramic layer on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com