Cross-linked phosphorus-containing macromolecular expansion flame-retardant char-forming agent and its preparation method and application

A technology of intumescent flame retardant and cross-linked structure, which is applied in the field of intumescent flame-retardant carbon-forming agent and its preparation of phosphorus-containing macromolecules in cross-linked structure, can solve the problem that the mechanical properties and flame retardant properties of materials are affected, and the water resistance and migration resistance are not ideal. , the problem of unsatisfactory flame retardant effect, etc., to achieve the effect of limiting oxygen index and vertical combustion level improvement, strong water resistance, and good charcoal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

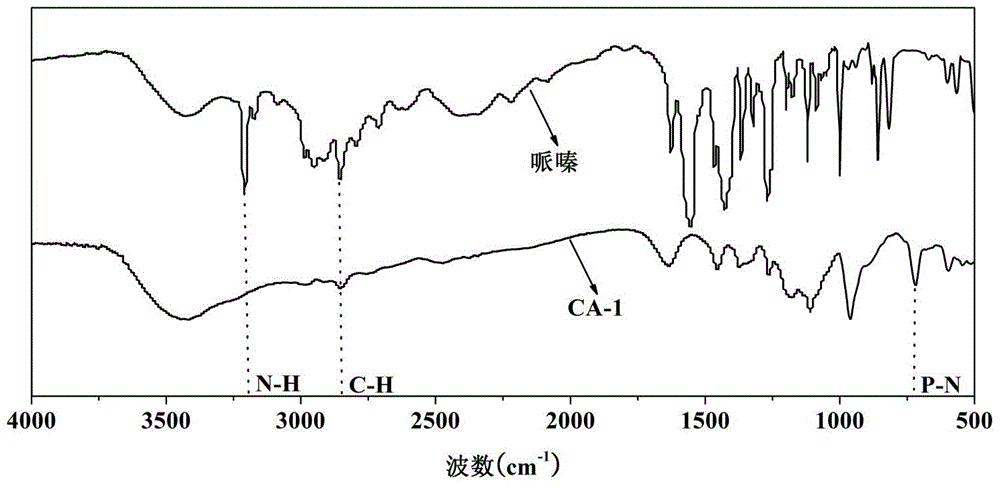

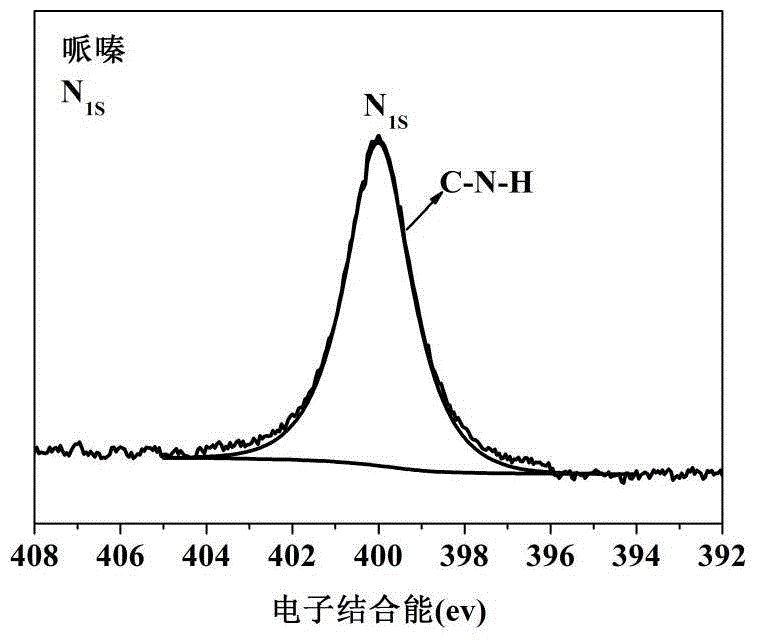

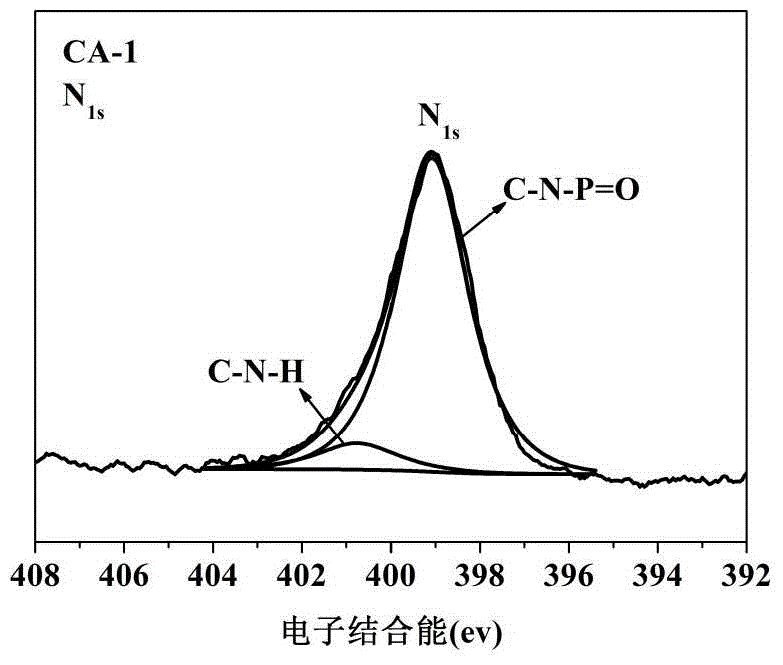

[0044] Add 1 mol of anhydrous piperazine that has been dried beforehand into 1L of chloroform, stir to disperse evenly under nitrogen protection, then add 2.0 mol of triethylamine acid-binding agent at 20°C, and then add 0.67 mol of phosphorus oxychloride, after the dropwise addition, the temperature was raised to 60°C, and the reaction was carried out for 12 hours. After the reaction was completed, the chloroform was removed, and 1L of water was added to the remaining solid, stirred and beaten, and then suction filtered. Repeat this process 3 times to obtain a light yellow solid. After drying It is the charcoal agent CA-1.

Embodiment 2

[0046] Add 1 mol of anhydrous piperazine that has been dried beforehand into 1L of toluene, stir to disperse evenly under the protection of nitrogen, then add 2.1 mol of triethylamine acid-binding agent at 40°C, and then add 0.68 mol of phosphorus oxychloride, after the dropwise addition, the temperature was raised to 110°C, and the reaction was carried out for 6 hours; after the reaction was completed, the toluene was removed, 1L of water was added to the remaining solid, stirred and beaten, and then suction filtered, and the process was repeated 3 times to obtain a light yellow solid. It is the charcoal agent CA-1.

Embodiment 3

[0048] Add 1 mol of ethylene glycol into 1L of 1,4-dioxane, under the protection of nitrogen, stir to disperse evenly, then add 1.9 mol of triethylamine acid-binding agent at 10°C, then add dropwise while stirring 0.70mol phosphorus oxychloride, after the dropwise addition, raise the temperature to 100°C, and react for 6 hours; after the reaction is completed, remove 1,4-dioxane, add 1L water to the remaining solid, stir and beat, then suction filter, repeat the process 3 times , to obtain a white solid, which is charcoal agent CA-2 after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com